Long-life aluminum electrolytic capacitor and manufacturing method thereof

An aluminum electrolytic capacitor and the technology of its manufacturing method are applied in the direction of electrolytic capacitors, capacitors, capacitor terminals, etc., which can solve the problems of high ripple current impact resistance, poor stable wave current resistance, and short service life, and achieve high temperature resistance. , prolong the service life, optimize the effect of high temperature characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

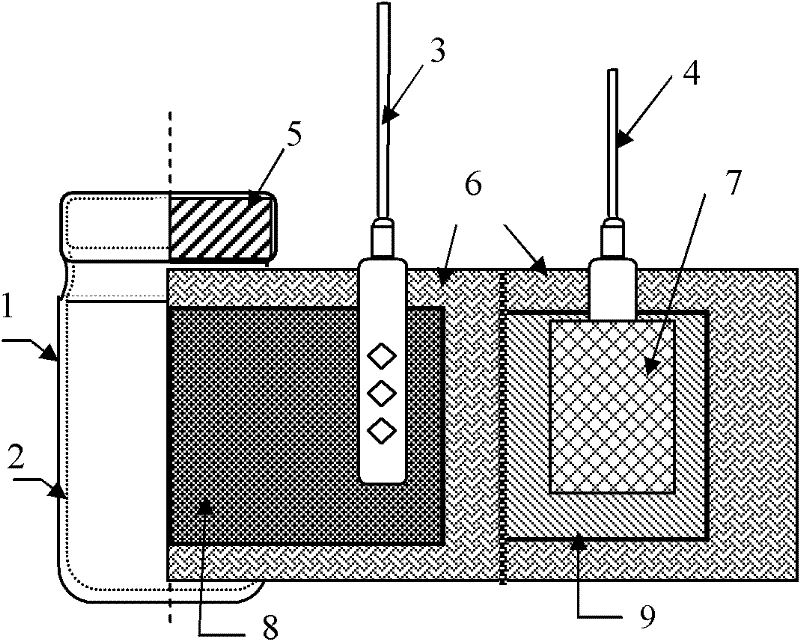

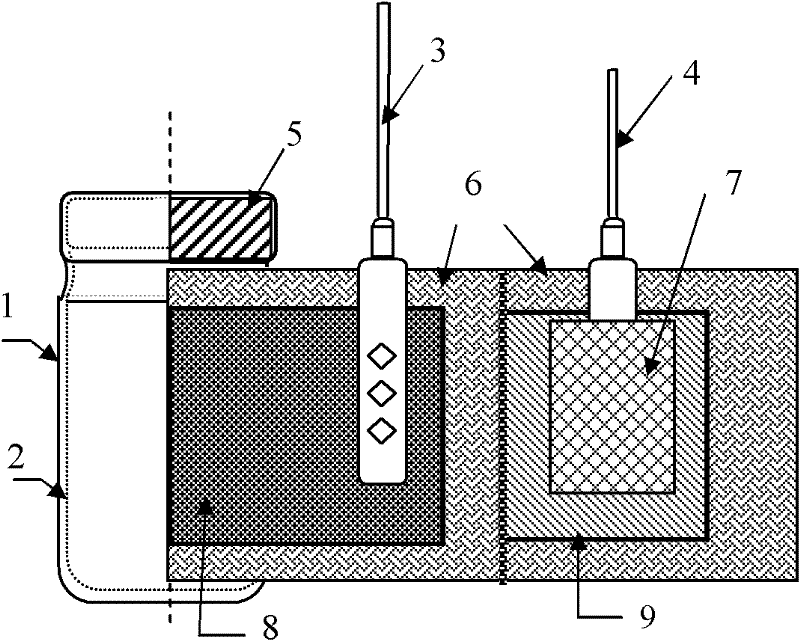

[0032] The special electrolytic capacitor for LED drive power supply according to the present invention includes aluminum shell 2, positive guide pin 3, anode foil 8, negative guide pin 4, cathode foil 9 and electrolytic paper 6, the positive guide pin 3 and anode foil 8 nails, the negative guide pin 4 is nailed to the cathode foil 9, the electrolytic paper 6 is placed between the anode foil 8 and the cathode foil 9 and wound together with the anode foil 8 and the cathode foil 9 to form a core package, and the core package is covered with The cover body 5 is placed in the aluminum shell 2, and a foil 7 is provided at the nail joint between the negative guide pin 4 and the cathode foil 9, and the foil 9 covers the nail joint hole between the cathode foil 9 and the negative guide pin 4, Described anode foil 8 is the anode foil of high withstand voltage and low specific volume, and this anode foil 8 adopts the chemically formed pressure-resistant aluminum foil of 1.8 times * capac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com