Method for manufacturing high-temperature-resistant high-reliability electrolytic capacitor

An electrolytic capacitor, reliability technology, applied in the direction of electrolytic capacitors, capacitors, capacitor parts, etc., can solve the problems of output waveform distortion, equipment damage, capacitor failure and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

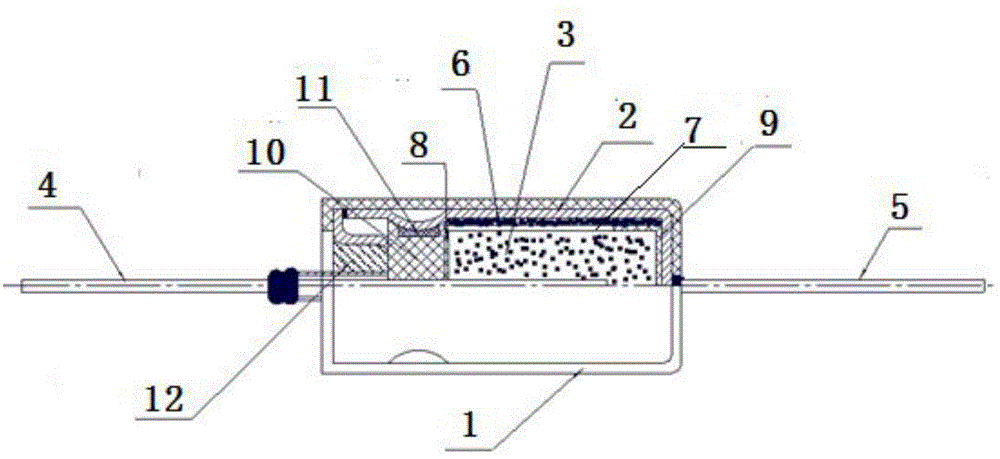

[0064] This embodiment provides a method for preparing an electrolytic capacitor with high temperature resistance and high reliability, and the specific steps are as follows:

[0065] 1. Pressing and sintering of anode pellets

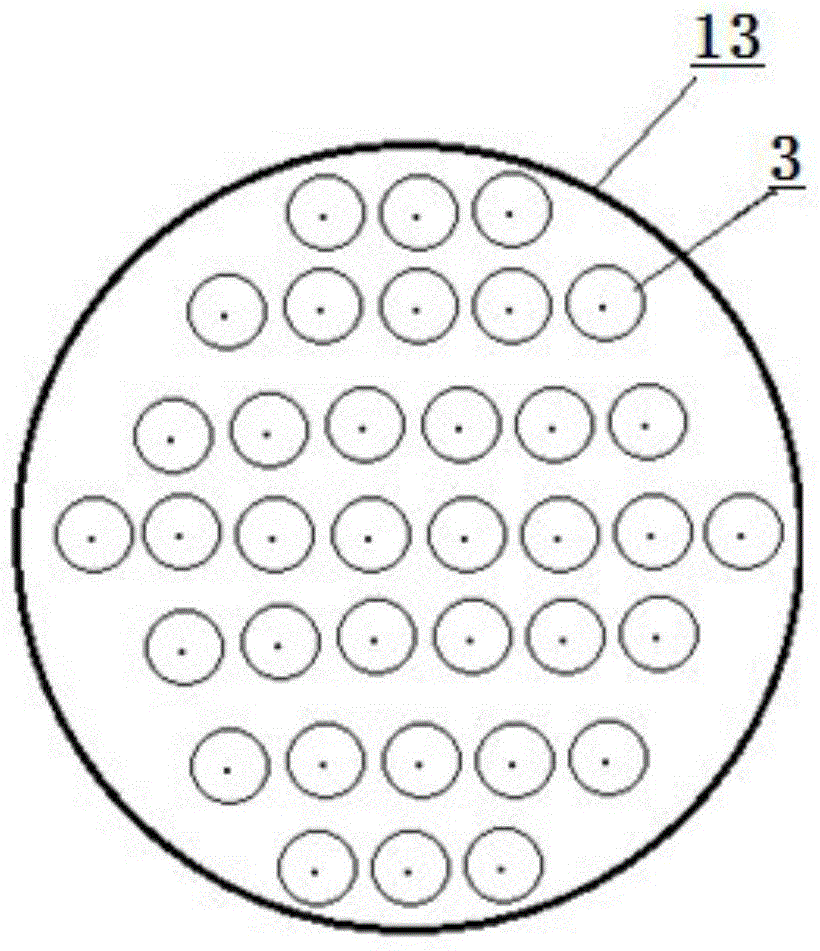

[0066] 1.1. For the pressing of anode pellets, the anode is designed according to the size of the product shell (such as cylindrical, square, rectangular, circular, oval, triangular, hexagonal, octagonal, heptagonal, and pentagonal). A special molding die for pellets, which presses the valve metal powder into an anode pellet, and the anode pellet occupies 50vol%-90vol% of the internal space of the tantalum shell, and the valve metal powder is lubricated with a mass fraction of 0.1%-8% before pressing lubricant, and put the lubricant in a volatile organic solvent before use;

[0067] 1.2. Pre-sintering, put the anode pellets into a vacuum of 1*10 -1 ~1*10 -2 Pre-sintering is carried out in a vacuum atmosphere of Pa, the temperature is 200°C-400°C, an...

experiment example 1

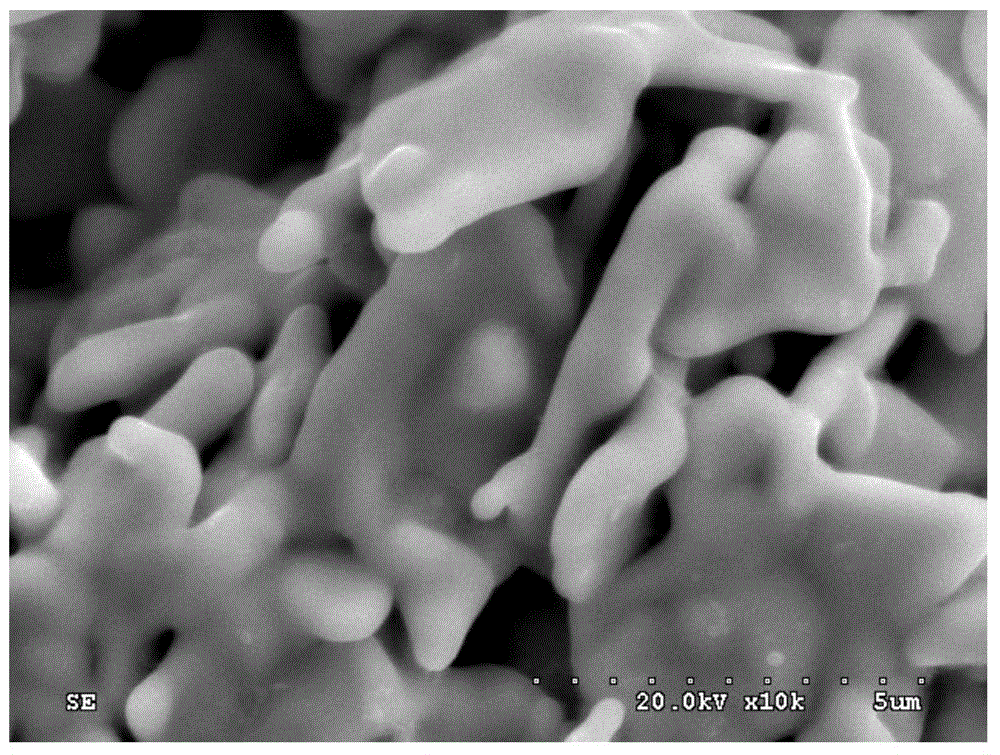

[0093] 1. Add tantalum powder with a specific volume ratio of 23000μF.V / g to 4% camphor and mix evenly. When using camphor, dissolve camphor in absolute ethanol; press it into A cylinder with a pressed density of 6.0g / cm 3 , and then place it in a vacuum higher than 1.5×10 -1 Pre-sintering for 30min under the condition of Torr and temperature 400°C to remove the camphor in the pellets, after cooling, place the pre-fired pellets vertically in a porous crucible, in a vacuum higher than 1.0×10 -6 Under the condition of Torr and temperature of 1450° C., high-temperature vacuum sintering for 30 minutes to obtain anode pellets.

[0094] 2. After mixing 20Kg ethylene glycol and 40Kg deionized evenly, add 60 grams of phosphoric acid (analytical pure), and add 6 grams of vanadyl sulfate (VOSO4.5H2O) into the solution and stir evenly, and use a cooling system to oxidize the temperature of the solution Control the temperature at -5°C to 5°C, then immerse the above-mentioned anode pell...

experiment example 2

[0105] The steps are the same as in Experimental Example 1; wherein, in Step 1, the specific volume of the tantalum powder is 3500 μF.V / g, 0.5% stearic acid is added, and the stearic acid is dissolved in a carbon tetrachloride solvent before adding the stearic acid; pressed into A cylinder with a pressed density of 6.0g / cm 3 . The high vacuum sintering temperature is 1800°C.

[0106] In step 2, the phosphoric acid is changed to 60g nitric acid, and the initial boost current density is 35mA / g. The voltage on the anode pellet is boosted by 10V, and the constant voltage is 10min. After each constant voltage, the boost current density is reduced by 2mA / g. Until the voltage of the positive and negative poles of the anode core block of the capacitor rises to 190V, the final constant voltage is 2.5h. The heat treatment temperature is 380°C, and the heat treatment time is 20 minutes;

[0107] Ethylene glycol butyl ether is substituted with equivalent dimethyl sulfoxide (DMSO) in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Leakage current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com