Ferrite-carbon nanotube composite wave absorption material and preparation method thereof

A carbon nanotube composite and composite wave-absorbing material technology, which is applied in the field of wave-absorbing materials, can solve the problems of unsatisfactory absorption frequency band extension, difficulty in matching electromagnetic parameters, and poor temperature stability, which is conducive to large-scale production and process Easy-to-control, easy-to-thickness effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

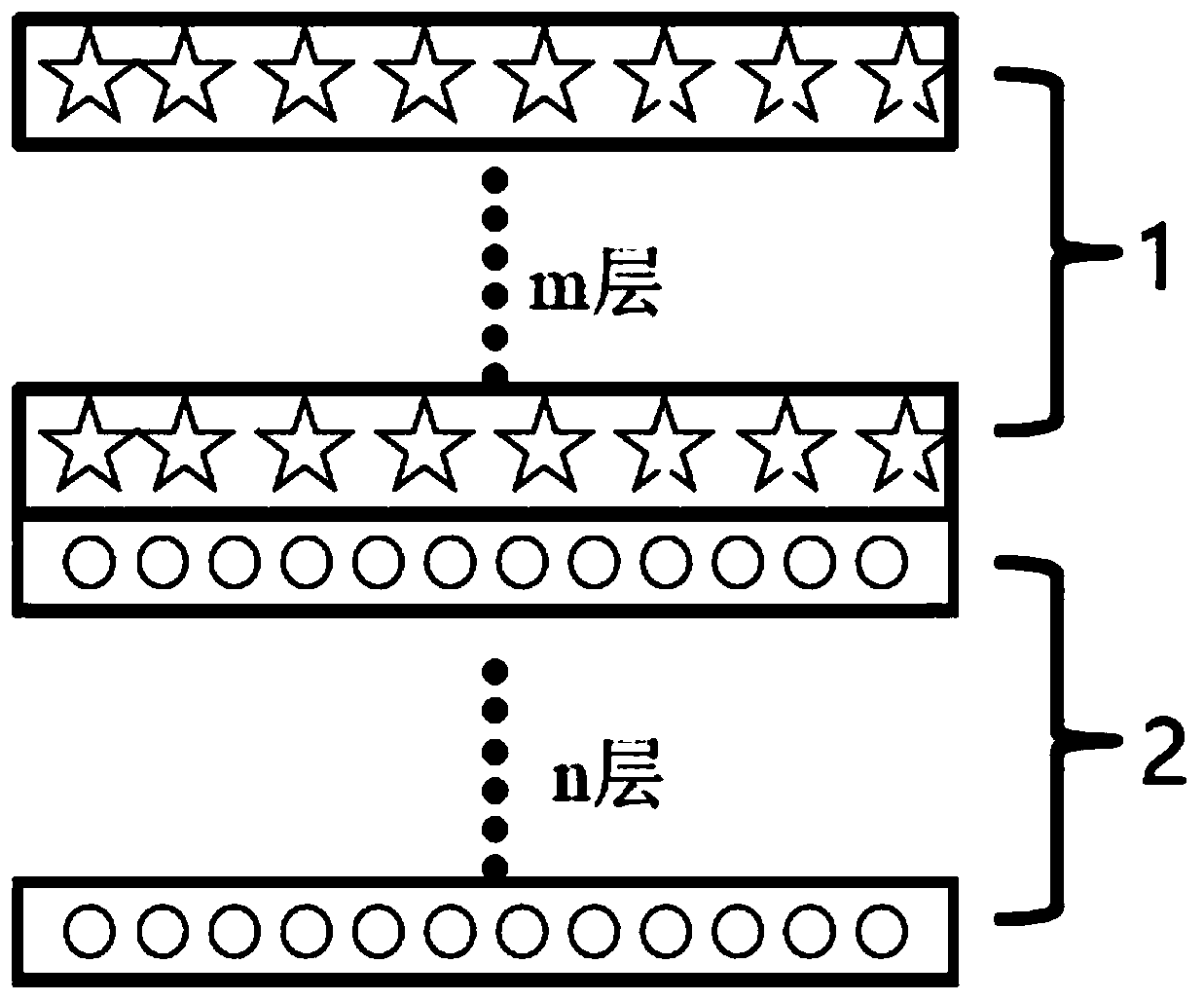

[0038] Such as figure 1 As shown, the ferrite-carbon nanotube composite absorbing material has a double-layer structure of carbon nanotube layer and ferrite layer. By adjusting the layer number, thickness, formula and process of the carbon nanotube layer and the ferrite layer in the composite absorbing material, the absorbing performance of the material can be regulated.

[0039] (1) The composition and weight percentage of the ferrite layer are:

[0040] Polymer binder: 10%

[0041] Nickel zinc ferrite powder: 88%

[0042] Auxiliary: 2%

[0043] The polymer binder is polyurethane, which is required to meet the requirements of the wave-absorbing material casting process.

[0044] The ferrite is NiZnFe 2 o 4 , Nickel-zinc ferrite is spherical with a diameter of 300-1500nm.

[0045] The auxiliary agent includes a dispersant, a polyurethane curing agent and a curing catalyst, and the mass ratio of the two is 1:8:1.

[0046] The thickness of the nickel-zinc ferrite single la...

Embodiment 2

[0065] Such as figure 1 As shown, the ferrite-carbon nanotube composite absorbing material has a double-layer structure of carbon nanotube layer and ferrite layer. By adjusting the layer number, thickness, formula and process of the carbon nanotube layer and the ferrite layer in the composite absorbing material, the absorbing performance of the material can be regulated.

[0066] (1) The composition and weight percentage of the ferrite layer are:

[0067] Polymer binder: 8%

[0068] Manganese zinc ferrite powder: 90%

[0069] Auxiliary: 2%

[0070] The polymer binder is ethyl cellulose, which is required to meet the requirements of the wave-absorbing material casting process.

[0071] The ferrite is MnZnFe 2 o 4 , MnZn ferrite is spherical with a diameter of 500-2000nm.

[0072] The auxiliary agent includes a dispersant, a curing agent and a curing catalyst, and the mass ratio of the two is 2:7:1.

[0073] The single layer thickness of the manganese zinc ferrite is 0.1...

Embodiment 3

[0089] Such as figure 1 As shown, the ferrite-carbon nanotube composite absorbing material has a double-layer structure of carbon nanotube layer and ferrite layer. By adjusting the layer number, thickness, formula and process of the carbon nanotube layer and the ferrite layer in the composite absorbing material, the absorbing performance of the material can be regulated.

[0090] (1) The composition and weight percentage of the ferrite layer are:

[0091] Polymer binder: 17%

[0092] Barium ferrite magnetic powder: 80%

[0093] Auxiliary: 3%

[0094] The polymer binder is polyvinyl acetal, which is required to meet the requirements of the wave-absorbing material casting process.

[0095] The ferrite is BaFe 12 o 19 , Barium ferrite is spherical with a diameter of 800-3000nm.

[0096] The auxiliary agent includes a dispersant, a curing agent and a curing catalyst, and the mass ratio of the two is 1:8:1.

[0097] The thickness of the barium ferrite single layer is 0.10mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com