Method for 3D printing of high-nitrogen steel product through nitrogen arc and nitrides

A 3D printing and high-nitrogen steel technology, which is applied in the direction of welding/welding/cutting items, manufacturing tools, arc welding equipment, etc., can solve problems such as inability to feed wire and add powder, powder cannot rotate, and gas powder flow direction is poorly restricted. , to achieve the effects of increasing nitrogen increasing effect, increasing nitrogen partial pressure and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

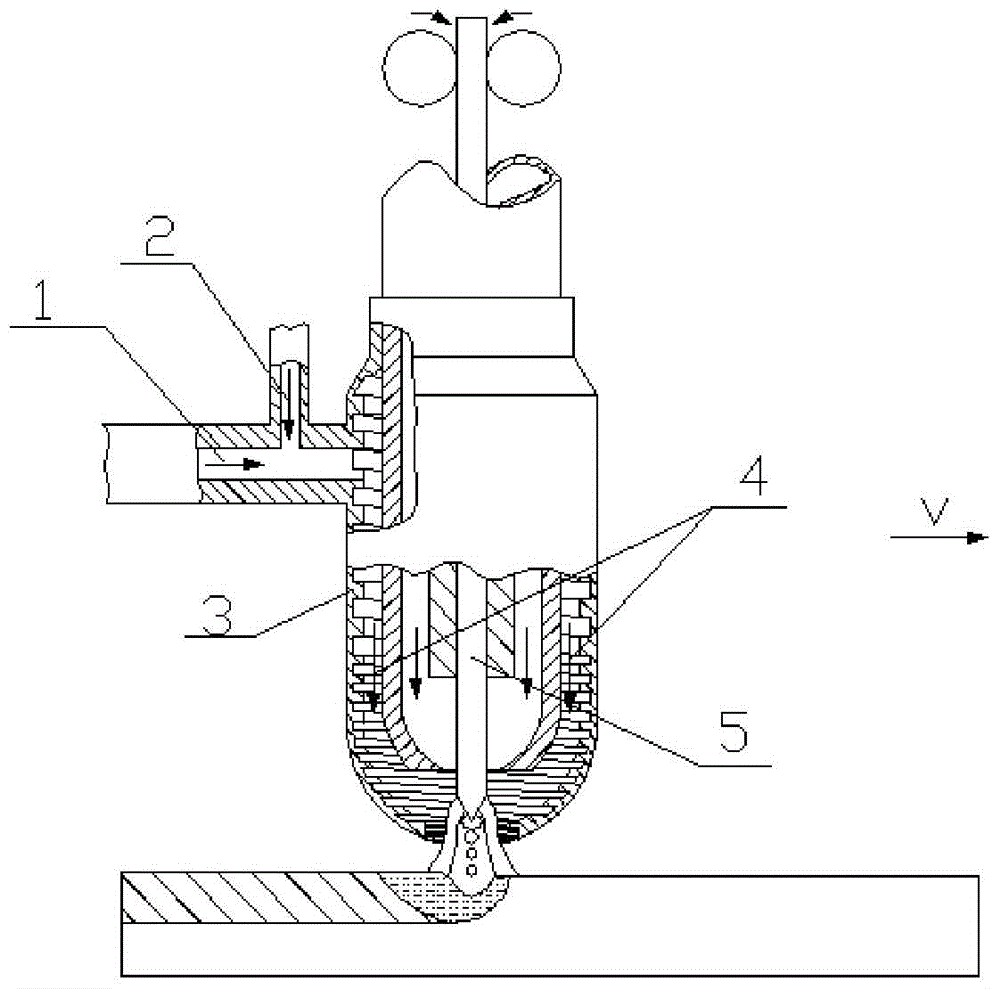

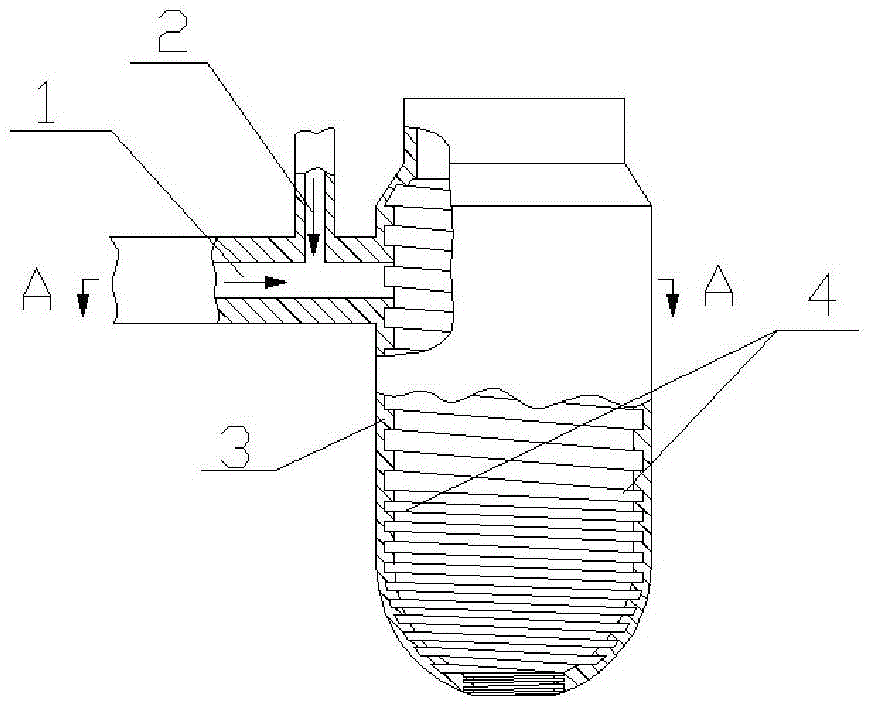

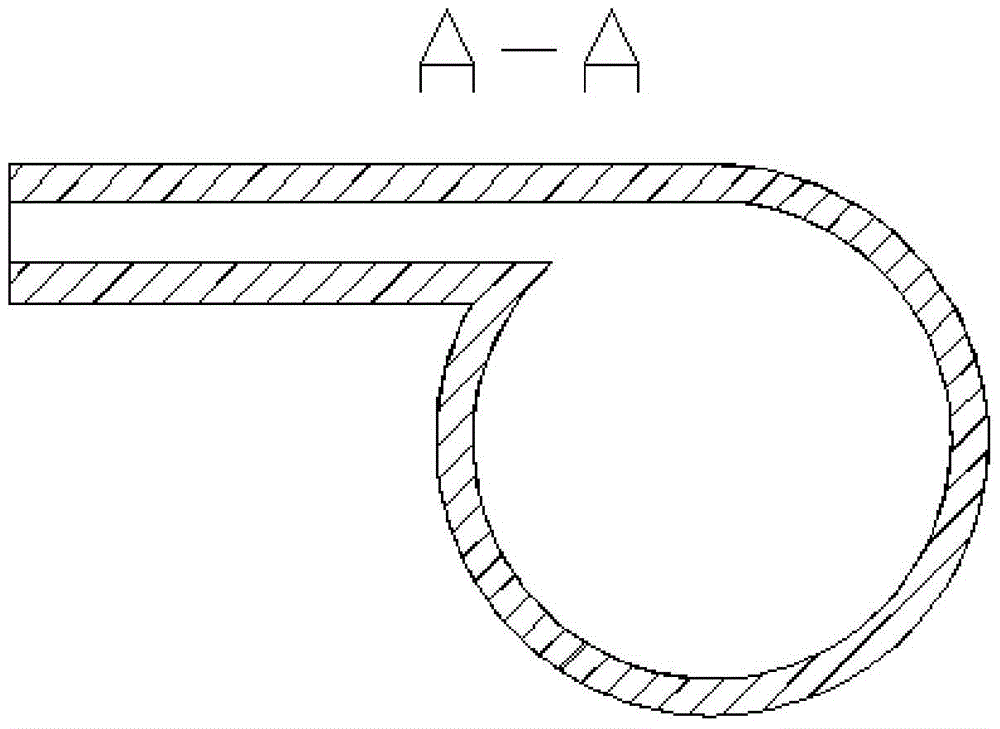

Method used

Image

Examples

Embodiment 1

[0048] Using the above device, high nitrogen steel components were prepared by using nitrogen arc and nitride 3D printing of high nitrogen steel products. Seam consists of 7 welds.

[0049] Using the method for 3D printing high-nitrogen steel products using nitrogen arc and nitride according to the present invention, the specific steps are:

[0050] Step 1, determine the iron element content W through the target alloy composition of the target high-nitrogen steel product Fe %; choose low carbon steel wire as wire feeding raw material;

[0051] According to the target alloy composition of the target high-nitrogen steel product, determine the content Wif% ratio of the alloying element i in the nitride alloy powder required as the powder feeding raw material, after correcting the relationship Wif 修正 %≈Wif%×(1+μi+ξ) is corrected to obtain the corrected value Wif of the alloying element [i] content in the powder 修正 %, and prepare nitride alloy powder; where μi is the burning los...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com