Microwave sintering of superfine grain base titanium carbonitride

A technology of titanium carbonitride and ultrafine grains, which is applied in the field of microwave sintering of ultrafine grain titanium carbonitride-based cermets, which can solve the problems of long sintering and holding time, coarse material grains, and high energy consumption. , to achieve the effect of uniform and reliable heating, simple process and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

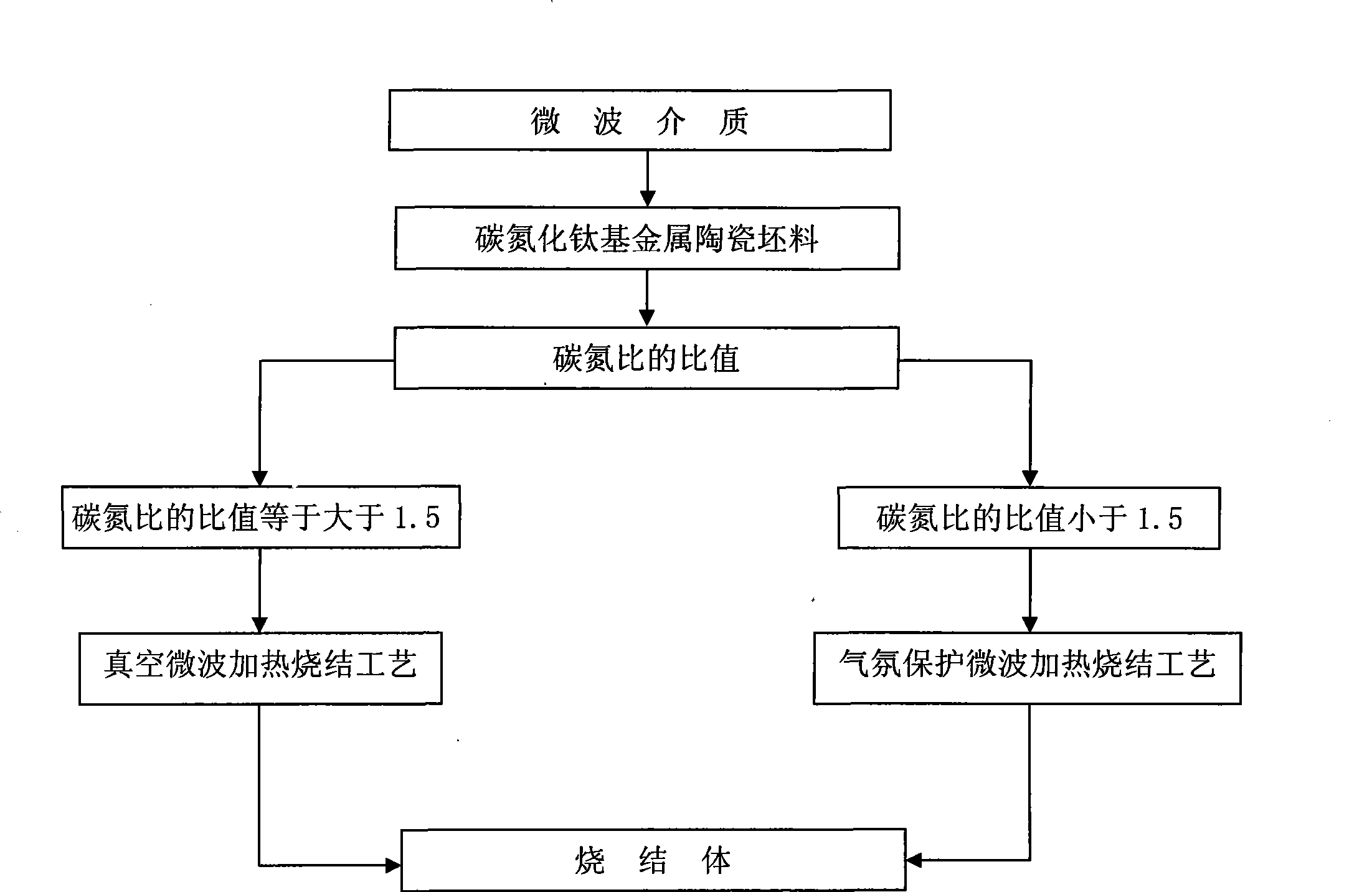

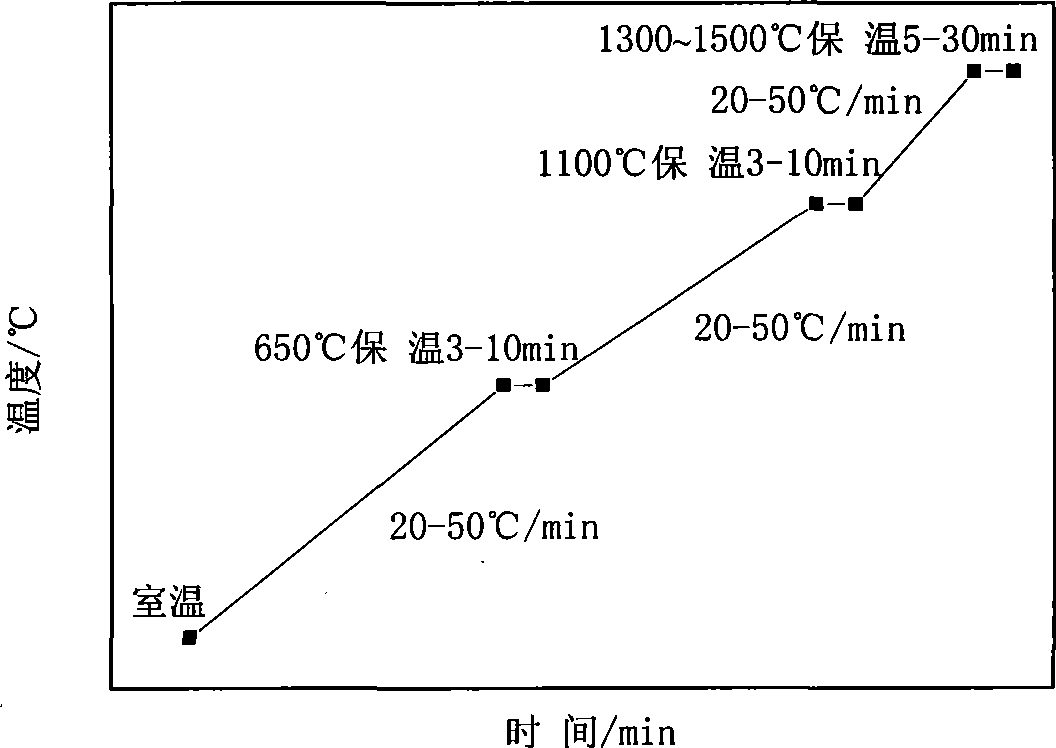

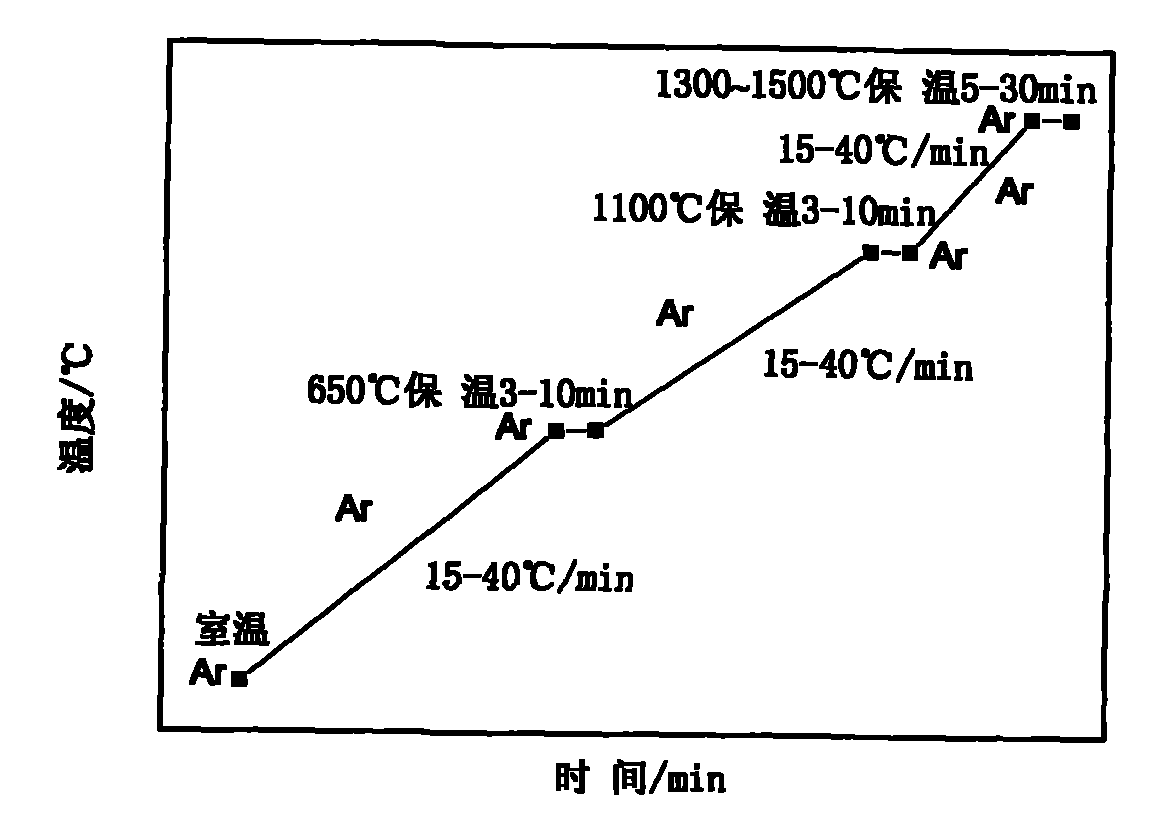

Method used

Image

Examples

Embodiment 1

[0032] Take a certain proportion of TiC 0.7 N 0.3 , WC, TaC, Co, Ni, Mo 2 C, ZrC, VC powder, according to the following mass ratio formulated into a mixture:

[0033] TiC 0.7 N 0.3 50.5wt% WC 15wt% TaC 10wt% Mo 2 C 8wt% Co 10wt% Ni 5wt% ZrC 1.0wt% VC 0.5wt%

[0034]The particle size of the powder of each of the above components is ≤1 μm.

[0035] Then the blank is made by powder metallurgy method, the process is:

[0036] (1) Wet grinding: Put the above mixed powder into the stainless steel ball mill tank of QM-1SP4 ball mill, add n-hexane at 200-400ml / l, select Φ5 hard alloy balls, the ball-to-material ratio is 5:1, and the speed is 200rpm , ball milling for 48 to 96 hours;

[0037] (2) Add molding agent: weigh paraffin wax by 3-5wt%, dissolve it in n-hexane, add ball mill tank and wet mill together with the mixture;

[0038] (3) Sieving: pass the ball milled slurry through a 60-mesh sieve, and settle for 1 to 2 hours;

[0039] (4) Drying: Put the precipitated mater...

Embodiment 2

[0050] Take a certain proportion of TiC 0.5 N 0.5 , WC, TaC, Co, Ni, Mo 2 C, ZrC, VC powder, according to the following mass ratio formulated into a mixture:

[0051] TiC 0.5 N 0.5 50.5wt% WC 15wt% TaC 10wt% Mo 2 C 8wt% Co 10wt% Ni 5wt% ZrC 1.0wt% VC 0.5wt%.

[0052] The particle size of the powder of each of the above components is ≤1 μm.

[0053] Then the blank is made by powder metallurgy technology, the process is:

[0054] (1) Wet grinding: put the above mixed powder into the stainless steel ball milling tank of QM-1SP4 ball mill, add n-hexane at 350ml / l, select Φ5 hard alloy balls, the ball-to-material ratio is 5:1, and the speed is 200rpm. 96 hours.

[0055] (2) Adding forming agent: weigh paraffin wax according to 5wt%, dissolve it in n-hexane, add ball mill jar and wet mill together with the mixture.

[0056] (3) Screening: pass the milled slurry through a 60-mesh sieve, and settle for 2 hours.

[0057] (4) Drying: Put the precipitated material into a ZK-82B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com