6H-SiC substrate reversed polarity AlGaInP LED chip

A reverse polarity, substrate technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as incompatibility with high current, high output power, etc., to improve high temperature characteristics, improve product reliability, and high thermal conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

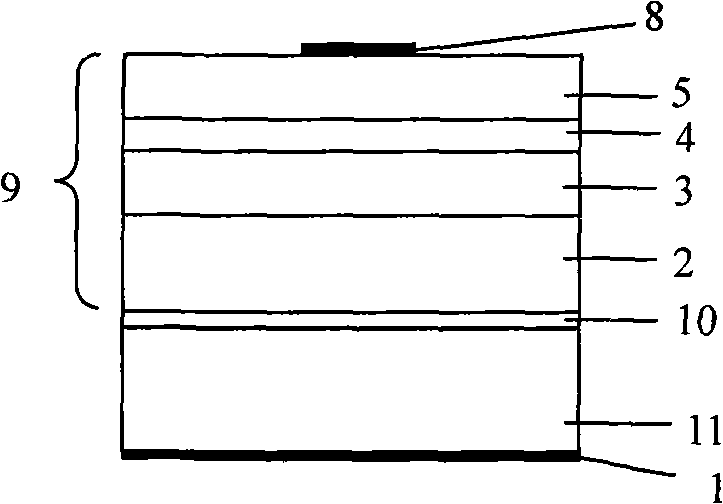

[0026] The 6H-SiC substrate reverse polarity AlGaInP LED chip of this embodiment is based on conductive 6H-SiC, and its chip structure is as follows figure 2 As shown, the epitaxial layer 9 is also included, but the epitaxial layer 9 is an N-type AlGaInP layer 5, a light-emitting layer 4, a P-type AlGaInP layer 3, a P-type GaP layer 2, and a metal reflection and bonding layer 10 (including An adhesive layer and a metal mirror), and an N-type electrode 8 is arranged on the N-type AlGaInP layer 5 (the top surface of the epitaxial layer 9). The epitaxial layer 9 is grown on the conductive 6H-SiC substrate 11 , and the P-type electrode 1 is arranged on the bottom surface of the conductive 6H-SiC substrate 11 . It can be seen that the present invention is based on the 6H-SiC material whose thermal conductivity is 10 times higher than the GaAs material, and transfers the LED light-emitting layer from the GaAs substrate to the 6H-SiC substrate, which is different from the existing A...

Embodiment 2

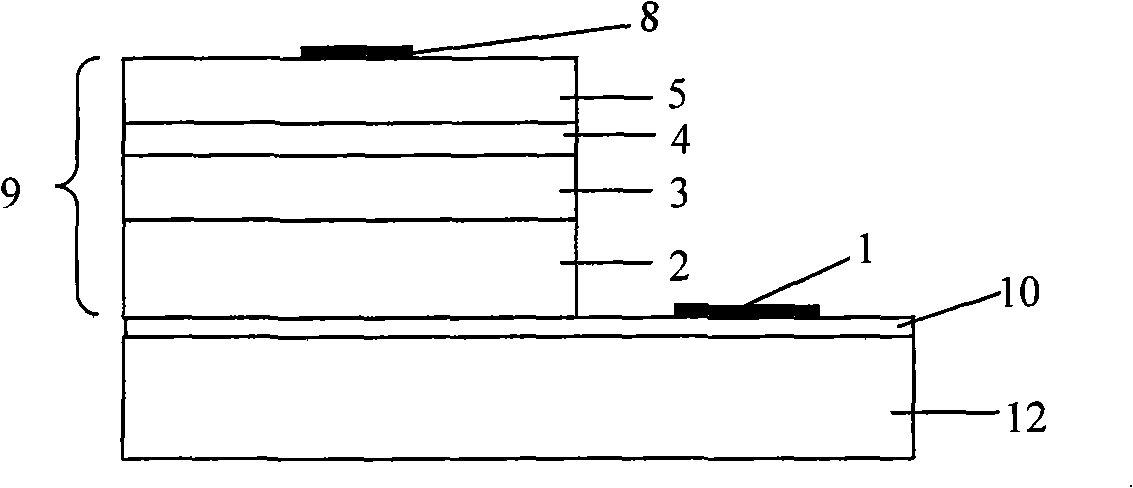

[0034] The 6H-SiC substrate reverse polarity AlGaInP LED chip of this embodiment is based on insulating 6H-SiC, such as image 3 As shown, the insulating 6H-SiC substrate 12 is used to replace the conductive 6H-SiC substrate 11 of Example 1, and the P-type electrode 1 is fabricated on the metal reflective and bonding layer 10, and the rest of the structure is the same as that of Example 1 with the conductive 6H-SiC substrate 11. The reverse polarity AlGaInP quaternary LED chip based on SiC is the same.

[0035] The manufacturing process steps of the reverse polarity AlGaInP LED chip based on the insulating 6H-SiC of the present embodiment are as follows:

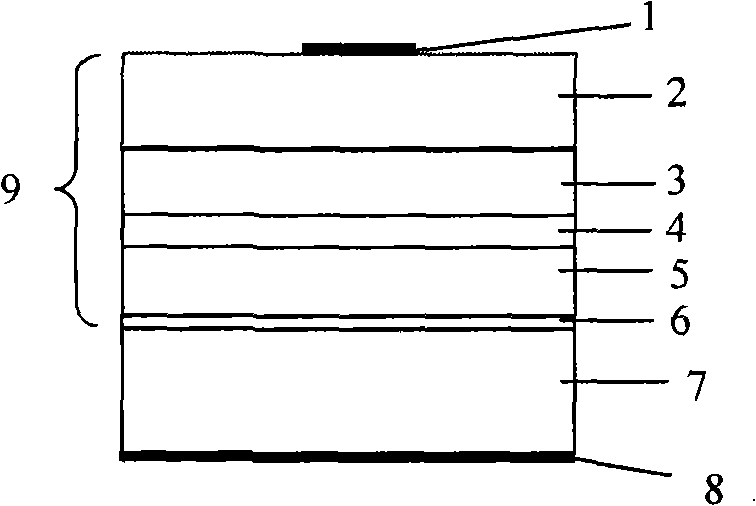

[0036] 1. If Figure 4 As shown, the LED epitaxial structure is also grown on the GaAs substrate 7 according to the conventional epitaxial growth, and the N-type AlGaInP layer 5, the light-emitting layer 4, the P-type AlGaInP layer 3 and the P-type GaP layer 2 are epitaxially grown in sequence from bottom to top to form an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com