A plastic-encapsulated power diode and its manufacturing process

A technology of power diodes and manufacturing process, which is applied in the field of plastic-encapsulated power diodes and semiconductor discrete devices. It can solve problems such as poor thermal stress resistance, deterioration of diode electrical parameters, and short baking time, so as to improve high-temperature characteristics and reduce high-temperature leakage. Current, the effect of relieving thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

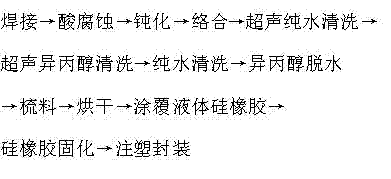

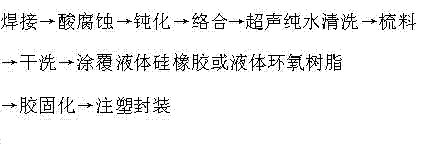

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing, the present invention will be further described:

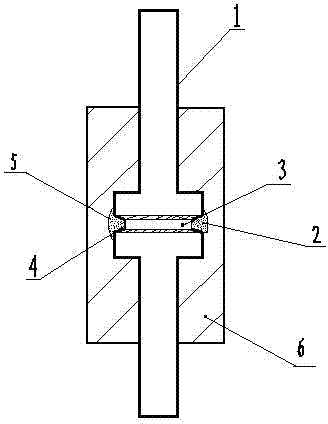

[0038] In the figure: 1. Nail head copper wire, 2. Lead-tin-silver solder sheet, 3. Silicon chip, 4. Silicon dioxide layer, 5. Epoxy resin glue, 6. Non-cavity plastic package.

[0039] ① Welding: Assemble the silicon chip, solder piece and oxygen-free copper wire into the welding boat, and connect the positive and negative electrodes of the diode through the welding furnace;

[0040] ②Acid corrosion: Insert the silicon chip connected with the wire into the pickling tray, and under the action of a mixed acid containing hydrofluoric acid, nitric acid, sulfuric acid, and glacial acetic acid, the scribing marks and oxide layer of the chip are etched away, making the surface of the chip table Smooth and clean, the PN junction exposed on the surface of the chip table has been cleaned, the composition of the acid etching solution (volume ratio): HNO 3 :HF:CH 3 COOH:H 2 SO 4 =...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com