Positive active material and nonaqueous electrolyte secondary battery produced using the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

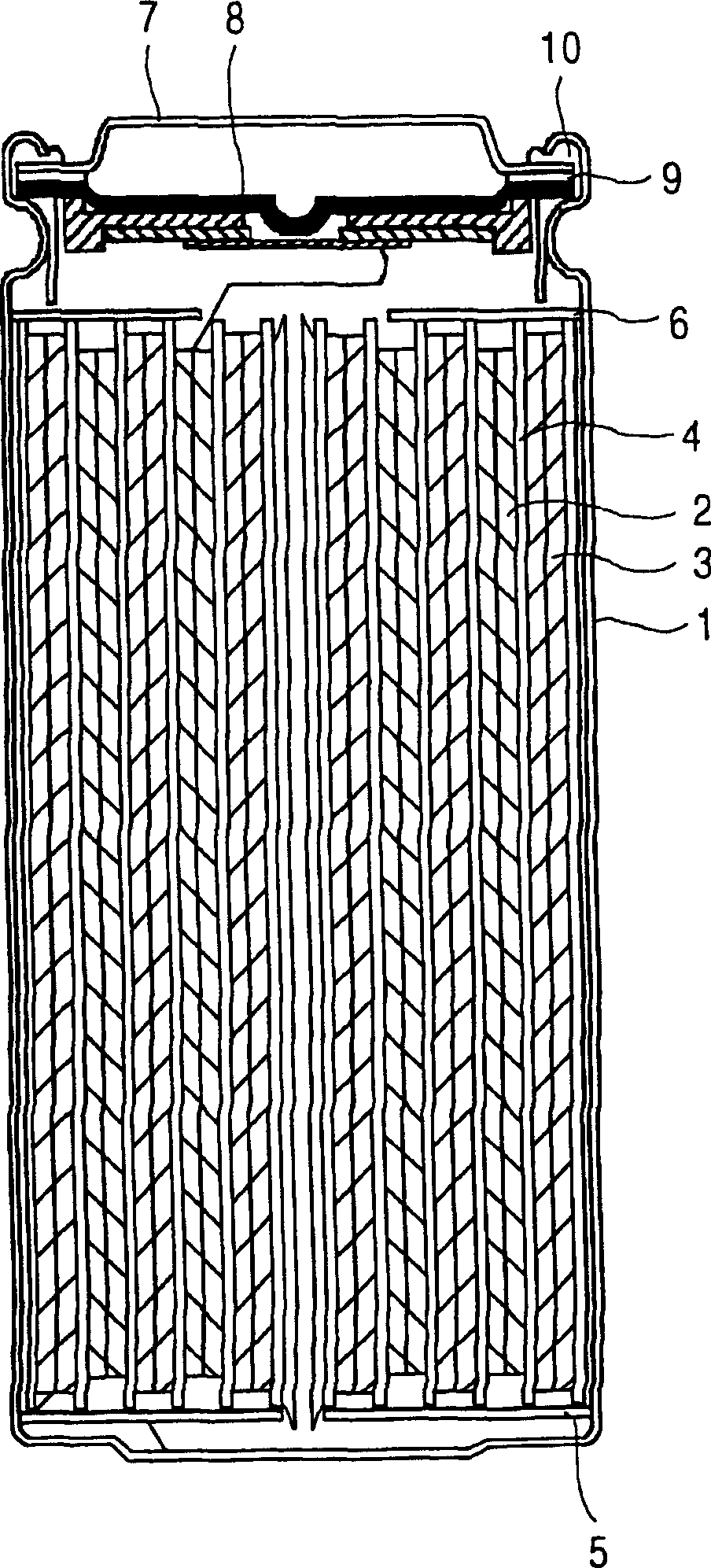

[0046] Embodiments of the present invention will now be described with reference to experimental results.

[0047] Sample 1

[0048] Synthesis of composite oxides of lithium and transition metals

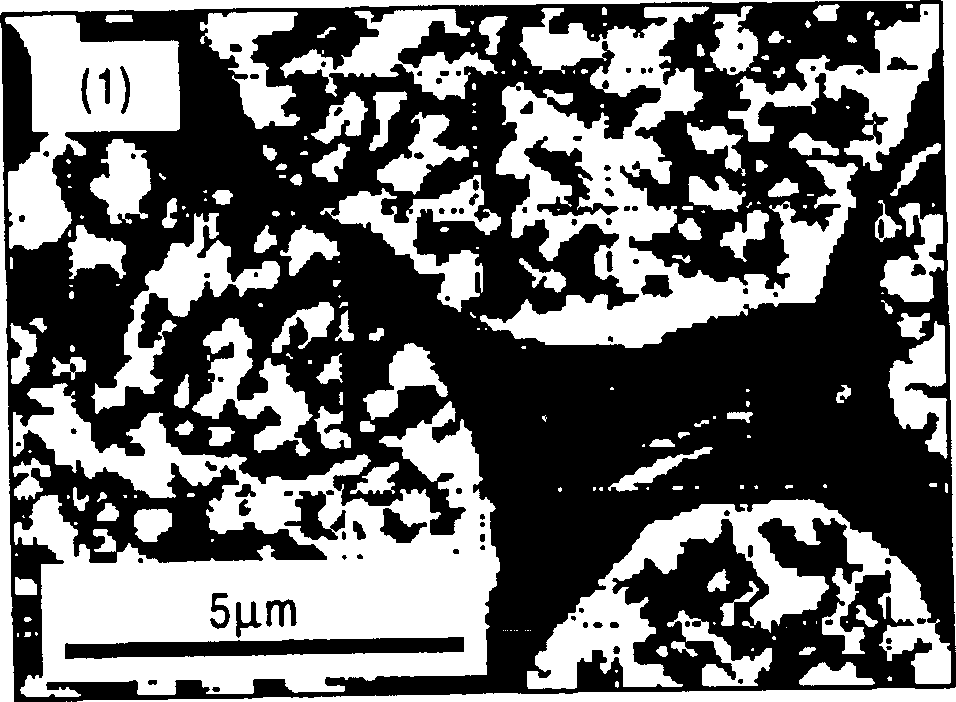

[0049] The purchased aqueous solution of nickel nitrate and the purchased aqueous solution of manganese nitrate are mixed so that the ratio of nickel element to manganese element is 7:3. Next, aqueous ammonia was added dropwise to the mixed solution and vigorously stirred to prepare a composite hydroxide. This composite hydroxide was mixed with lithium hydroxide. The mixture was sintered in oxygen at 850° C. for 10 hours, and ground to prepare lithium-nickel-manganese oxide powder. Laser diffraction measurement revealed that the powder had an average particle diameter of 13 μm. In addition, X-ray diffraction measurements show that the specific structure of the powder is similar to that of LiNiO in ICDD 09-0063 2 specific structure. The similarity proves that the powder is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com