Pre-processing method for extracting tobacco leaf lignin by using enhanced enzymolysis method

A technology of lignin and enzymatic hydrolysis, applied in the field of lignin extraction, can solve the problems of time-consuming, low yield of structural change, long time-consuming, etc., and achieve the effects of improving enzymatic hydrolysis efficiency, avoiding dissolution loss, and simple and efficient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

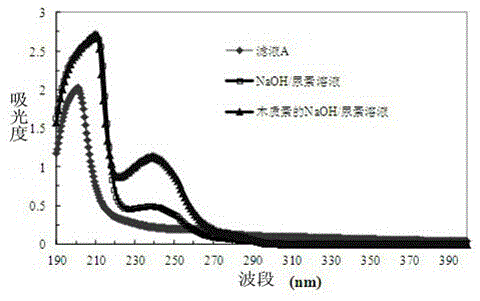

Embodiment 1

[0025] Weigh 10g of tobacco leaf powder, and disperse the tobacco leaf powder in a mixed solution of 250ml of sodium hydroxide, urea and water at -10°C, the mass ratio of sodium hydroxide, urea and water in the mixed solution is 7:12:81 . After stirring for 30 minutes at -10°C, filter with a 600-mesh filter cloth, and keep the filtrate A for UV testing. The solid was washed with pure water to neutrality, and vacuum-dried at 50° C. for 24 hours to obtain 3.6738 g of pretreated tobacco leaf powder. The cellulose content of pretreated tobacco leaves was determined by the National Renewable Energy Laboratory analytical test method (NREL / TP-510-42618, Determination of Structural Carbohydrates and Lignin in Biomass.2008). Weigh 1g of the above-mentioned pretreated tobacco leaf powder, add it into 50mL acetic acid-sodium acetate buffer solution, the pH is 4.8, and the ionic strength is 50mmol / L, then add 20FPU / g dextran cellulase (CTec2, Novi Letter China Biotechnology Co., Ltd.), ...

Embodiment 2

[0029]Weigh 10g of tobacco leaf powder, and disperse the tobacco leaf powder in a mixed solution of 250ml of sodium hydroxide, urea and water at -10°C, the mass ratio of sodium hydroxide, urea and water in the mixed solution is 8:12:80 . After stirring for 30 minutes at -10°C, filter with a 600-mesh filter cloth, and keep the filtrate A for UV testing. The solid was washed with pure water to neutrality, and vacuum-dried at 50° C. for 24 hours to obtain 3.4737 g of pretreated tobacco leaf powder. The cellulose content of pretreated tobacco leaves was determined by the National Renewable Energy Laboratory analytical test method (NREL / TP-510-42618, Determination of Structural Carbohydrates and Lignin in Biomass.2008). Weigh 1g of the above-mentioned pretreated tobacco leaf powder, add it into 50mL acetic acid-sodium acetate buffer solution, the pH is 4.8, and the ionic strength is 50mmol / L, then add 20FPU / g dextran cellulase (CTec2, Novi Letter China Biotechnology Co., Ltd.), r...

Embodiment 3

[0031] Weigh 10g of tobacco leaf powder, and disperse the tobacco leaf powder in a mixed solution of 250ml of sodium hydroxide, urea and water at -10°C, the mass ratio of sodium hydroxide, urea and water in the mixed solution is 5:15:80 . After stirring for 30 minutes under the condition of maintaining -10°C, filter with a 600-mesh filter cloth, and keep the filtrate (named A) for ultraviolet testing. The solid was washed with pure water to neutrality, and vacuum-dried at 50° C. for 24 hours to obtain 3.7052 g of pretreated tobacco leaf powder. The cellulose content of pretreated tobacco leaves was determined by the National Renewable Energy Laboratory analytical test method (NREL / TP-510-42618, Determination of Structural Carbohydrates and Lignin in Biomass.2008). Weigh 1g of the above-mentioned pretreated tobacco leaf powder, add it into 50mL acetic acid-sodium acetate buffer solution, the pH is 5.0, and the ionic strength is 50mmol / L, then add 20FPU / g dextran cellulase (CTe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| ionic strength | aaaaa | aaaaa |

| ionic strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com