Electric heater

A technology of electric heaters and electric heating wires, applied in the direction of ohmic resistance heating parts, heating element shapes, etc., can solve the problems of electric heating tube outer tube crushing, unreasonable pressing treatment, excessive pressing, etc., and achieve high voltage resistance, etc. Improve electrical performance, improve product safety performance, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

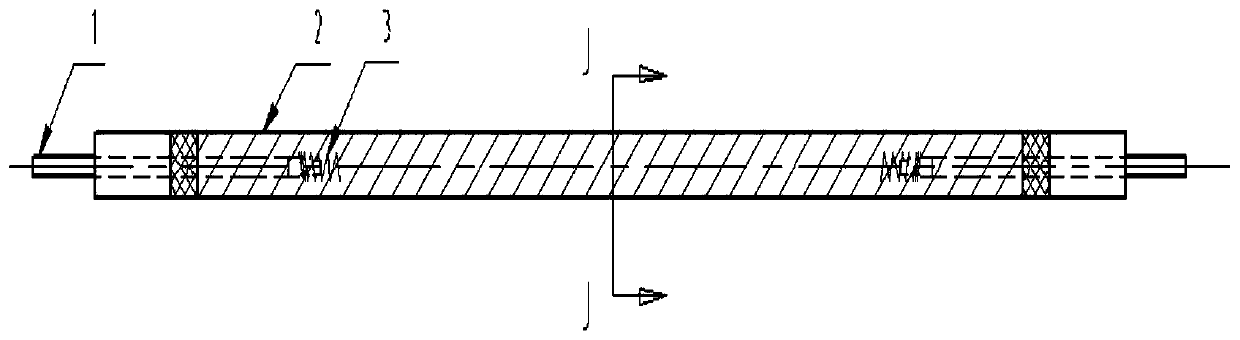

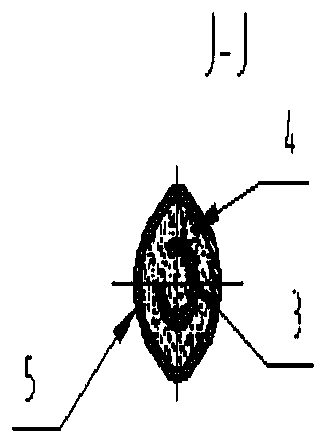

[0028] Such as figure 1 The straight tube shown can be pressed at different positions on the heating tube. The straight pipe is integrally suppressed, and the lead-out rod 1 is a non-heating section, which may not be suppressed.

Embodiment 2

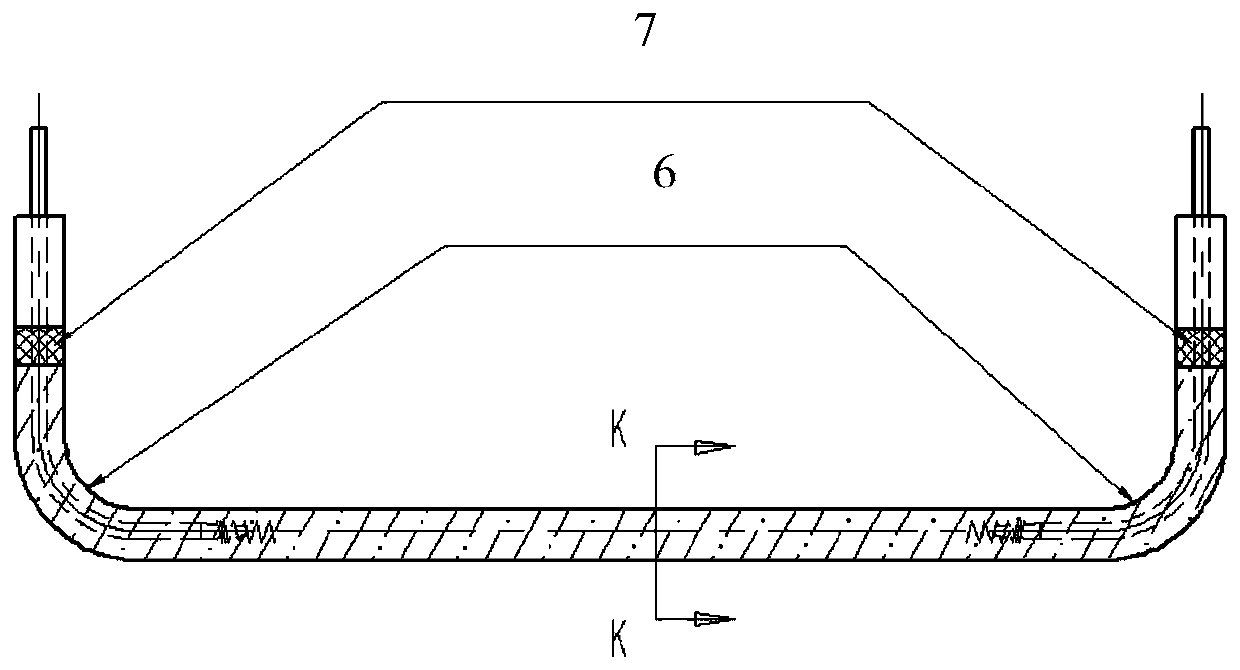

[0030] As shown in Figure 3, the heating tube is formed by bending both ends of a straight tube, and is pressed as a whole after bending. In order to ensure a smooth transition between the pressed part and the non-pressed part, it is necessary to use the pressed transition area 7 for processing.

Embodiment 3

[0032] Such as Figure 5 The spiral heating tube shown in the cup or tank heater is a straight tube that is rolled and then bent, and then coiled after the overall pressing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com