Molecular cage modified fuel battery proton exchange membrane and preparation method thereof

A proton exchange membrane, fuel cell technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of affecting the service life of membrane materials, easy loss and dissolution, complex procedures, etc., to improve stability, simple compound conditions, The effect of simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

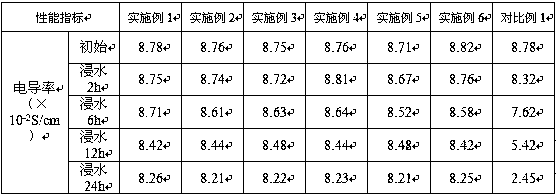

Examples

Embodiment 1

[0029] The preparation process is:

[0030] (1) Add trimesin to ethyl acetate solvent and let it stand for 5 minutes, then add hydrated heteropolyacid for ultrasonic stirring treatment, and then stand for 30 minutes, trimesaldehyde is adsorbed on the hydrated heteropolyacid due to the hydrophilic property of The surface of polyacid, then slowly add ethylenediamine solution dropwise and let it stand for 24 hours, and finally put the solution system in a vacuum furnace for heat treatment, so that trimesaldehyde and ethylenediamine form molecular cages on the surface of heteropolyacid particles for encapsulation After the solvent is completely volatilized, the colloidal material of the organic molecular cage coated heteropolyacid particles is obtained; the ultrasonic power density of the ultrasonic stirring treatment is 3W / cm 2 , the stirring speed is 140r / min, and the treatment time is 18min; the temperature of heat treatment is 260°C, and the time is 3h; the parts by weight of ...

Embodiment 2

[0036] The preparation process is:

[0037] (1) Add trimesin to ethyl acetate solvent and let it stand for 5 minutes, then add hydrated heteropolyacid for ultrasonic stirring treatment, and then stand for 30 minutes, trimesaldehyde is adsorbed on the hydrated heteropolyacid due to the hydrophilic property of The surface of polyacid, then slowly add ethylenediamine solution dropwise and let it stand for 24 hours, and finally put the solution system in a vacuum furnace for heat treatment, so that trimesaldehyde and ethylenediamine form molecular cages on the surface of heteropolyacid particles for encapsulation After the solvent is completely volatilized, the colloidal material of the organic molecular cage coated heteropolyacid particles is obtained; the ultrasonic power density of the ultrasonic stirring treatment is 2W / cm 2 , the stirring speed is 120r / min, and the treatment time is 30min; the heat treatment temperature is 200°C, and the time is 4h; the parts by weight of eac...

Embodiment 3

[0044] The preparation process is:

[0045] (1) Add trimesin to ethyl acetate solvent and let it stand for 5 minutes, then add hydrated heteropolyacid for ultrasonic stirring treatment, and then stand for 30 minutes, trimesaldehyde is adsorbed on the hydrated heteropolyacid due to the hydrophilic property of The surface of polyacid, then slowly add ethylenediamine solution dropwise and let it stand for 24 hours, and finally put the solution system in a vacuum furnace for heat treatment, so that trimesaldehyde and ethylenediamine form molecular cages on the surface of heteropolyacid particles for encapsulation After the solvent is completely volatilized, the colloidal material of the organic molecular cage coated heteropolyacid particles is obtained; the ultrasonic power density of the ultrasonic stirring treatment is 4W / cm 2 , the stirring speed is 180r / min, and the treatment time is 10min; the temperature of heat treatment is 300°C, and the time is 2h; the parts by weight of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com