Aerated concrete block produced from vanadium smelting slag and preparation method thereof

A technology of aerated concrete and smelting slag, which is applied to clay preparation devices, chemical instruments and methods, ceramic products, etc., can solve the problems of waste, unqualified aerated concrete blocks, and the effect of autoclaving, etc., to achieve convenient operation, Facilitate mechanized production and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

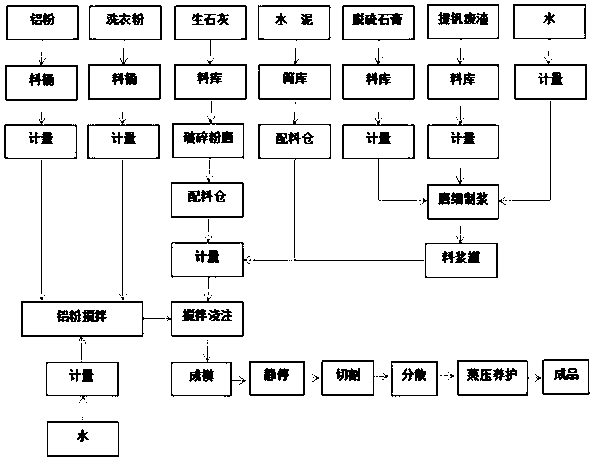

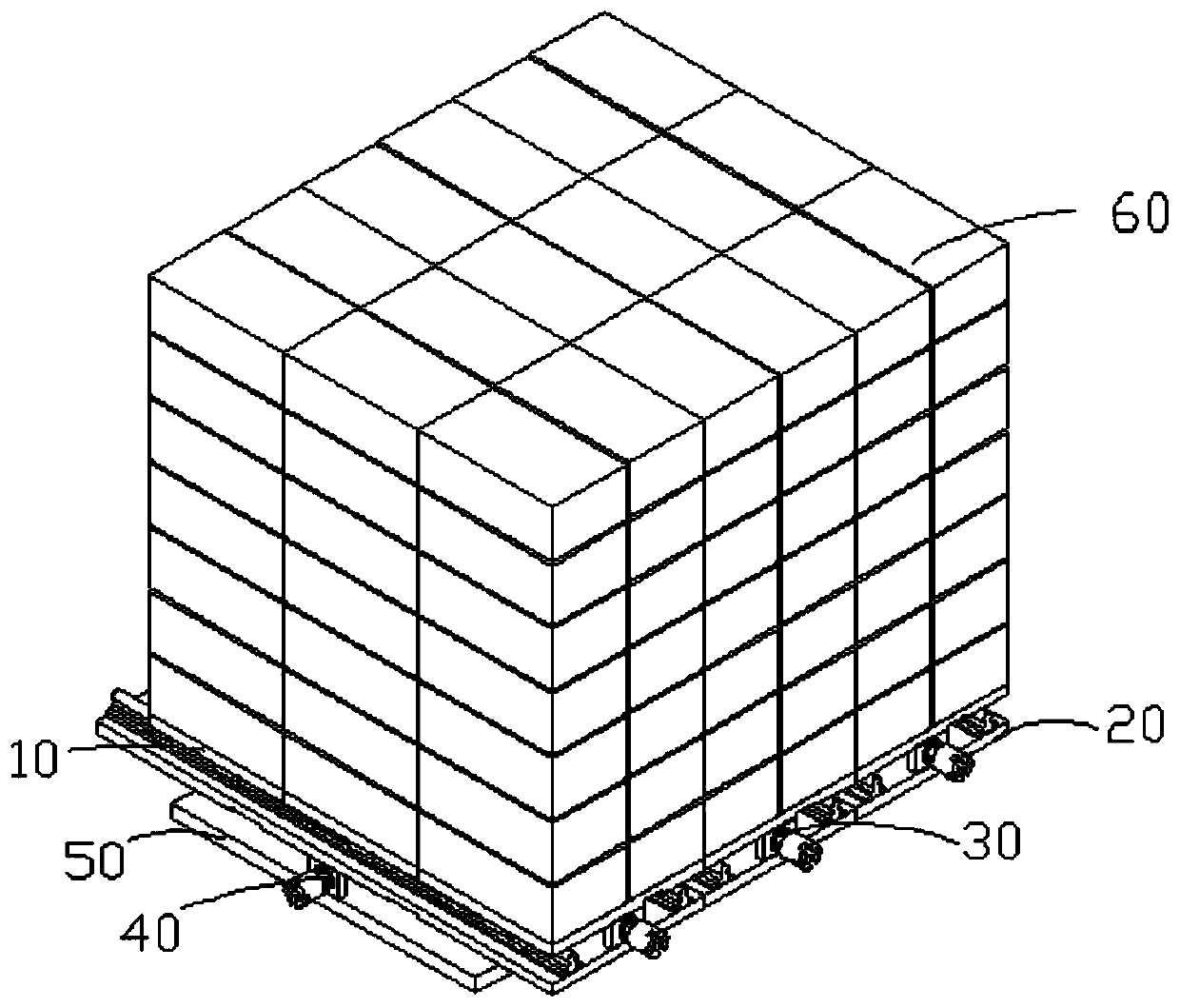

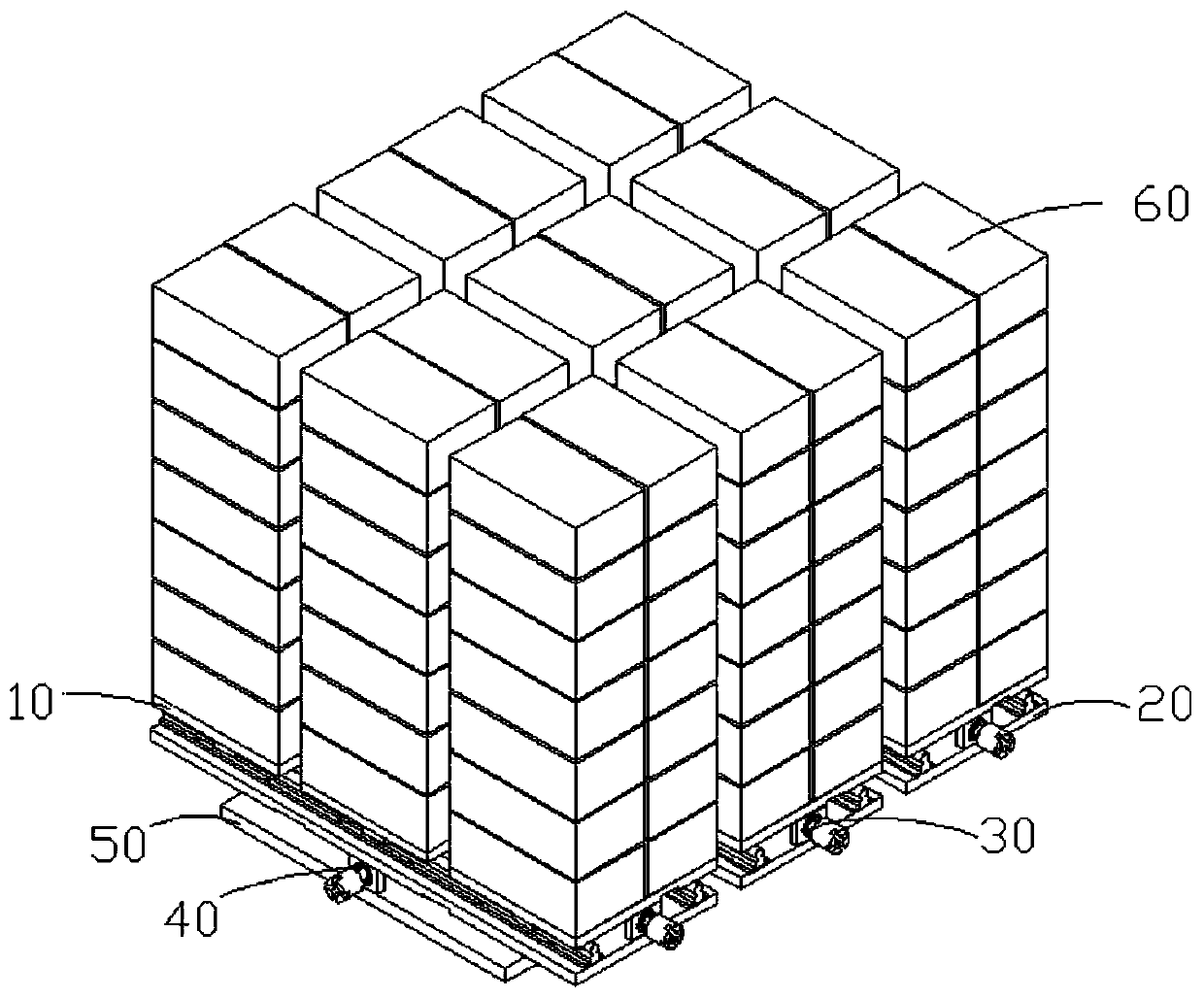

[0054] refer to Figure 1 to Figure 8 , in one embodiment of the present invention, a kind of vanadium smelting slag is provided to produce aerated concrete block and its preparation method, and its formula consists of

[0055] Basic raw materials: 40% to 50% of vanadium smelting slag, 20% to 30% of silica sand, 8% to 15% of quicklime, 3% to 5% of gypsum, and 8% to 15% of cement, and the percentages mentioned are percentages by weight;

[0056] Additives: based on 100% of the basic raw materials, the aluminum powder is 0.8-1.2‰ of the basic raw materials, and the washing powder is 0.05-0.1‰, and the stated percentages are percentages by weight;

[0057] The solvent may be water, and the water-to-material mass ratio of the water to the basic raw material is 0.6-0.7.

[0058] In one embodiment of the present invention, choose vanadium smelting slag 40...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com