Desulfurization, denitrification and dust removal ultralow emission process and system for production of cement from low-sulfur raw materials

A desulfurization, denitrification and emission system technology, which is applied in the field of ultra-low emission processes and systems for desulfurization, denitrification and dust removal, can solve the problems of low frequency of use, large investment costs, and reduced equipment efficiency, so as to reduce overall costs, improve efficiency, and avoid ammonia escape. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

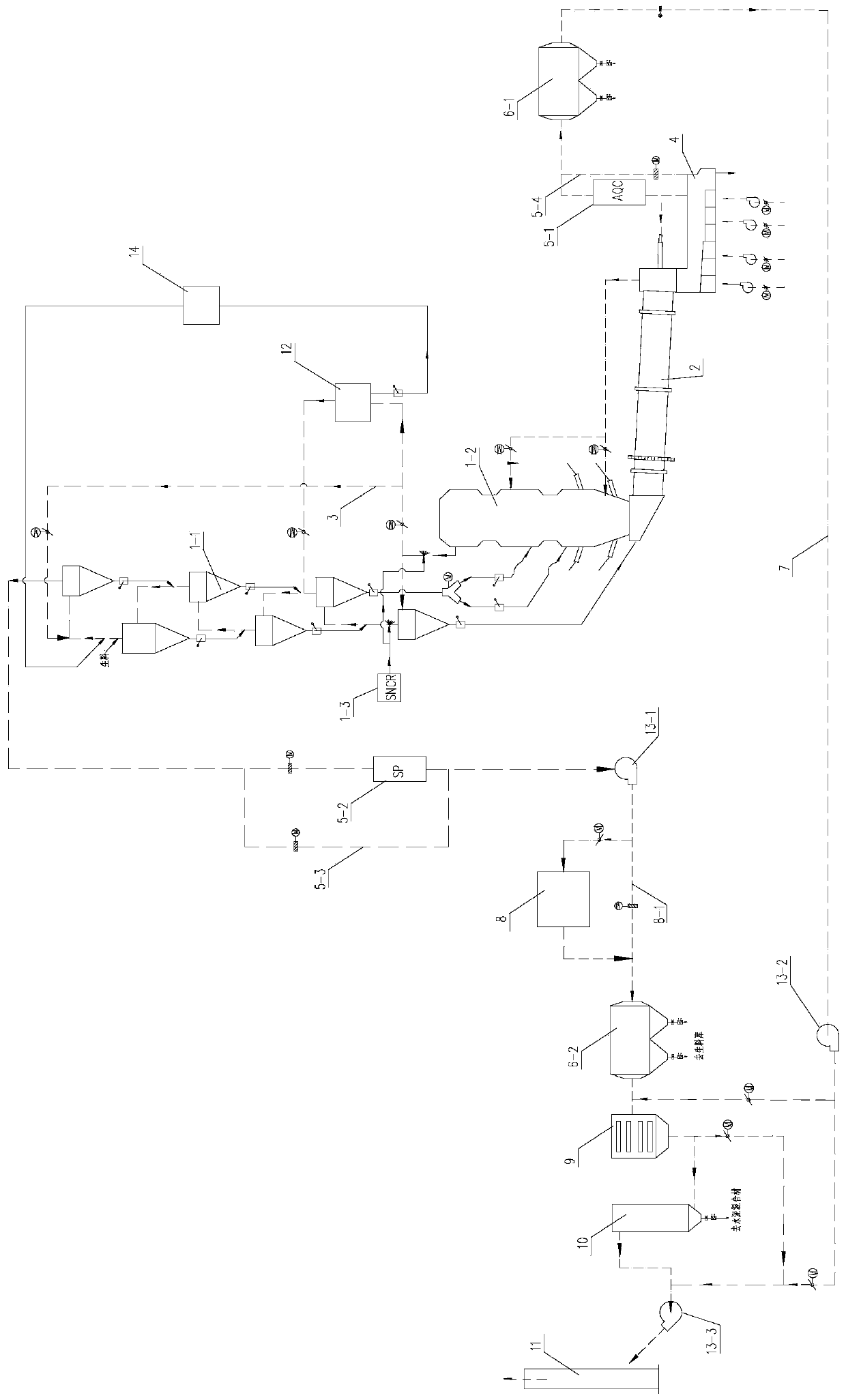

[0047] See Figure 1~3 The embodiment of the present invention provides an ultra-low emission process for desulfurization, denitrification, and dust removal for producing cement from low-sulfur raw materials, including the following steps:

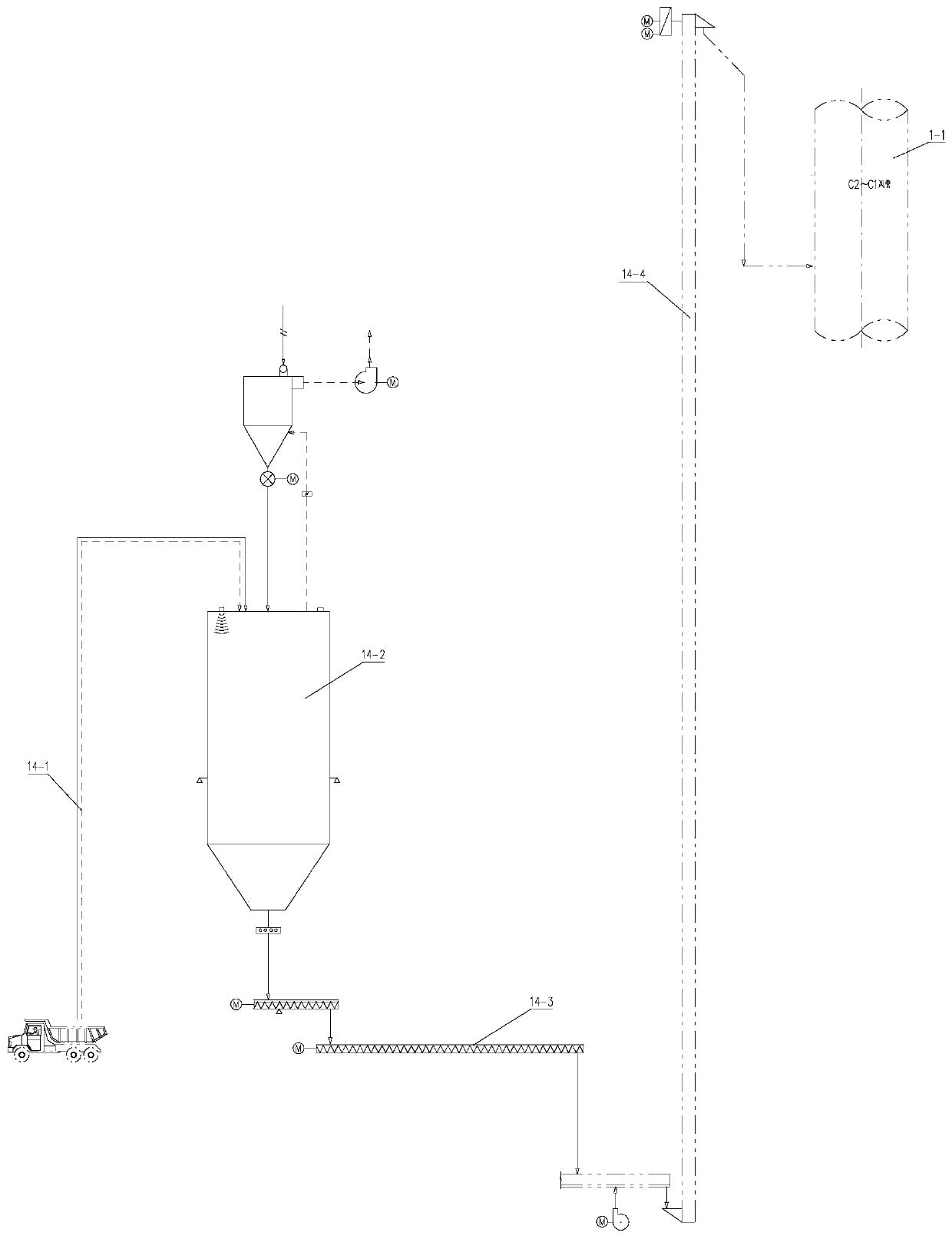

[0048] S1. Cement clinker firing: low-sulfur raw materials are fed into the decomposition furnace 1-2 through heat exchange with the hot flue gas through the kiln tail preheater 1-1, and then calcined in the rotary kiln 2, and then enter the cooler 4 to cool the cement clinker. When the cement clinker is fired, the firing system performs self-denitration, SNCR, self-desulfurization and dry desulfurization in the calciner. The self-denitration and SNCR of the calciner make the NOx in the flue gas exiting the kiln tail preheater control Within the lowest NOx emission range where ammonia escapes, NOx can be controlled at 50-200mg / Nm 3 (@10%O 2 ), self-desulfurization and dry desulfurization make SO 2 Control within the emission range that does n...

Embodiment 2

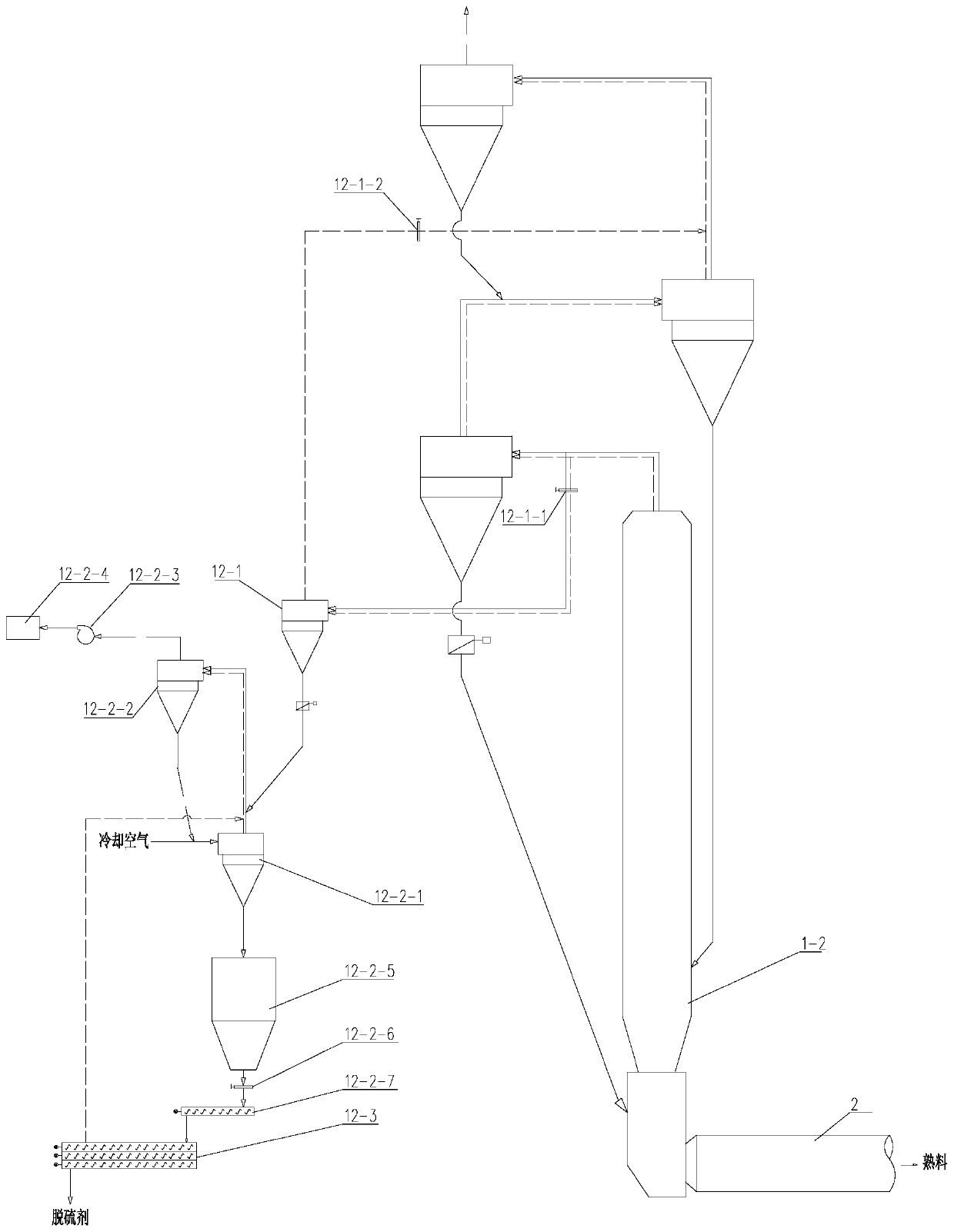

[0075] See Figure 1~3 , A desulfurization, denitrification and dust removal ultra-low emission system for producing cement with low-sulfur raw materials using the above process, including a cement clinker burning system, which includes a kiln tail preheater 1-1 and a decomposition furnace 1-2 , Cement kiln 2 and cooler 4, also including kiln tail high temperature fan 13-1, grinding system 8, kiln tail dust collector 6-2, low temperature SCR denitrification reactor 9, wet desulfurization tower 10, kiln head dust collection The outlet of the kiln tail preheater C1 is connected to the inlet of the grinding system 8 through the kiln tail high temperature fan 13-1, and the outlet of the grinding system 8 is connected to the kiln tail dust collector 6-2. The outlet of the kiln tail dust collector 6-2 is connected to the inlet of the low temperature SCR denitrification reactor 9, the outlet of the low temperature SCR denitrification reactor 9 is connected to the inlet of the wet desu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com