Absorption tower for simultaneously removing sulfur dioxide and nitrogen oxide in smoke

A technology of sulfur dioxide and nitrogen oxides, which is applied to the absorption tower of nitrogen oxides and the field of combined removal of sulfur dioxide in flue gas, can solve the problems of reducing added value, carrying and escaping ammonia, and volatile ammonia, etc., so as to reduce the production of SO3, The effect of saving ammonia consumption and reducing system resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

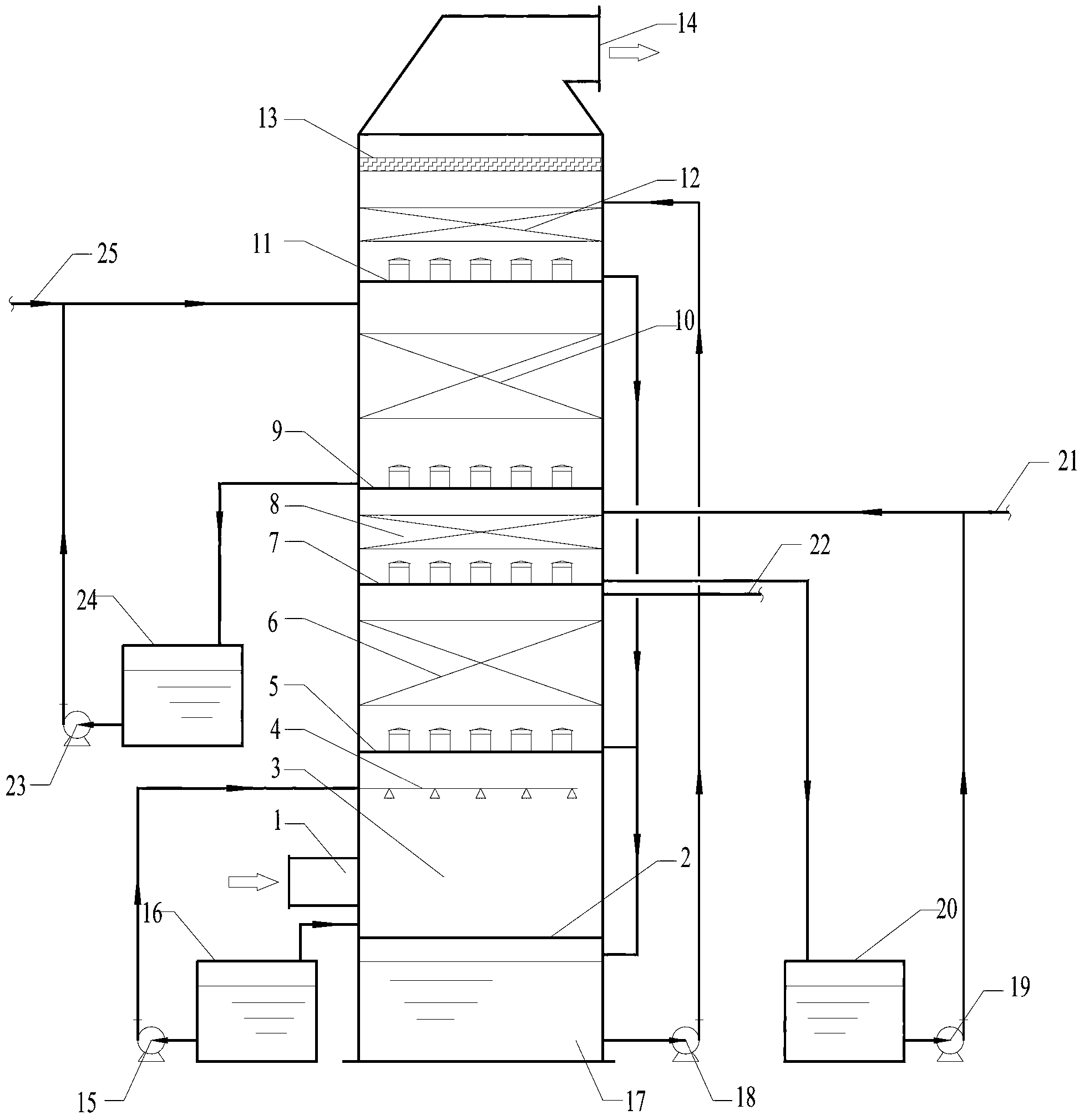

[0023] like figure 1 As shown, the interior of the absorption tower of the present invention is divided into a plurality of functional areas, and the absorption tower includes successively from bottom to top: a desulfurization absorption liquid circulation tank 17, a concentrated cooling area 3, a desulfurization absorption area 6, a flue gas conditioning area 8, Denitrification absorption area 10, ammonia escape control area 12, and mist removal area 13. When the desulfurization and denitrification absorption liquid has no volatility, the ammonia escape control zone 12 may not be set in the absorption tower.

[0024] The bottom of the absorption tower is a desulfurization absorption liquid circulation tank 17, and above it is a concentrated cooling zone 3, which is separated by a sealed tray 2, and the flue gas inlet 1 is set at the lower end of the concentrated cooling zone 3; the desulfurization absorption zone 6 is set in Above the concentration and cooling zone 3, the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com