System for direct-injection removing NOX and SO3 in bypass flues of boiler

A bypass flue and boiler technology, applied in chemical instruments and methods, gas treatment, membrane technology, etc., can solve problems such as clogging, and achieve the effect of high-efficiency and low-cost removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

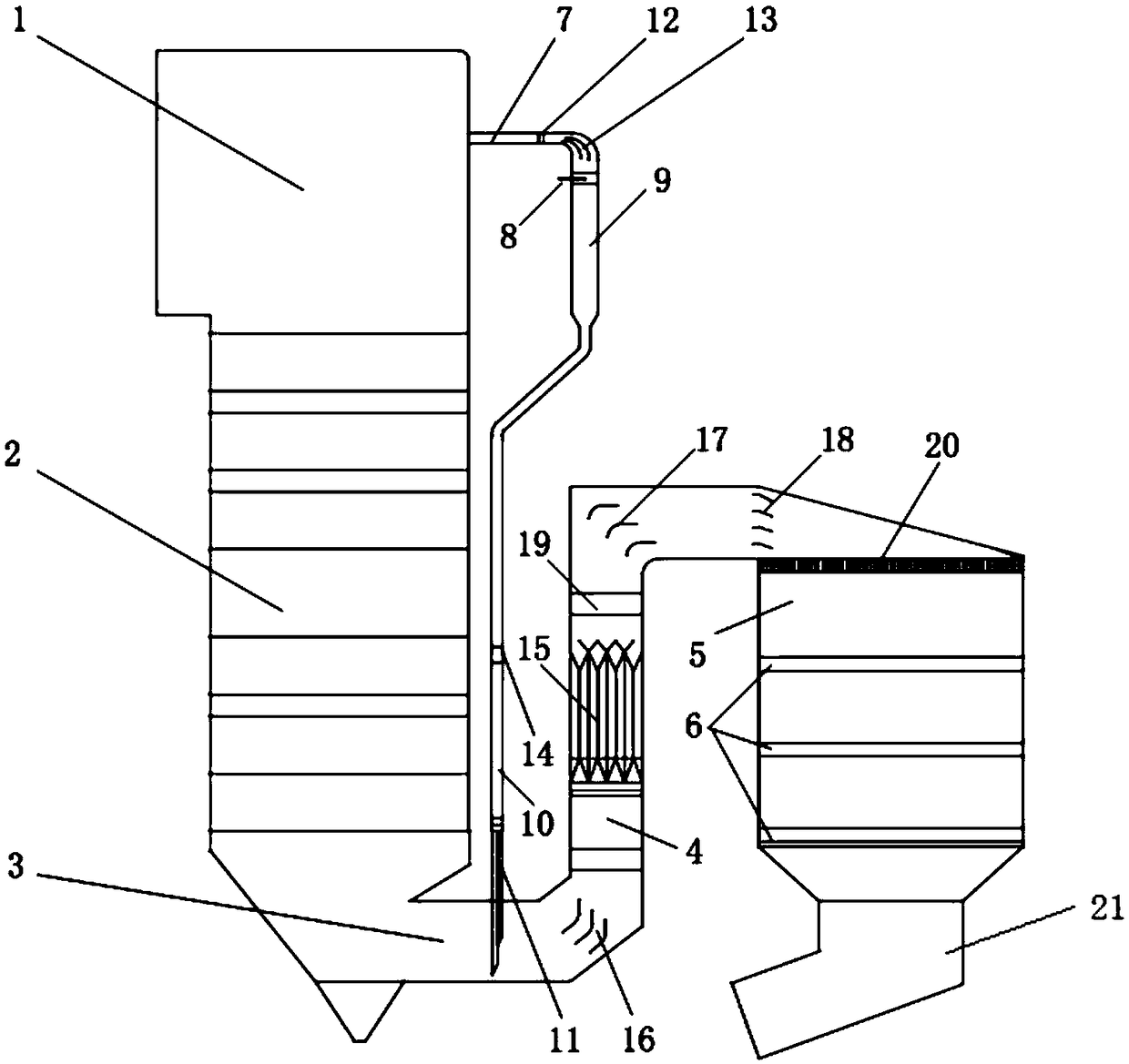

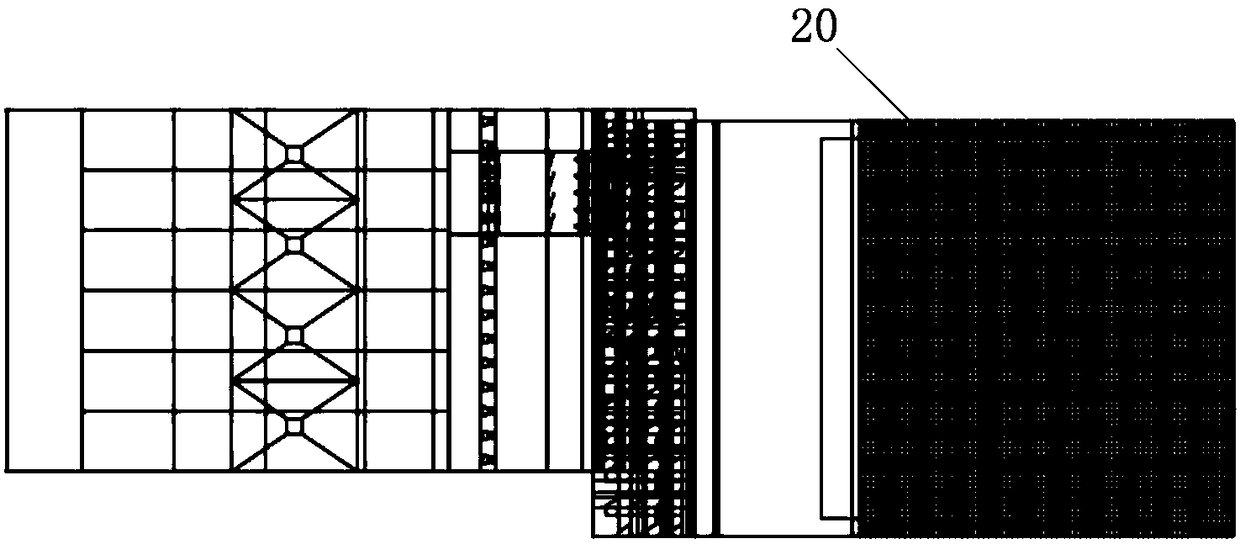

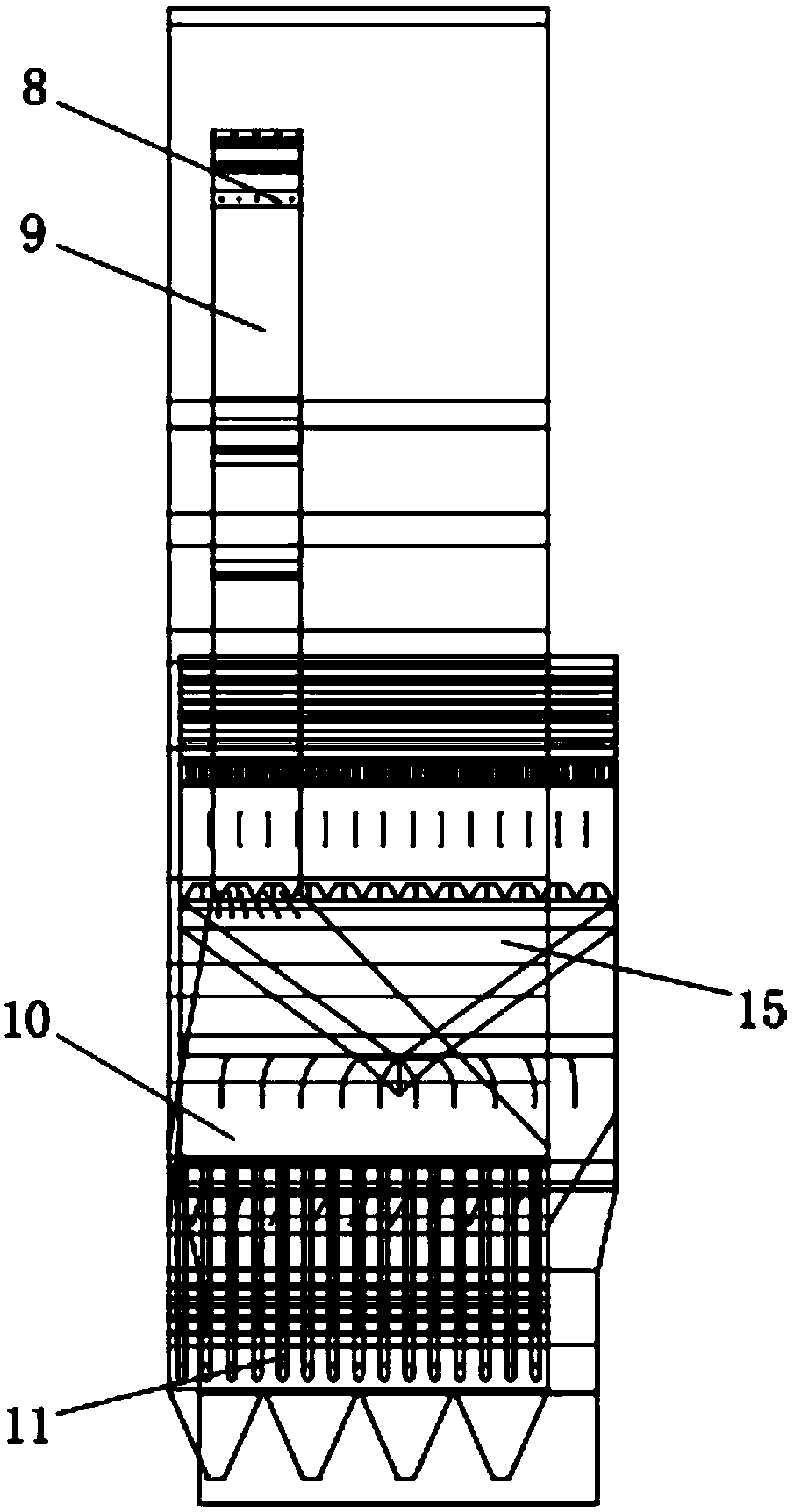

[0027] Reference figure 1 As shown, the boiler bypass flue direct injection in this embodiment removes NO X and SO 3 system, including boiler bypass flue direct injection device and SCR denitrification device, boiler bypass flue direct injection device includes boiler bypass flue 7, pyrolysis chamber 9, conical header 10 and injection device 11 connected in sequence , also includes a spray gun 8 arranged on the top side of the vertical section of the boiler bypass flue 7; the SCR denitrification device includes a horizontal flue 3 at the outlet of the economizer, an ascending flue 4 at the inlet of the SCR denitrification device, and an SCR reactor 5 And SCR reactor outlet flue 21. Spray gun 8 is used to spray reductant / adsorbent; in this example specifically urea and SO 3 Stripper mixture, SO 3 The removal agent is a base adsorbent that is easily soluble in water, preferably using Na 2 CO 3 solution. The urea sprayed from the spray gun 8 is pyrolyzed in the pyrolysis c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com