A Small Circulating Lubrication System Using Liquid Nitrogen Cooling

A circulating lubrication and liquid nitrogen cooling technology, which is applied in the field of laboratory friction and lubrication research, can solve the problems of large laboratory area, expensive low-temperature box, and complicated lubricating oil circuit connection, and achieves a simple structure of the device, which is conducive to environmental protection. Easy cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

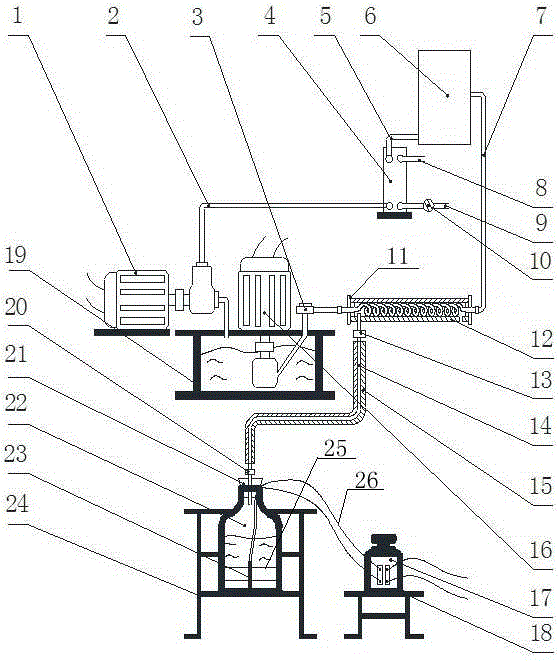

[0028] The present invention will be described in further detail below according to the accompanying drawings.

[0029] As shown in the figure, the liquid nitrogen thermos is filled with liquid nitrogen, the electric heating core is fixed in the liquid nitrogen thermos, and the electric heating core is connected with the contact voltage regulator through wires. The oil supply pump is fixed on the oil tank, and is connected to the device to be lubricated through the oil supply copper pipe for lubrication. The amount of oil supply can be realized by controlling the rotation angle of the oil outlet valve. A plate radiator is installed on the oil return road, and the cooled lubricating oil is returned to normal temperature through the circulation of tap water in the plate radiator. The oil pump is connected to the oil outlet of the plate radiator through an oil return copper pipe, and the oil pump pumps the lubricating oil back into the oil tank to realize recycling.

[0030] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com