Device for producing methyl methacrylate by using waste and old organic glass and using method thereof

A technology of methyl methacrylate and plexiglass, which is applied in the preparation of organic compounds, separation/purification of carboxylic acid esters, organic chemistry, etc., and can solve problems such as environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

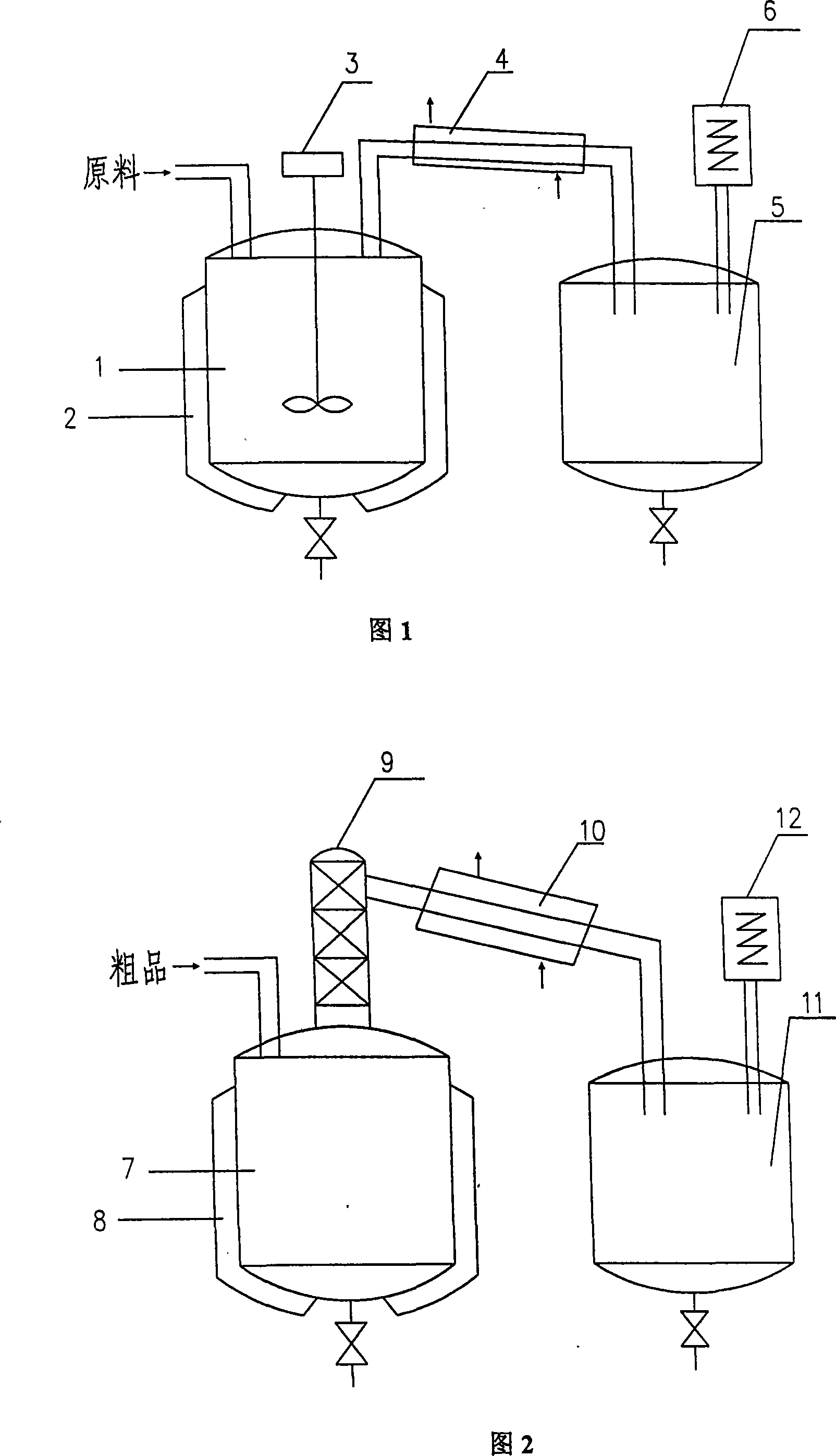

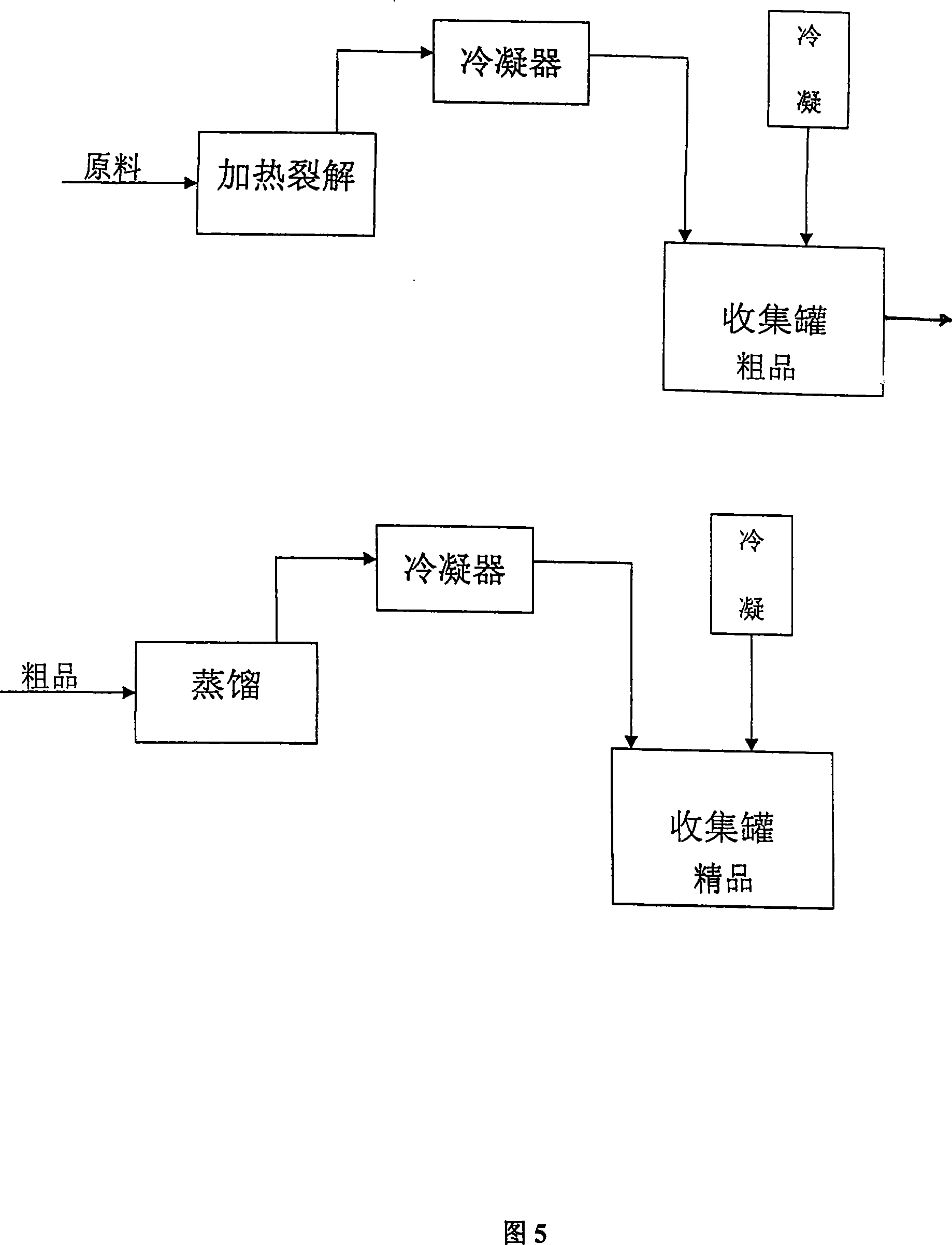

[0023] The detailed description of this process cracking device, referring to accompanying drawing 1, accompanying drawing 3:

[0024] 1. In order to avoid the generation of exhaust gas, the entire cracking device is sealed and connected to ensure no leakage. After the installed pyrolysis device is evacuated by a vacuum pump, close the corresponding valve for 24 hours to ensure that the vacuum does not leak, indicating that the device has good airtightness.

[0025] 2. The stainless steel reaction kettle is used as the cracking kettle.

[0026] 3. The pyrolysis process of the cracking kettle adopts direct heating and cracking with an open flame, or chooses an oil bath with a jacketed reactor, and the latter is safer.

[0027] 4. A vacuum device can be used to extract the pyrolysis gas, so as to reduce the pyrolysis temperature, accelerate the pyrolysis speed and reduce energy loss.

[0028] 5. You can choose to install a stirrer on the cracking kettle, so as to stir the wast...

Embodiment 2

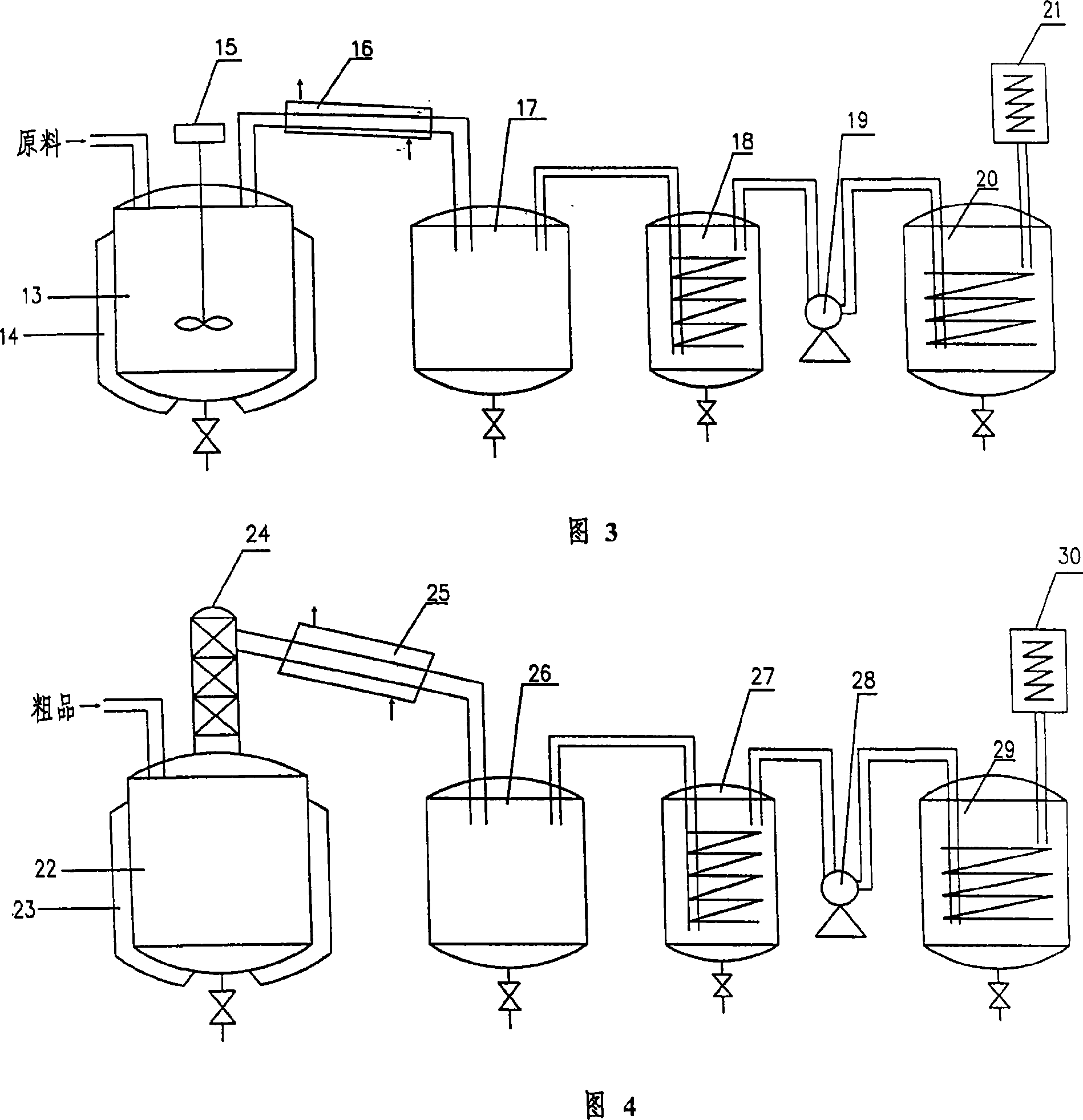

[0032] For the invention of the green process distillation device, please refer to attached drawings 2 and 4:

[0033] 1. The installed distillation device is sealed and inspected. After the vacuum pump is pumped, the relevant valves are closed. After 24 hours, ensure that the vacuum does not leak, indicating that the airtightness of the device is intact.

[0034] 2. After distilling the obtained MMA crude product collected by cracking through the distillation tower, collect the required distillate. After condensing through the cooling system, the high-purity MMA flows into the high-quality collection tank, and a condenser is installed on the vent pipe of the high-quality collection tank. The vented gas is condensed into a liquid and flows into the collection tank to prevent the stench of MMA gas from escaping.

[0035] 3. If vacuum distillation is used, in order to limit the emission of waste gas to the maximum extent, after the condensation of the two-stage cold well, most o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com