Patents

Literature

33results about How to "Control escape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

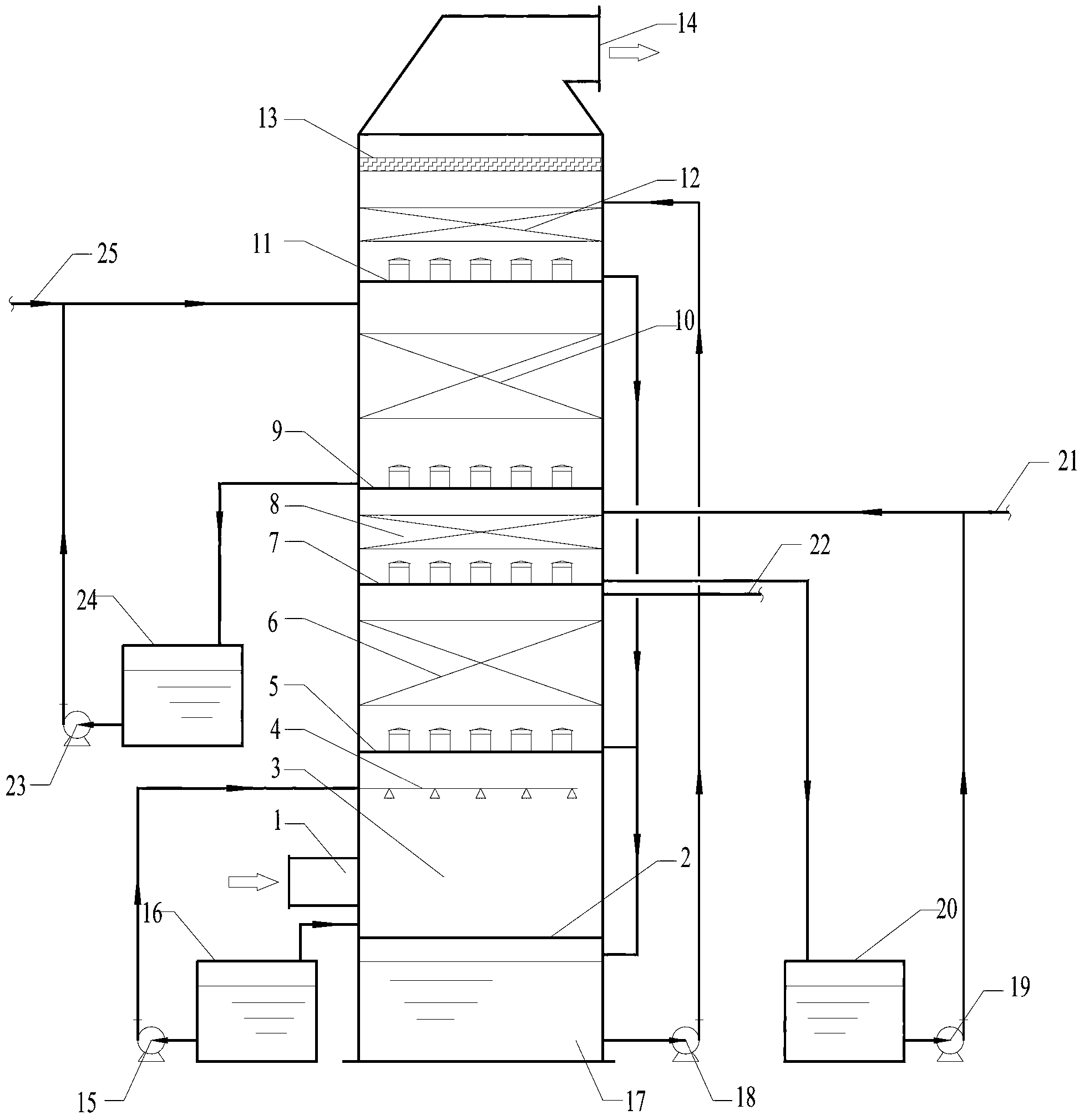

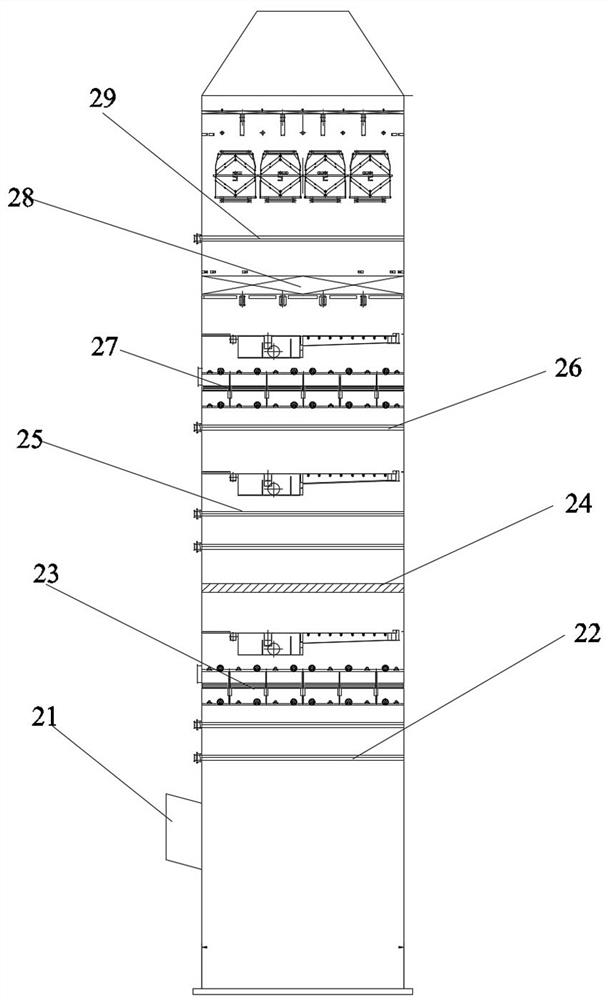

Absorption tower for simultaneously removing sulfur dioxide and nitrogen oxide in smoke

InactiveCN103272468AReduce the temperaturePromote absorptionDispersed particle separationControl areaPhotochemistry

An absorption tower for simultaneously removing sulfur dioxide and nitrogen oxide in smoke comprises a removed sulfur absorption liquid circulation tank, a concentration cooling area, a removed sulfur absorption area, a smoke hardening and tempering area, a removed niter absorption area, an ammonia escape control area and a demisting area, wherein the removed sulfur absorption liquid circulation tank and the concentration cooling area are isolated through a sealing tower plate; every two adjacent areas of the concentration cooling area, the removed sulfur absorption area, the smoke hardening and tempering area, the removed niter absorption area and the ammonia escape control area are separated by one tower plate provided with uniform distribution hoods; and a smoke inlet is formed in the lower end of the concentration cooling area, and a smoke outlet is formed above the demisting area. Removed sulfur and removed niter in the absorption tower can be absorbed in absorption manners such as spraying absorption, spraying and filling absorption, tower plate type absorption, and the like, and the absorption manners can be conveniently combined; a smoke hardening and tempering device can perform hardening and tempering in a gas state manner or a liquid state manner; and with the adoption of acid characteristics of a removed sulfur absorption liquid, the escape of ammonia in the denitration smoke is controlled. The absorption tower integrates multiple functions, so that system energy consumption is reduced.

Owner:北京中环新锐环保技术有限公司 +2

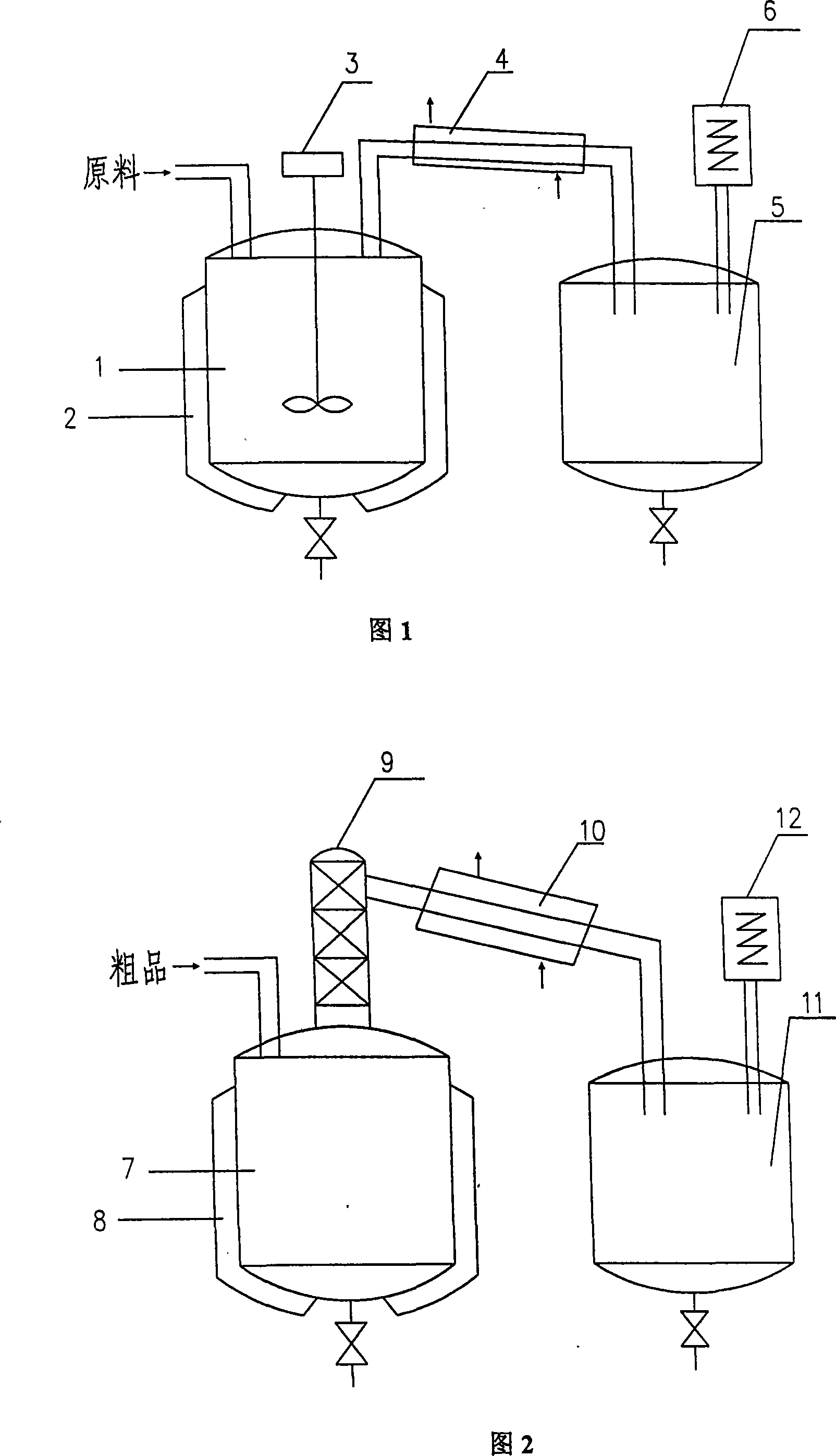

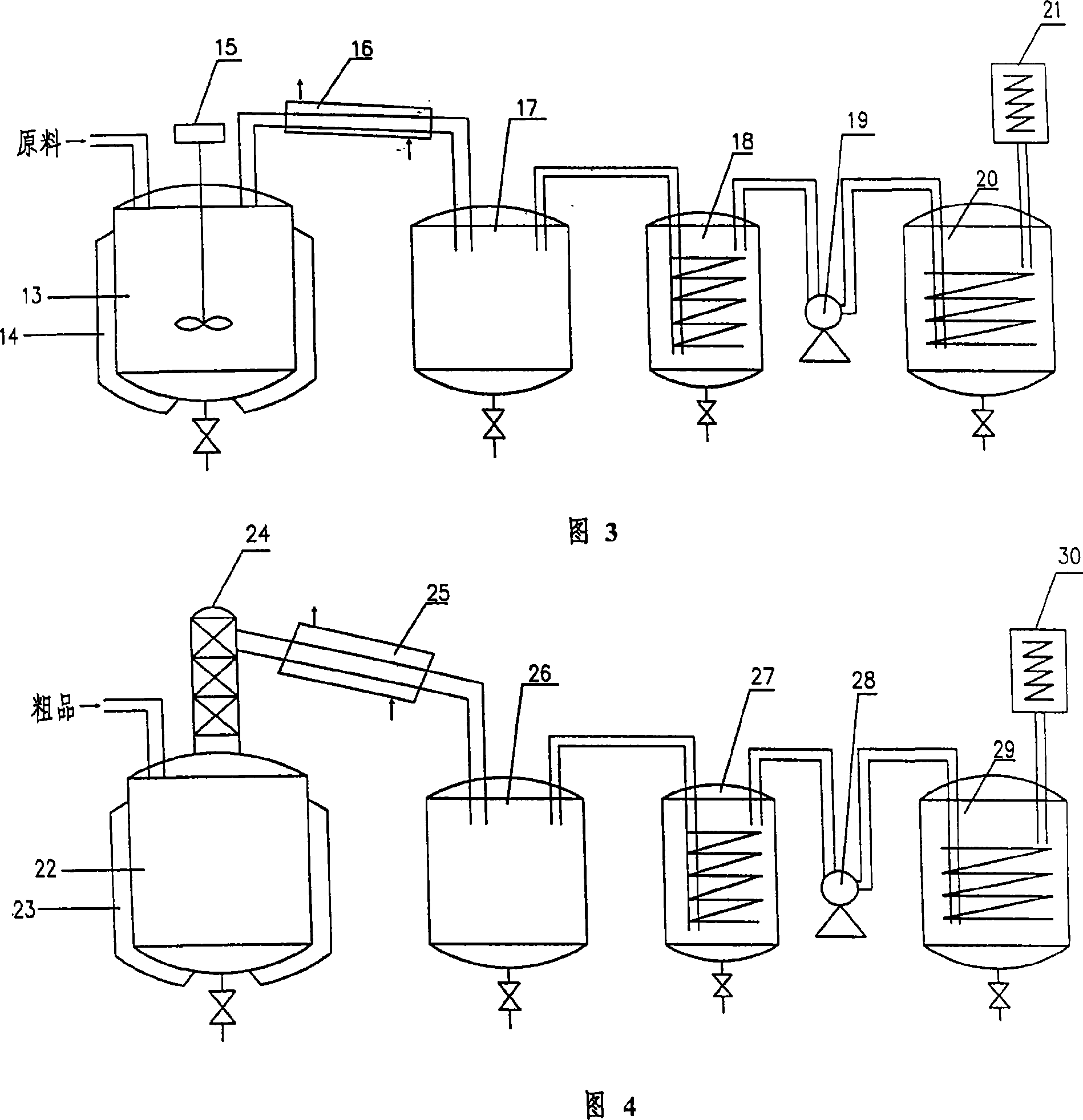

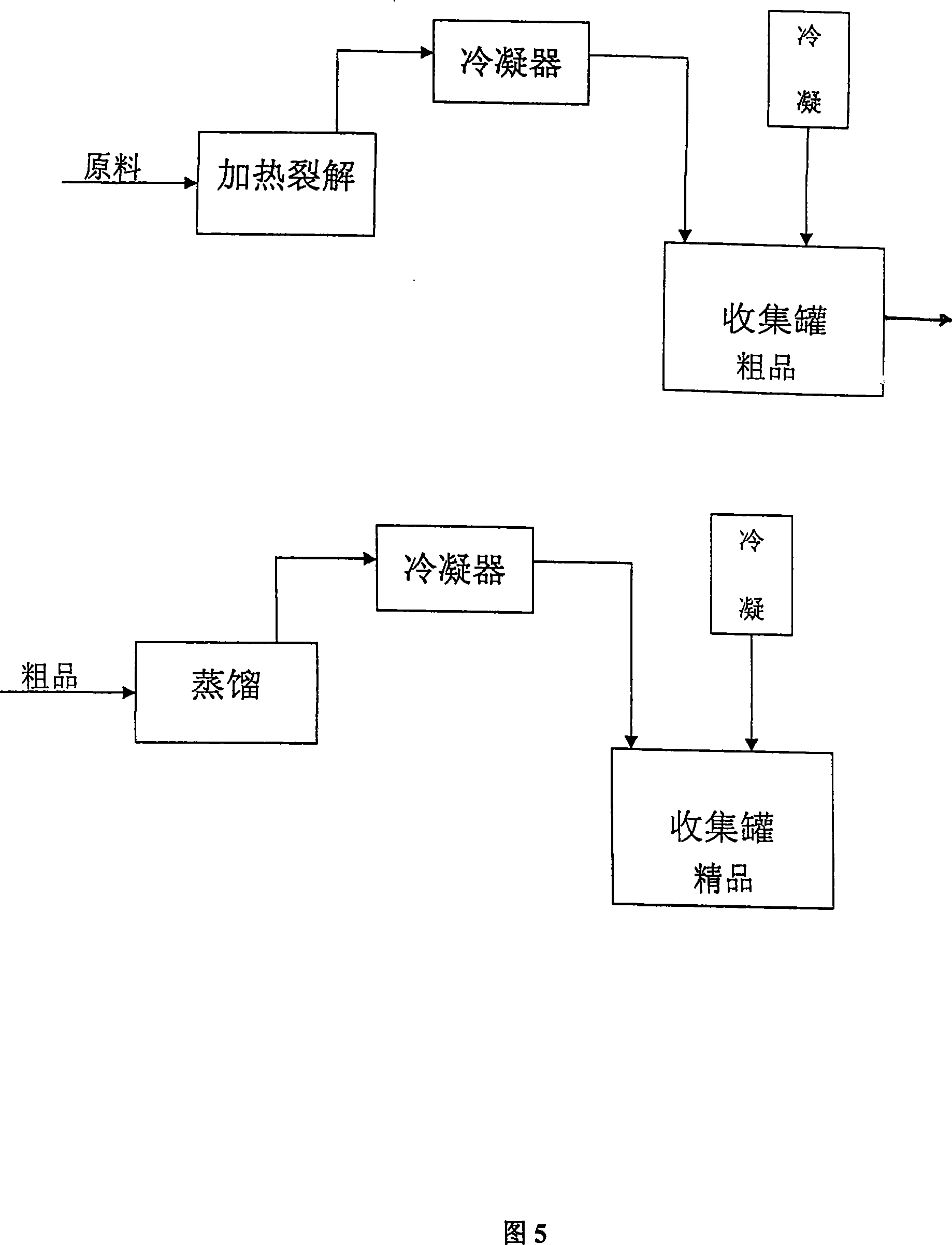

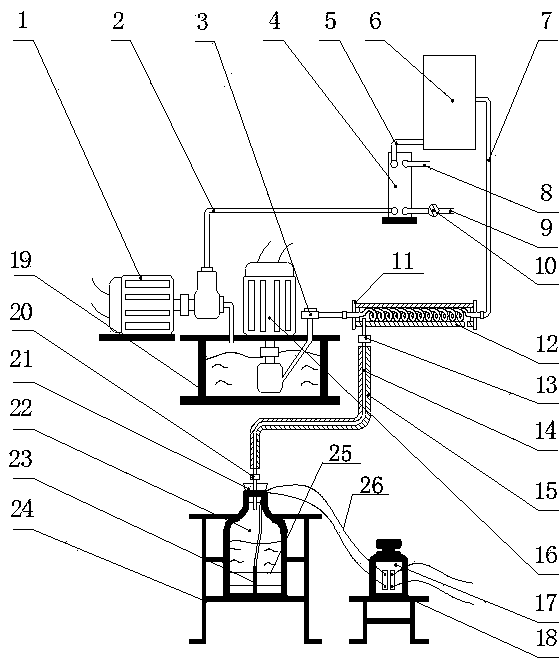

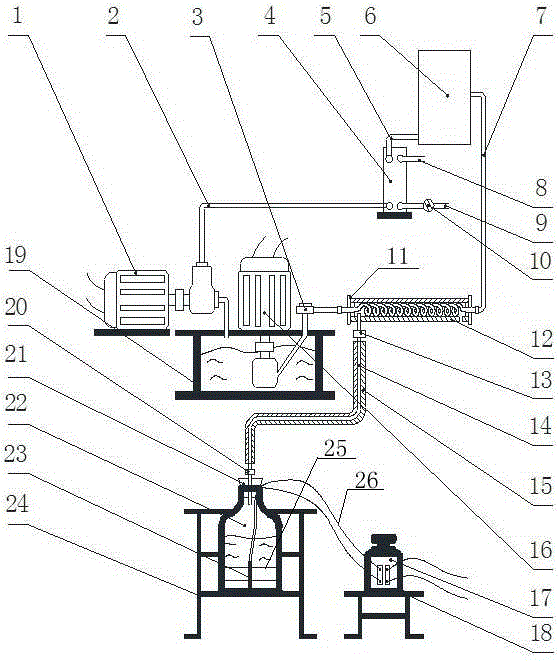

Device for producing methyl methacrylate by using waste and old organic glass and using method thereof

InactiveCN101104585AControl generationEmission controlOrganic compound preparationCarboxylic acid esters separation/purificationDistillationProduct gas

The invention discloses a device to produce methyl methacrylate (MMA) with waste synthetic glass. The cracking unit comprises an airproof cracking reaction cauldron with an oil bath jacket; the airproof cracking reaction cauldron is connected to a crude product gathering tank through a pipeline which passes through a condenser which is connected above the crude product gathering tank; a stirrer is arranged in the airproof cracking reaction cauldron. The distillation unit comprises an airproof distillation reaction cauldron with an oil bath jacket; the airproof distillation reaction cauldron is connected to a finished product gathering tank through a pipeline which passes through a condenser which is connected above the finished product gathering tank. The condensers of the crude product gathering tank and the finished product gathering tank can be replaced with two relief cooling wells. The characteristic of the invention is that all the process of heating, transporting, cooling, gathering, complete cracking and distilling of the raw materials are done in an thoroughly airproof device, effectively controlling the generation and the emission of the gas MMA, meeting the requirements of green technology.

Owner:郑金星

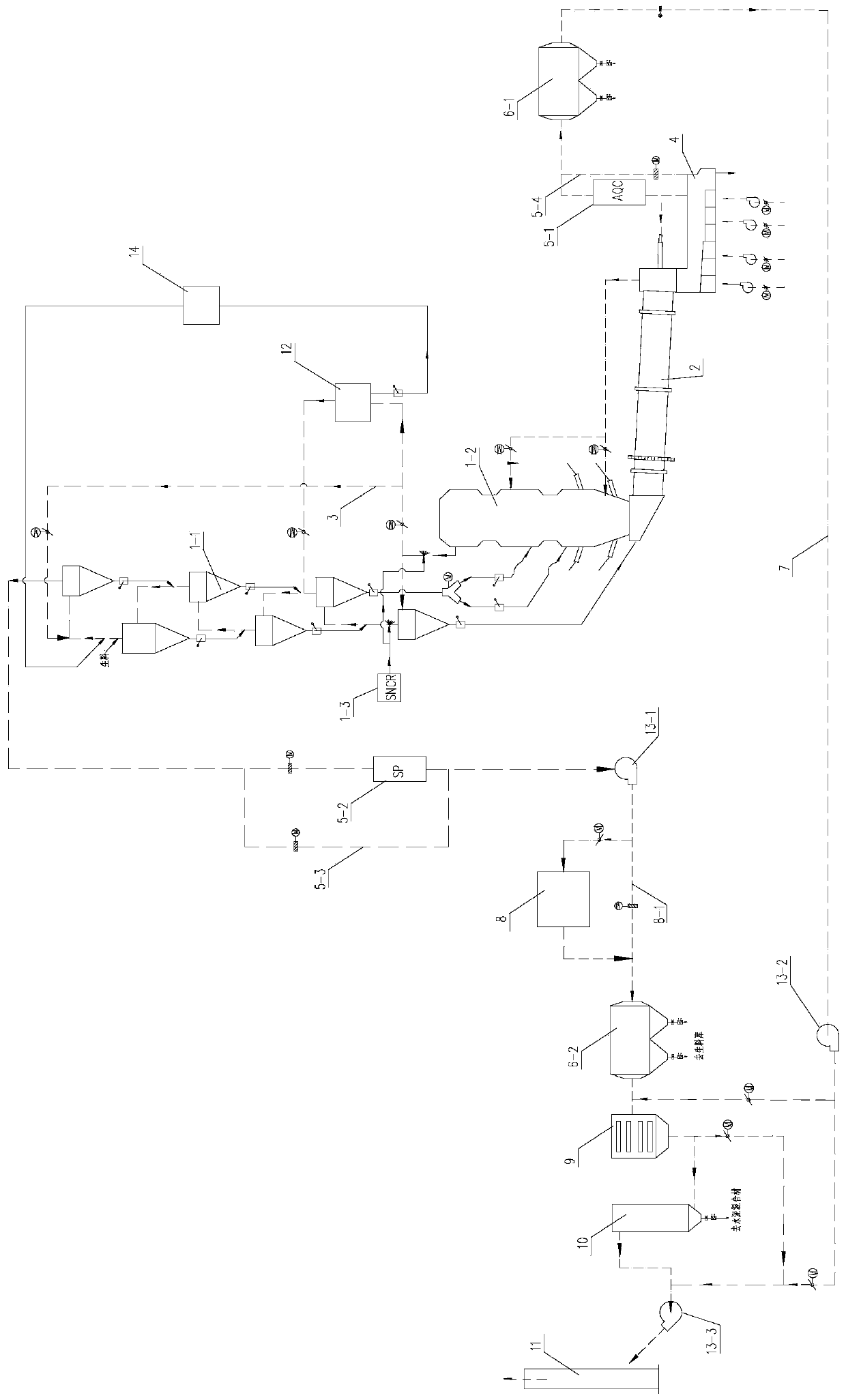

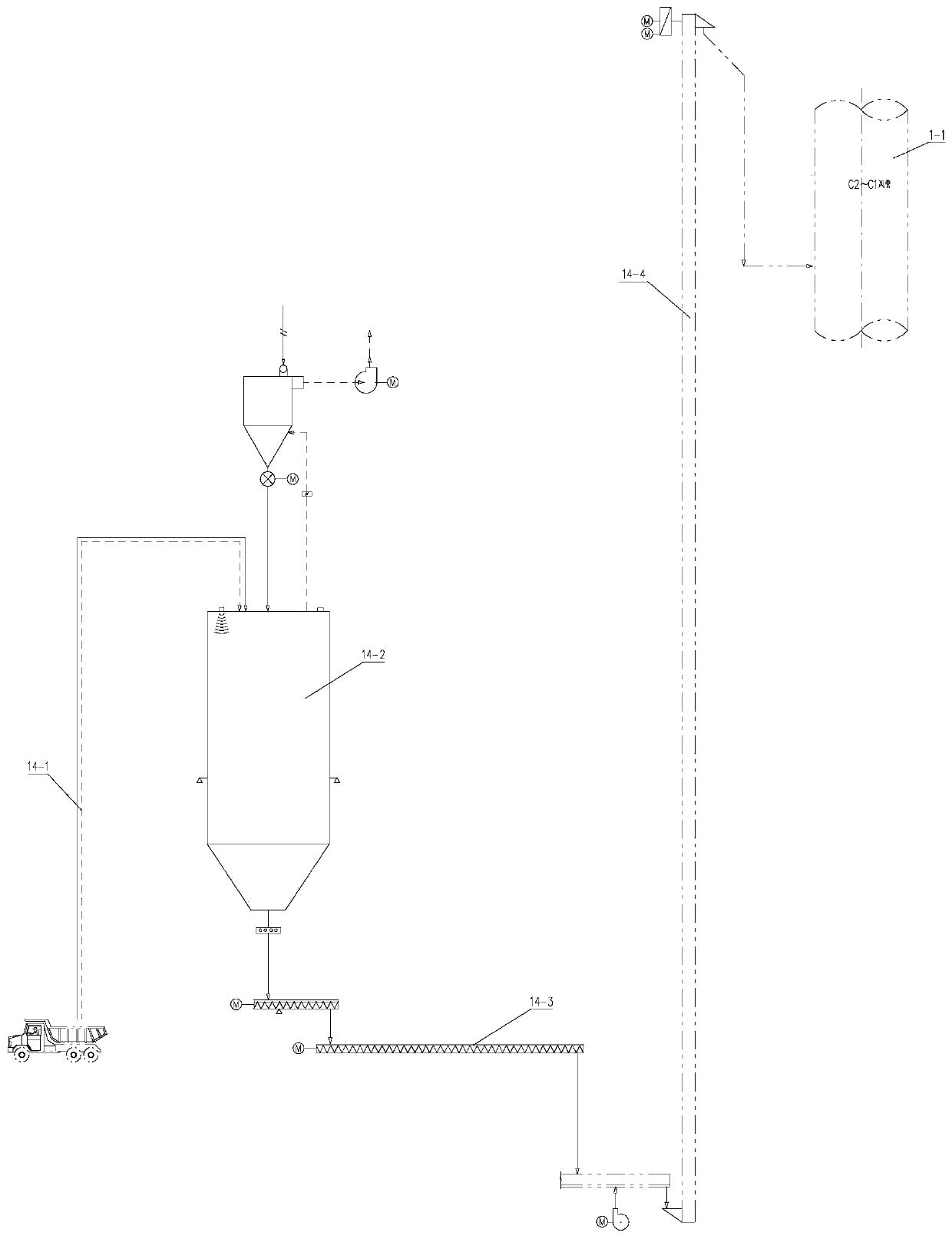

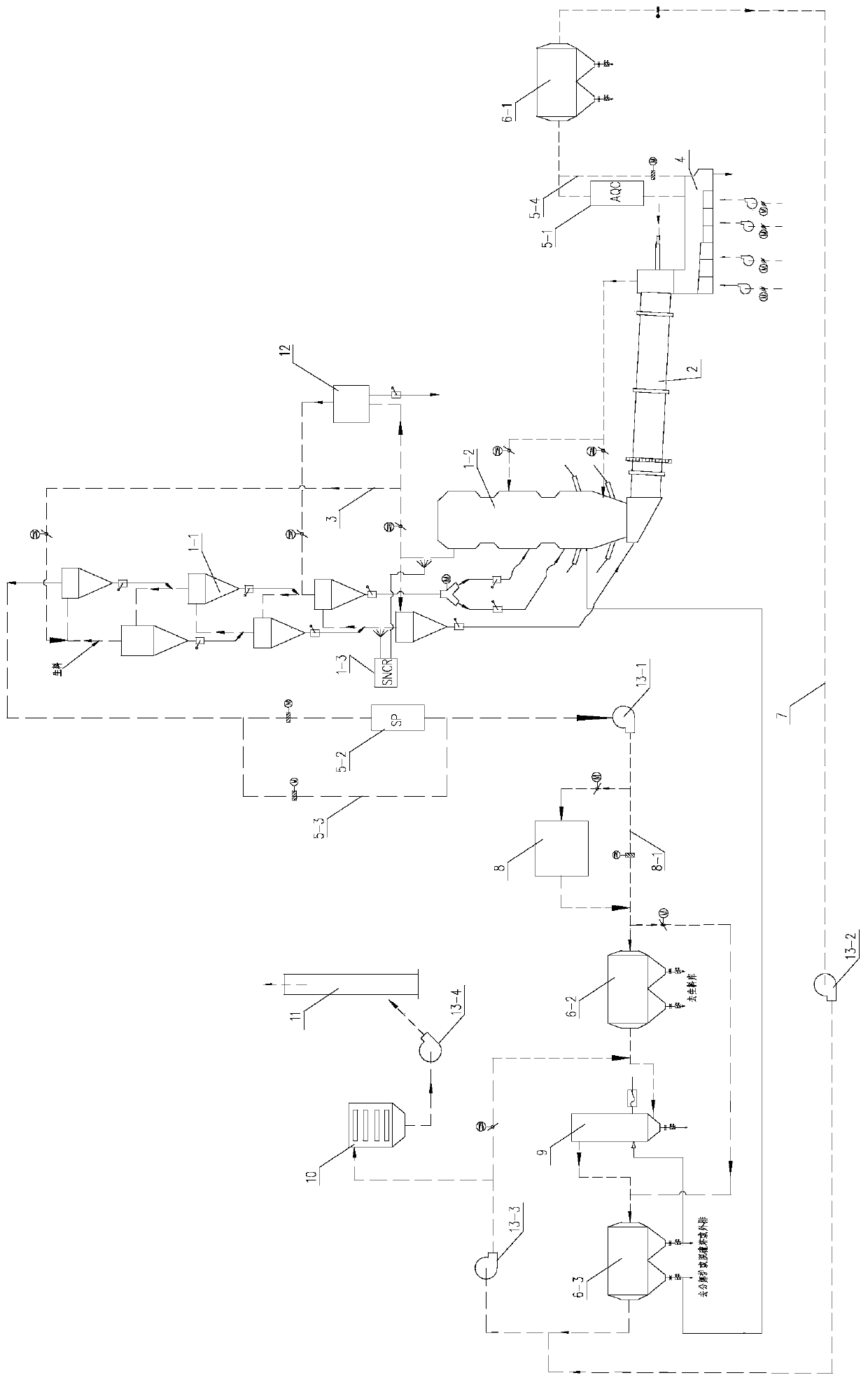

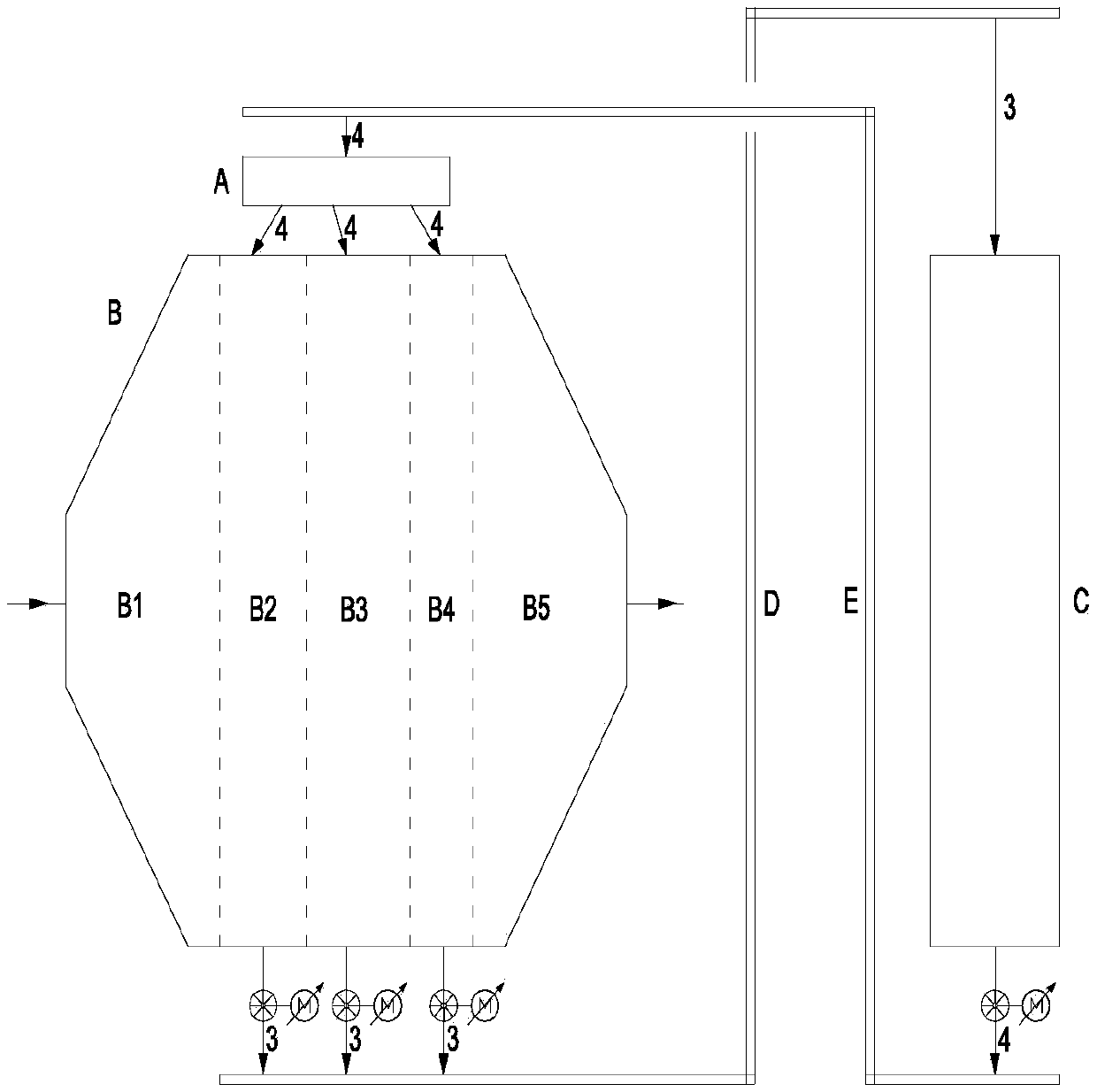

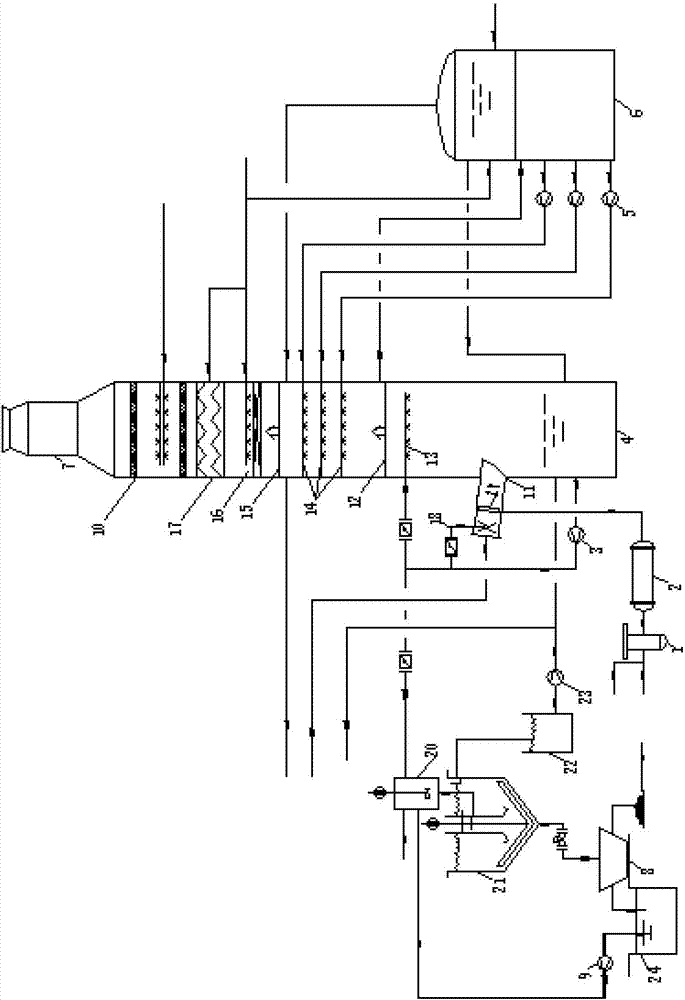

Desulfurization, denitrification and dust removal ultralow emission process and system for production of cement from low-sulfur raw materials

PendingCN110075680ALow comprehensive costAvoid ammonia slipGas treatmentDispersed particle separationFlue gasKiln

The invention discloses a desulfurization, denitrification and dust removal ultralow emission process and system for production of cement from low-sulfur raw materials. The process comprises the stepsas follows: firing of cement clinker, dust removal, flue gas blending, low-temperature SCR denitrification and wet desulfurization. The system comprises a cement clinker firing system, a kiln tail high-temperature fan, a grinding system, a kiln tail dust collector, a low-temperature SCR denitrification reactor, a wet desulfurization tower, a kiln head dust collector and a kiln head induced draftfan; a kiln tail preheater C1 gas outlet, the kiln tail high-temperature fan, the grinding system, the kiln tail dust collector, the low-temperature SCR denitrification reactor, the wet desulfurization tower, an exhaust fan and a kiln tail chimney are sequentially arranged; a cooler, a kiln head dust collector and the kiln head induced draft fan are sequentially connected; an outlet of the kiln head induced draft fan is connected with a gas outlet of the kiln tail dust collector. Dry desulfurization, SCR and wet desulfurization processes are adopted for production of cement from the low-sulfurraw materials, and desulfurization and denitrification ultralow emission during production of the cement from the low-sulfur raw materials is realized.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

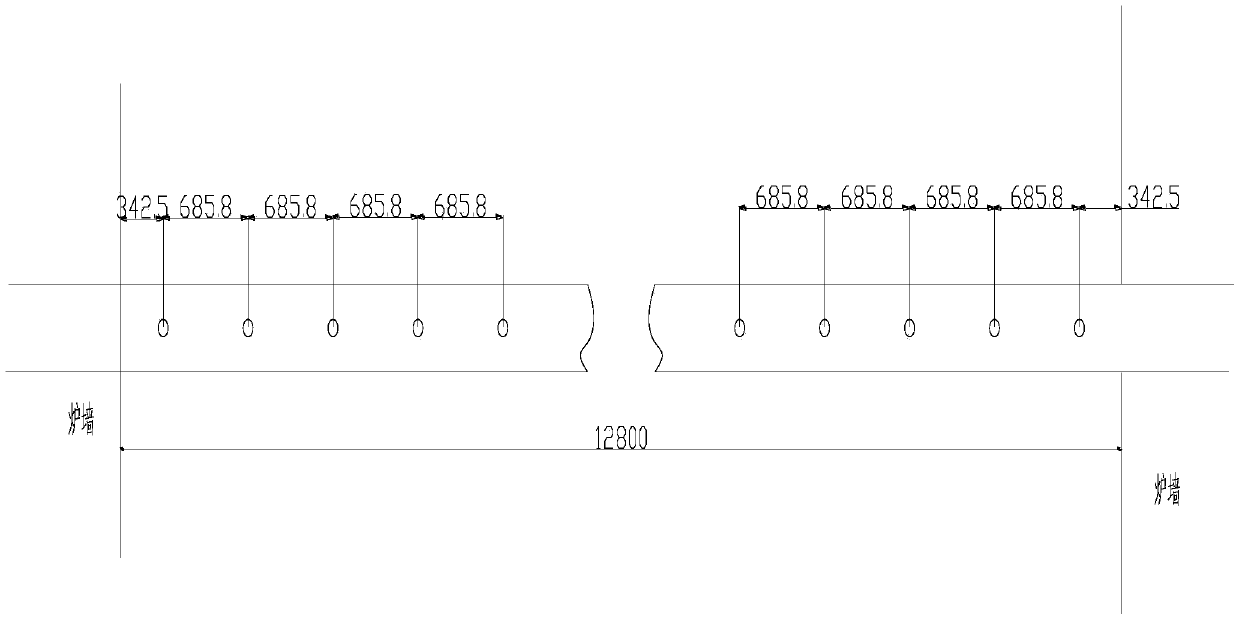

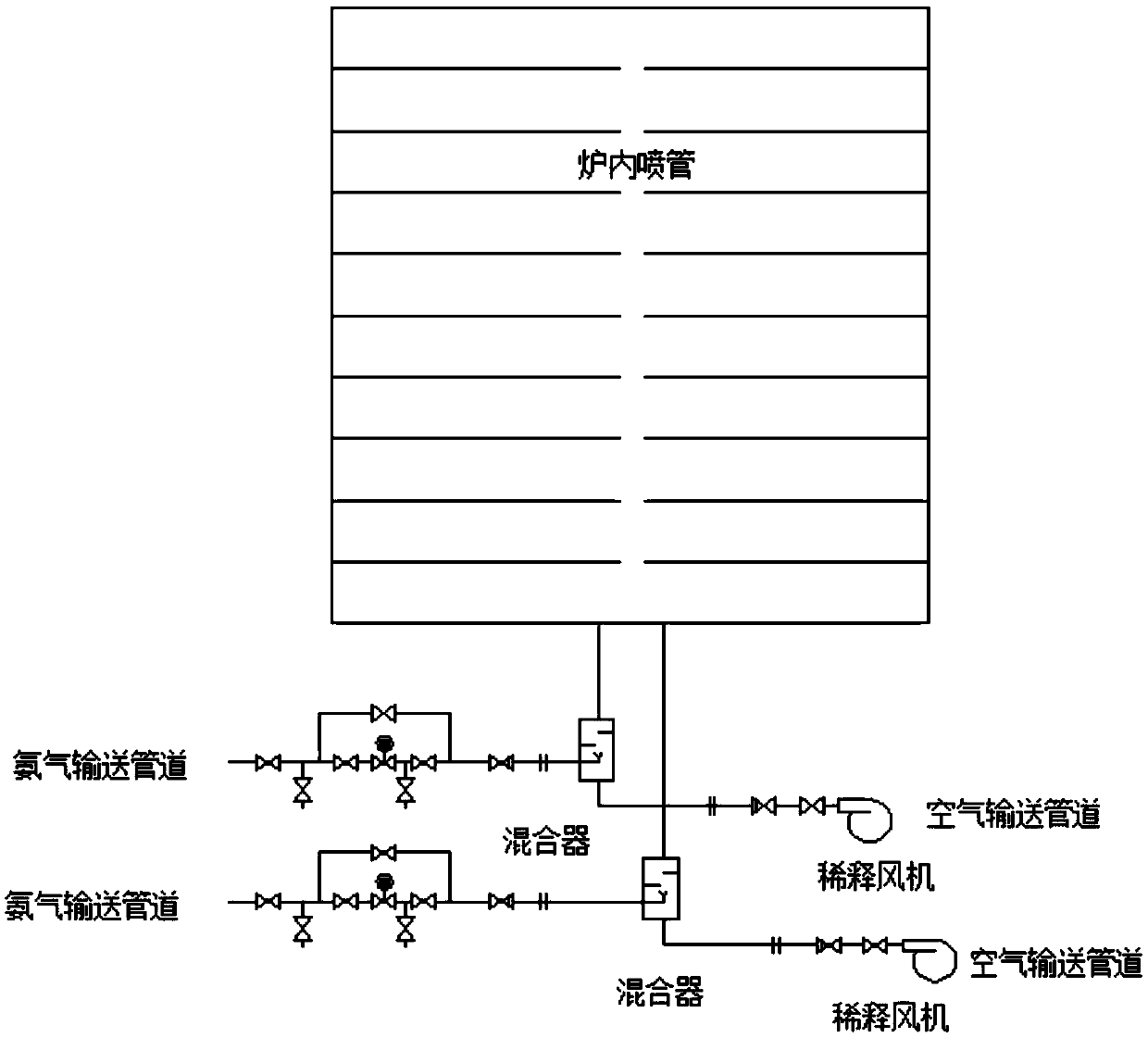

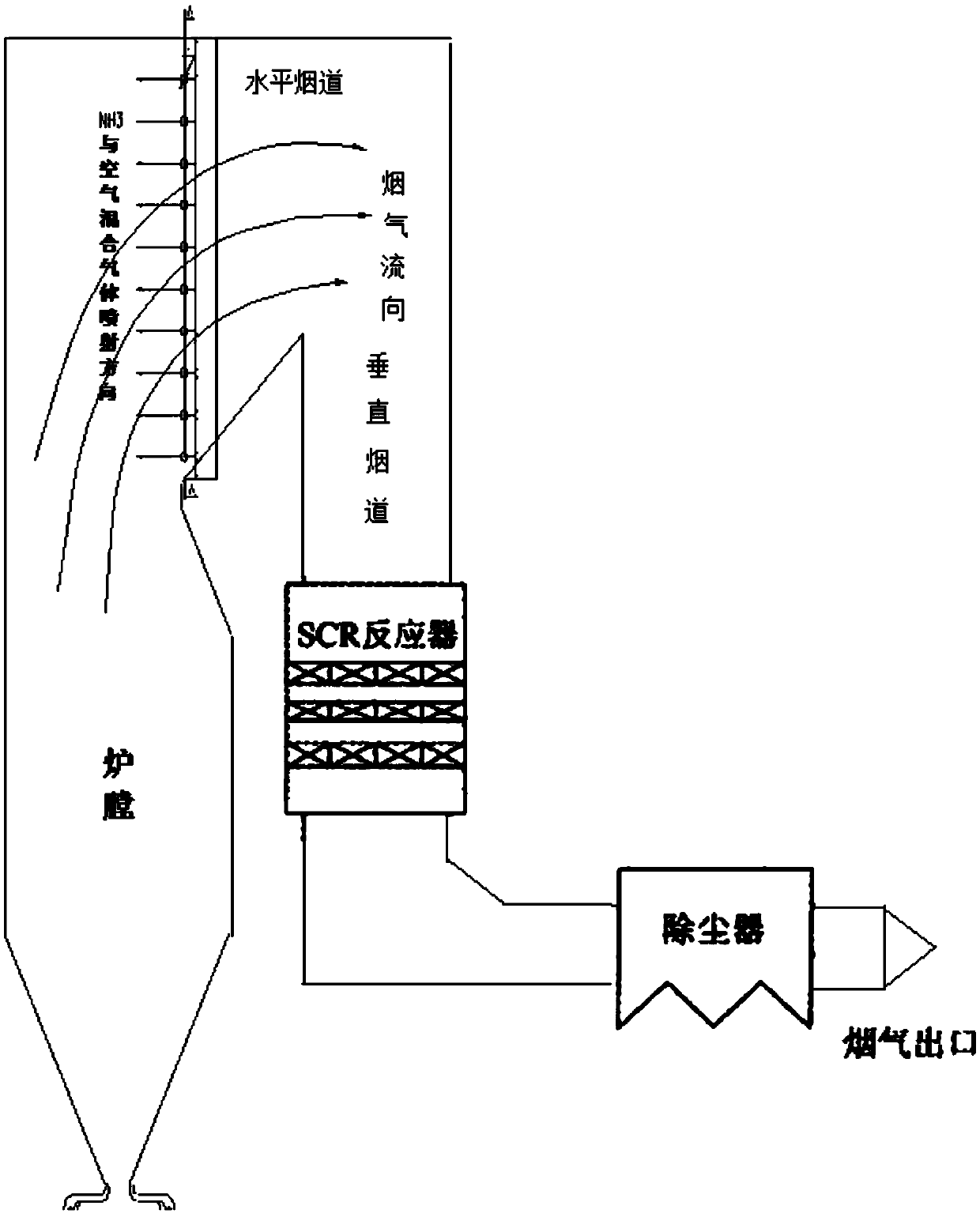

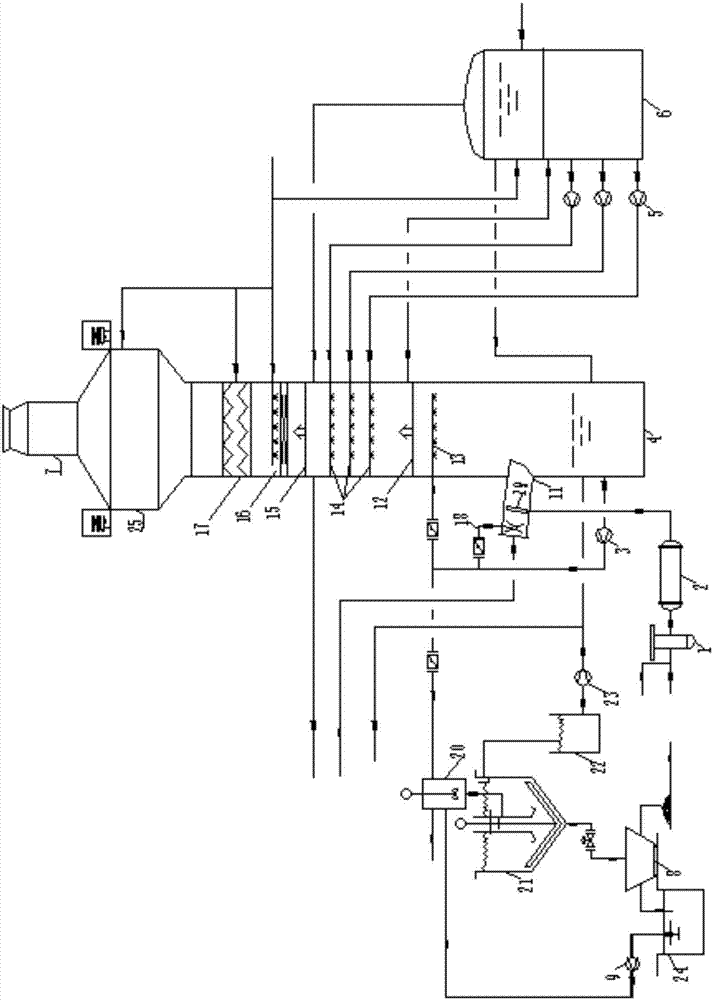

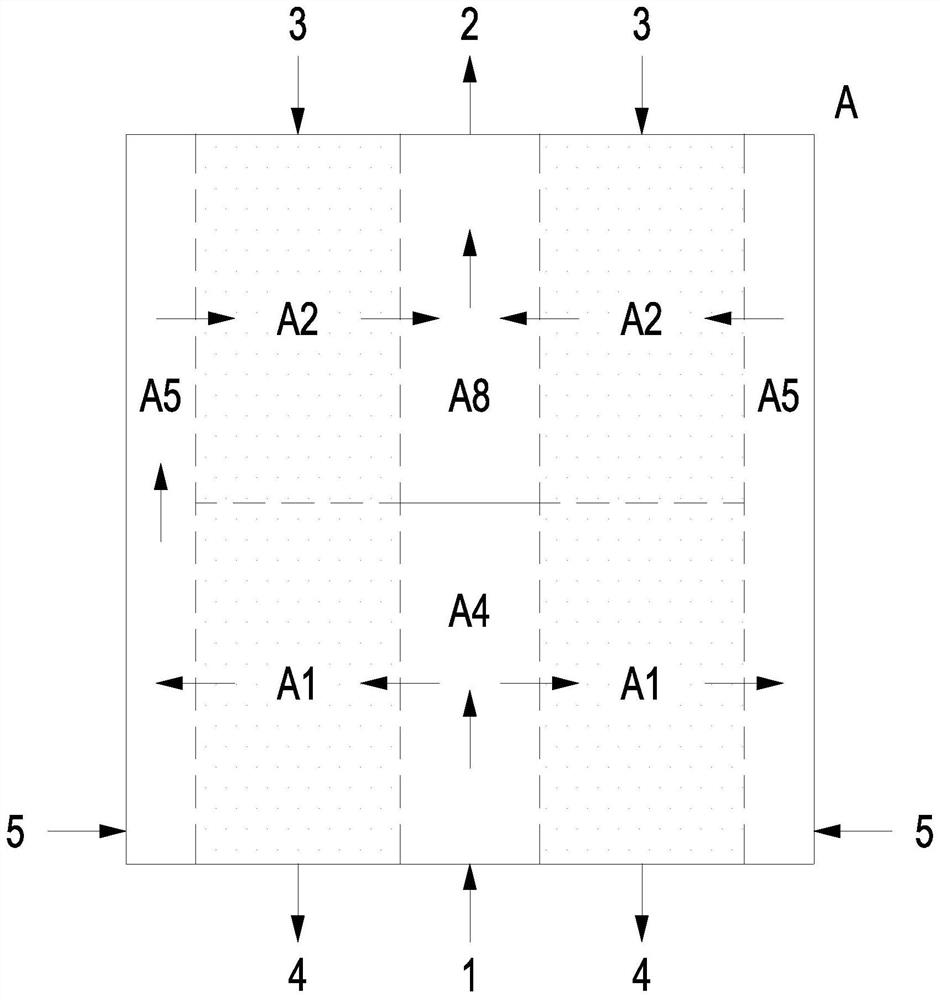

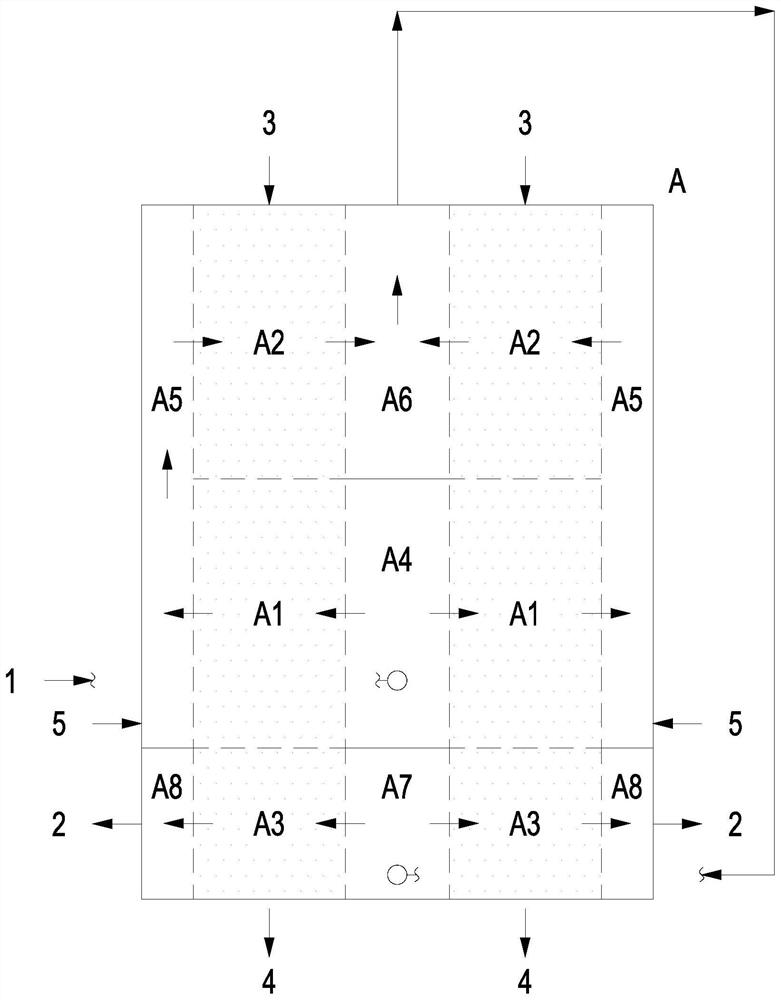

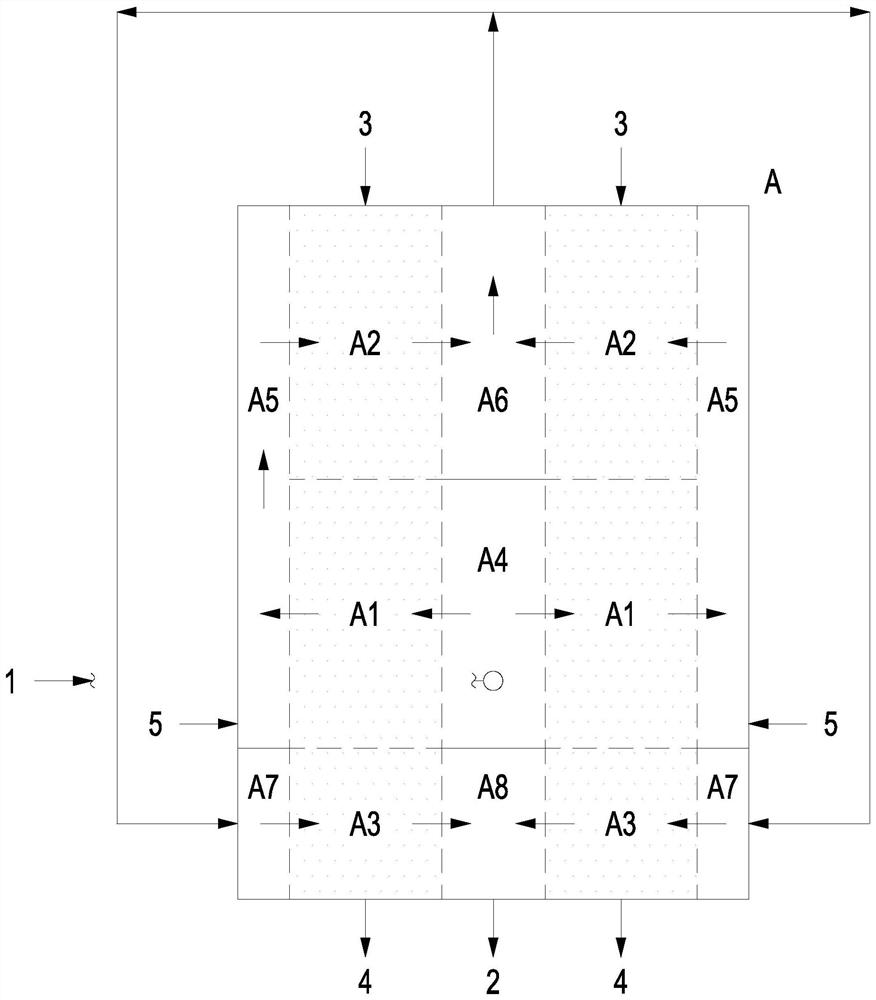

System and process for denitration by spraying ammonia gas in large-sized boiler high-temperature flue gas area

ActiveCN105509081AGuarantee the effect of denitrification onceGuaranteed denitrification effectGas treatmentEmission preventionFlue gasEngineering

The invention belongs to the technical field of flue gas denitration and relates to a system for denitration by spraying ammonia gas in a large-sized boiler high-temperature flue gas area. A boiler comprises a horizontal flue and a vertical flue. The system comprises an SNCR (selective non-catalytic reduction) system provided with a reducing agent injector, the reducing agent injector is a spray pipe disposed on the transverse section of the horizontal flue, an input end of the spray pipe is connected with a reducing agent conveyer, the other end of the spray pipe is closed, and the wall of the spray pipe opposite to flue gas is provided with a spray hole. The invention also discloses a denitration process for denitration treatment using the system, the denitration treatment with the system gives high denitration rate and low ammonia escape quantity as well as full flue gas purification, this product is applicable to present coal-consuming boilers for thermal power generation, iron and steel, chemicals, cements and the like, and satisfactory NOx emission index of these boilers can be ensured.

Owner:杜梦凡

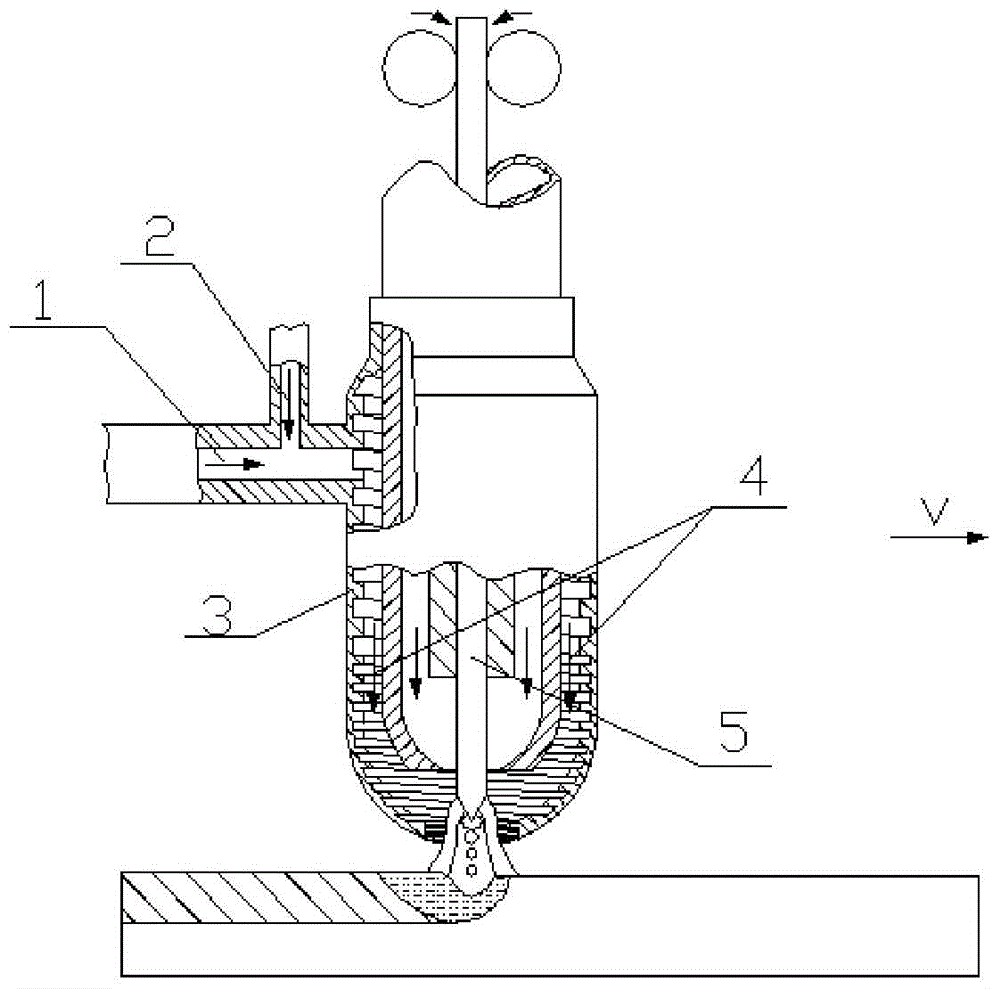

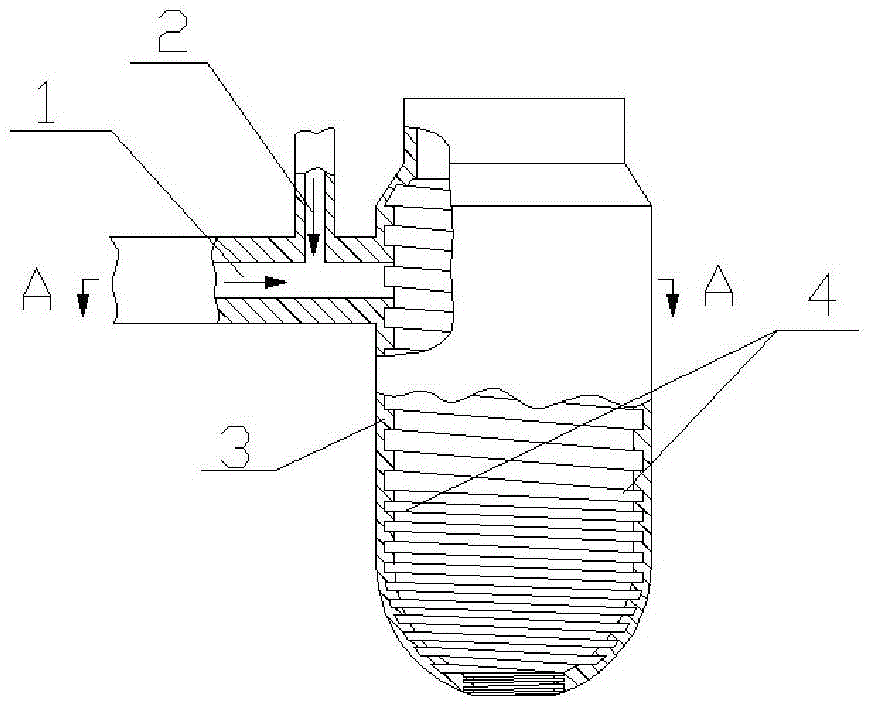

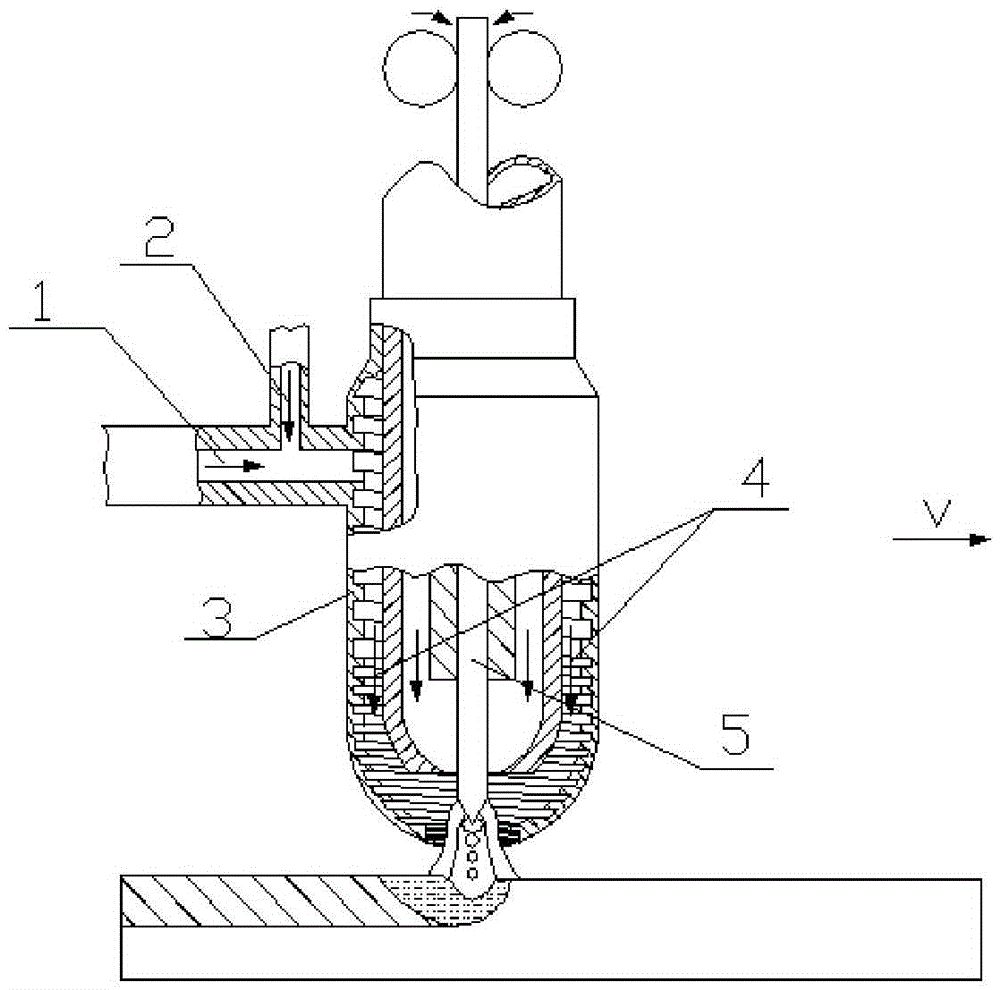

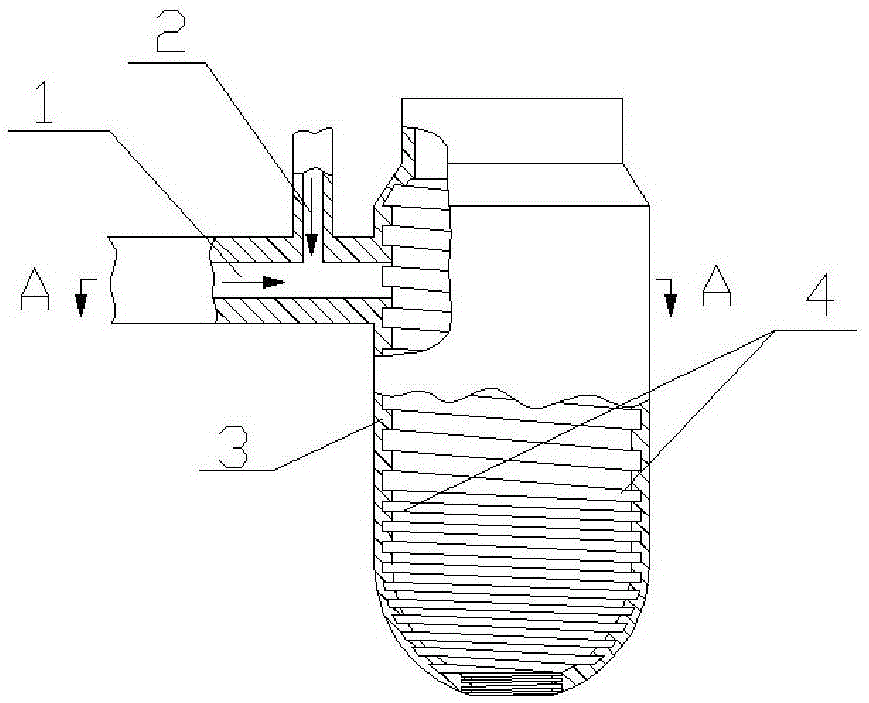

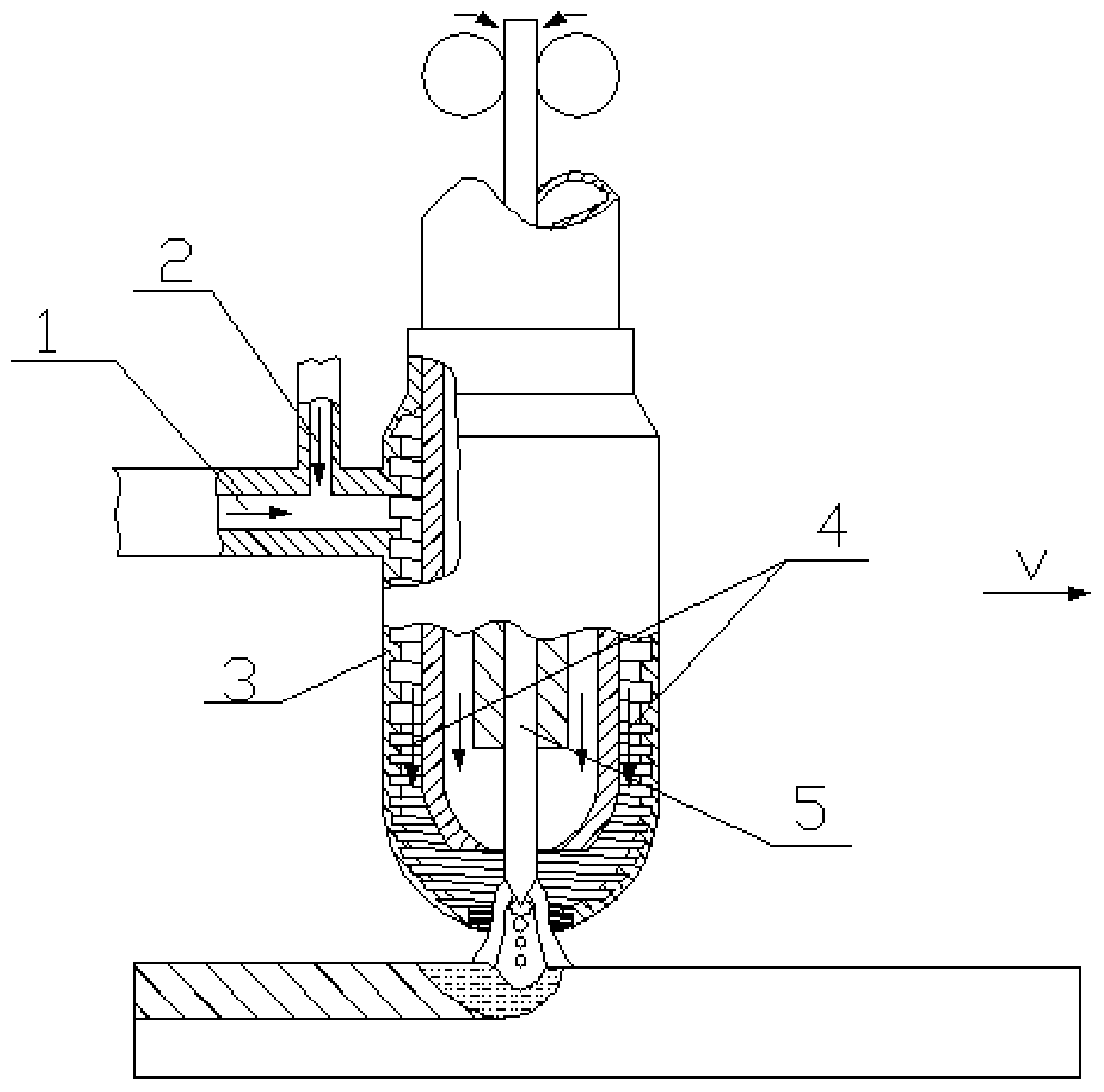

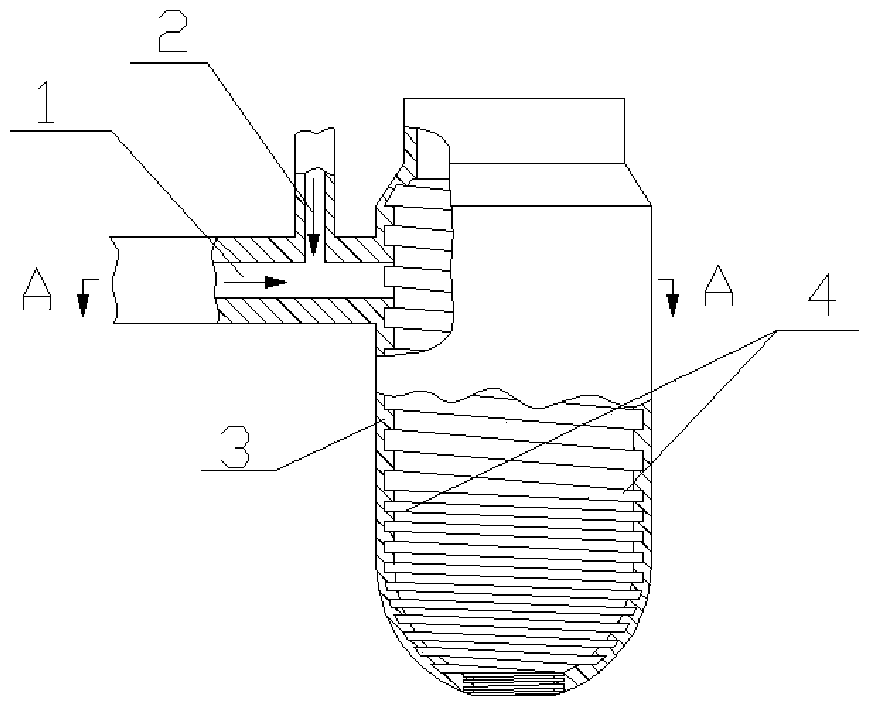

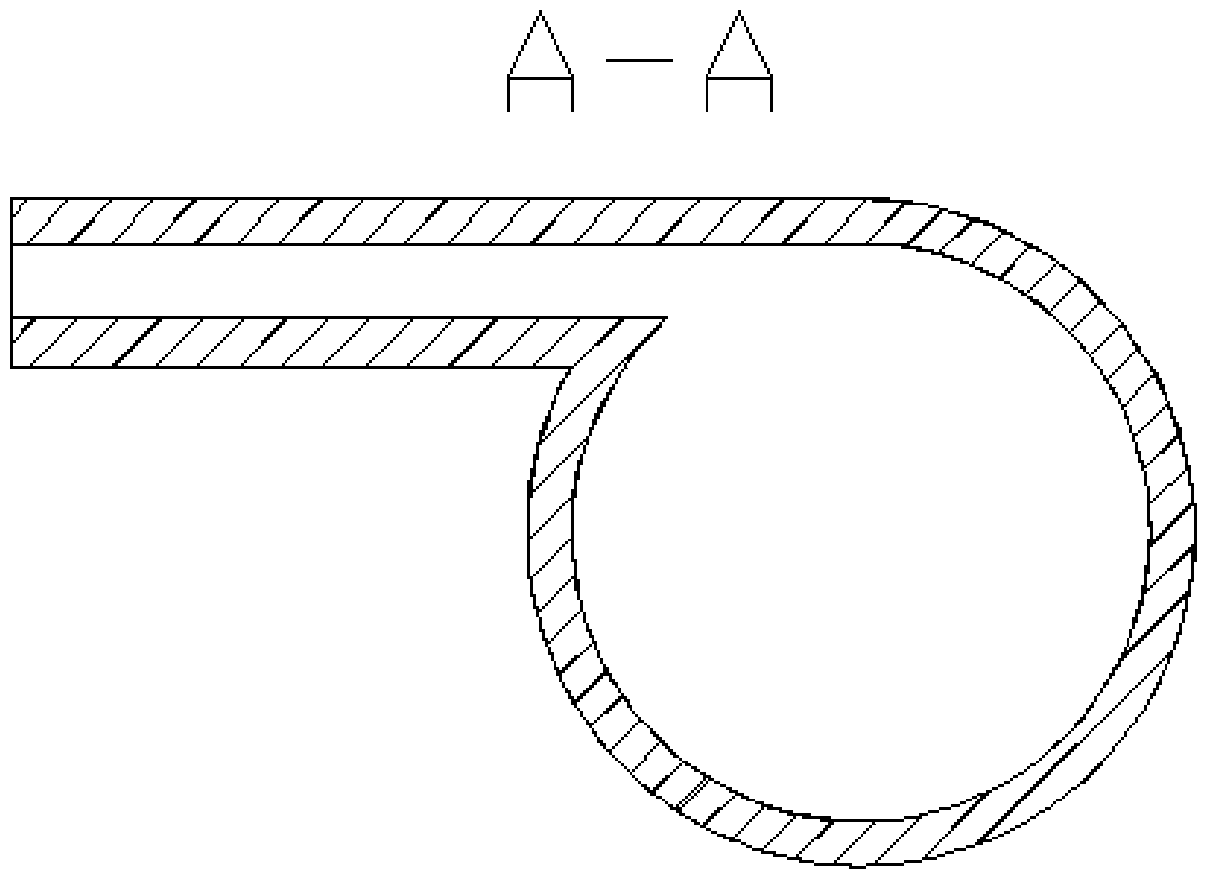

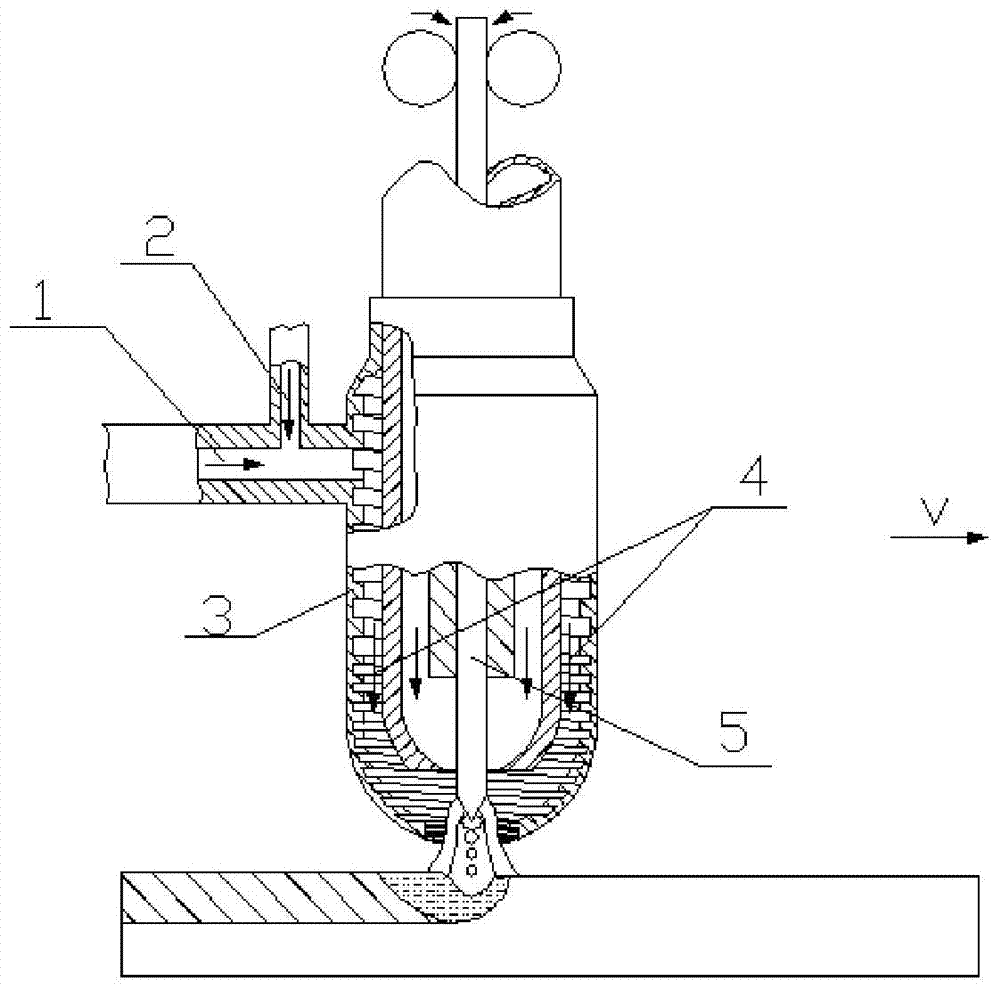

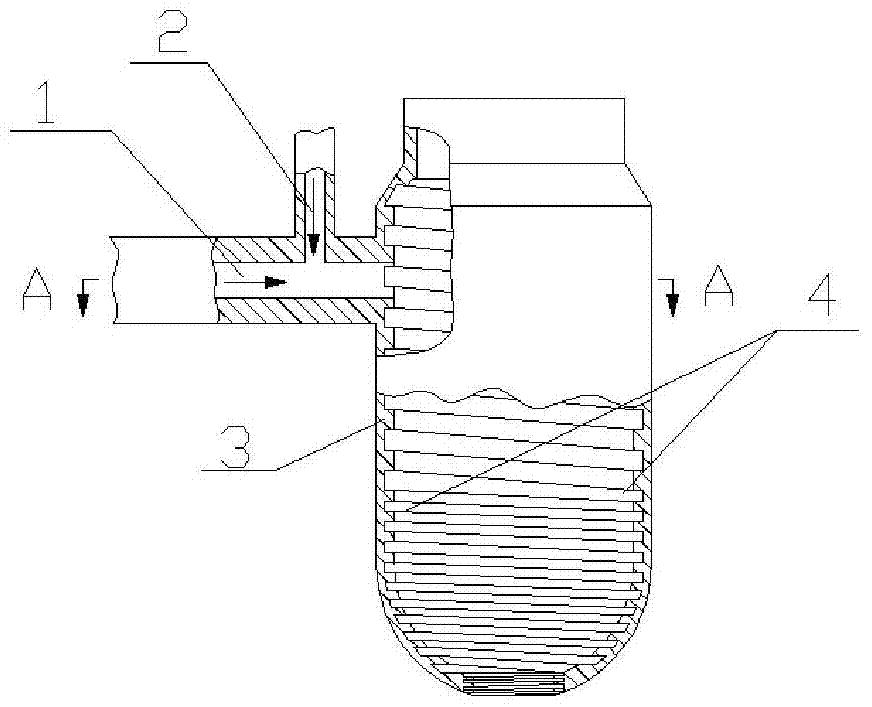

Method for 3D printing of high-nitrogen steel product through nitrogen arc and nitrides

ActiveCN105772909AUniform compositionConducive to full metallurgical smeltingWelding/soldering/cutting articlesWelding accessoriesPower addedAlloy

The invention provides a device for 3D printing of a high-nitrogen steel product through nitrogen arc and nitrides and a method thereof. Surfacing forming of high-nitrogen steel with set layers is achieved at the ordinary pressure through a nitrogen arc wire feeding additive manufacturing method, and nitride alloy powder is added into a molten pool through nitrogen powder feeding. Spiral gas powder grooves are bored in the inner wall of a coaxial spiral gas powder cover. The nitride alloy powder forms rotary gas powder flow at a welding gun muzzle, the loss caused by scattering when the nitride alloy powder flows out of the gun muzzle is reduced, and the effect that the nitride alloy powder and molten drops at the ends of welding wires are fully and metallurgically smelted and then enter the molten pool is ensured. By controlling parameter matching of 3D printing, high-nitrogen steel printing layers with different nitrogen contents can be obtained. The mode of nitride alloy powder and welding wire synchronous coaxial power adding and wire feeding is adopted, and 3D printing of the high-nitrogen steel product at the ordinary pressure is achieved through a common steel welding wire-nitride alloy powder-nitrogen arc composite technology.

Owner:JIANGSU SHUOSHI WELDING SCI & TECH

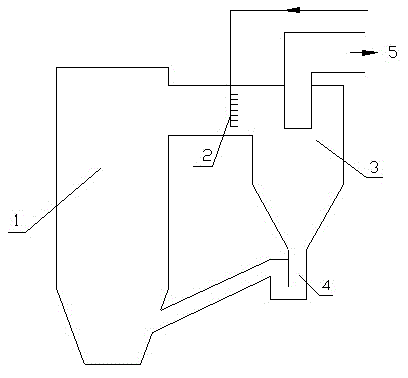

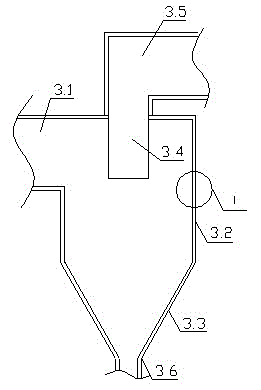

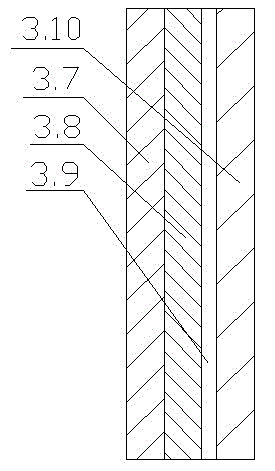

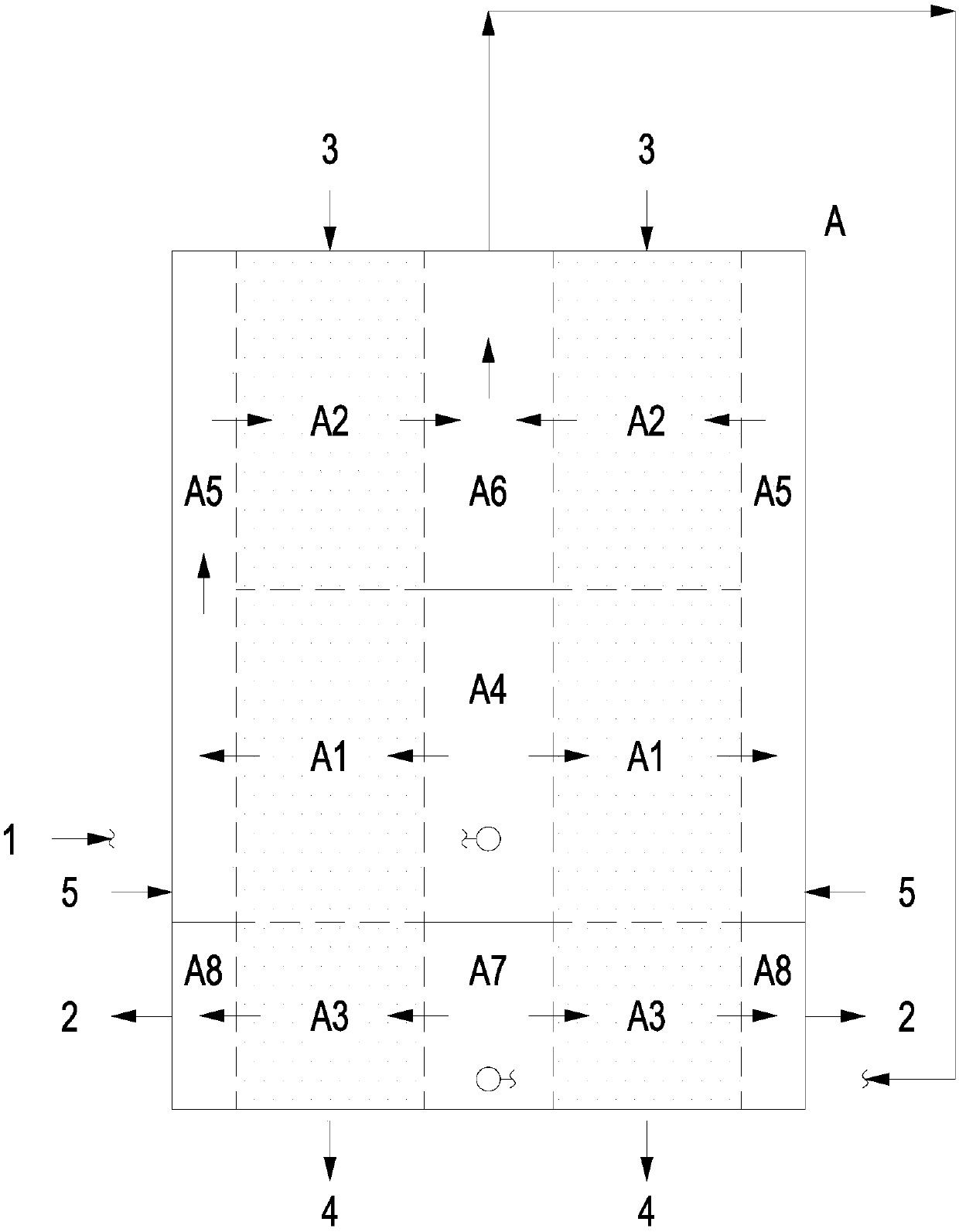

Reaction device for SNCR (selective non-catalytic reduction) denitration system of circulating fluid bed

InactiveCN102974204AAchieve normal operationHigh emission requirementsLighting and heating apparatusDispersed particle separationFluidized bedEngineering

The invention discloses a reaction device for an SNCR (selective non-catalytic reduction) denitration system of a circulating fluid bed, and relates to a smoke denitration reactor in a power plant. The reaction device provided by the invention is characterized in that one side of a circulating fluid bed boiler is connected with one ends of a horizontal flue and a material returning device respectively, the other end of the horizontal flue is provided with a tail flue, and a cyclone separator is arranged between the other ends of the horizontal flue and the material returning device; one side of the upper part of a cylinder body is provided with an air inlet connected with the horizontal flue, a center cylinder connected with one end of an exhaust port is arranged at the upper part of the cylinder body, the other end of the exhaust port is connected with the tail flue, the lower part of the cylinder body forms a cone which is gradually shrunken, one end, which is far from the cylinder body, of the cone is provided with a discharge port, and the tail end of the discharge port is connected with the material returning device; and a phase change heat storage material layer is arranged on the inner wall of the cylinder body. The reaction device provided by the invention can well control the escape quantity of a reducing agent, has wide load range of the boiler, can meet the discharage of NOX with high requirements, and realizes the purpose that the SNCR system runs normally.

Owner:江苏百灵天地环境设计研究院有限公司

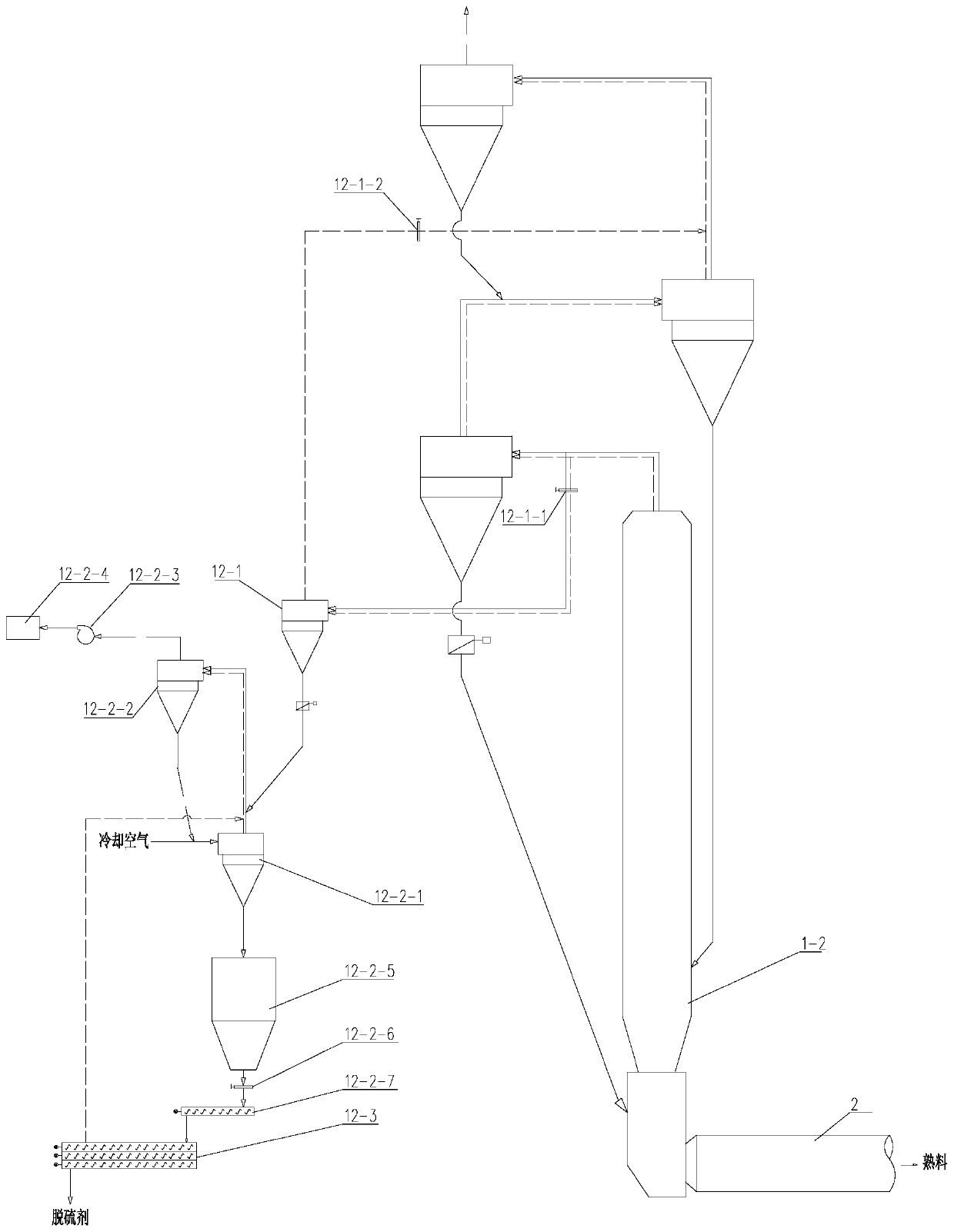

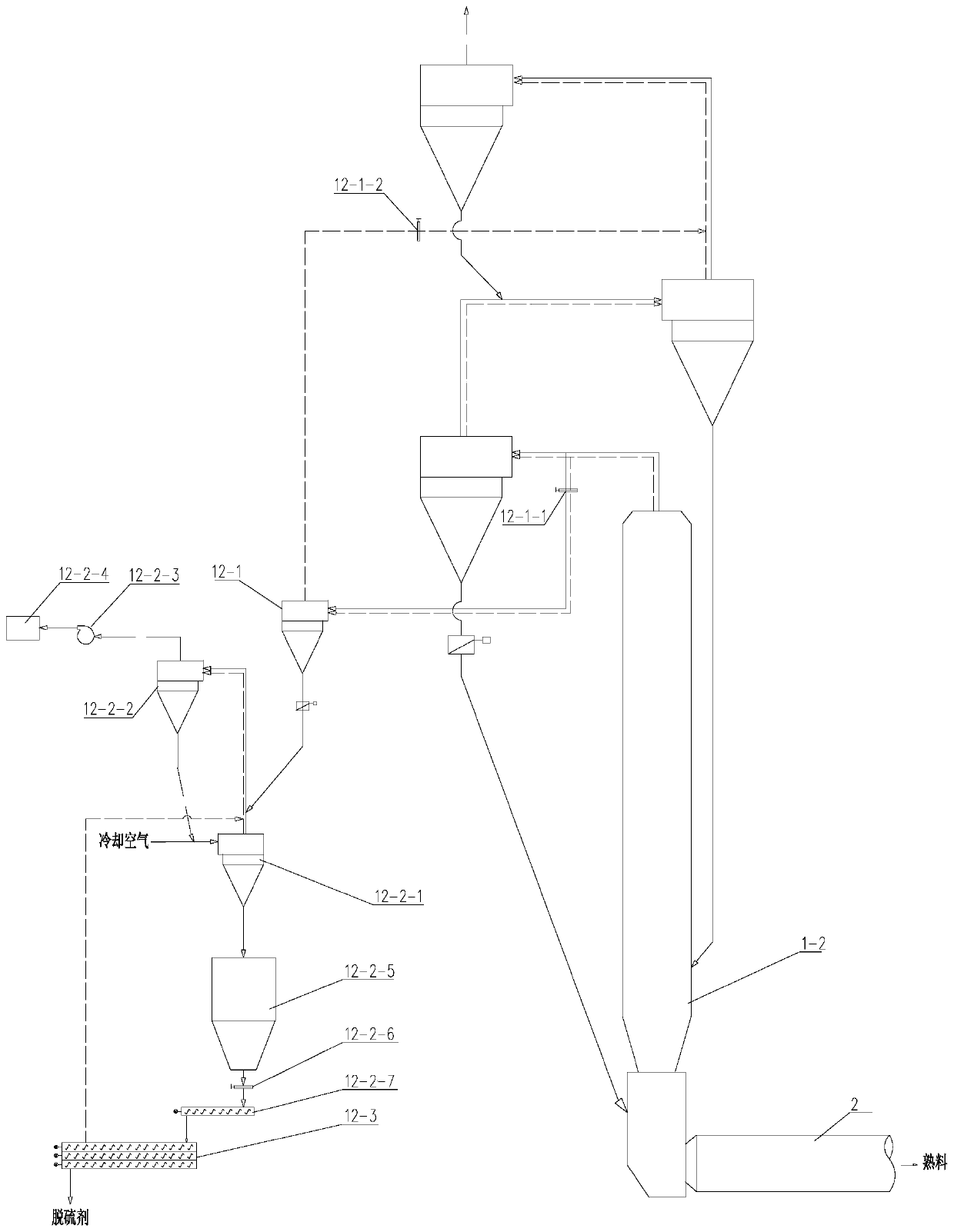

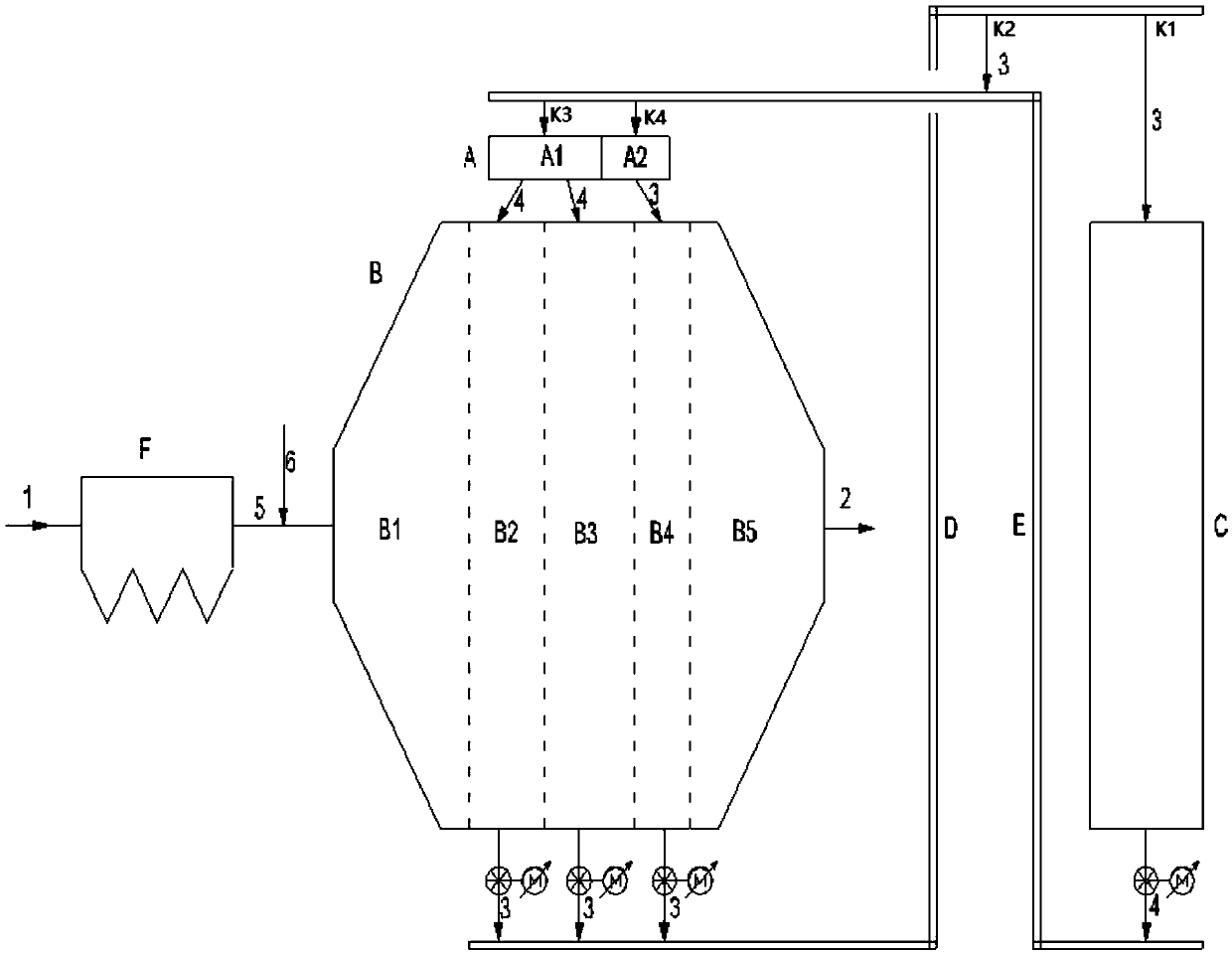

Desulfurization denitration dedusting ultra-low discharge process and system for producing cement from high-sulfur raw materials

PendingCN110052141ASolve the problem of desulfurization and denitrification ultra-low emissionsSolution to short lifeGas treatmentDispersed particle separationSulfurFlue gas

The invention discloses a desulphurization denitration dedusting ultra-low discharge process and system for producing cement from high-sulfur raw materials. The process comprises the steps of cement clinker firing, coarse dedusting, semi-dry desulphurization, fine dedusting, desulphurization ash treatment, flue gas blending and low-temperature SCR denitration. The system comprises a cement clinkerfiring system, a kiln tail high-temperature fan, a grinding system, a first dust collector, a semi-dry desulphurization tower, a second dust collector, a low-temperature SCR denitration reactor, a kiln head dust collector and a kiln head induced draft fan. A gas outlet of the kiln tail preheater C1, the kiln tail high-temperature fan, the grinding system, the first dust collector, the semi-dry desulfurization tower, the second dust collector, a relay fan, the low-temperature SCR denitration reactor, an exhaust fan and a kiln tail chimney are sequentially connected and arranged; an air outletof a cooler, the kiln head dust collector and the kiln head induced draft fan are sequentially connected; and the outlet of the kiln head induced draft fan is connected with a gas outlet of the seconddust collector. According to the invention, a semi-dry desulfurization and low-temperature SCR denitration process is adopted, so that ultra-low discharge of desulfurization, denitration and dedusting for producing the cement from the high-sulfur raw materials is realized.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

Device for 3D printing of high-nitrogen steel products through nitrogen arc and nitride

ActiveCN105522264AUniform compositionConducive to full metallurgical smeltingElectrode supporting devicesWelding/soldering/cutting articlesAlloyNitrogen gas

The invention provides a device and method for 3D printing of high-nitrogen steel products through a nitrogen arc and nitride. Overlaying shaping of high-nitrogen steel with a set layer height is carried out through a nitrogen arc wire feeding material increase manufacturing method under normal pressure, and meanwhile nitride alloy powder is added into a molten pool through nitrogen powder feeding. A spiral air powder groove is bored in the inner wall of a coaxial spiral air powder cover, the nitride alloy powder forms air powder cyclone at a welding gun opening, the loss caused by scattering of the nitride alloy powder when the nitride alloy powder flows out of the welding gun opening is reduced, and meanwhile the effect that the nitride alloy powder and molten drops at the end of a solder wire are fully metallurgically smelted and then enter the molten pool is guaranteed. By controlling parameter matching of 3D printing, high-nitrogen steel printing layers with different nitrogen contents can be obtained. A synchronous and coaxial powder adding and wire feeding method with the nitride alloy powder and the solder wire is adopted, so that 3D printing of the high-nitrogen steel products through a technology integrating the common steel solder wire, the nitride alloy powder and the nitrogen arc is realized under normal pressure.

Owner:JIANGSU SHUOSHI WELDING SCI & TECH

Stainless steel acid-washing acid mist inhibitor and preparation method thereof

The invention discloses a stainless steel acid-washing acid mist inhibitor and a preparation method thereof. The stainless steel acid-washing acid mist inhibitor comprises the following components in percentage by weight: 0.2 to 1.0 percent of non-ionic surfactant, 0.1 to 0.3 percent of anionic surfactant, 0.5 to 1.0 percent of foam stabilizer and the balance of water. The non-ionic surfactant is one or more of higher fatty alcohol polyoxyethylene ether, higher fatty acid polyoxyethylene ether and higher fatty amine polyoxyethylene ether, wherein the number of alkyl carbon is 10 to 26; and the addition number of ethylene oxide is 5 to 20. The anionic surfactant is long chain alkyl sodium sulfonate, long chain alkyl sulfate or long chain alkyl sodium benzenesulfonate, wherein the number of alkyl carbon is 8 to 18. The foam stabilizer is low-carbon fatty amine or inorganic ammonium salt. The stainless steel acid-washing acid mist inhibitor has the characteristics of simple components, no organic solvent and the like, has high film-forming speed, high and stable film-forming thickness and high acid mist inhibition efficiency, and has obvious acid mist inhibition effect particularly under the condition of high nitric acid concentration when stainless steel is mixed with acid to perform acid washing.

Owner:ZHEJIANG UNIV

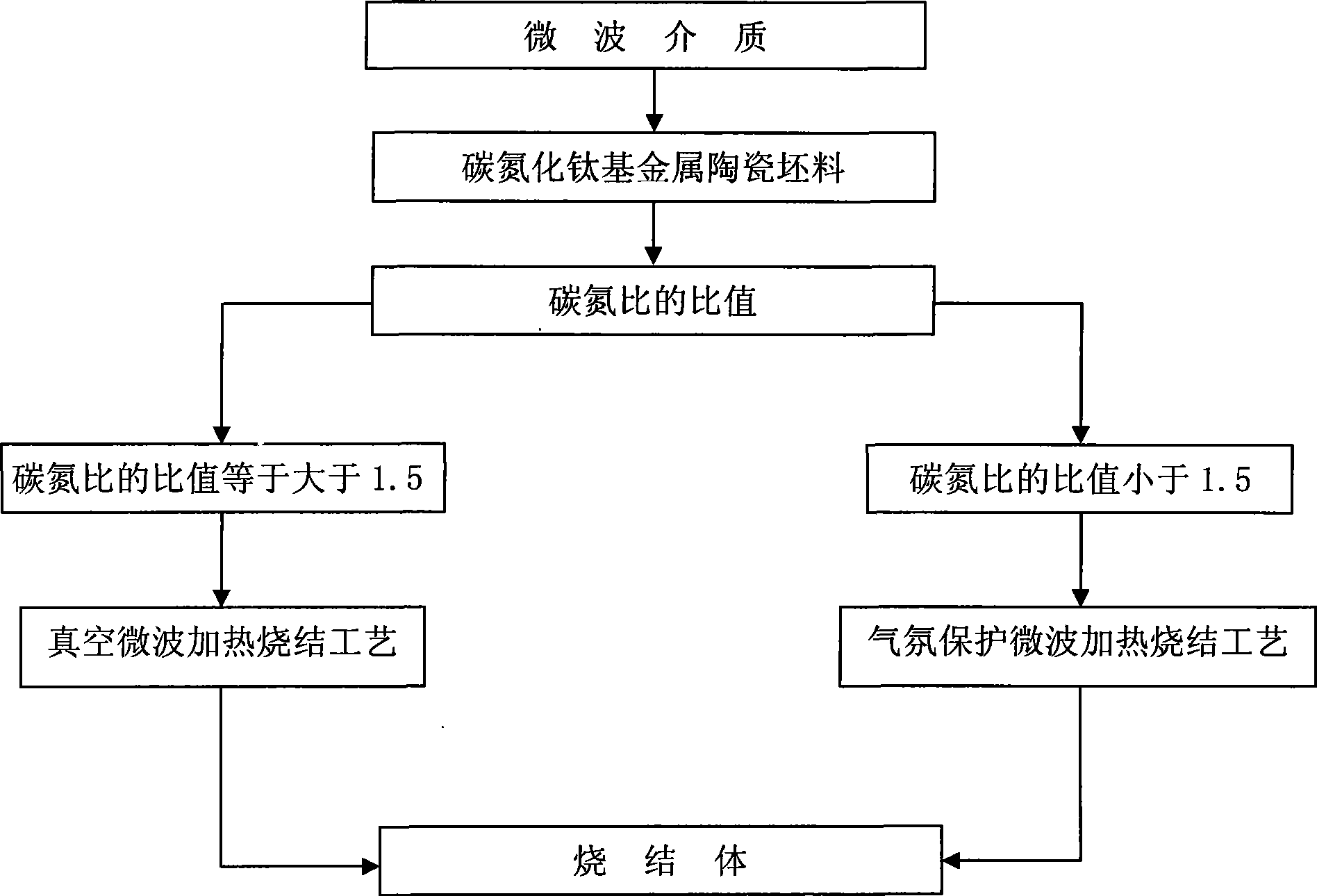

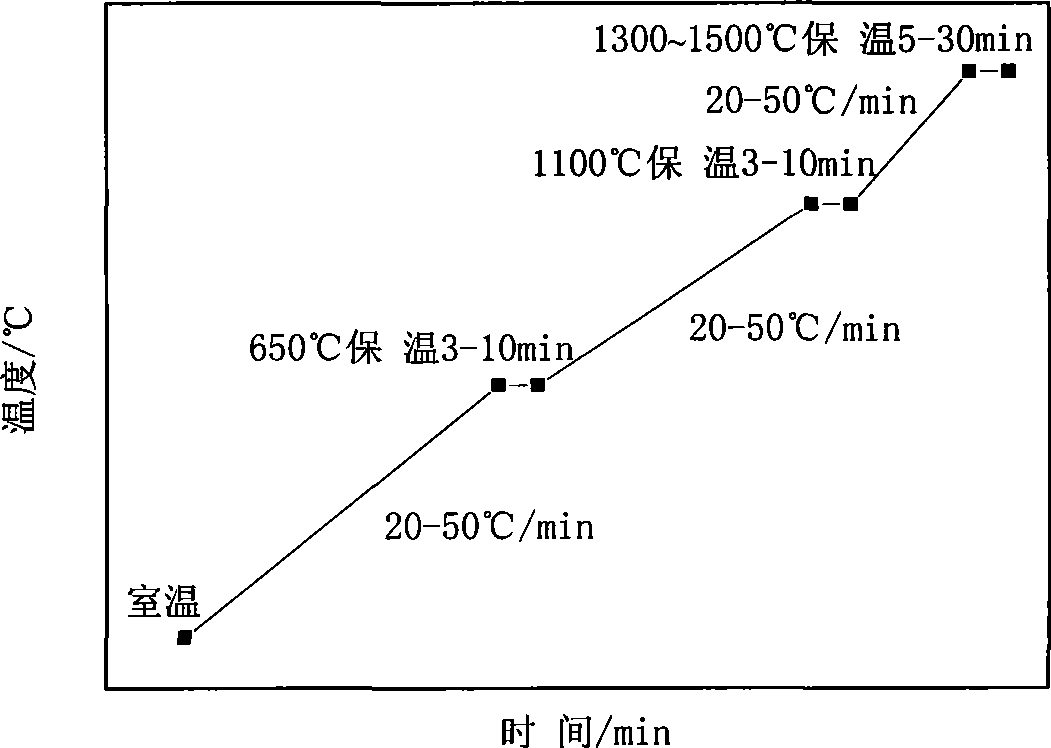

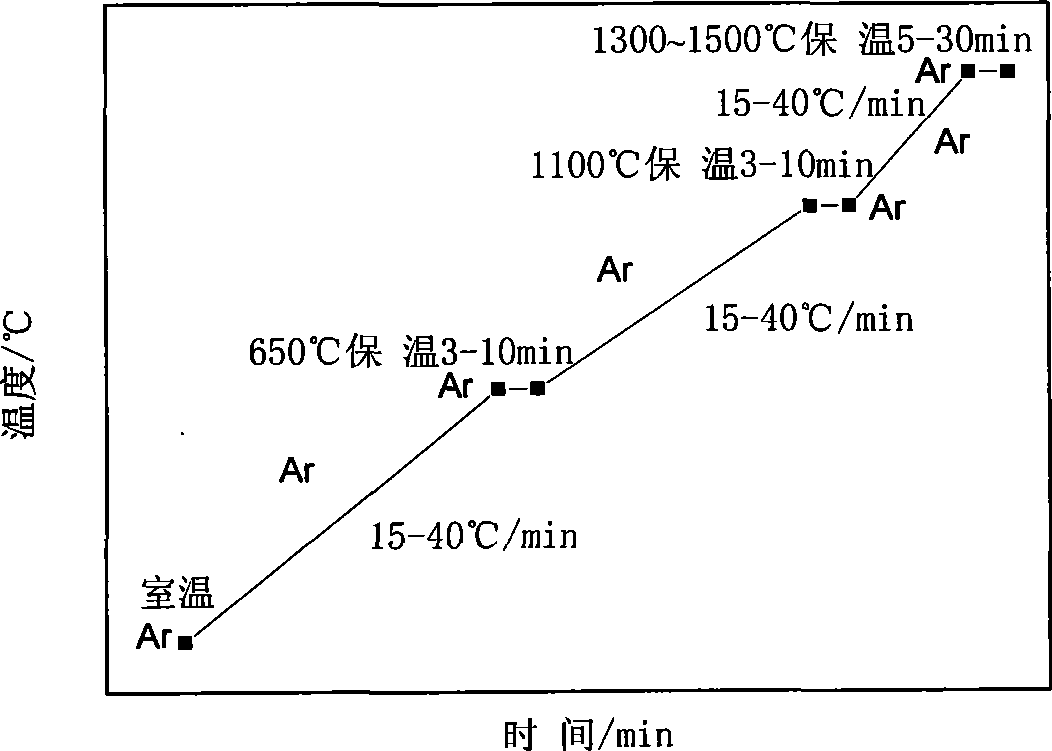

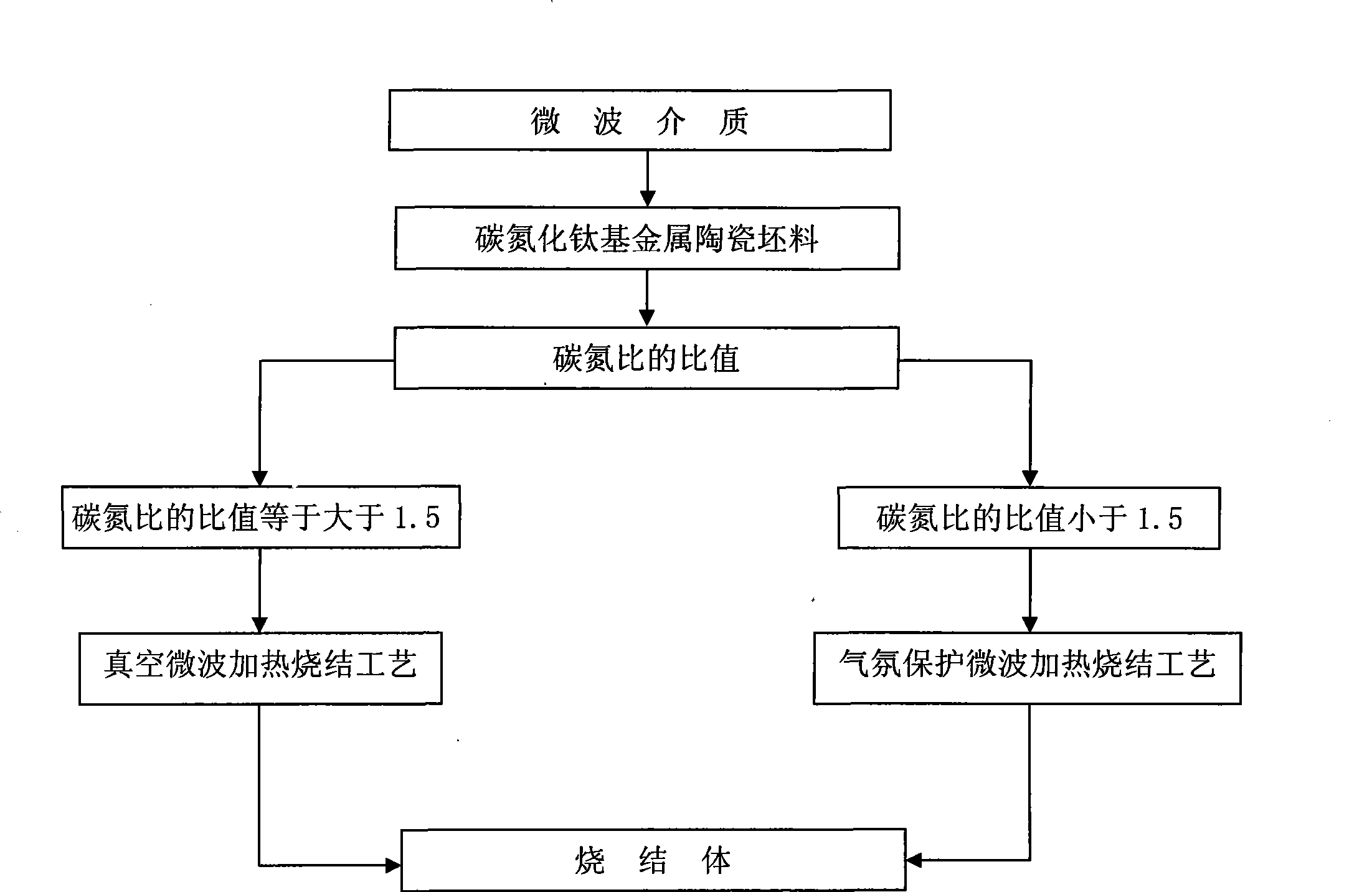

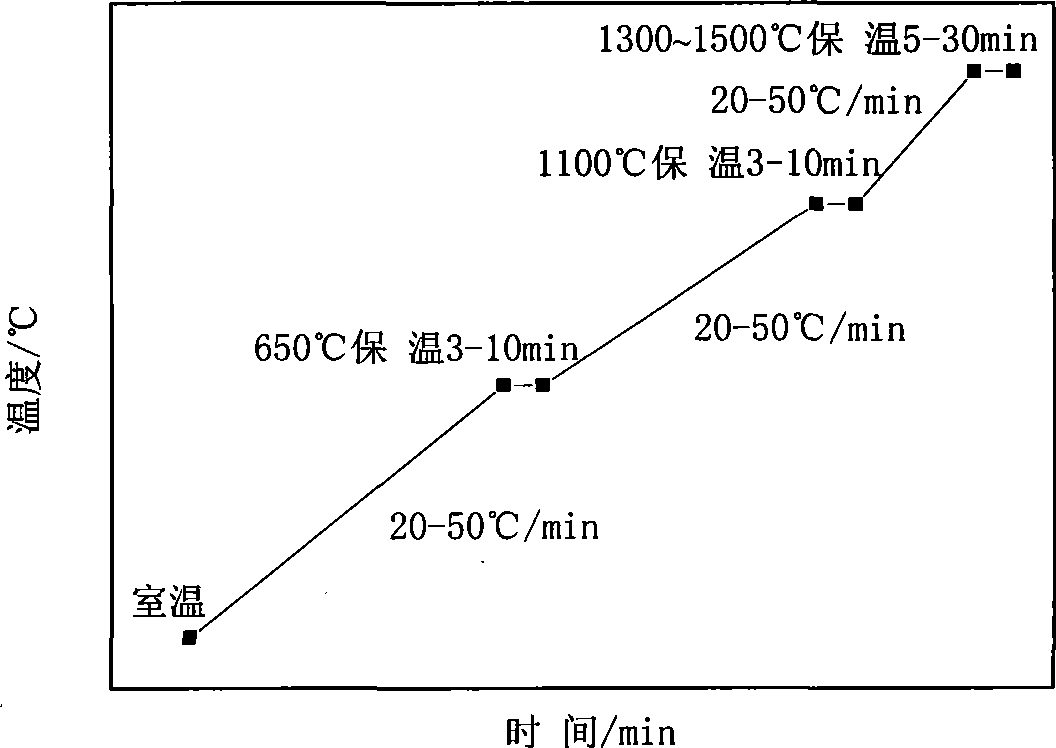

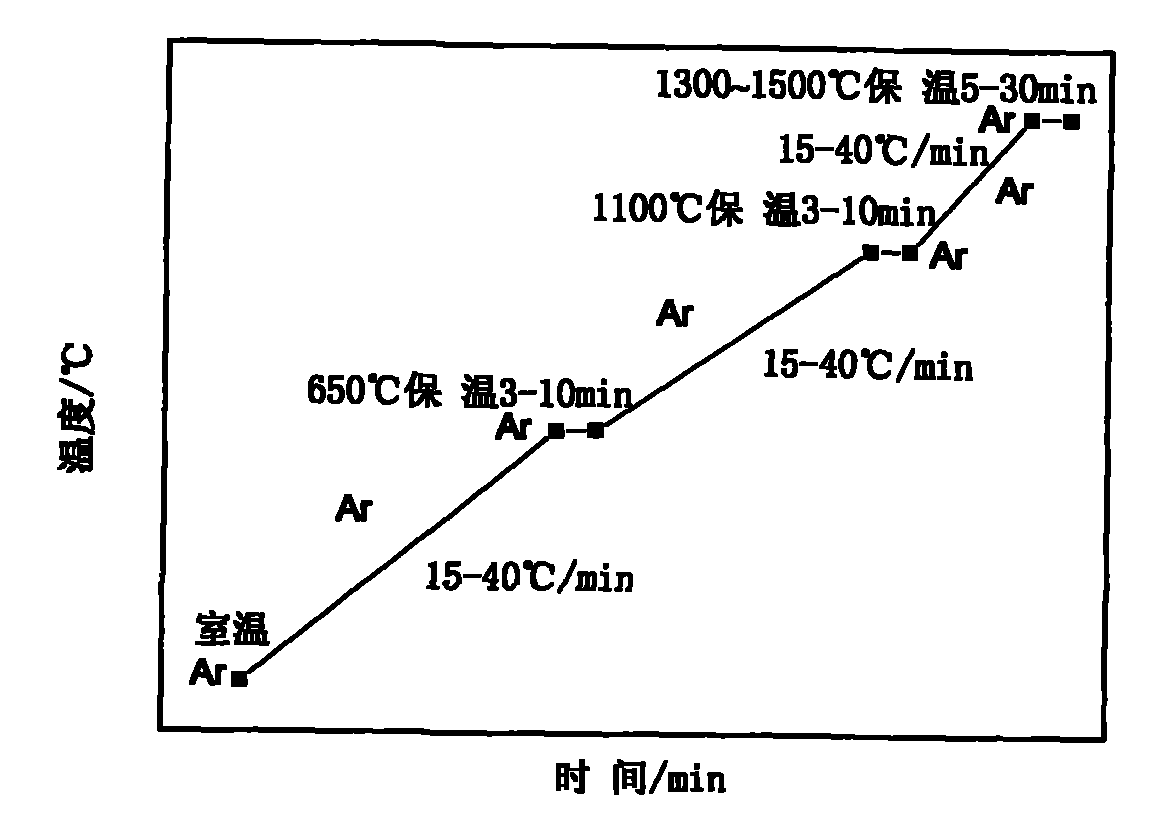

Microwave sintering of superfine grain base titanium carbonitride

The utility model provides microwave sintering of an ultra-fine grain titanium carbonitride group cermet. A 300MHz to 8GHz microwave frequency medium is used as a heat source to enable a billet of the ultra-fine grain titanium carbonitride group cermet to absorb microwave energy to complete the sintering process. During the sintering process, vacuum and atmosphere protection microwave heating and sintering techniques are adopted respectively according to the ratio of carbon to nitrogen of the billet of the ultra-fine grain carbon titanium nitride cermet. The 300MHz to 8GHz microwave frequency is used to heat and sinter the billets of the titanium carbonitride group cermet with different ratio of carbon to nitrogen and vacuum microwave sintering and atmosphere protection microwave sintering technological proposals are used respectively for the billets of the titanium carbonitride group cermet with the different ratio of carbon to nitrogen, which overcomes the defects of the prior vacuum or atmosphere protection sintering techniques, such as low heating efficiency, long sintering time, large energy consumption, serious environment pollution and oversized grains, and the like. The microwave sintering can be widely applied to sintering other ceramics, ceramic matrix composites and intermetallic compound materials with stronger microwave absorbing capacity.

Owner:HUNAN UNIV OF SCI & TECH

System and method for adsorbing and purifying flue gas by using active coke

InactiveCN110856792AAvoid secondary pollutionAvoid frequent reloadingGas treatmentDispersed particle separationFlue gasCoke

The invention relates to a system and a method for adsorbing and purifying flue gas by using active coke. The system comprises an ammonia spraying device, an adsorption tower, a regeneration tower anda lifting device, wherein a flue gas inlet, a regenerated coke adsorption area, a to-be-generated coke adsorption area and a flue gas outlet are in gas communication and are sequentially arranged inthe adsorption tower along a flue gas flowing direction, the to-be-generated coke adsorption area is used for loading to-be-generated coke formed after adsorption of sulfur oxide with active coke, theammonia spraying device is arranged between the inlet of the system and the flue gas inlet of the adsorption tower and is used for supplementing ammonia into a flue gas raw material, and the liftingdevice is respectively communicated with the adsorption tower and the regeneration tower and is used for lifting the to-be-regenerated coke obtained by the adsorption tower to the top of the adsorption tower and / or the regeneration tower and lifting the regenerated coke obtained by the regeneration tower to the top of the adsorption tower. According to the flue gas purification system disclosed bythe invention, the adsorption tower is internally provided with the to-be-coked adsorption area filled with the to-be-coked coke, the reaction activity of the to-be-coked coke to ammonia is high, andthe ammonia in flue gas can be fully captured, so that the reaction activity of ammonia escape of purified flue gas to ammonia can be effectively controlled.

Owner:SINOPEC ENG +1

Small circulating lubrication system cooled by using liquid nitrogen

InactiveCN103822078AImprove leakageEasy to polluteLubrication elementsLiquid nitrogen coolingEngineering

A small circulating lubrication system cooled by using liquid nitrogen comprises a liquid nitrogen refrigerating system and a lubrication oil circulating system. The cooling speed of lubricating oil in an oil supply pipe of the lubrication system is increased; and moreover, the lubrication oil which is heated by using a plate radiator is recycled. The whole small circulating lubrication system is simple in structure and convenient to operate, and is economical and practical.

Owner:HENAN UNIV OF SCI & TECH

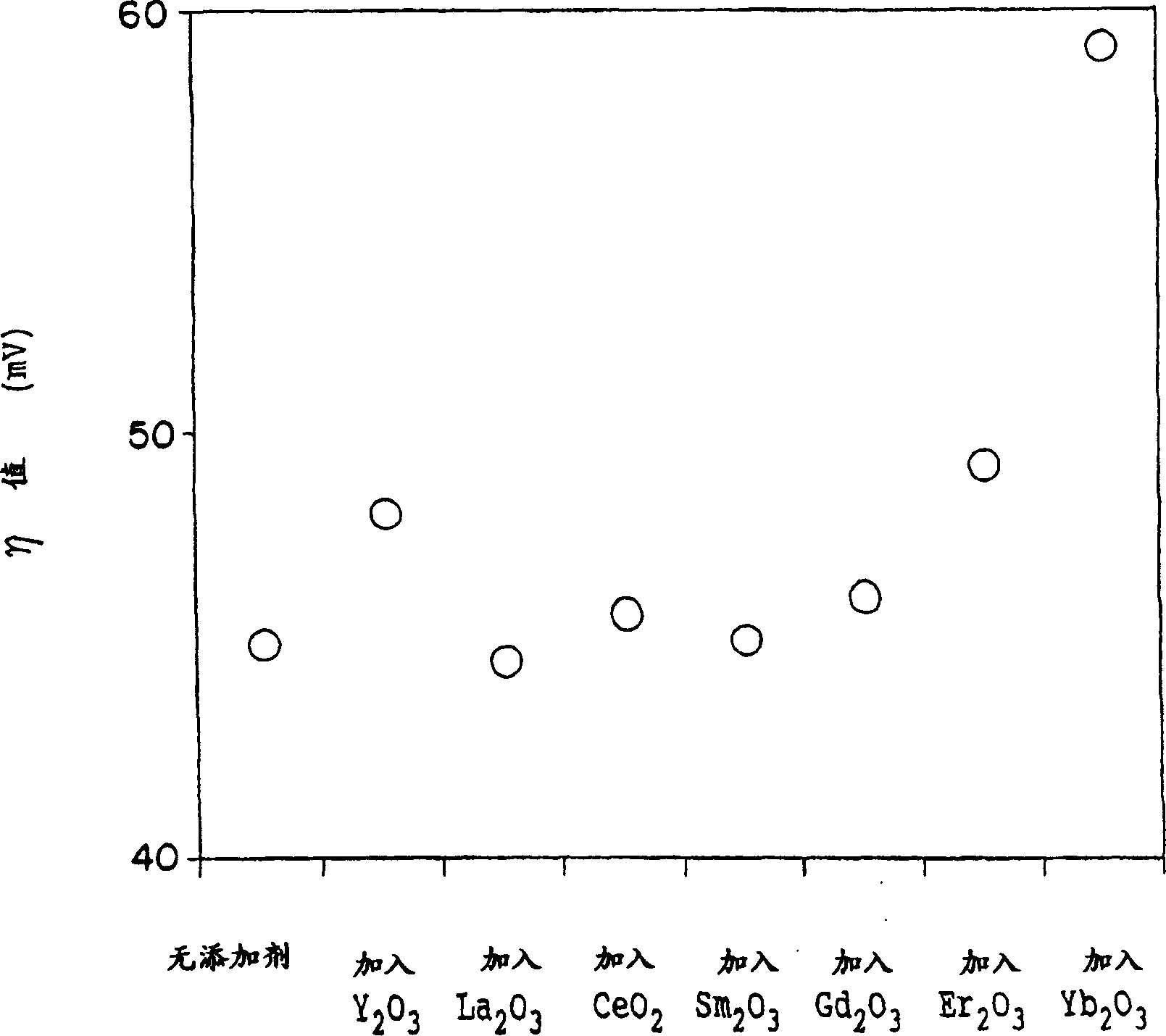

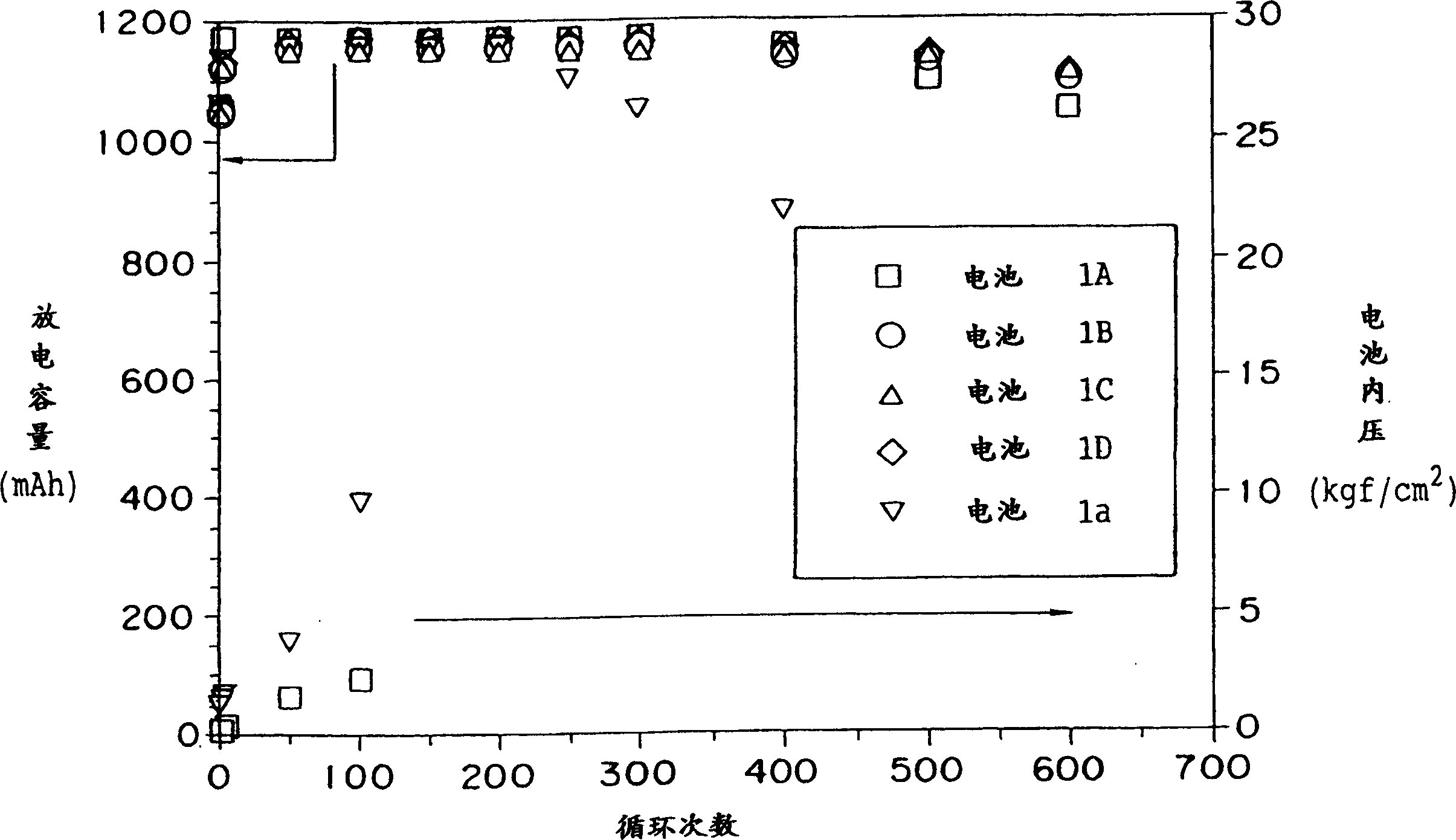

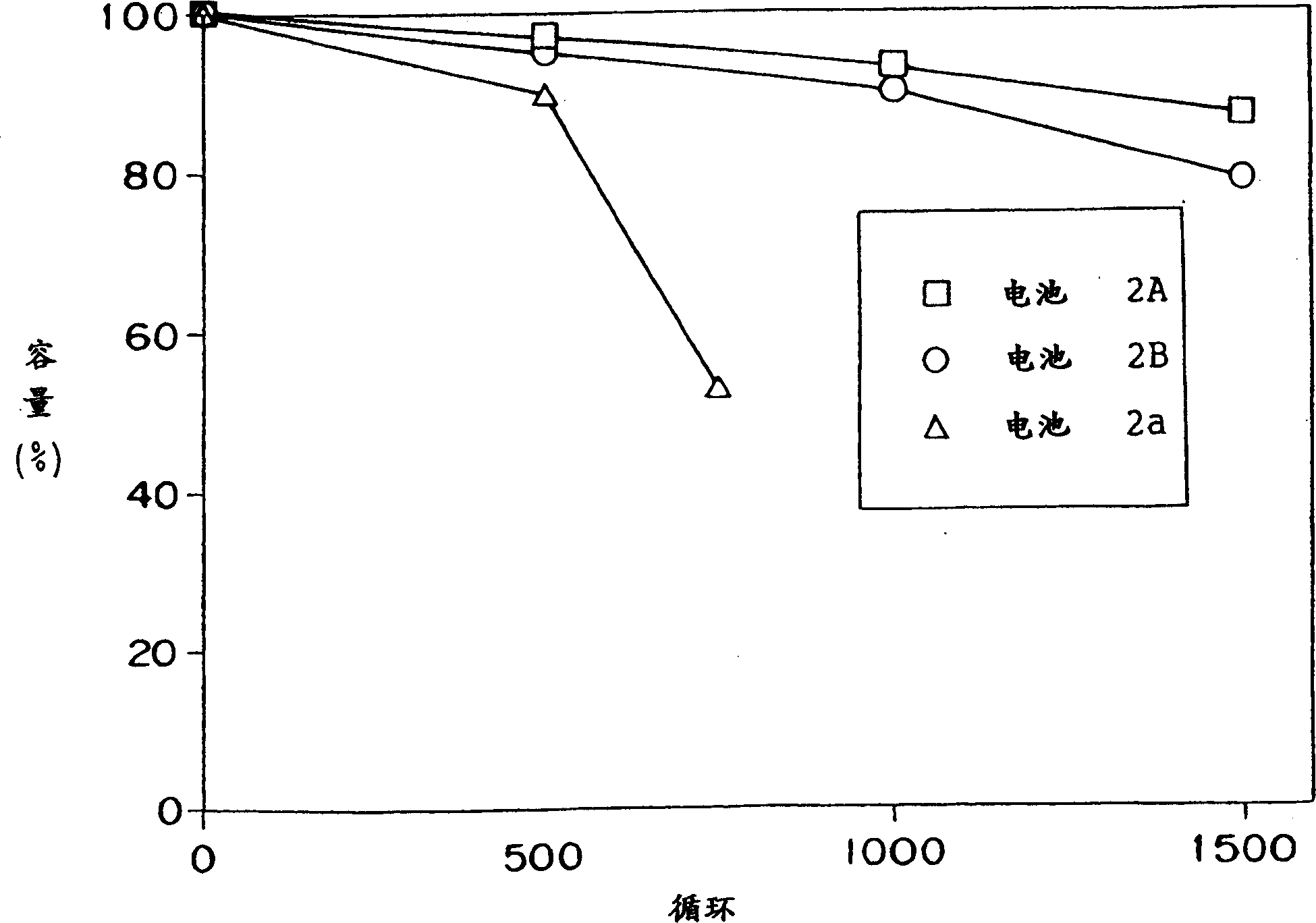

Hydrogen storage electrode, nickel electrode and alkaline storage battery

InactiveCN1536691AControl escapeImprove corrosion resistanceAlkaline accumulatorsCell seperators/membranes/diaphragms/spacersRare-earth elementNickel oxide hydroxide

This invention relates to a hydrogen absorbing electrode, in which a rare earth element having a basicity weaker than that of La is mixed to a hydrogen absorbing alloy or contained in it for serving as a component element. The invention relates to a nickel electrode, in which a rare earth element is mixed to a nickel hydroxide or contained in it as a solid solution. The invention further relates to an alkaline storage battery, in which a rare earth element is coated on a surface of a nickel electrode or a surface of a separator.

Owner:株式会社杰士汤浅工业

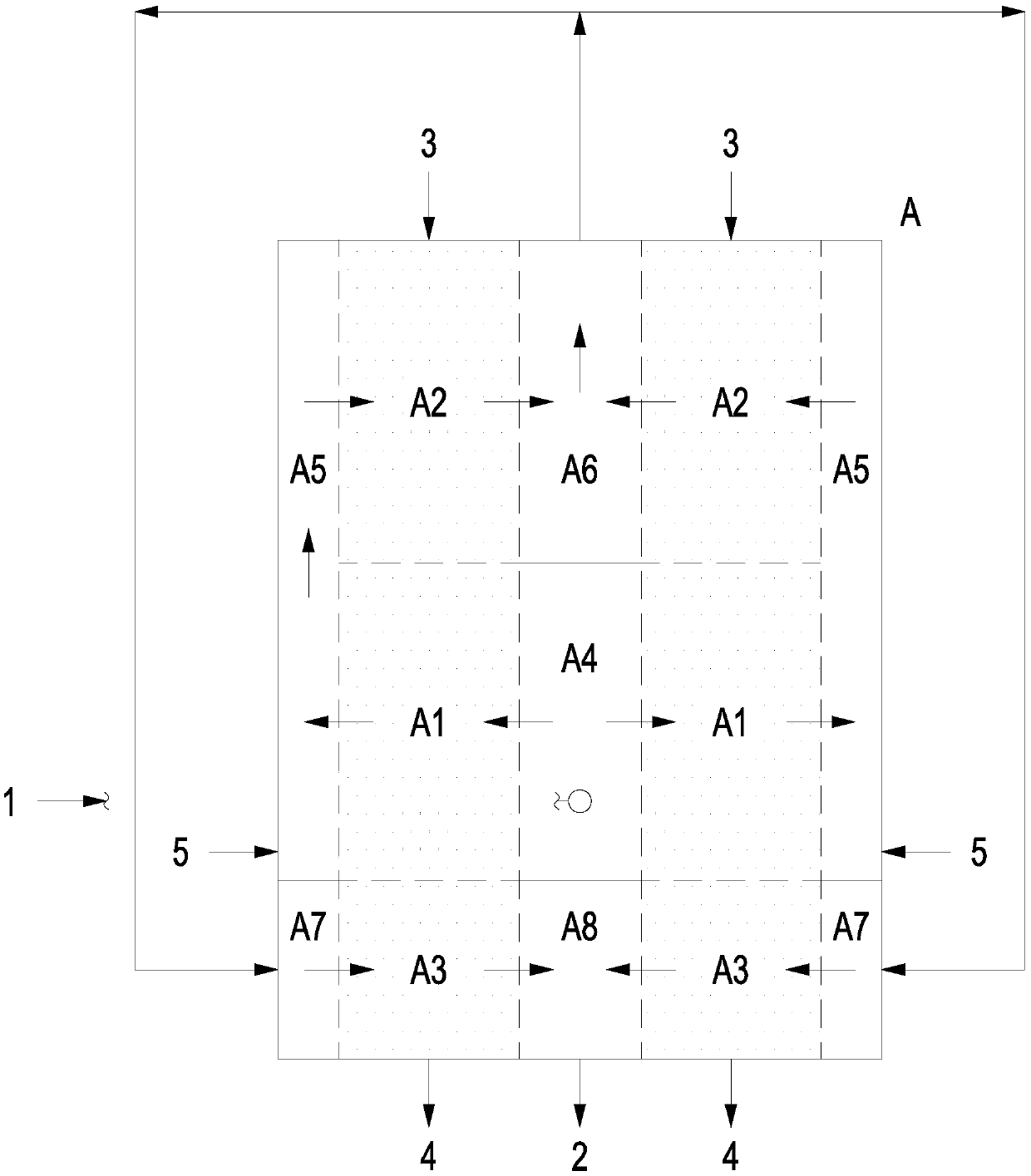

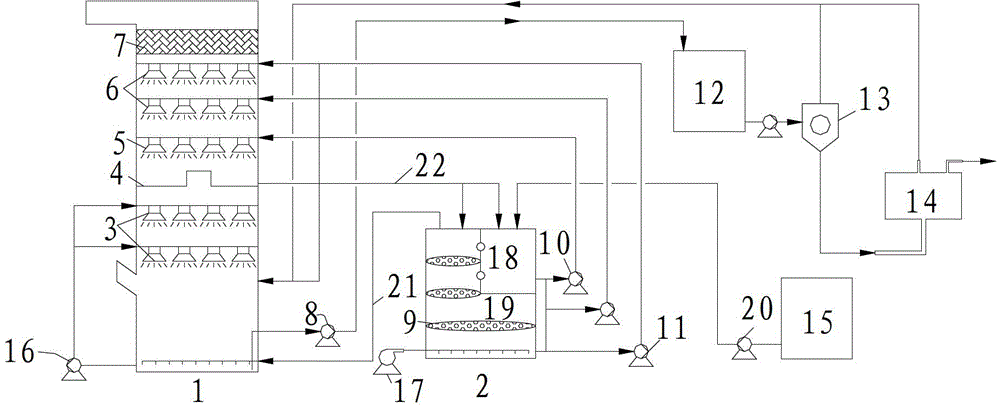

Efficient ammonia desulphurization and dust removal device and application method thereof

InactiveCN112403246AControl escapeControl formationCombination devicesGas treatmentAmmonium sulfateProcess engineering

The invention discloses an efficient ammonia desulphurization and dust removal device and an application method thereof. The device comprises a desulfurization tower, an ammonium sulfate discharge pump connected with the bottom of the desulfurization tower, an ammonium sulfate post-treatment system and / or a drying system connected to the downstream of the ammonium sulfate discharge pump, a concentration circulating pump connected between a concentration crystallization area in the desulfurization tower and the bottom of the desulfurization tower, an oxidation tank connected with a segmented absorption area in the desulfurization tower, an absorption pump which is connected between the oxidation tank and the deep washing demisting area, a liquid ammonia supply equipment which is connected to the upstream of the oxidation tank, and a washing circulation box and a washing pump which are connected to the deep washing demisting area. The desulfurizing tower is arranged in a partitioned manner, so that dust and mist can be absorbed in a graded manner; the sectional absorption area is divided into two sections, so that the SO2 absorption rate is increased, and flue gas dust is effectivelyremoved. By arranging the filler, the gas-liquid contact area is increased, and ammonia escape and aerosol components carried in the flue gas can be effectively removed. And through the ammonium sulfate post-treatment system and the drying system, the crystallized slurry can be reutilized and treated.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG

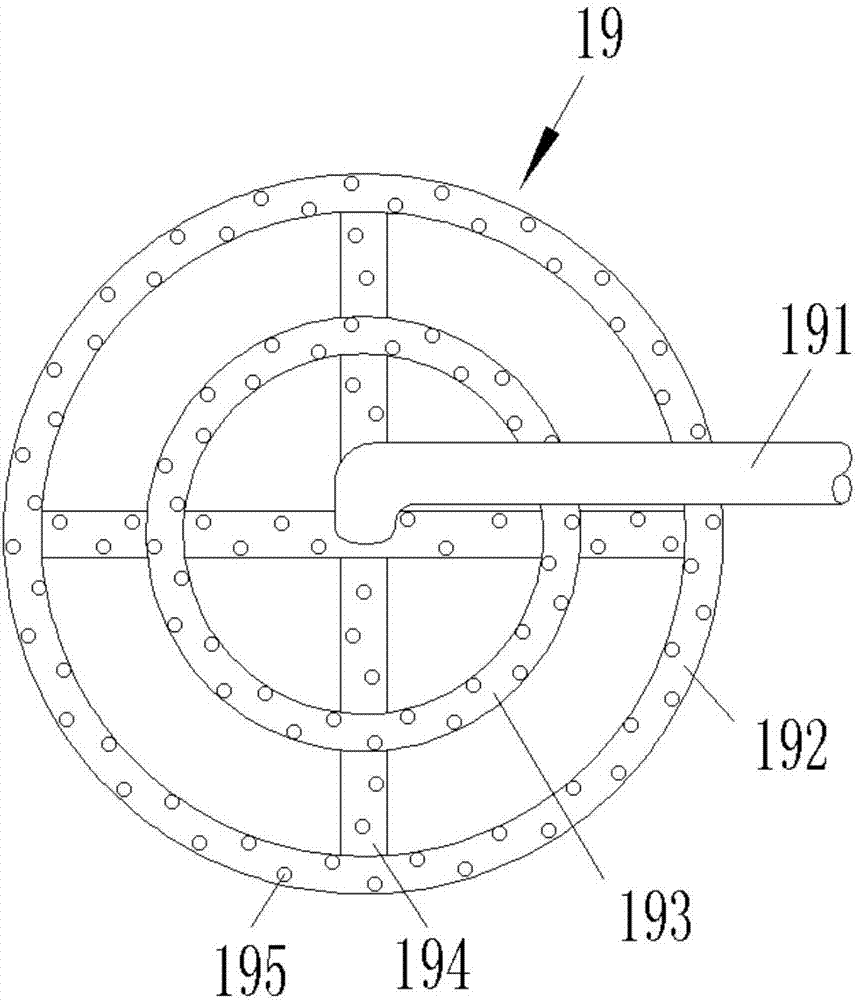

Integrated device for catalytic-cracking-flue-gas desulfurization, denitration, dust removing and acid mist removing and method

PendingCN107952352AImprove desulfurization efficiencySolve tailingCombination devicesGas treatmentFlue gasIntegrated devices

The invention discloses an integrated device for catalytic-cracking-flue-gas desulfurization, denitration, dust removing and acid mist removing. The integrated device comprises an ozone generator anda desulfurization tower; a slant flue and a chimney are arranged on the desulfurization tower, and a rapid-cooling spraying pipe, an ozone distribution disc, an accident spraying pipe, a first riser cap, a plurality of empty tower spraying pipes, a second riser cap, an ammonia demister, a ridge demister and a mesh demister are sequentially arranged at the portion, between the slant flue and the chimney, in the desulfurization tower in the flue-gas flowing direction; the ozone generator is communicated with the ozone distribution disc through a pipe. The integrated device has the advantages that the desulphurization efficiency of flue gas can be effectively improved, generation of ammonia escaping, aerosol and acid mist can be effectively controlled, and meanwhile both Sox and NOx enter thefollow-up working procedure. Dust in the flue gas is removed through a flue gas-dust separating device, the desulfurization rate of the device is larger than or equal to 99%, the denitration rate islarger than or equal to 60%, the dust removing rate is larger than or equal to 80%, the removing rate of acid mist is larger than or equal to 90% when mist is removed with electricity, and the removing rate of the acid mist is larger than or equal to 60% when mist is removed with screen meshes.

Owner:ASIA PACIFIC ENVIRONMENTAL CORP

System for direct-injection removing NOX and SO3 in bypass flues of boiler

PendingCN109012104ASolve the ABS problemFully pyrolyzedGas treatmentDispersed particle separationFluePyrolysis

The invention discloses a system for direct-injection removing NOX and SO3 in bypass flues of a boiler. The system for direct-injection removing NOX and SO3 in bypass flues of athe boiler comprises adirect injection device of the bypass flues of the boiler and an SCR (SelectiveCatalytic Reduction)denitration device which are in communication with each other. The direct-injection device of the bypass flues of the boiler comprises sequentially connected boiler bypass flues, a pyrolysis chamber, a conical collection box and an injection device. An injection gun is further comprised. The SCR denitration device comprises an economizer outlet horizontal flue, an SCR inlet ascending flue, an SCR reactor and an SCR reactor outlet flue. According to the system for direct-injection removing NOX andSO3 in bypass flues of the boiler provided by the invention, an ammonia-contained gas injection device at the bypass flue outlet and a large-scale gas mixing device at the denitration inlet are designed for a process of direct-injection carbamide pyrolysis and denitration at bypass flues of the boiler, and a high efficient and low-cost removal of NOX and SO3 can be realized, so as to fundamentally solve the ABS (Ammonium Bisulfate)problem. According to the invention, the ammonia-nitrogen molar ratio distribution uniformity of the catalyst inlet reaches a level of the existing SCR denitrationdevice, and the key technical problem for the practical application of the process of direct-injection carbamide pyrolysis and denitration at bypass flues of the boiler is solved.

Owner:SUZHOU XIRE ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

Molecular cage modified fuel battery proton exchange membrane and preparation method thereof

InactiveCN109326809AAvoid dissolution lossImprove stabilityFinal product manufactureFuel cellsSolventProton mobility

The invention provides a molecular cage modified fuel battery proton exchange membrane and a preparation method thereof. Benzenetricarboxaldehyde and hydrated heteropoly acid are added into an ethyl acetate solvent; after stirring treatment, an ethylenediamine solution is added; an organic molecular cage coated heteropoly acid particle colloid material is obtained through heat treatment; then, mixing and ball milling are performed on the organic molecular cage coated heteropoly acid particle colloid material and solid nafion resin powder in an organic solvent; casting film forming is performedto obtain the molecular cage modified fuel battery proton exchange membrane. The method has the advantages that an organic molecular cage coat the heteropoly acid particles; the escape of the heteropoly acid particles from the molecular cage is effectively controlled; water molecules can freely flow inside the molecular cage; the dissolution loss of heteropoly acid is effectively avoided; the stability of the heteropoly acid compounds is improved; meanwhile, the whole protolysis rate of the film material cannot be reduced; meanwhile, in the preparation, the compounding conditions are simple,so that the technical flow process is simplified; the mass production of the proton exchange membrane can be promoted.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

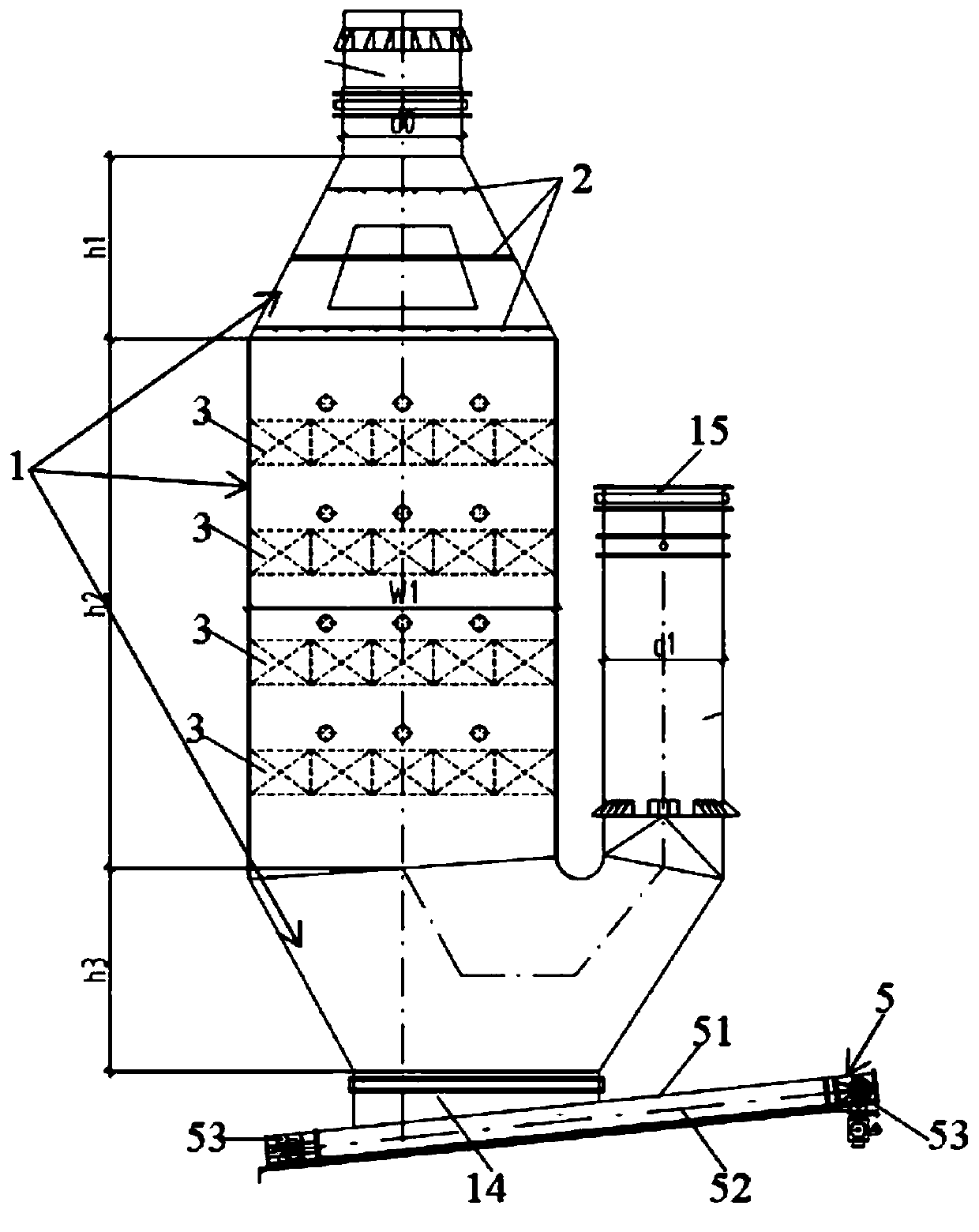

Active coke adsorption tower and method for adsorbing and purifying flue gas by active coke

ActiveCN110898607AControl escapeAvoid secondary pollutionGas treatmentDispersed particle separationFlue gasPhysical chemistry

The invention relates to an active coke adsorption tower and a method for adsorbing and purifying flue gas by active coke. According to the active coke adsorption tower disclosed by the invention, anactive coke adsorption area and a gas buffer area are arranged; flue gas firstly enters the upper gas buffer area, so that the flue gas is adsorbed through cross-flow contact with active coke at the upper portion of the active coke adsorption area, and is subjected to horizontal flow baffling in the tower so as to penetrate through the active coke adsorption area multiple times to form multi-stageadsorption; the flue gas adsorbed at the upper portion is fed into the lower portion of the active coke adsorption area through a gas pipeline, and is subjected to cross-flow contact with the activecoke flowing down from the upper portion of the adsorption area and adsorbing sulfur oxide; H2SO4 converted in the desulfurization process is stored in the pores of the active coke on the lower portion, wherein the H2SO4-containing active coke has high reaction activity to ammonia and can completely capture excessive ammonia in flue gas so as to effectively control ammonia escape of purified fluegas and avoid secondary pollution of ammonia.

Owner:SINOPEC ENG +1

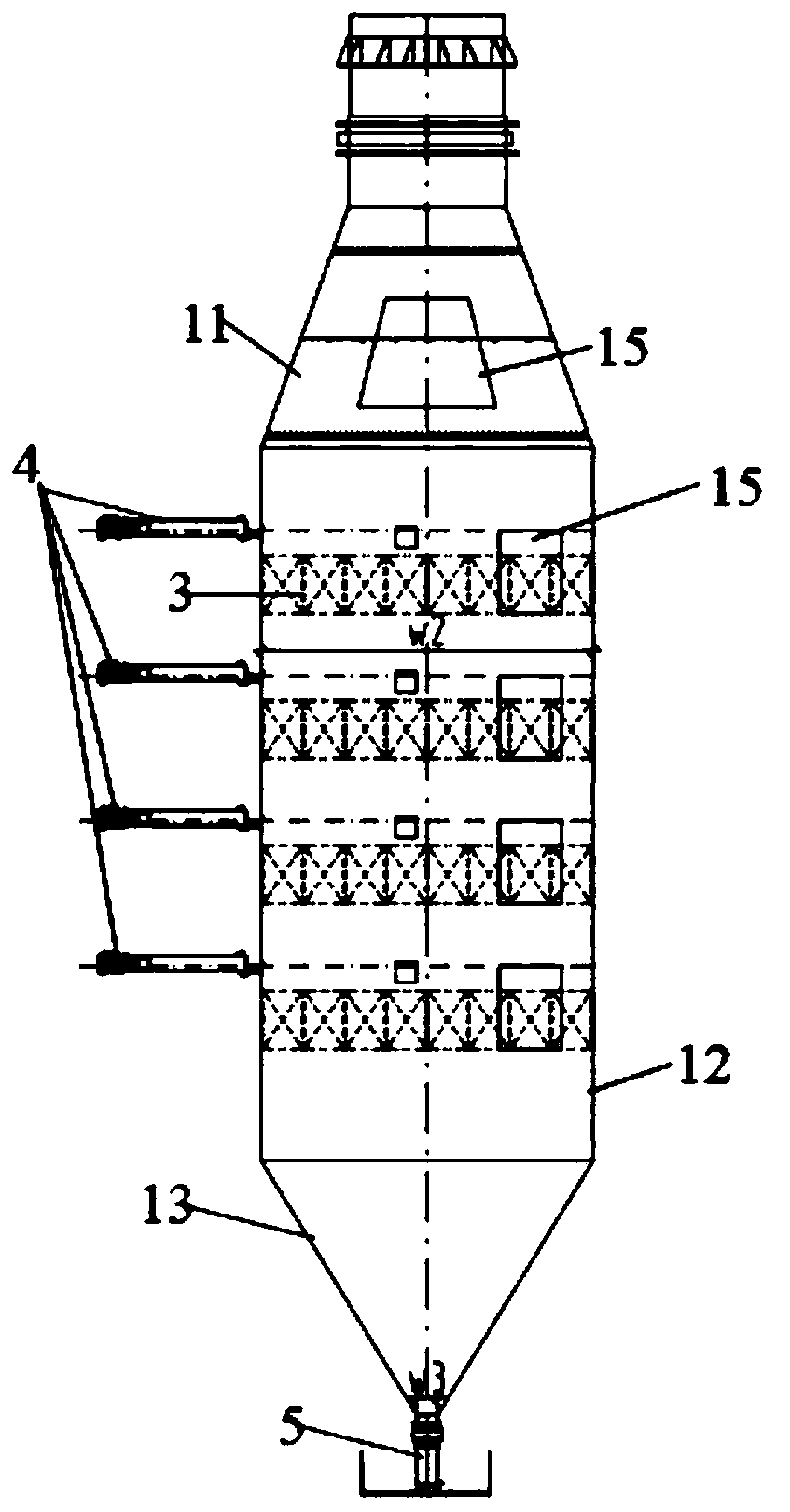

A pre-injection ammonia system and process for activated carbon desulfurization and denitrification

ActiveCN110201527BGood effectImprove denitrification efficiencyGas treatmentDispersed particle separationActivated carbonEnvironmental engineering

The invention provides an ammonia pre-spraying system and process for desulfurizing and denitrating activated carbon. The ammonia pre-spraying system comprises an ammonia pre-spraying device and an adsorption tower; the ammonia pre-spraying device comprises an ammonia pre-saturation bin, the activated carbon pre-arranged in the ammonia pre-saturation bin adsorbs ammonia gas entering the ammonia pre-saturation bin to obtain ammonia pre-saturated activated carbon, the adsorption tower is provided with an activated carbon inlet, the ammonia pre-saturated activated carbon from the ammonia pre- spraying device enters the adsorption tower through the activated carbon inlet, and the adsorption tower is used for flue gas desulfurization and denitration reactions. The ammonia pre-spraying process for desulfurizing and denitrating the activated carbon adopts the combination of the ammonia pre-spraying device and an ammonia spraying section to form a combined cooperative denitration process, andthe activated carbon is subjected to ammonia pre-saturation treatment before entering the adsorption tower, so that denitration efficiency is further improved, ammonia escape can be controlled, ammonia consumption is saved, and economy is improved.

Owner:BEIJING ZHTD ENVIRONMENTAL PROTECTION TECH CO LTD

A device for 3D printing high-nitrogen steel products using nitrogen arc and nitride

ActiveCN105522264BUniform compositionConducive to full metallurgical smeltingElectrode supporting devicesWelding/soldering/cutting articlesMelting tankCyclone

The invention provides a device and method for 3D printing of high-nitrogen steel products through a nitrogen arc and nitride. Overlaying shaping of high-nitrogen steel with a set layer height is carried out through a nitrogen arc wire feeding material increase manufacturing method under normal pressure, and meanwhile nitride alloy powder is added into a molten pool through nitrogen powder feeding. A spiral air powder groove is bored in the inner wall of a coaxial spiral air powder cover, the nitride alloy powder forms air powder cyclone at a welding gun opening, the loss caused by scattering of the nitride alloy powder when the nitride alloy powder flows out of the welding gun opening is reduced, and meanwhile the effect that the nitride alloy powder and molten drops at the end of a solder wire are fully metallurgically smelted and then enter the molten pool is guaranteed. By controlling parameter matching of 3D printing, high-nitrogen steel printing layers with different nitrogen contents can be obtained. A synchronous and coaxial powder adding and wire feeding method with the nitride alloy powder and the solder wire is adopted, so that 3D printing of the high-nitrogen steel products through a technology integrating the common steel solder wire, the nitride alloy powder and the nitrogen arc is realized under normal pressure.

Owner:JIANGSU SHUOSHI WELDING SCI & TECH

A method of 3D printing high nitrogen steel products using nitrogen arc and nitride

ActiveCN105772909BUniform compositionConducive to full metallurgical smeltingWelding/soldering/cutting articlesWelding accessoriesPower addedNitrogen

The invention provides a device for 3D printing of a high-nitrogen steel product through nitrogen arc and nitrides and a method thereof. Surfacing forming of high-nitrogen steel with set layers is achieved at the ordinary pressure through a nitrogen arc wire feeding additive manufacturing method, and nitride alloy powder is added into a molten pool through nitrogen powder feeding. Spiral gas powder grooves are bored in the inner wall of a coaxial spiral gas powder cover. The nitride alloy powder forms rotary gas powder flow at a welding gun muzzle, the loss caused by scattering when the nitride alloy powder flows out of the gun muzzle is reduced, and the effect that the nitride alloy powder and molten drops at the ends of welding wires are fully and metallurgically smelted and then enter the molten pool is ensured. By controlling parameter matching of 3D printing, high-nitrogen steel printing layers with different nitrogen contents can be obtained. The mode of nitride alloy powder and welding wire synchronous coaxial power adding and wire feeding is adopted, and 3D printing of the high-nitrogen steel product at the ordinary pressure is achieved through a common steel welding wire-nitride alloy powder-nitrogen arc composite technology.

Owner:JIANGSU SHUOSHI WELDING SCI & TECH

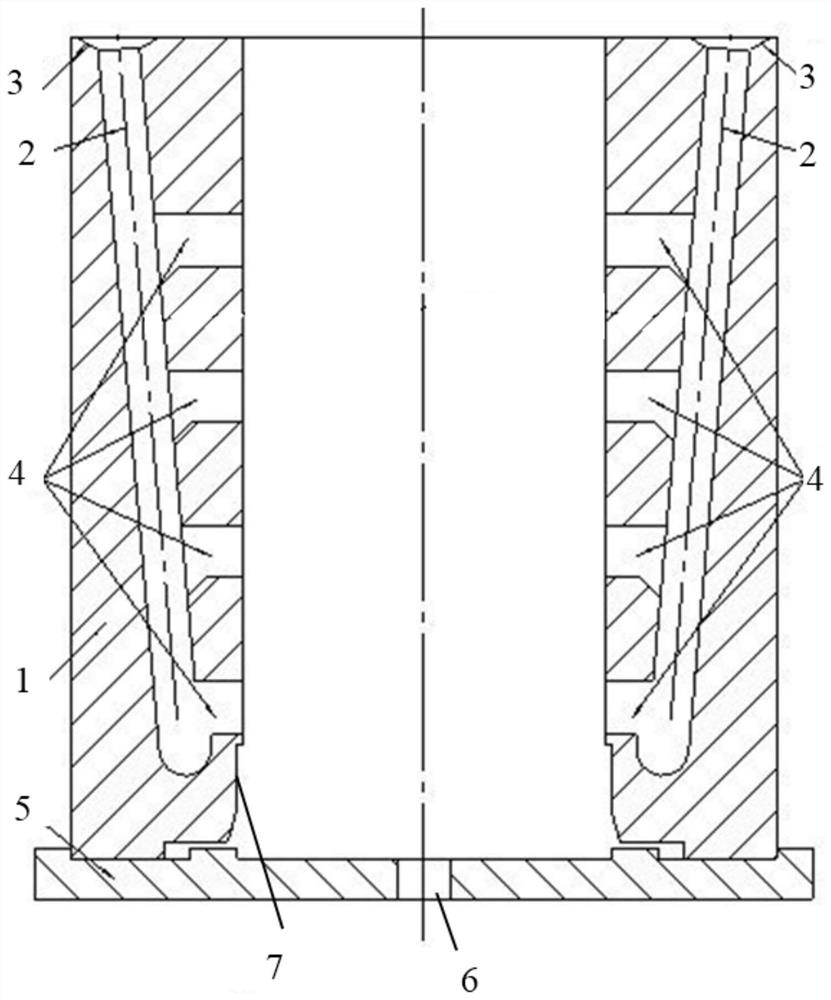

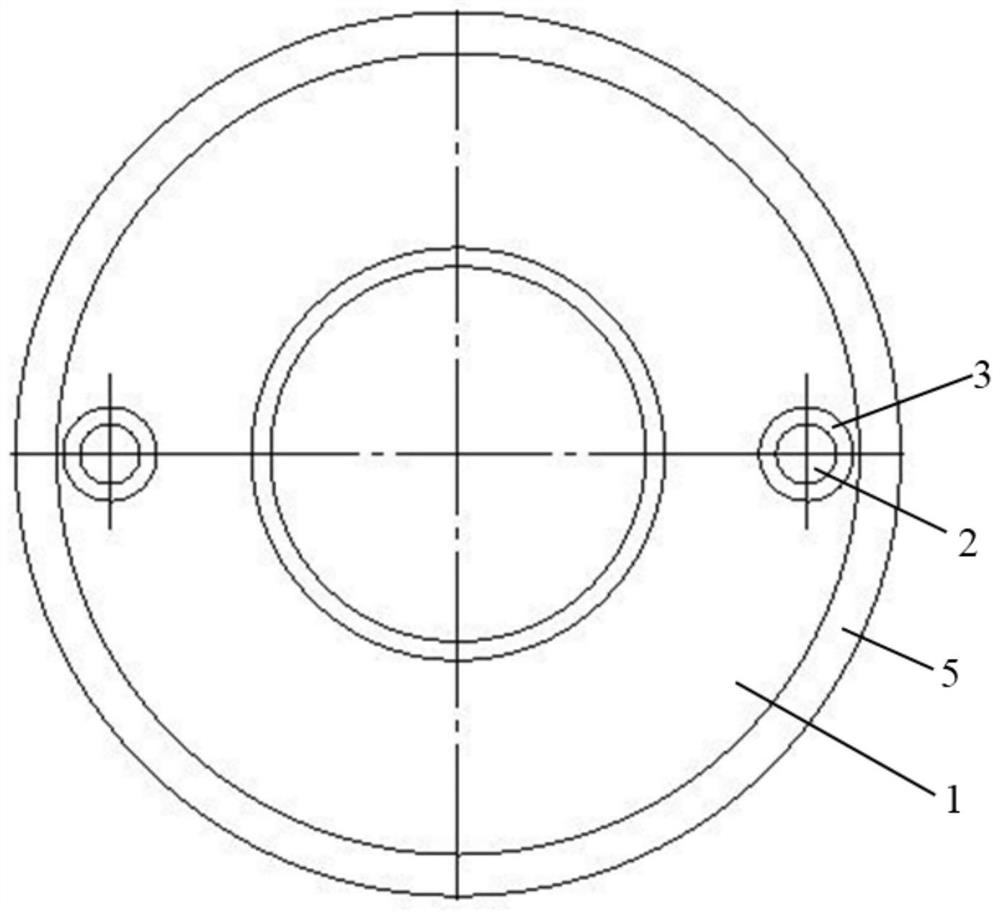

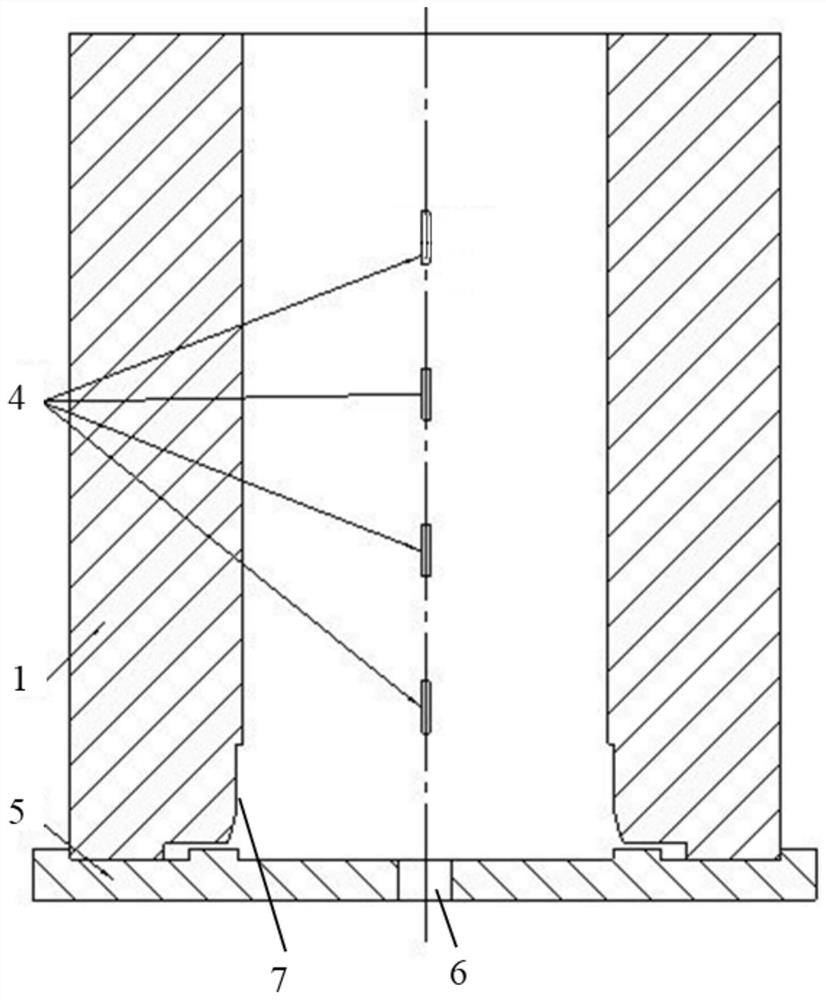

Planet wheel bearing outer circle alloy layer pouring mold

The invention discloses a planet wheel bearing outer circle alloy layer pouring mold which comprises a cylindrical mold body, a pouring bottom plate is arranged at the bottom of the mold body, inclined pouring gates are arranged in the two opposite side walls of the mold body, sprues are formed in the tops of the inclined pouring gates, horizontal pouring gates are arranged on the side faces of the inclined pouring gates, and the horizontal pouring gates penetrate through the inner wall of the mold body. Oxidizing slag generated by splashing of alloy liquid can be effectively reduced through the inclined pouring gates, the horizontal pouring gates have the effects of filtering the oxidizing slag and stabilizing flow, and gas escape during mold filling of the alloy liquid can be effectively controlled, so that the performance of an alloy layer on the outer circle of the planet wheel bearing is improved, the cylindrical mold body can be cooled through an inner hole during pouring, and the mold is convenient to use. And the solidification sequence of the tin-based alloy from the surface of the carbon structural steel substrate in the planet wheel bearing to the inner wall of the mold body is ensured, so that the bonding strength of the excircle alloy layer of the planet wheel bearing and the internal carbon structural steel substrate is improved.

Owner:CSIC NO 12 RES INST

Ammonia pre- spraying system and process for desulfurizing and denitrating activated carbon

ActiveCN110201527AGood effectImprove denitrification efficiencyGas treatmentDispersed particle separationActivated carbonTower

The invention provides an ammonia pre-spraying system and process for desulfurizing and denitrating activated carbon. The ammonia pre-spraying system comprises an ammonia pre-spraying device and an adsorption tower; the ammonia pre-spraying device comprises an ammonia pre-saturation bin, the activated carbon pre-arranged in the ammonia pre-saturation bin adsorbs ammonia gas entering the ammonia pre-saturation bin to obtain ammonia pre-saturated activated carbon, the adsorption tower is provided with an activated carbon inlet, the ammonia pre-saturated activated carbon from the ammonia pre- spraying device enters the adsorption tower through the activated carbon inlet, and the adsorption tower is used for flue gas desulfurization and denitration reactions. The ammonia pre-spraying process for desulfurizing and denitrating the activated carbon adopts the combination of the ammonia pre-spraying device and an ammonia spraying section to form a combined cooperative denitration process, andthe activated carbon is subjected to ammonia pre-saturation treatment before entering the adsorption tower, so that denitration efficiency is further improved, ammonia escape can be controlled, ammonia consumption is saved, and economy is improved.

Owner:BEIJING ZHTD ENVIRONMENTAL PROTECTION TECH CO LTD

Preparation method of ginseng instant tablets

InactiveCN112007063AThe production process is simpleEasy to operateDigestive systemPharmaceutical delivery mechanismNutritionMouthfeel

The invention provides a preparation method of ginseng instant tablets, which comprises the following steps: screening fresh ginseng, and removing fresh ginseng with spots or insufficient water content and nutrient content on the ginseng; soaking and cleaning the screened fresh ginseng in clear water, steaming the ginseng in a container, and thoroughly steaming the ginseng; placing the thoroughlysteamed ginseng in a shade place, performing natural cooling, and placing the cooled ginseng in a refrigeration house to be quickly frozen; uniformly slicing the quick-frozen ginseng, adding honey, performing uniform stirring, and performing cooling in a freeze dryer; and carrying out vacuum decompression drying on the ginseng subjected to vacuum freezing to obtain the ginseng instant tablets. Theginseng instant tablets have Qi and blood tonifying efficacy, moreover, the preparation process is simple and easy to operate, the ginseng instant tablets prepared by the method are convenient to carry, instant after being unpacked, sweet in taste, slightly soft and agreeable in sweetness, the natural activity of the ginseng is maintained, volatile components of the ginseng are prevented from escaping, the complementary function of traditional Chinese medicines is exerted, the effect of tonifying without dryness is achieved, and the nutrition is easy to absorb.

Owner:黑龙江涵容医药科技有限公司

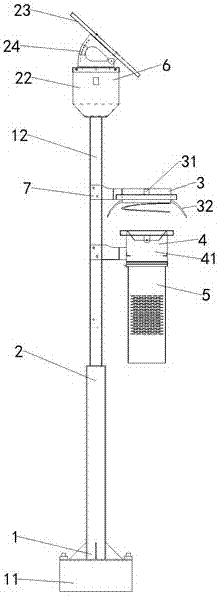

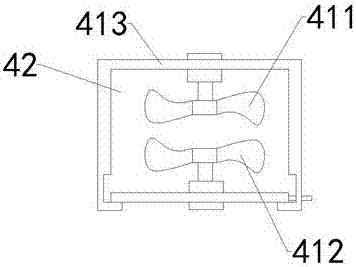

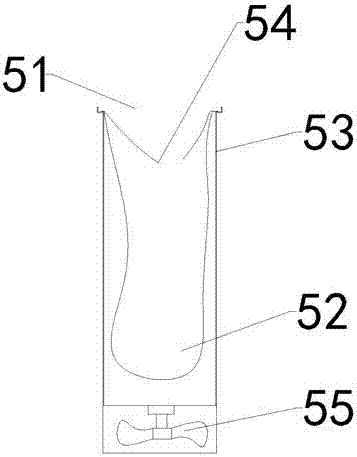

an insecticidal lamp

ActiveCN104222047BAchieve structural strengthExtended service lifeAnimal trapsInsect catchers and killersAgricultural engineeringEnergy supply

The invention provides a novel insecticidal lamp and relates to the technical field of agricultural pest killing. The novel insecticidal lamp comprises an insecticidal base, a supporting part, a pest trap device, a pest killing device, a pest collecting device and an energy supply device, wherein the insecticidal base comprises a foundation layer arranged on the level ground and a fixing support arranged in the foundation layer. The fixing support comprises a middle shaft and two rotary pieces arranged at the upper portion and the lower portion of the middle shaft, wherein a fixing rod is arranged between the two rotary pieces at the upper portion and the lower portion of the middle shaft to enable the rotary pieces and the fixing rod to form two rectangles rotating along the middle shaft. The fixing rod is fixedly connected with the supporting part. By means of the scheme, insecticidal efficiency is maximized.

Owner:安吉安宁生物科技有限公司

A Small Circulating Lubrication System Using Liquid Nitrogen Cooling

InactiveCN103822078BImprove leakageEasy to polluteLubrication elementsLiquid nitrogen coolingLubrication

Owner:HENAN UNIV OF SCI & TECH

An activated coke adsorption tower and a method for activated coke adsorption and purification of flue gas

ActiveCN110898607BControl escapeAvoid secondary pollutionGas treatmentDispersed particle separationFlue gasPhysical chemistry

The disclosure relates to an activated coke adsorption tower and a method for activated coke adsorption and purification of flue gas. The activated coke adsorption tower of the present disclosure sets the active coke adsorption zone and the gas buffer zone and makes the flue gas enter the upper gas buffer zone first, so that the flue gas is adsorbed by cross-flow contact with the active coke in the upper part of the active coke adsorption zone and is absorbed in the tower. Horizontal baffle flow to pass through the active coke adsorption area multiple times to form multi-stage adsorption, and then the flue gas adsorbed in the upper part is sent to the lower part of the active coke adsorption area through the gas pipeline, and the adsorbed flue gas flowing down from the upper part of the adsorption area Active coke cross-flow contact of sulfur oxides, the pores of the lower active coke store the converted H in the desulfurization process 2 SO 4 , containing H 2 SO 4 Activated coke has a high reactivity to ammonia and can fully capture excess ammonia in the flue gas, thereby effectively controlling the escape of ammonia in the clean flue gas and avoiding secondary pollution of ammonia.

Owner:SINOPEC ENG +1

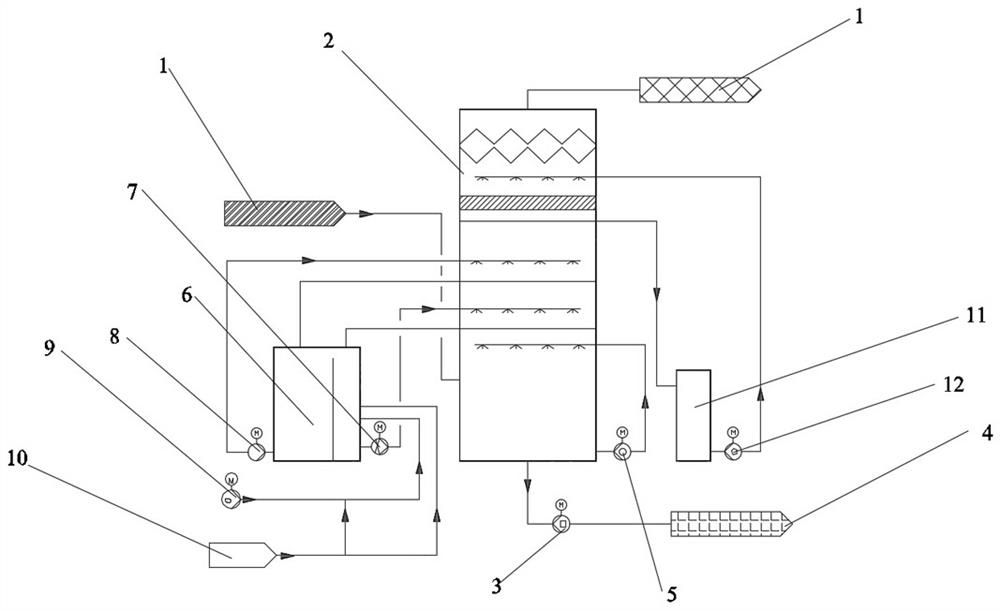

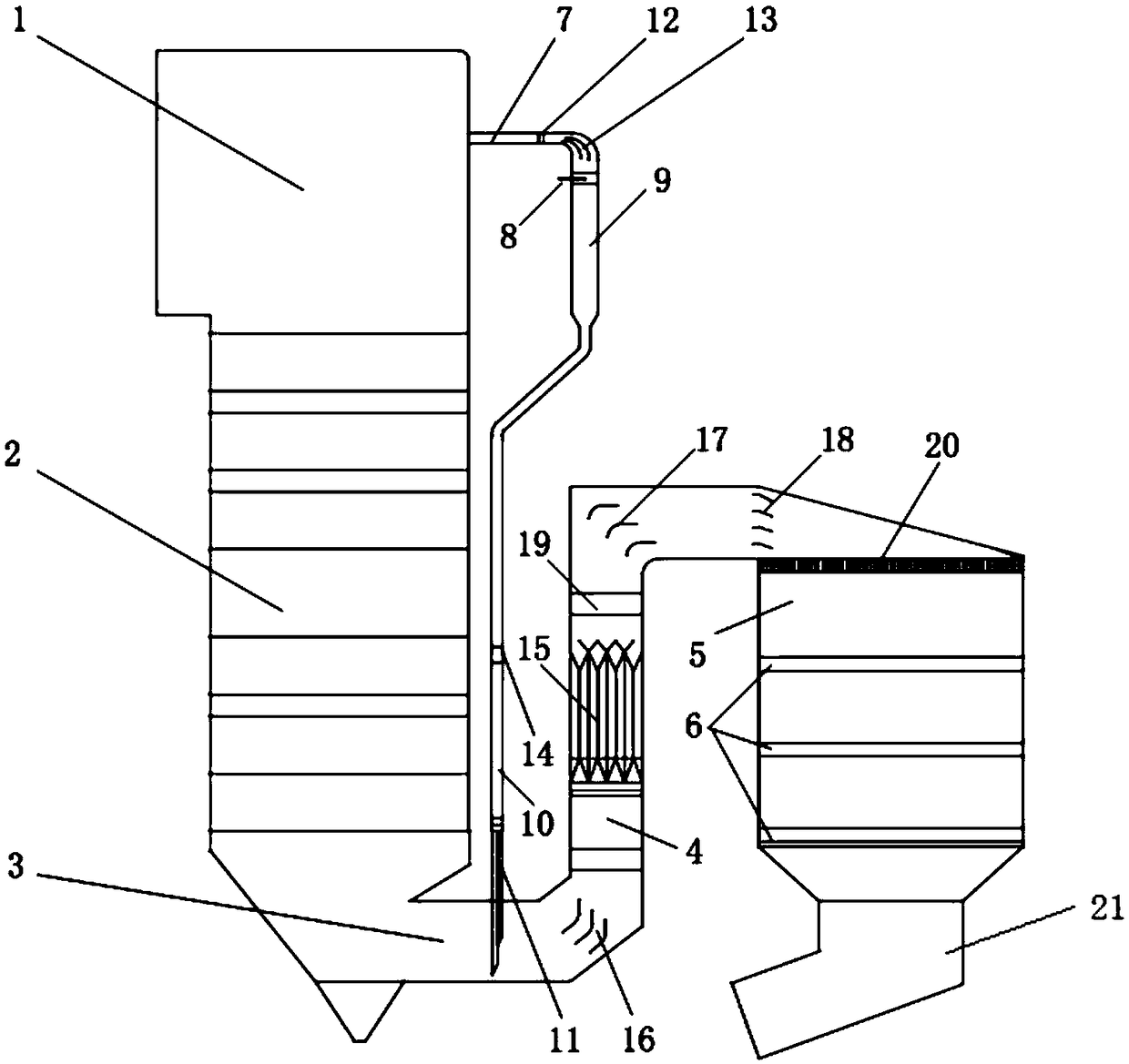

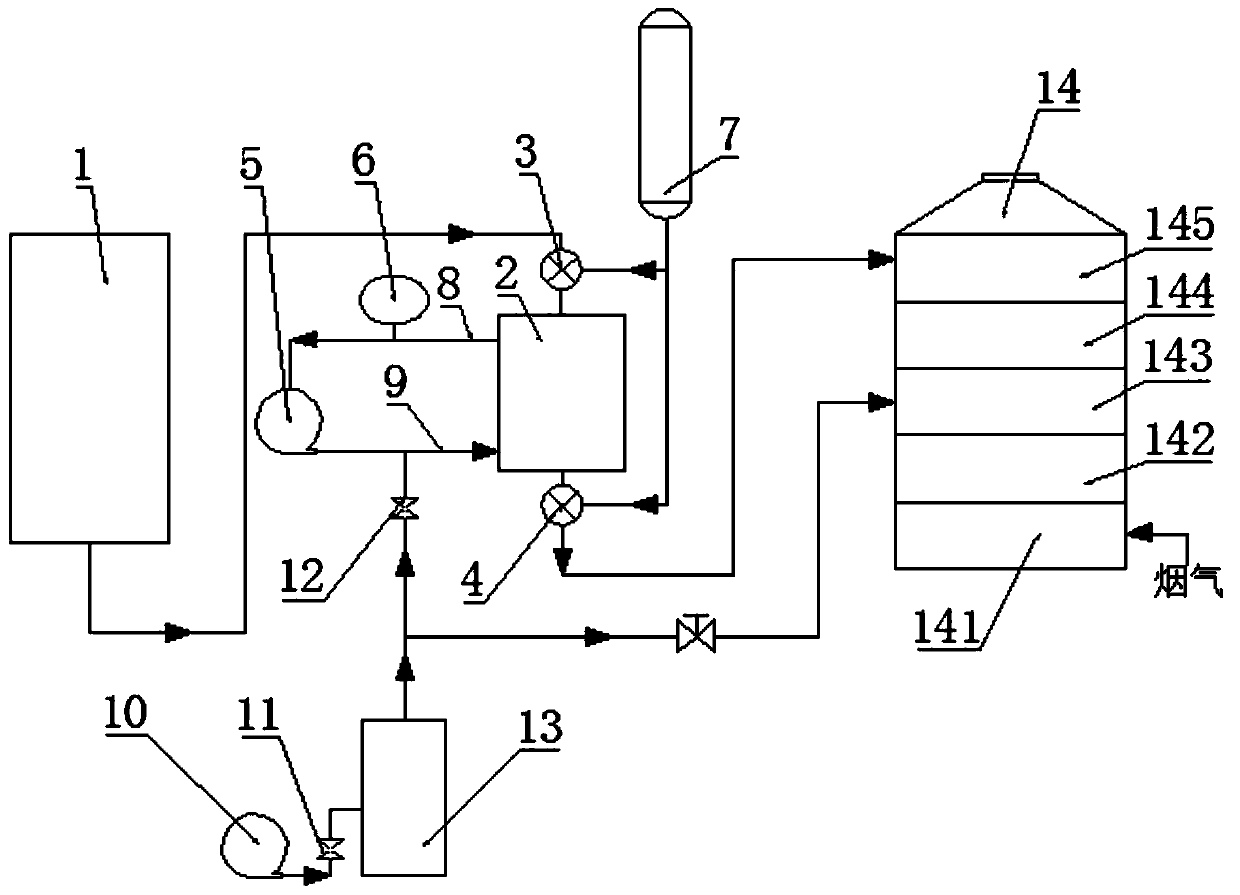

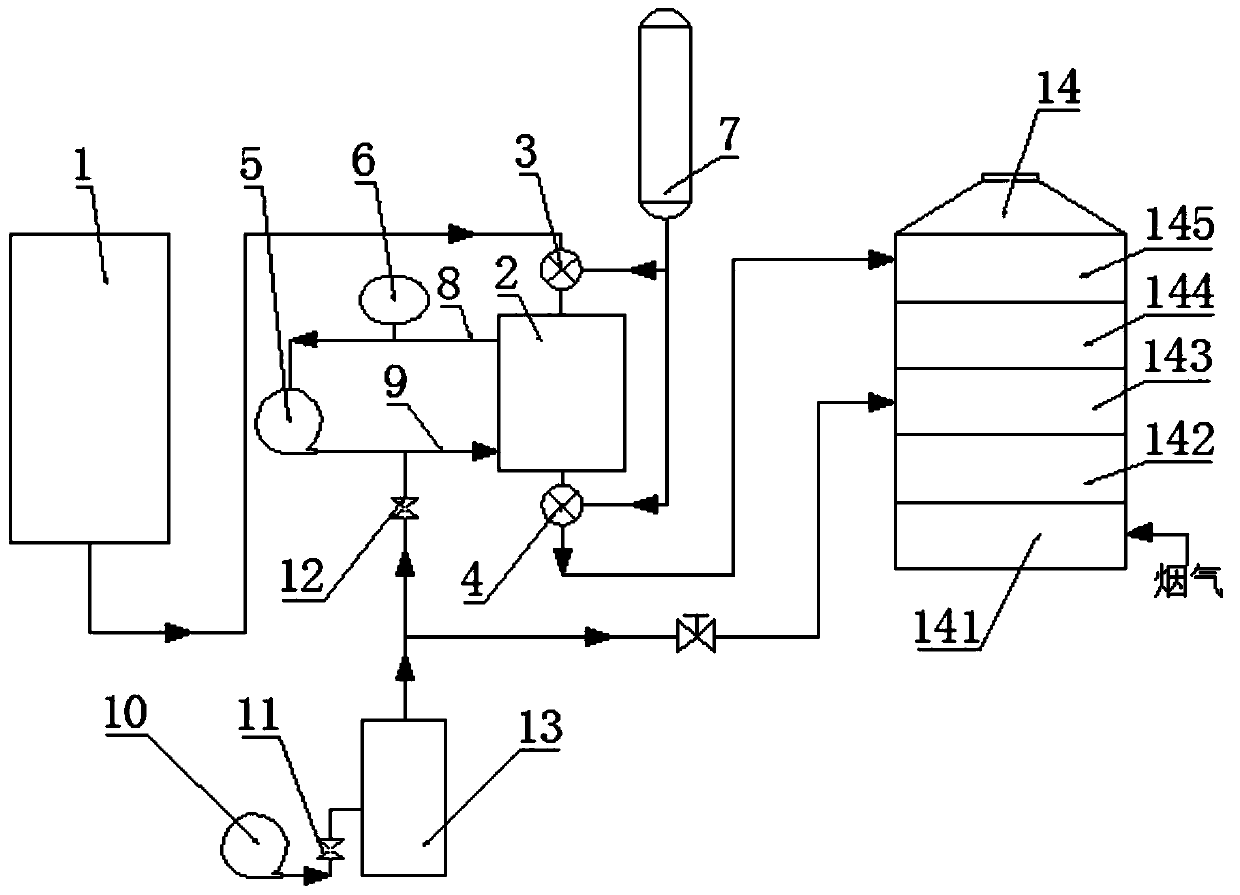

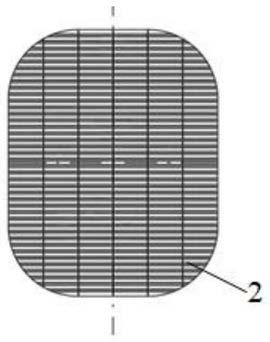

Flue gas desulfurization and denitration process and device for recovering ammonium sulfate

ActiveCN103203175BImprove instabilityReduce desulfurization capacityDispersed particle separationAmmonia compoundsOxygen tankAmmonia storage

The invention discloses a flue gas desulfurization and denitration process and device for recovering ammonium sulfate. The flue gas desulfurization and denitration device comprises an absorption tower, a crystal extracting and concentrating tank and an ammonia storage tank, wherein the absorption tower is sequentially provided with a defogger layer, a desulfurization spraying layer, a denitration spraying layer, a liquid accumulation layer, a concentrated solution spraying layer and a concentration tank from top to bottom; the crystal extracting and concentrating tank is communicated with the concentration tank, and the downstream side of the crystal extracting and concentrating tank is sequentially connected with a swirler and a centrifuge; the inside of an oxygen tank is partitioned into a regulation zone and an oxidation zone which are both communicated to the liquid accumulation layer, the regulation zone is communicated with the denitration spraying layer through a denitration circulating pump, the oxidation layer is respectively communicated with the desulfurization spraying layer and the concentration tank through a desulfurization circulating pump, and the bottom of the oxidation zone is provided with an oxidation air duct above which a plurality of layers of porous plates are arranged; and the ammonia storage tank is used for adjusting the pH value of slurry from the liquid accumulation layer. On the premise of ensuring higher desulfurization efficiency, the flue gas desulfurization and denitration process and device can be used for effectively controlling escape of sulfur dioxide and ammonia of a system, greatly increasing the denitration efficiency of the system and realizing the large-particle crystallization of ammonium sulfate crystals.

Owner:ZHEJIANG TIANLAN ENVIRONMENTAL PROTECTION TECH

SCR denitration reaction tower of cement kiln

PendingCN111097286AGuaranteed denitrification efficiencyAvoid secondary pollutionDispersed particle separationExhaust fumesCement kiln

The invention discloses an SCR denitration reaction tower of a cement kiln. The tower comprises a reaction tower, and a flow guide uniform distribution plate, a catalyst and an ash removal device arearranged in the reaction tower; the flow guide uniform distribution plate is arranged at the inlet of the reaction tower, the flow guide uniform distribution plate is connected to the tower body of the reaction tower, the catalyst is connected to the tower body of the reaction tower and is positioned below the flow guide uniform distribution plate, and an ash removal device is arranged above the catalyst and is connected to the tower body of the reaction tower and is positioned below the flow guide uniform distribution plate. The flow guide uniform distribution plate is made of inverted anglesteel, that is, when the flow guide uniform distribution plate is installed in the reaction tower, the opening part of the angle steel faces downwards, the included angle part faces upwards, a gap isformed between every two adjacent angle steel, and gas passes through the gap between every two adjacent angle steel. The arrangement of the flow guide uniform distribution plate has a flow guide effect on the waste gas entering the reaction tower, and the waste gas is uniformly distributed in the reaction tower, so that the uniformity of the waste gas entering the catalyst reaction tower is effectively ensured, and the reaction of the waste gas and the catalyst is more thorough.

Owner:ANHUI CONCH DESIGN & RES INST OF BUILDING MATERIALS CO LTD +1

Microwave sintering of superfine grain base titanium carbonitride

The utility model provides microwave sintering of an ultra-fine grain titanium carbonitride group cermet. A 300MHz to 8GHz microwave frequency medium is used as a heat source to enable a billet of the ultra-fine grain titanium carbonitride group cermet to absorb microwave energy to complete the sintering process. During the sintering process, vacuum and atmosphere protection microwave heating andsintering techniques are adopted respectively according to the ratio of carbon to nitrogen of the billet of the ultra-fine grain carbon titanium nitride cermet. The 300MHz to 8GHz microwave frequencyis used to heat and sinter the billets of the titanium carbonitride group cermet with different ratio of carbon to nitrogen and vacuum microwave sintering and atmosphere protection microwave sintering technological proposals are used respectively for the billets of the titanium carbonitride group cermet with the different ratio of carbon to nitrogen, which overcomes the defects of the prior vacuum or atmosphere protection sintering techniques, such as low heating efficiency, long sintering time, large energy consumption, serious environment pollution and oversized grains, and the like. The microwave sintering can be widely applied to sintering other ceramics, ceramic matrix composites and intermetallic compound materials with stronger microwave absorbing capacity.

Owner:HUNAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com