Heat-resisting steel for exhaust valves

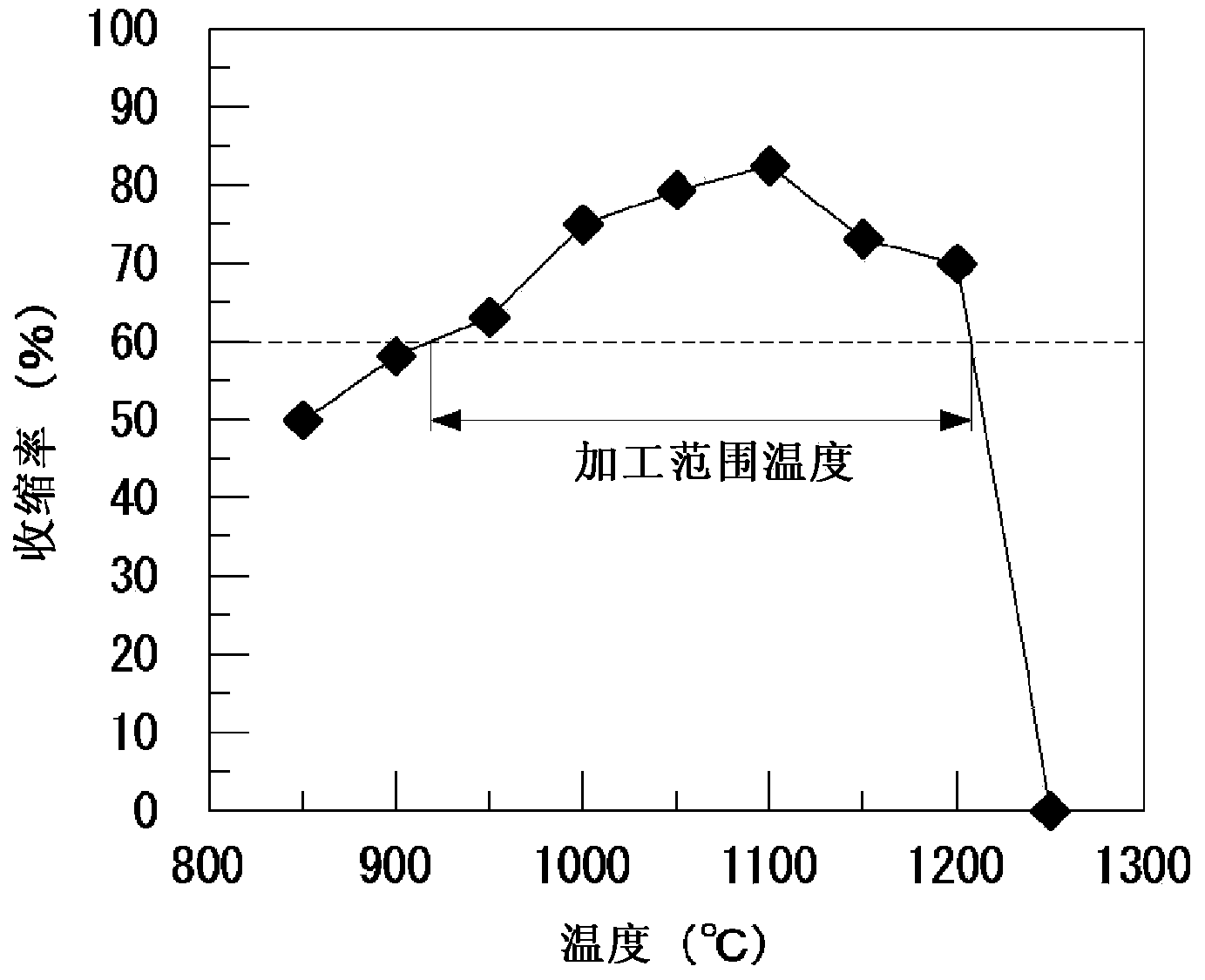

A technology of heat-resistant steel and exhaust valve, which can be used in lift valves, valve devices, heat treatment furnaces, etc., and can solve the problems of poor hot workability and difficult structure control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~34

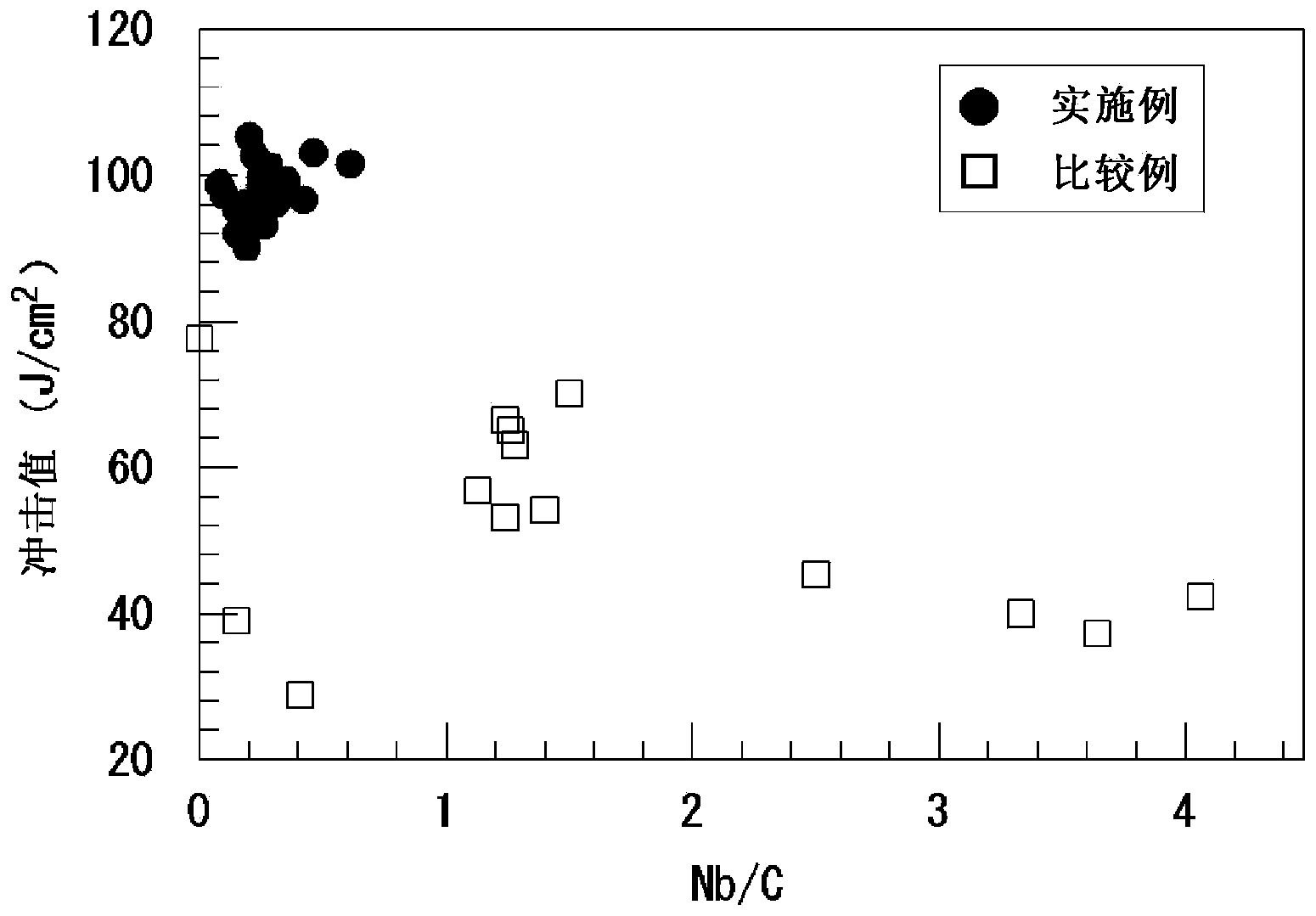

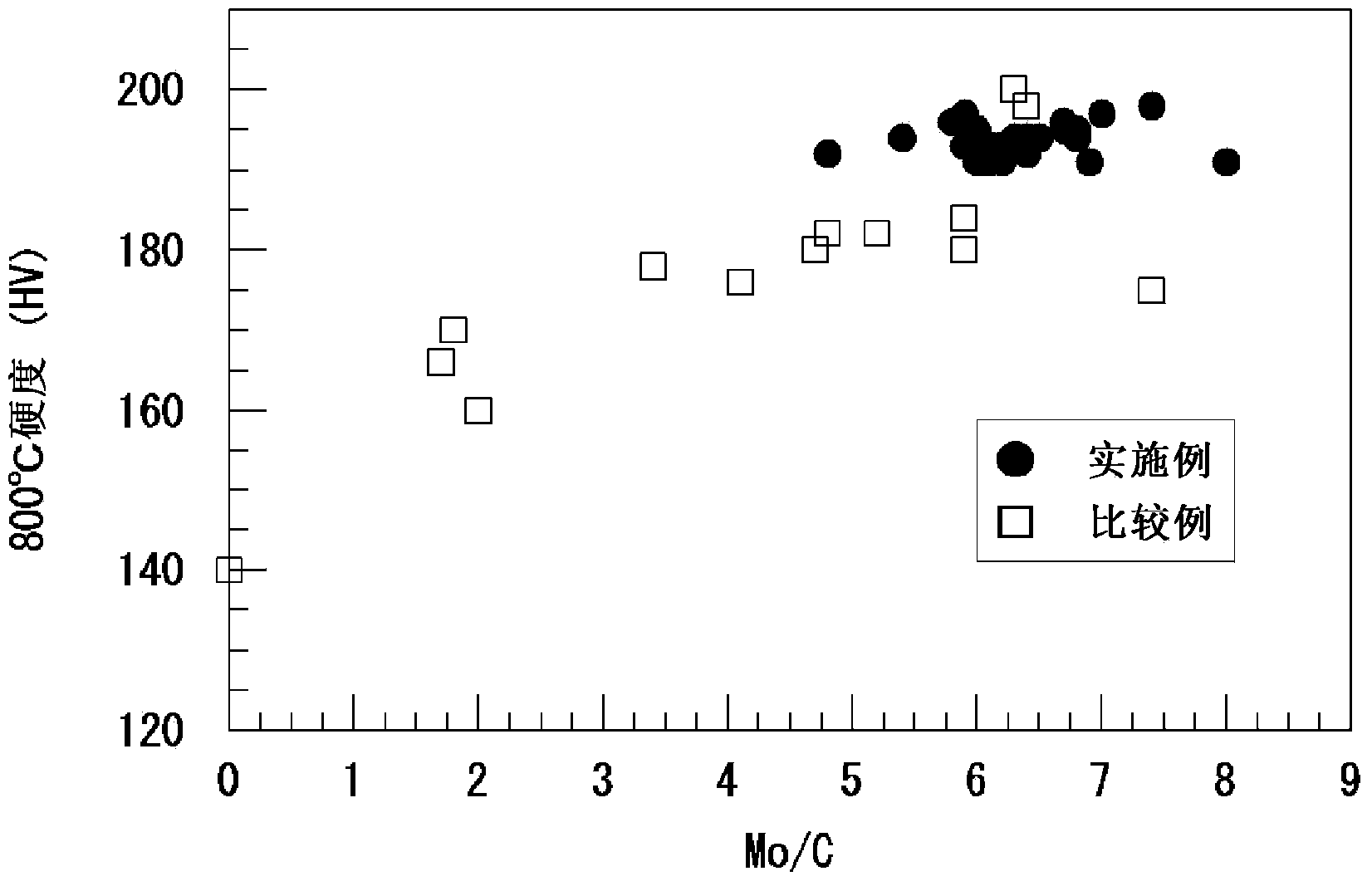

[0114] (Examples 1 to 34, Comparative Examples 1 to 14)

[0115] [1. Production of samples]

[0116] The alloys with the compositions shown in Table 1 and Table 2 were melted in a high frequency induction furnace to obtain a 50 kg steel ingot. The smelted steel ingot was subjected to homogenization heat treatment at 1180°C for 16 hours, and then forged into a φ18 mm bar. The forged material is subjected to a solution heat treatment (ST) of 1050°C×30 minutes-oil cooling. Furthermore, the material after ST was subjected to aging treatment (AG) of 750° C.×4 hours-air cooling.

[0117] It should be noted that in Comparative Example 2, "Mo / C" means "W / C". This is because W is considered to have an effect similar to Mo in terms of solid solution strengthening.

[0118] In addition, in Comparative Examples 4 and 5, "Nb / C" means "V / C" or "Ti / C", respectively. This is because with regard to the formation of carbonitrides, it is considered that V and Ti respectively have effects similar to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com