A kind of preparation method and application of metal oxide-coated lithium-ion battery cathode material

A cathode material and ion battery technology, which is applied to the preparation of battery cathode materials and the preparation of metal oxide-coated lithium ion battery cathode materials can solve the problems of cumbersome preparation process, high cost, complicated operation process and the like, and achieve a simple process. , Improve efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

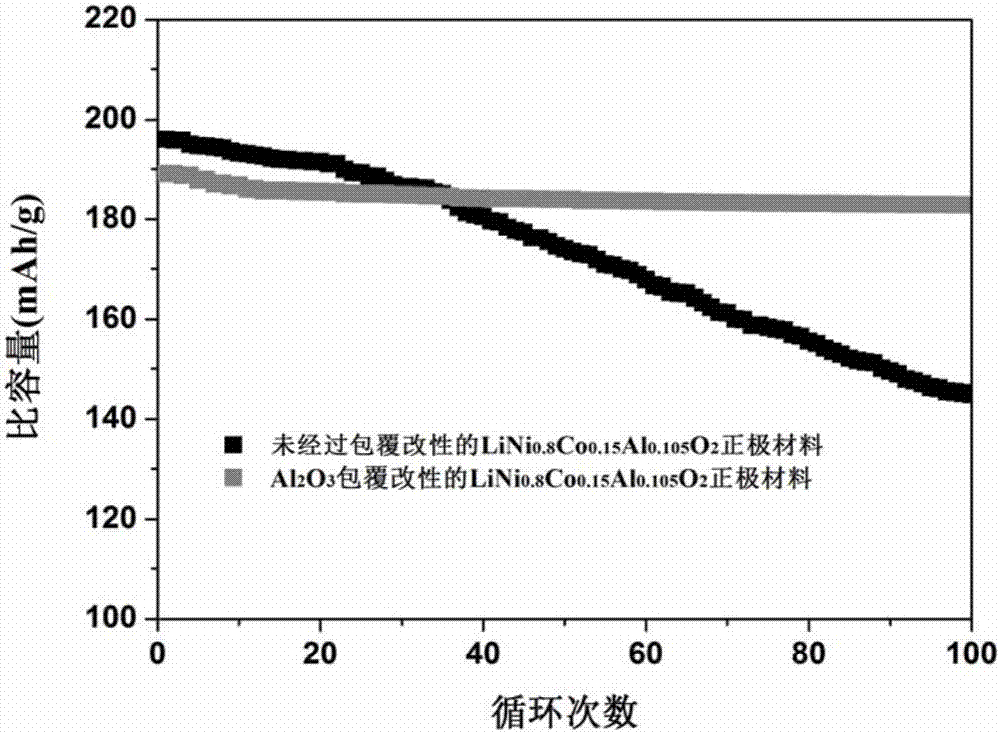

Embodiment 1

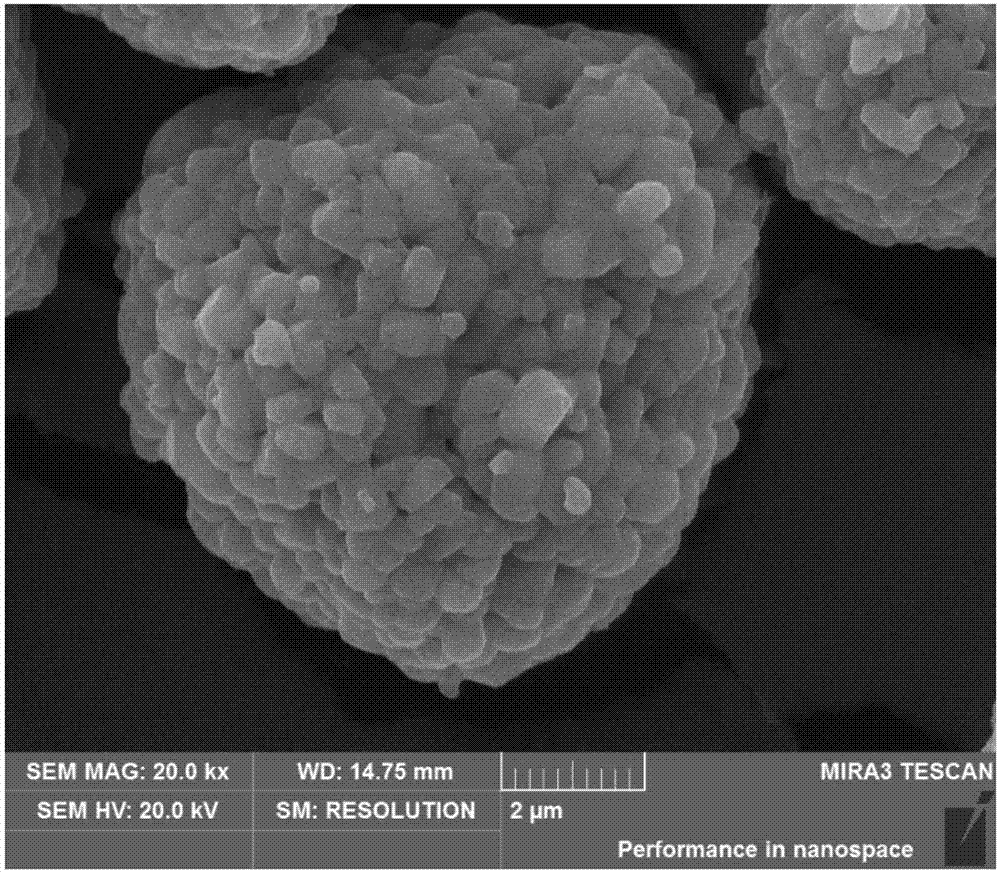

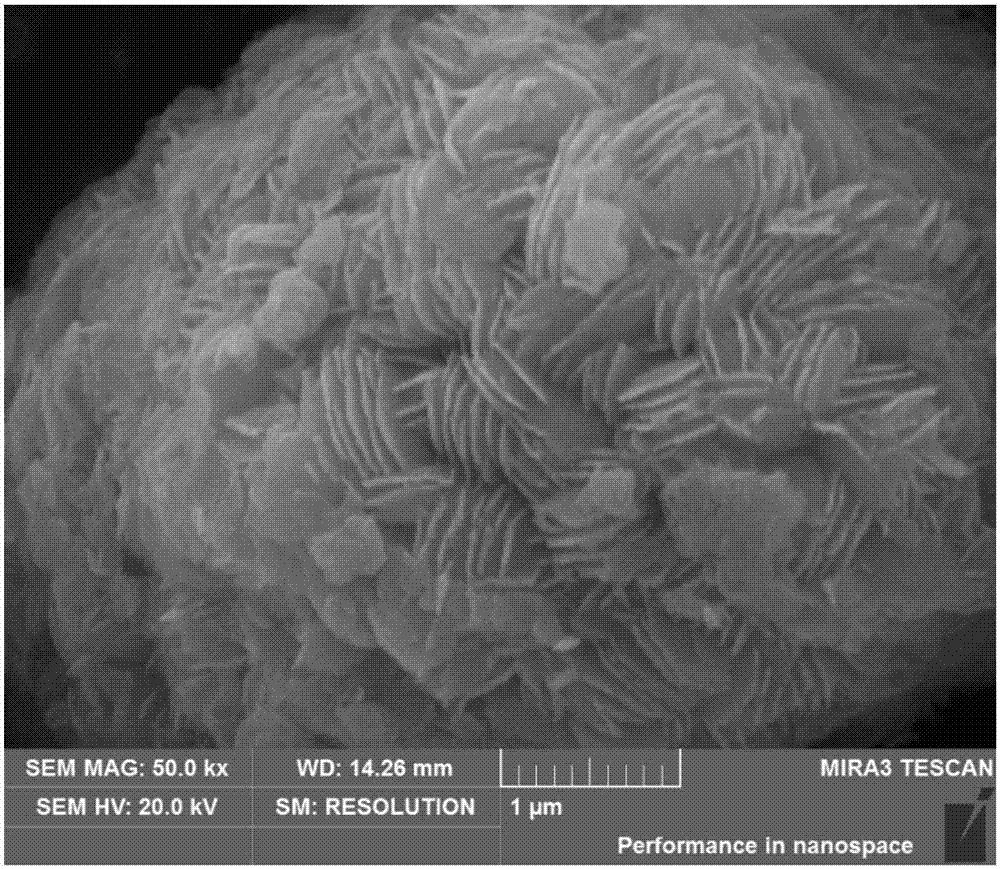

[0035] (1) The ultra-fine aluminum powder with a particle size of 50nm is weighed respectively according to the mass percentage of 1% relative to the positive electrode material for aluminum powder and LiNi 0.8 co 0.15 al 0.05 o 2 The positive electrode material was added to an agate ball mill jar with a capacity of 250mL and filled with zirconia balls, and then the rotation speed was adjusted to 400p / min for grinding for 2h.

[0036](2) Add the ground mixture into a three-necked flask with a capacity of 250 mL and add 100 mL of deionized water, and stir and react at 50° C. for 1 h.

[0037] (3) Wash the precipitate obtained in step (2) with deionized water for 3 times, then wash with absolute ethanol for 3 times, then filter, and keep the filter cake in a blast oven at 80°C for 12 hours to obtain an aluminum hydroxide package Covered LiNi 0.8 co 0.15 Al 0.05 o 2 Precursors of cathode materials.

[0038] (4) Put the precursor obtained in step (3) into a crucible and ke...

Embodiment 2

[0045] (1) The superfine magnesium powder that particle diameter is 100nm weighs magnesium powder and 0.3Li respectively according to relative cathode material being 0.5% mass percent 2 MnO 3 0.7LiNi 0.333 co 0.333 mn 0.333 o 2 The positive electrode material was added to a corundum ball mill jar with a capacity of 250mL and filled with steel balls, and then the rotation speed was adjusted to 500p / min for grinding for 4h.

[0046] (2) Add the ground mixture into a three-necked flask with a capacity of 250 mL and add 100 mL of deionized water, and stir and react at 40° C. for 2 h.

[0047] (3) Wash the precipitate obtained in step (2) with deionized water for 3 times, then wash with absolute ethanol for 3 times, then filter, and filter the cake in a blast oven at 80°C for 12 hours to obtain a magnesium hydroxide package Covered 0.3Li 2 MnO 3 0.7LiNi 0.333 co 0.333 mn 0.333 o 2 Precursors of cathode materials.

[0048] (4) Put the precursor obtained in step (3) into ...

Embodiment 3

[0052] (1) The ultrafine cerium powder with a particle diameter of 200nm is weighed respectively according to the mass percentage of 2.0% of the positive electrode material and 0.5Li 2 MnO 3 0.5LiNi 0.5 co 0.2 mn 0.3 o 2 The positive electrode material was added to a nylon ball mill jar with a capacity of 250mL and filled with agate balls, and then the rotation speed was adjusted to 600p / min for grinding for 6h.

[0053] (2) Add the ground mixture into a three-necked flask with a capacity of 250 mL and add 100 mL of deionized water, and stir and react at 60° C. for 3 h.

[0054] (3) Wash the precipitate obtained in step (2) with deionized water for 3 times, then wash with absolute ethanol for 3 times, then filter, and keep the filter cake in a blast oven at 80°C for 12 hours to obtain a cerium hydroxide package Covered 0.5Li 2 MnO 3 0.5LiNi 0.5 co 0.2 mn 0.3 o 2 Precursors of cathode materials.

[0055] (4) Put the precursor obtained in step (3) into a crucible and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com