Planet wheel bearing outer circle alloy layer pouring mold

A planetary wheel and alloy layer technology, which is applied in the field of casting molds for the outer cylindrical alloy layer of planetary wheel bearings, can solve the problems of many casting defects, low bonding force between tin-based alloy and carbon structural steel matrix, and improve performance and bonding The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

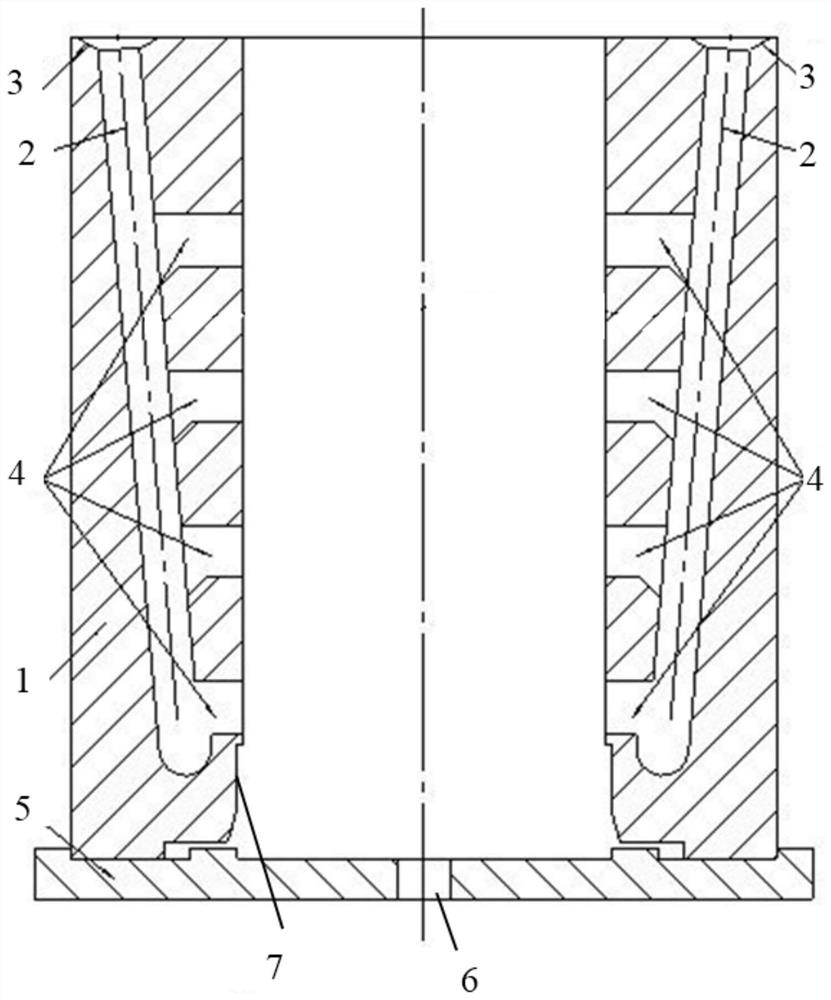

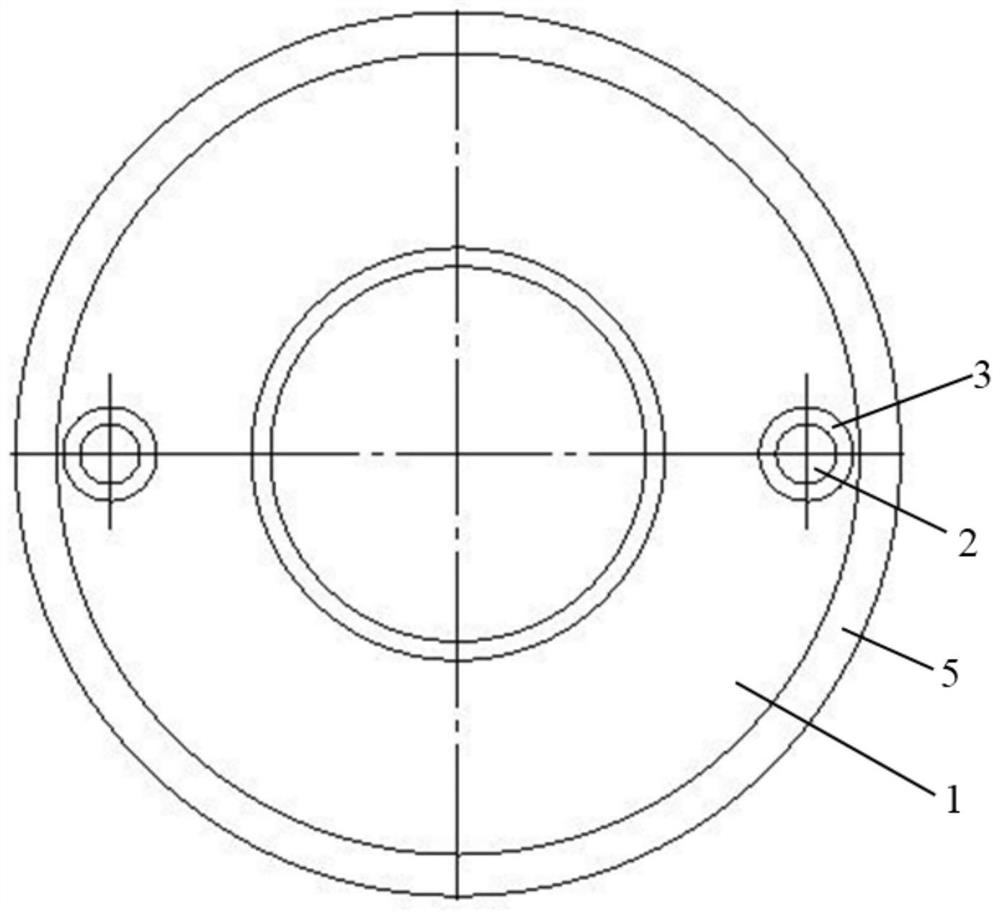

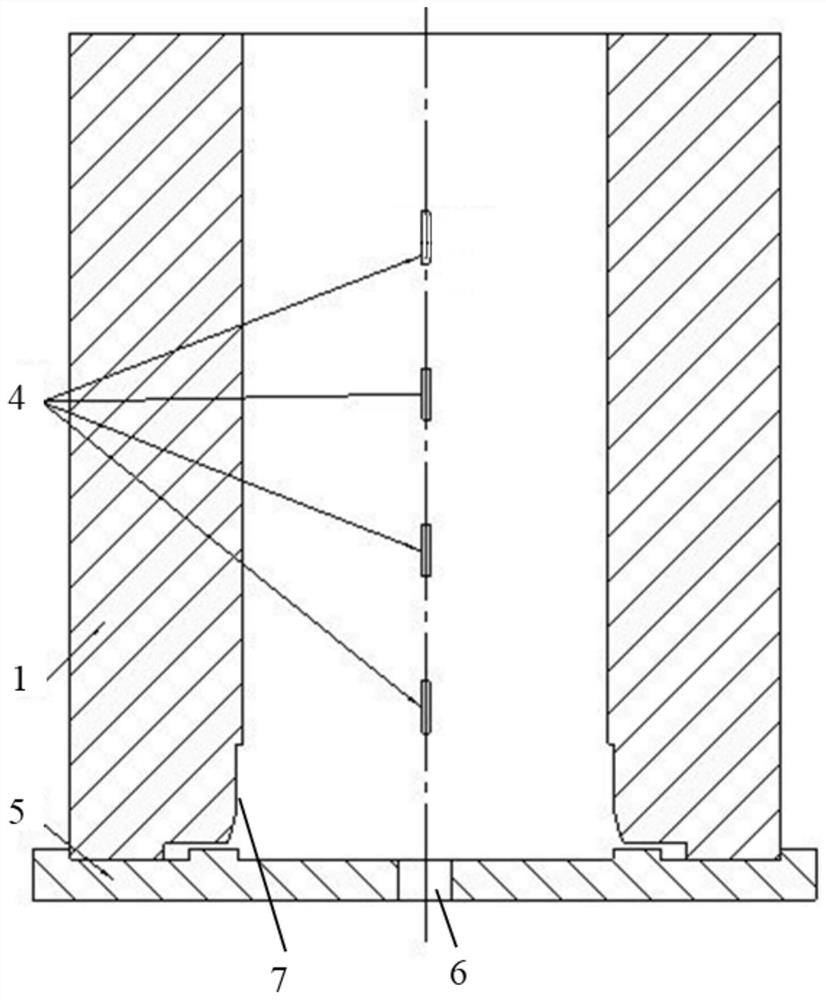

[0019] A casting mold for the outer circle alloy layer of a planetary wheel bearing according to the present invention, referring to figure 1 and figure 2 , including a cylindrical mold body 1, the bottom of the mold body 1 is provided with a pouring bottom plate 5, and the center of the pouring bottom plate 5 is provided with a circular water outlet channel 6, and the interior of the opposite side wall of the mold body 1 is provided with an inclined runner 2 for oblique pouring. The gate 3 is arranged on the top of the channel 2, and the horizontal runner 4 is arranged on the side, and the horizontal runner 4 runs through the inner wall of the mold body 1 . The bottom of the inner wall of the mold body 1 is provided with a groove 7, which is convenient for fitting with the inner carbon structural steel matrix of the planetary wheel bearing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com