Efficient ammonia desulphurization and dust removal device and application method thereof

A technology of ammonia-based desulfurization and dedusting equipment, which is applied in the direction of combined equipment, separation methods, chemical instruments and methods, etc., can solve the problems of flue gas tailing, ammonia escape aerosol, etc., to ensure safe construction and increase gas-liquid mass transfer area, the effect of increasing the gas-liquid contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

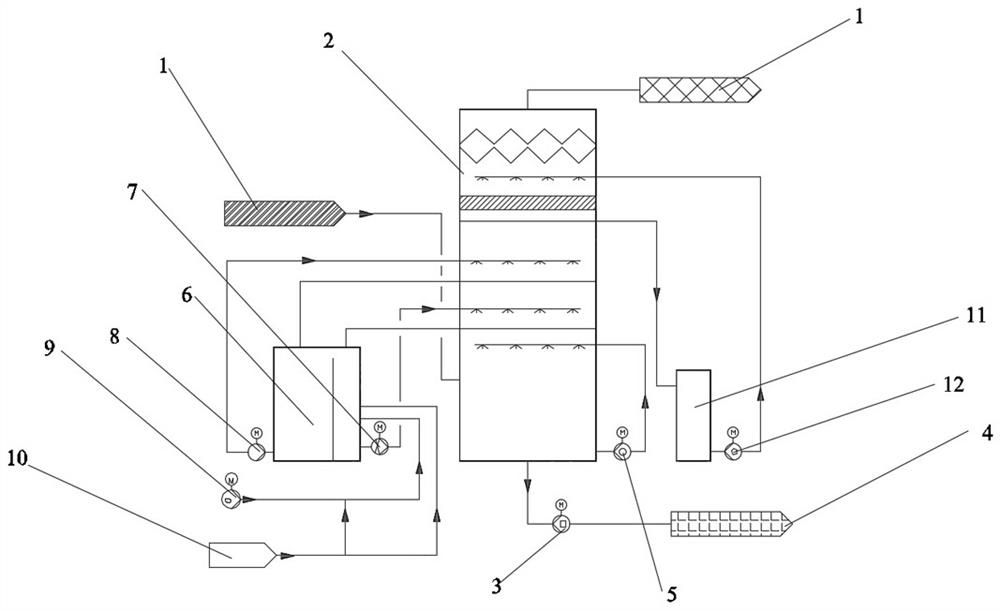

[0040] The flue gas flow rate of an industrial boiler is 750,000 Nm3 / h, the sulfur content of the flue gas is 3000mg / Nm3, the flue gas desulfurization process adopts the ammonia desulfurization process, the diameter of the desulfurization tower 2 is 11m, and the flue gas flow rate is controlled between 2.5-3 . The raw flue gas 1 is discharged up to the standard through the high-efficiency ammonia desulfurization and dust removal device.

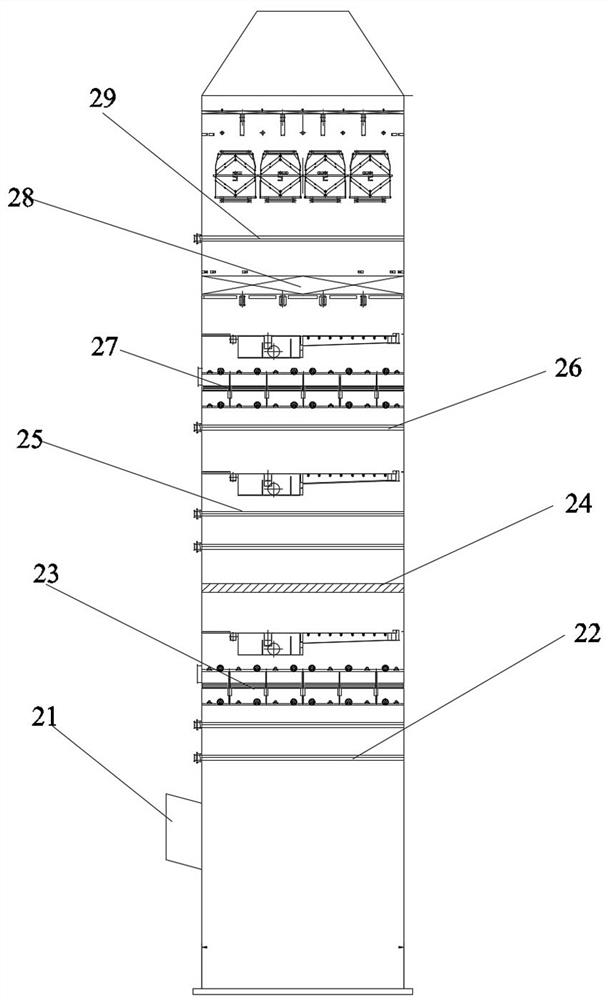

[0041] Such as figure 1 with figure 2 As shown, a high-efficiency ammonia desulfurization and dust removal device includes a desulfurization tower 2, an ammonium sulfate discharge pump 3 connected to the bottom of the desulfurization tower 2, an ammonium sulfate post-treatment system 4 and / or a drying system connected to the downstream of the ammonium sulfate discharge pump 3 , the concentrated circulation pump 5 connected between the concentrated crystallization area in the desulfurization tower 2 and the bottom of the desulfurization tow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com