Patents

Literature

34results about How to "Not easy to expand and deform" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

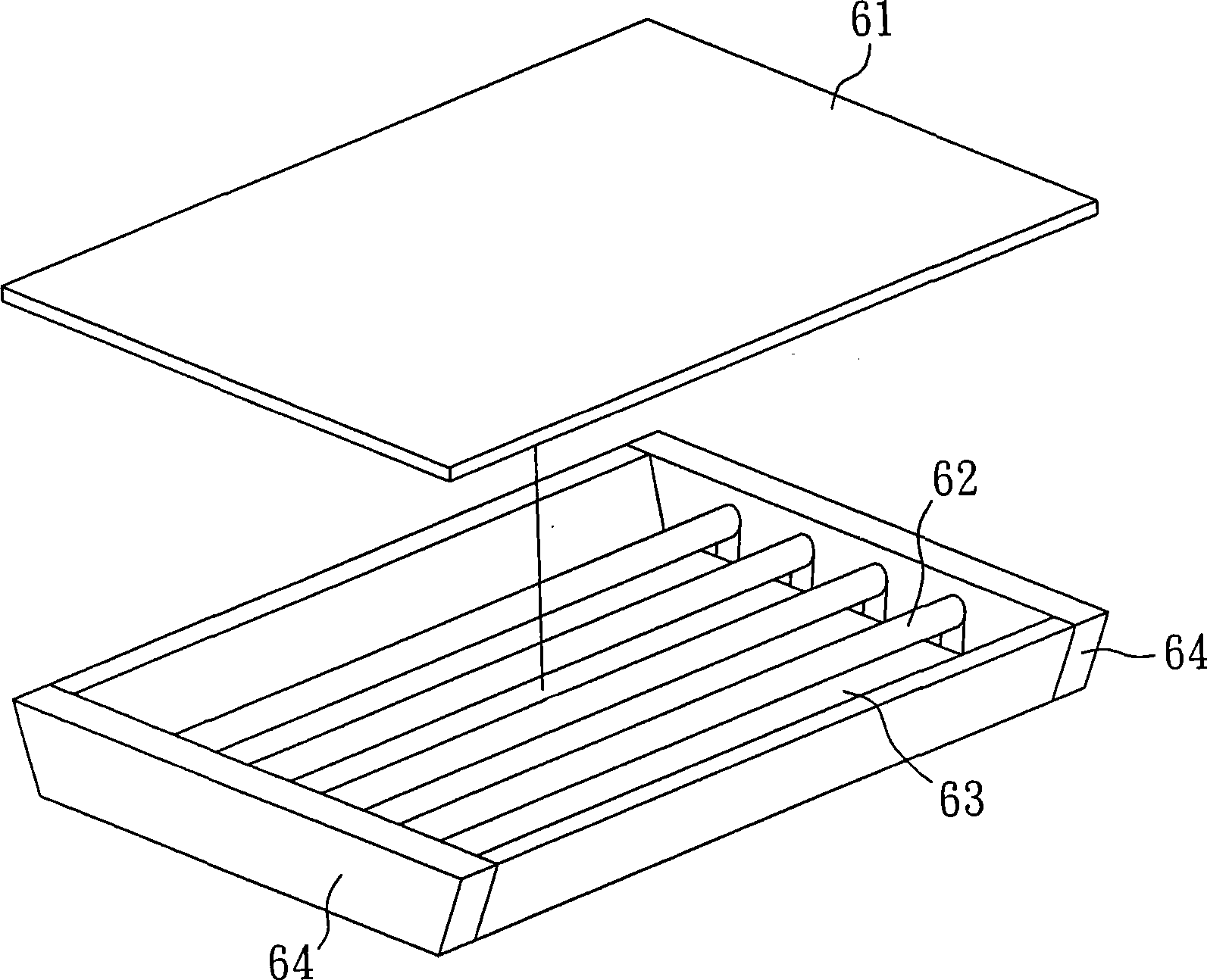

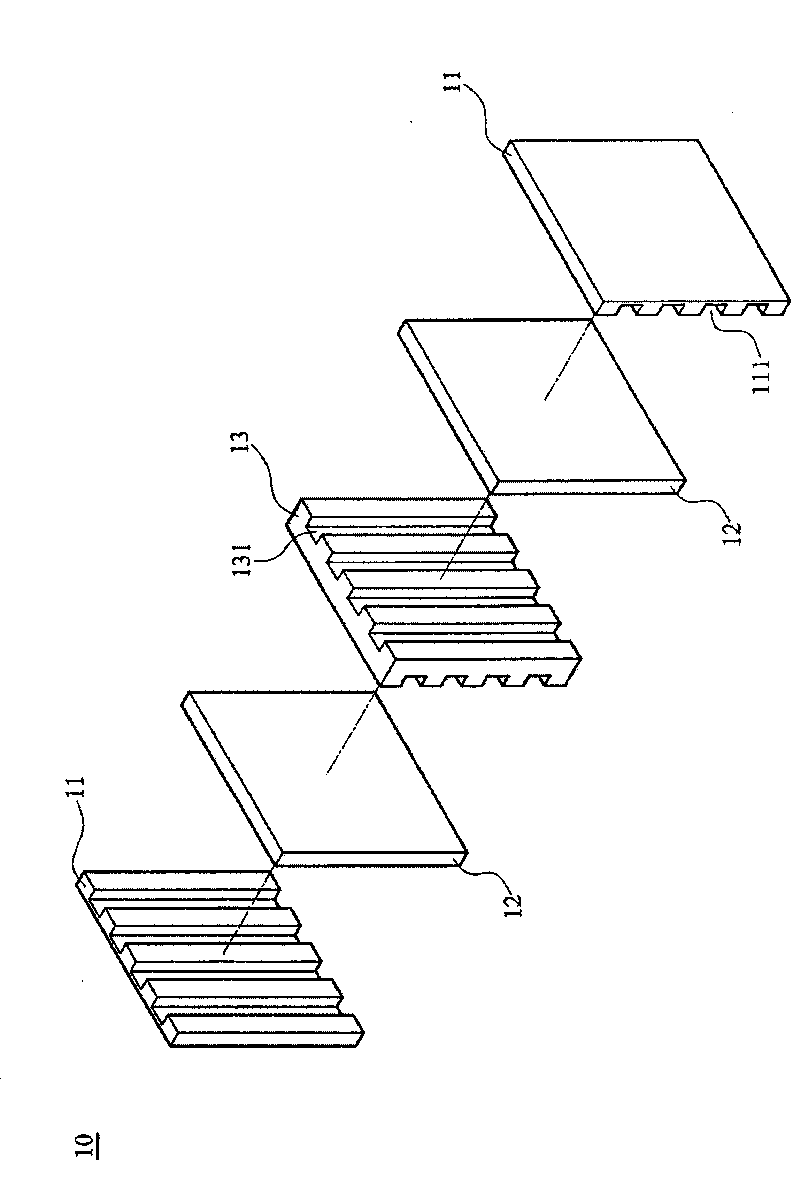

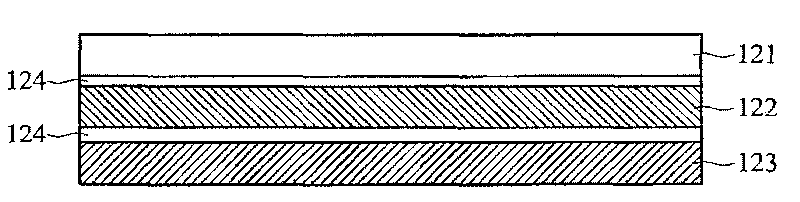

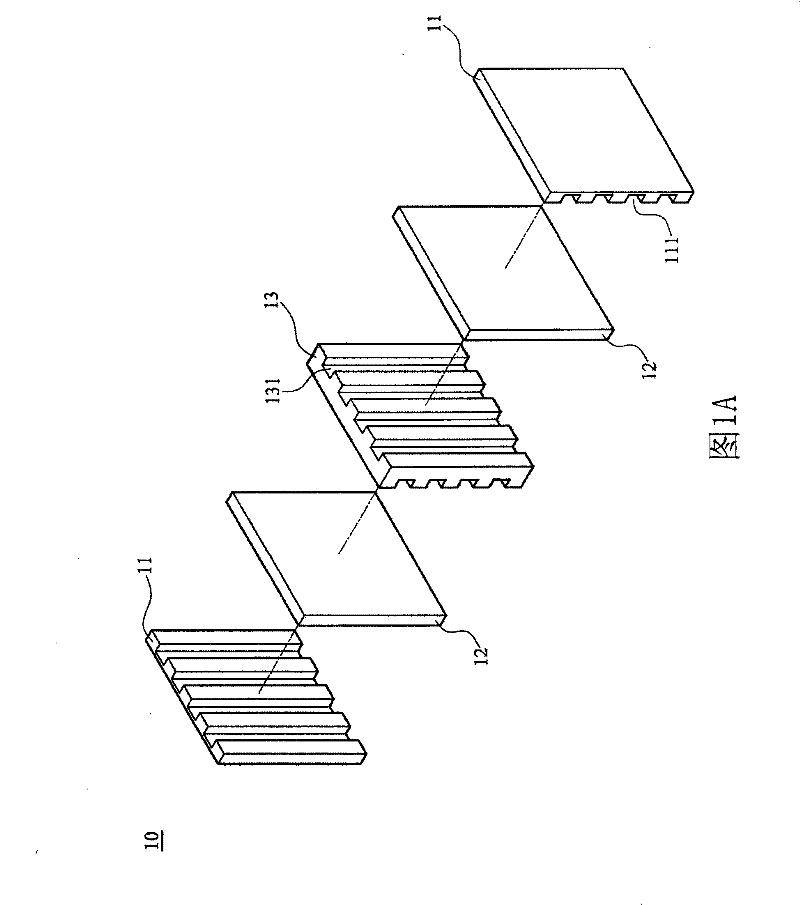

Area light source device and method for making same

InactiveCN101452146ALittle loss of brightnessStrong penetrating powerElectric light circuit arrangementOptical light guidesLight guideOptoelectronics

The present invention relates to a method for preparing area light source and the structure thereof. The area light source comprises a high-transparency ultra-white glass light conducting plate with penetration degree higher than 90% and at least one side radiation light source, wherein, the glass light conducting plate is provided with a first surface, a second surface opposite to the first surface, and a light entering surface which is at least perpendicular with the first surface and the second surface. The side radiation light source is configured on the light entering surface of glass light conducting plate and radiates light into the glass light conducting plate. The glass light conducting plate is also provided with a conducting pattern configured on the second surface for radiating the light uniformly through the pattern.

Owner:CHIN WEI MIAO IND

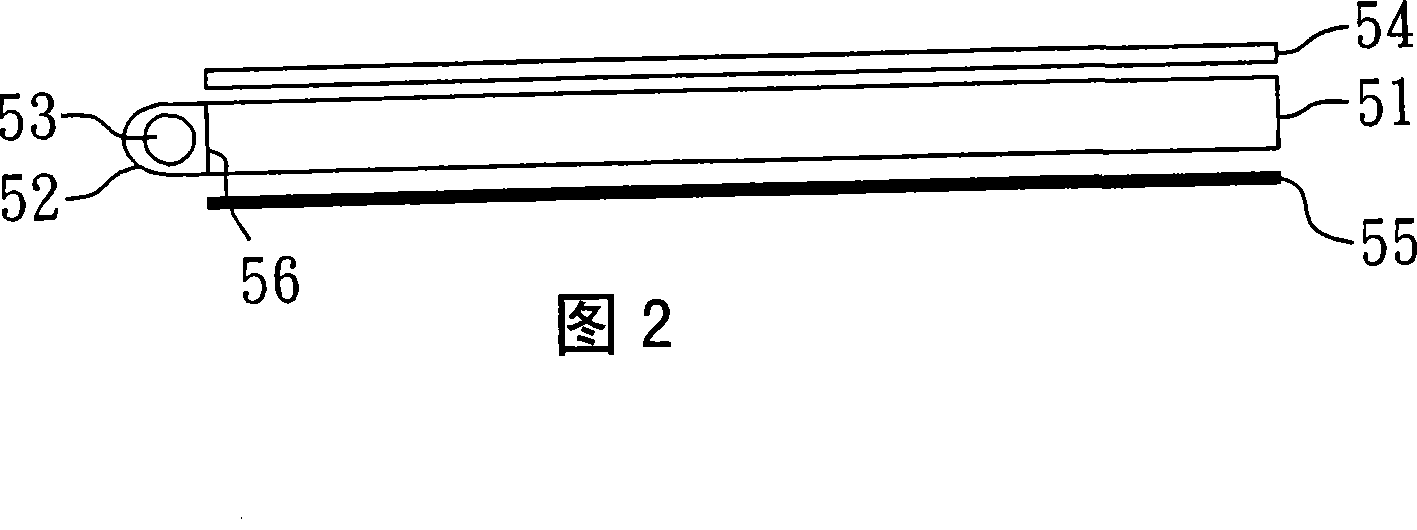

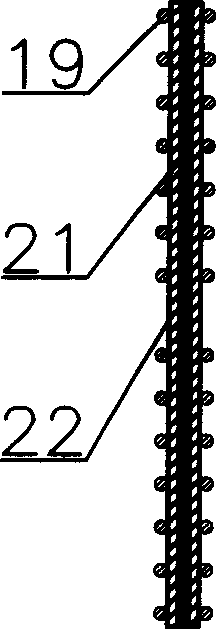

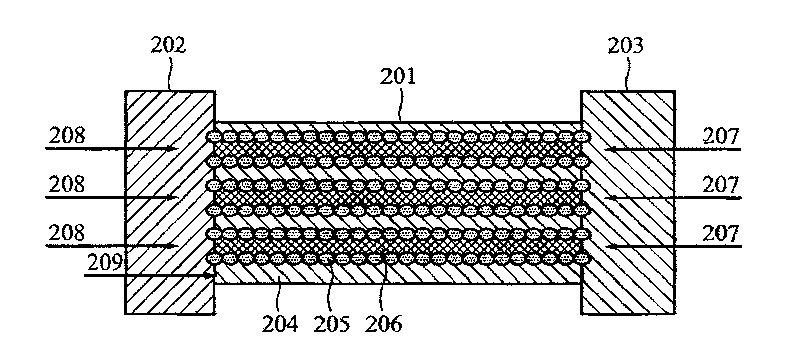

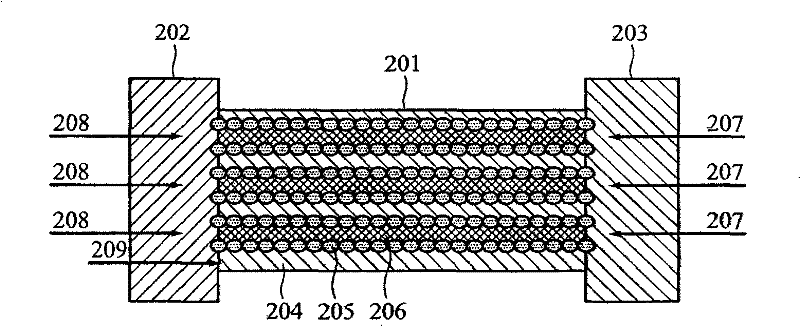

Quasi-two-pole winding-structure lead-acid battery and making method

InactiveCN1677736AIncrease specific energyImprove connection reliabilityFinal product manufactureLead-acid accumulators constructionInternal resistanceElectrical polarity

Positive active material and negative active material separated by lead wires are coated on two sides of composite slab lattice so as to constitute bipolar plate. The said lead wires can be cut into certainshape to become positive pole plate or negative pole plate with single pole. Single adjacent batteries separated by lead wires can be connected in series. Positive pole plate, diaphragm, and negative pole plate of single battery are winded on same core axle. Winded pole plates and diaphragm fixed by plastic fixture becomes battery core. Dried battery core is installed inside cylindrical battery box so as to complete electrochemical procedure. Then, firming agent is filled into the box. The invention combines advantages of both of quasi-bipolar battery and cylindrical winded battery, possessing features of low internal resistance, high specific energy, high specific power, and long service life.

Owner:李向秀

Drying method for rosewood

ActiveCN105666618ANot easy to absorb waterNot easy to expand and deformWood treatment detailsWood dampingVegetable oilProcess engineering

The invention discloses a drying method for rosewood. The drying method comprises the following steps that 1, the rosewood is sawed into a finished material which is dried through a steam drying box; 2, the finished rosewood material is put into a pot to be boiled with boiling water and is subjected to degreasing for 110-130 min; 3, then the boiled finished rosewood material is subjected to drying and dewatering treatment; 4, the dewatered finished rosewood material is put into an oil tank to be soaked for six to eight days with vegetable oil and alums and is heated to 72 DEG C-78 DEG C; and 5, the soaked finished rosewood material is placed in a ventilated place so that the oil can be dried through blowing. The rosewood material obtained through the method is environmentally friendly, colorless and tasteless, and a human body is not injured through close contact. A rosewood plate processed through the method is not prone to absorbing water and being swelled and deformed as well as shrunk and torn through high-temperature baking and is especially suitable for production of seamless furniture.

Owner:南通美霆紫檀艺术品有限公司

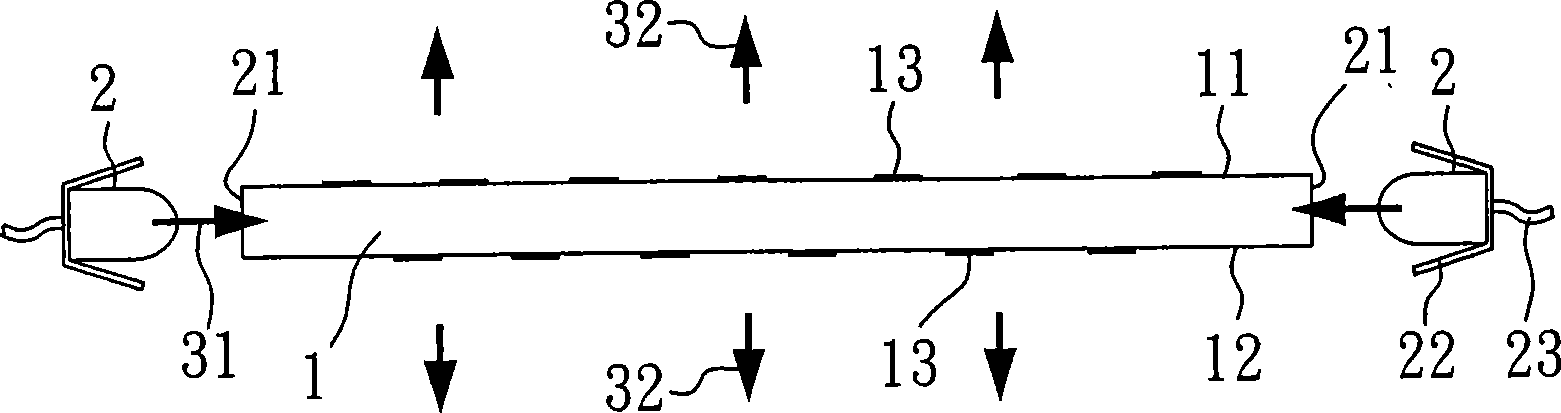

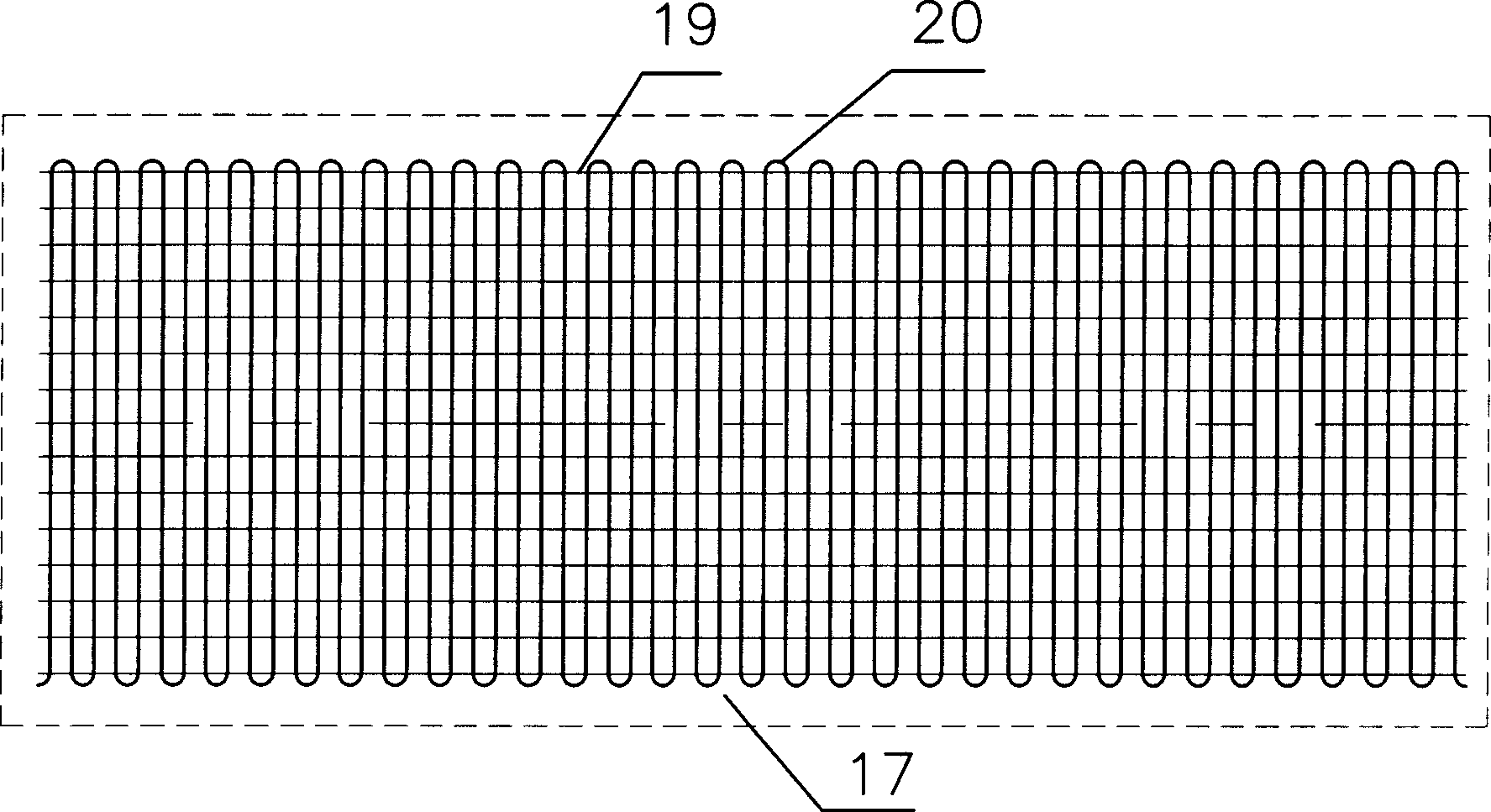

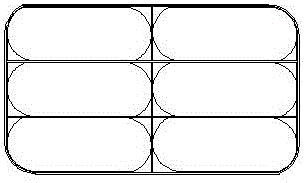

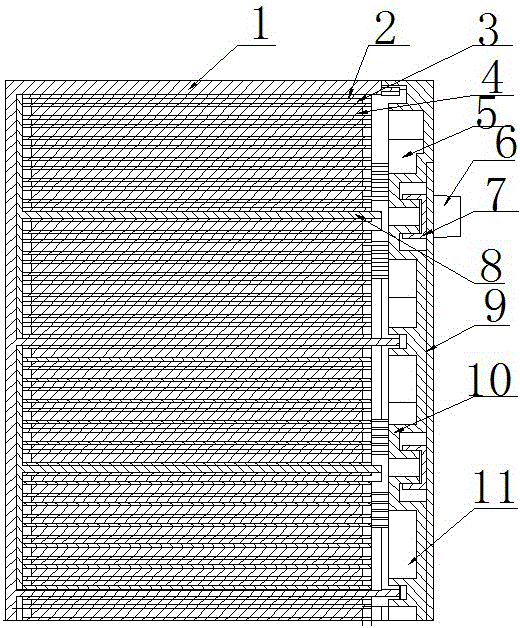

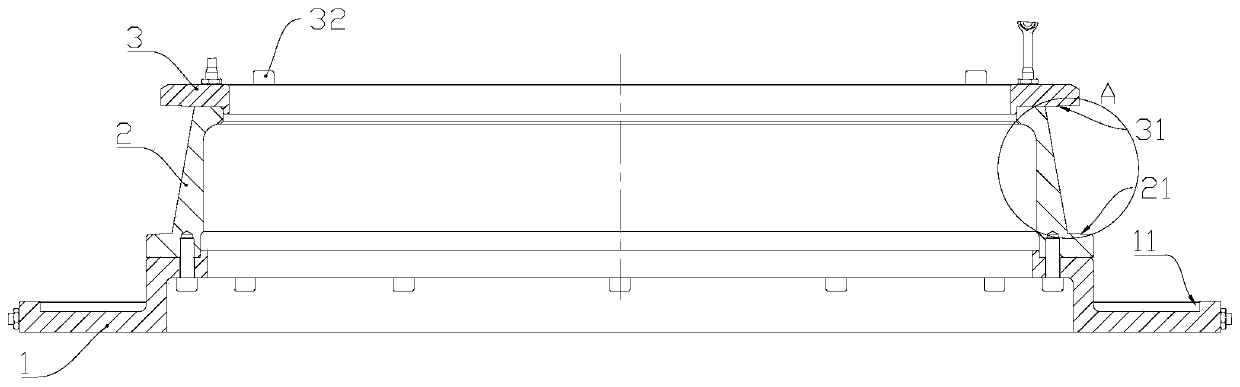

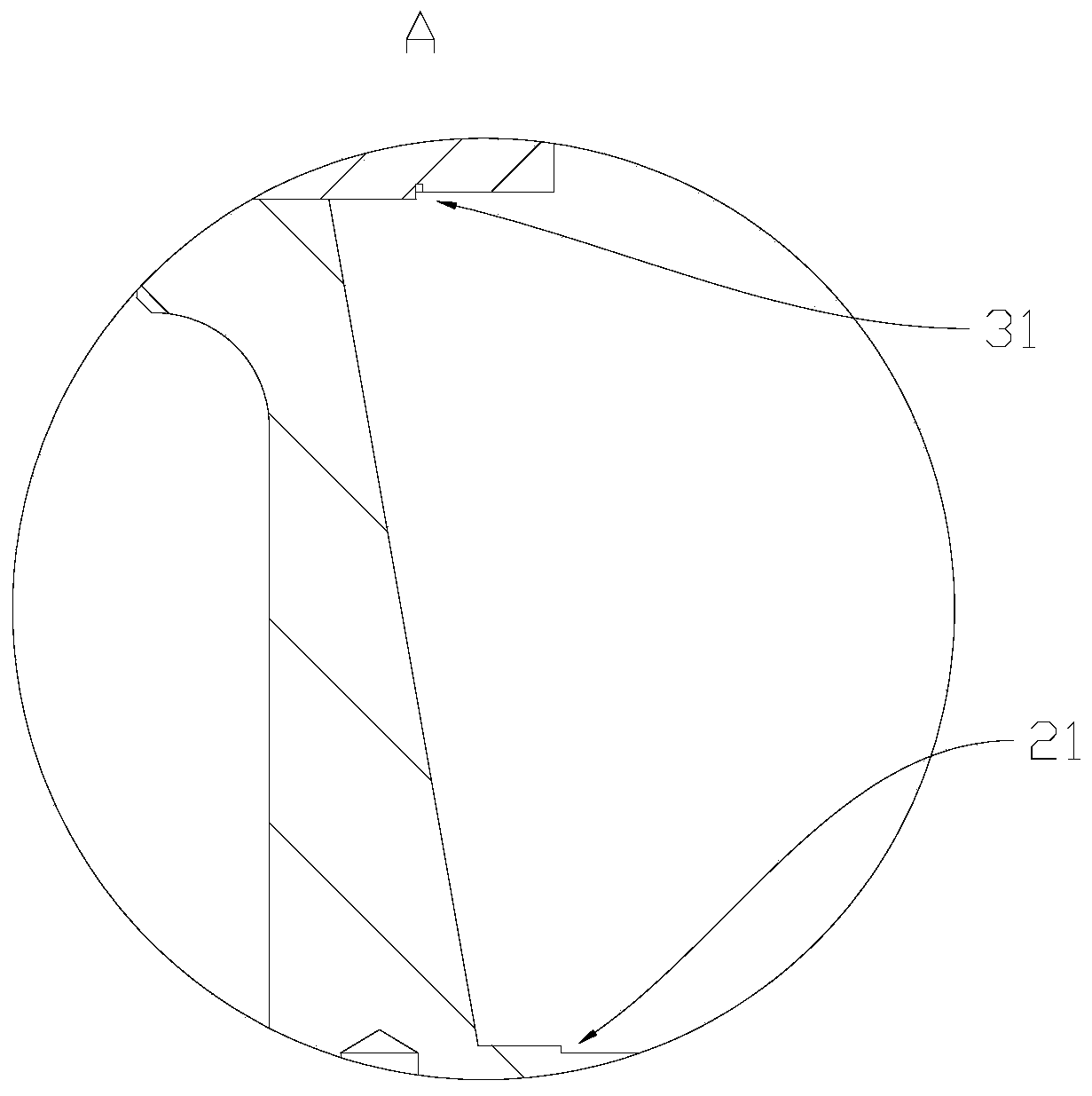

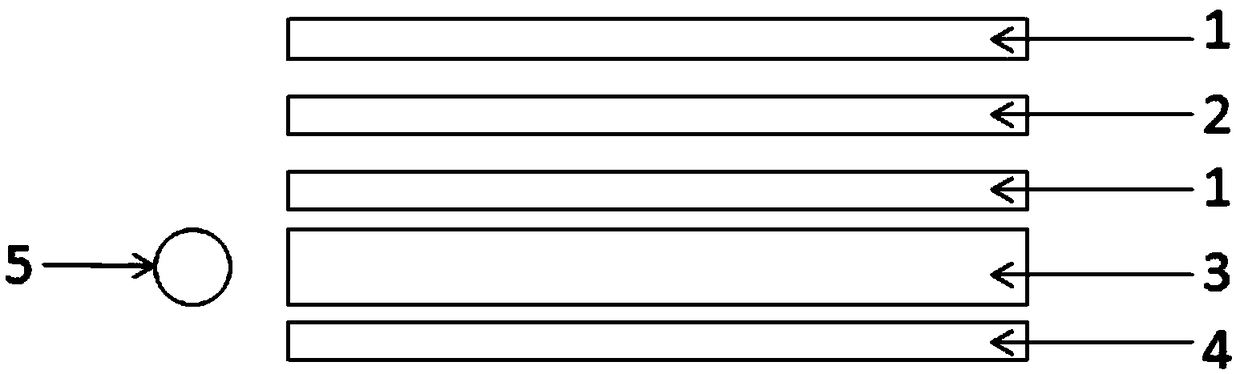

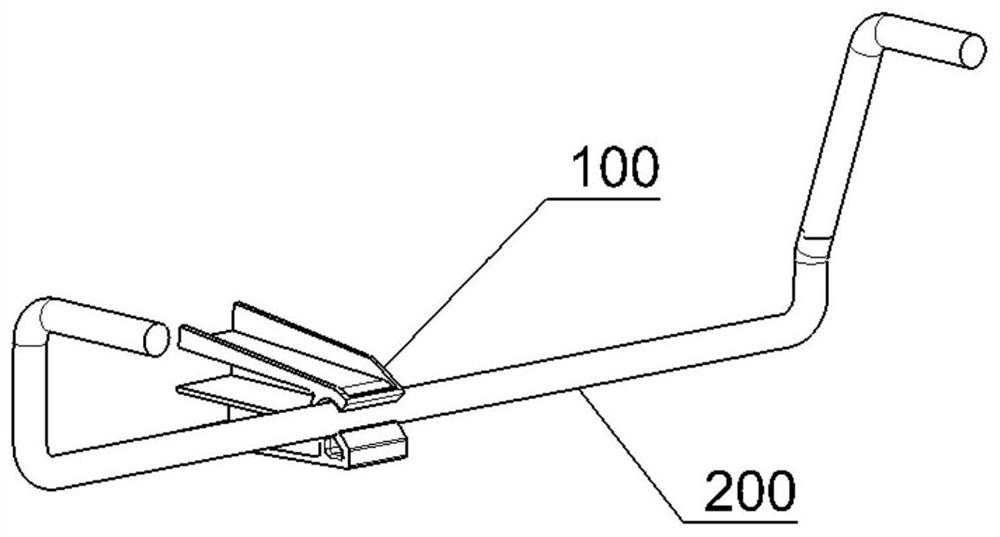

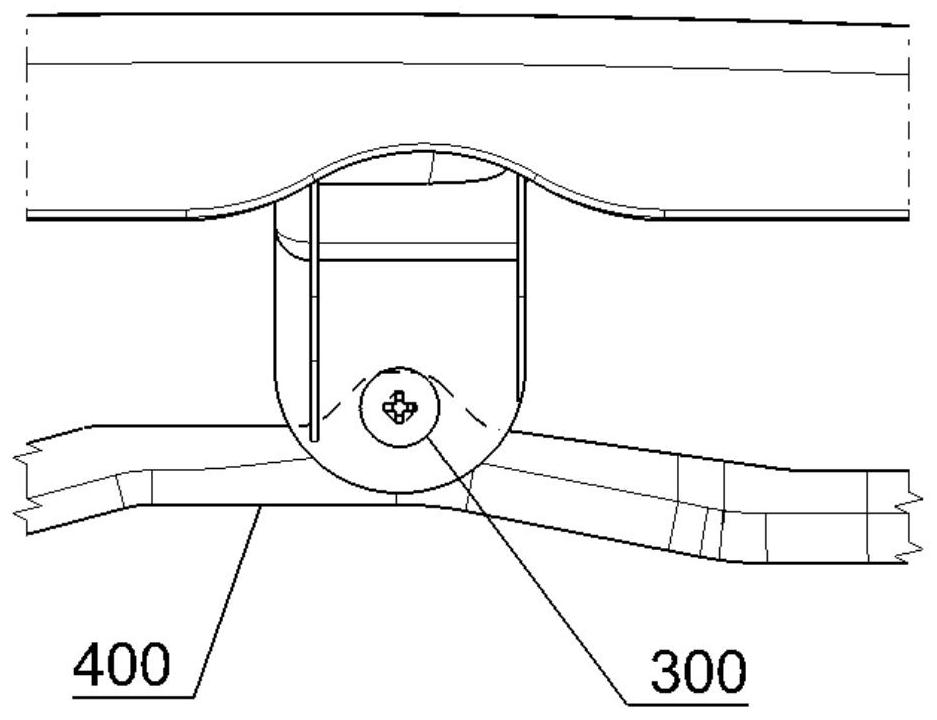

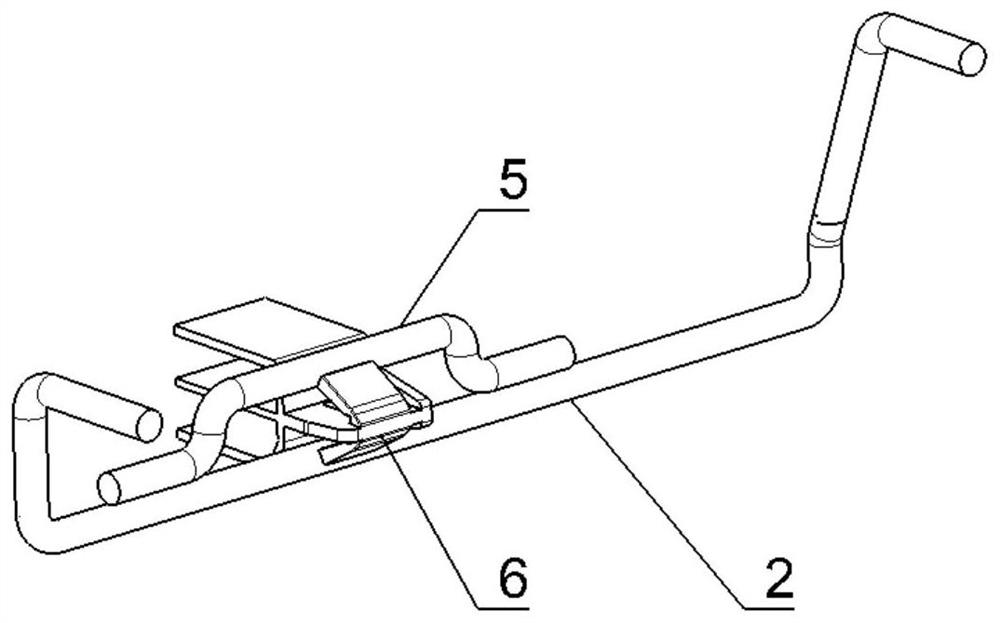

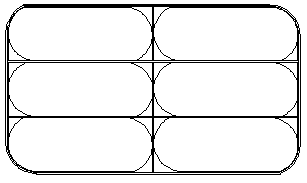

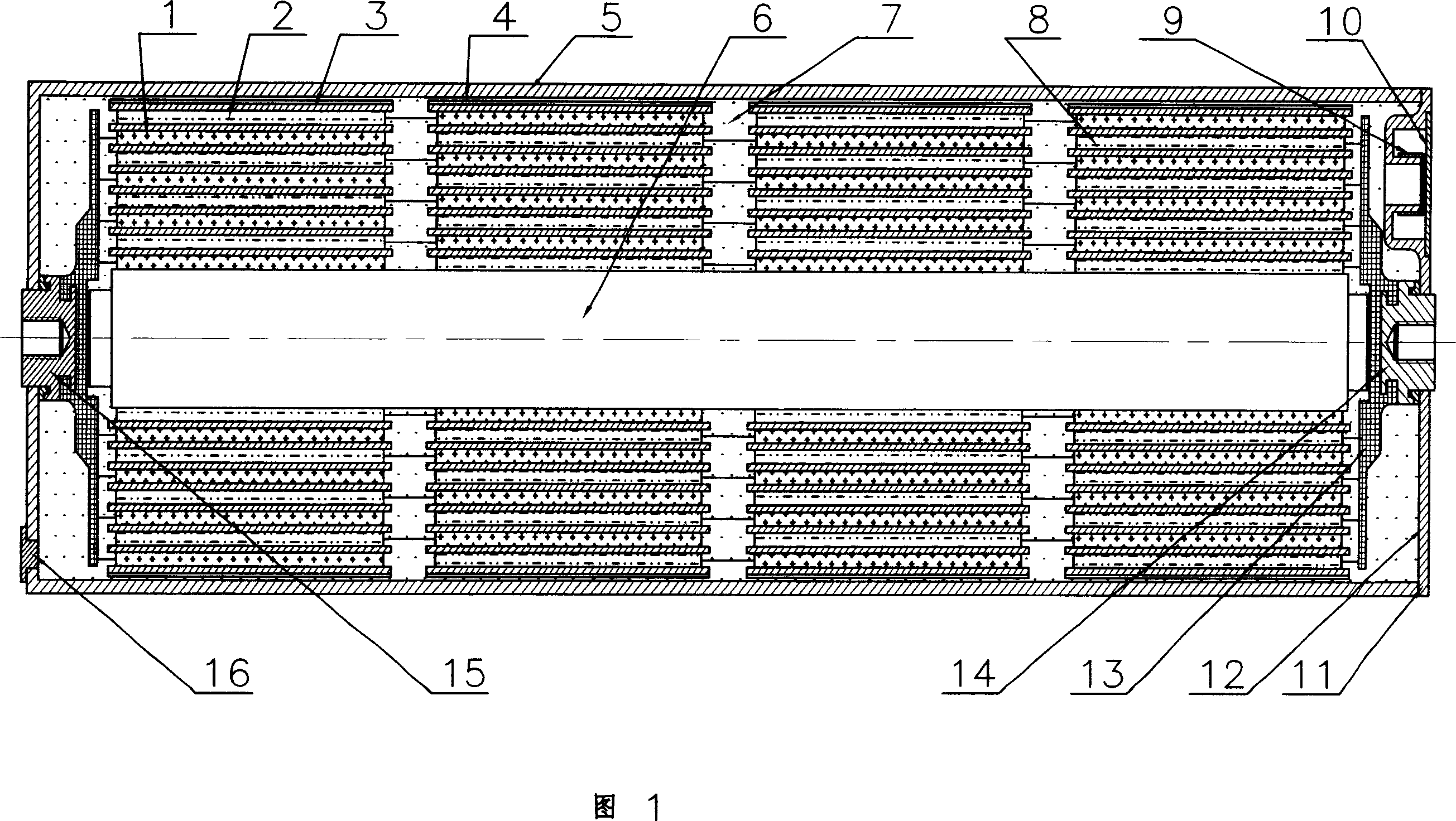

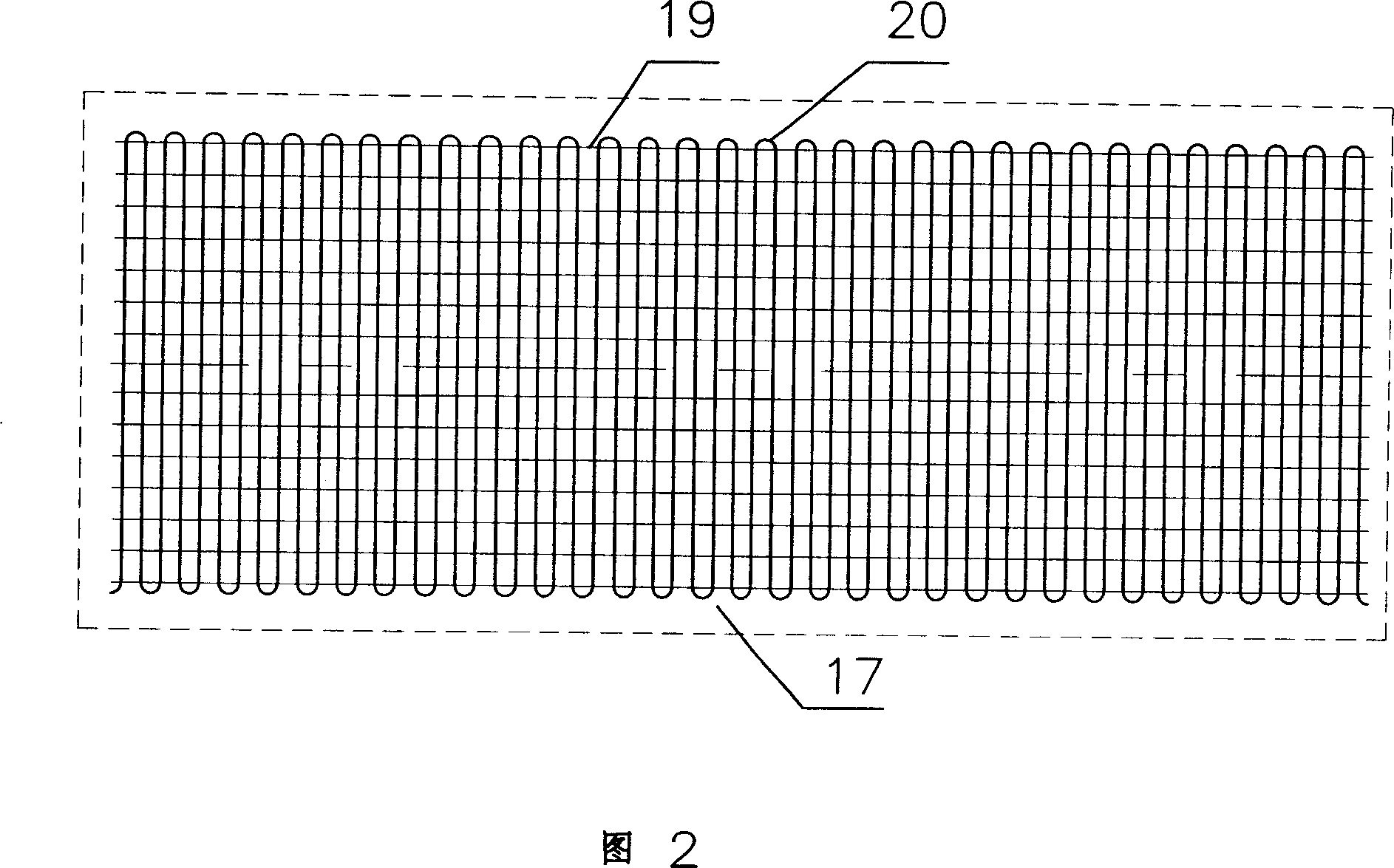

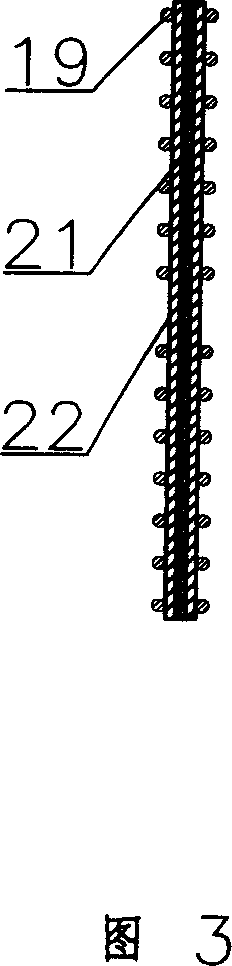

Lead-acid storage battery with square winding structure and manufacturing method of lead-acid storage battery

ActiveCN106159128AReduce weightIncreased energy-to-weight ratioFinal product manufactureSmall-sized cells cases/jacketsPunchingInternal resistance

The invention discloses a lead-acid storage battery with a square winding structure and a manufacturing method of the lead-acid storage battery. Flexible plate grids obtained by expanding, punching, continuous casting or other forms are respectively coated with positive electrode and negative electrode active substances to form a positive electrode plate and a negative electrode plate; the positive electrode plate, a separation board and the negative electrode plate are wound on the same core plate to form a battery cell; the battery cell is arranged in a battery jar with circular arc transition at two ends and a straight line in the middle; after the battery cell is dried by a special technology, a series of physical and electrochemical processes of cast welding, sealing, acid filling, forming and the like are finished, and finally, the lead-acid storage battery which can be repeatedly charged and discharged for use is obtained. The lead-acid storage battery disclosed by the invention combines the advantages of a cylindrical winding battery and a traditional square flat plate battery, has the characteristics of low internal resistance, high specific power and long service life of the winding battery as well as high volume utilization rate and wide application range of the traditional battery, and has broad application prospect; the limit that the cylindrical winding battery is only suitable for being produced into medium-small capacity batteries is broken through.

Owner:山东超威磁窑电源有限公司

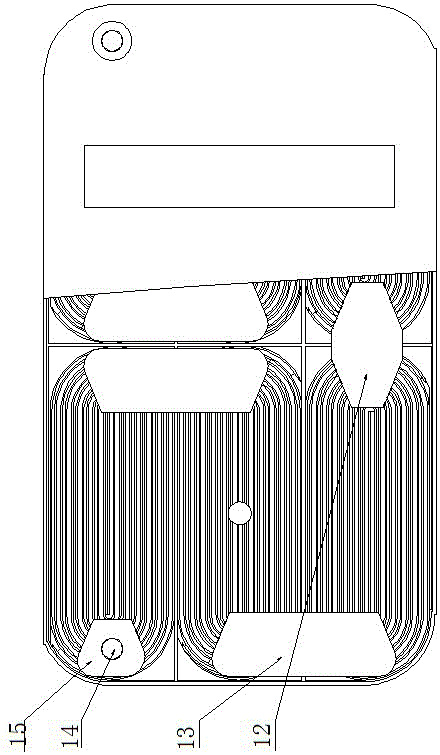

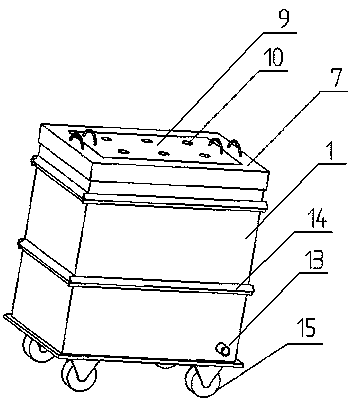

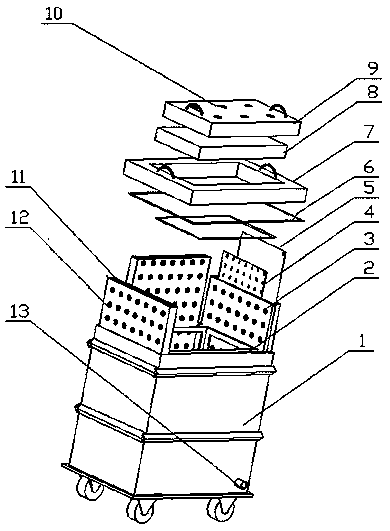

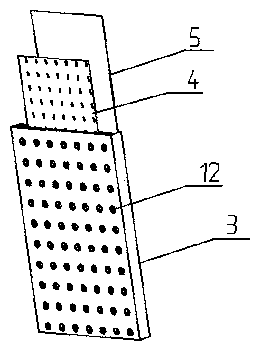

Slow cooling sand box for lost foam casting

PendingCN110405145AIncrease stiffnessNot easy to expand and deformFoundry mouldsFoundry coresPressure systemAir pump

The invention discloses a slow cooling sand box for lost foam casting, and the slow cooling sand box comprises a rectangular box body, wherein the upper part of the box body is opened and is covered by a box cover, four partition plates which are matched with the shape of a cavity in the box body are arranged in the box body, the head and the tail of each partition plate are spliced with one another, the bottom of the box body is provided with an installation clamping groove for the partition plates to be inserted in the direction of the inner wall of the box body, each partition plate is inserted into the corresponding installation clamping groove, a gap is formed between each partition plate and the inner wall of the box body, so that the partition plates and the inner wall of the box body form an air pumping chamber together, and the plate surface of each partition plate is provided with a plurality of through holes; one side surface of the outer wall surface of the box body is provided with an exhaust pipe, one end of the exhaust pipe communicates with an exhaust chamber in the box body, and the other end of the exhaust pipe is connected with a negative pressure system; and aninterlayer is arranged in the partition plate, a gauze layer and a heat-preservation cotton layer are inserted into the interlayer, the gauze layer is close to the center of the box body relative to the heat-preservation cotton layer, and the heat-preservation cotton layer comprises a plurality of layers of heat-preservation cotton. The slow cooling sand box for lost foam casting solves the problem that the cooling time of the sand box is too short, thereby ensuring the quality of castings.

Owner:宝武特冶航研科技有限公司

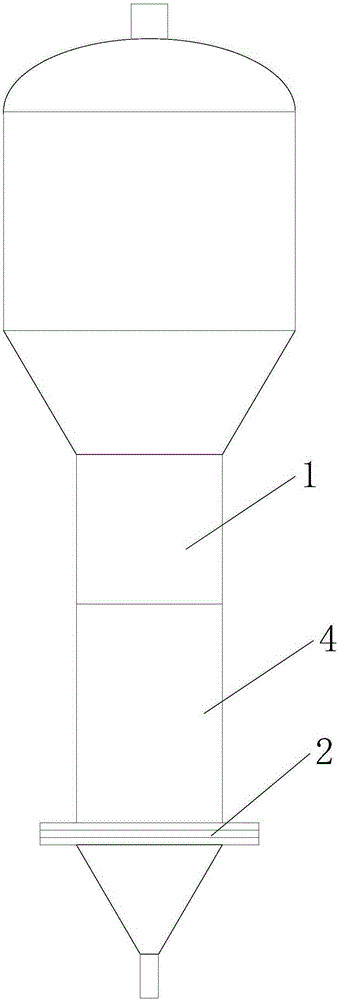

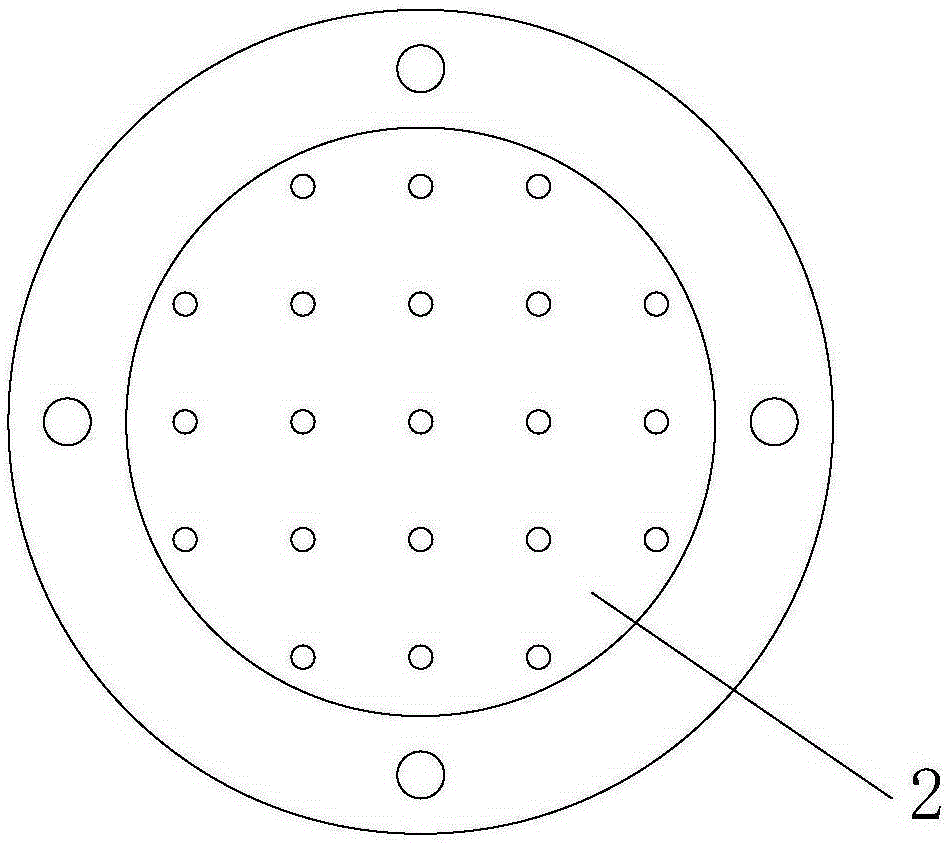

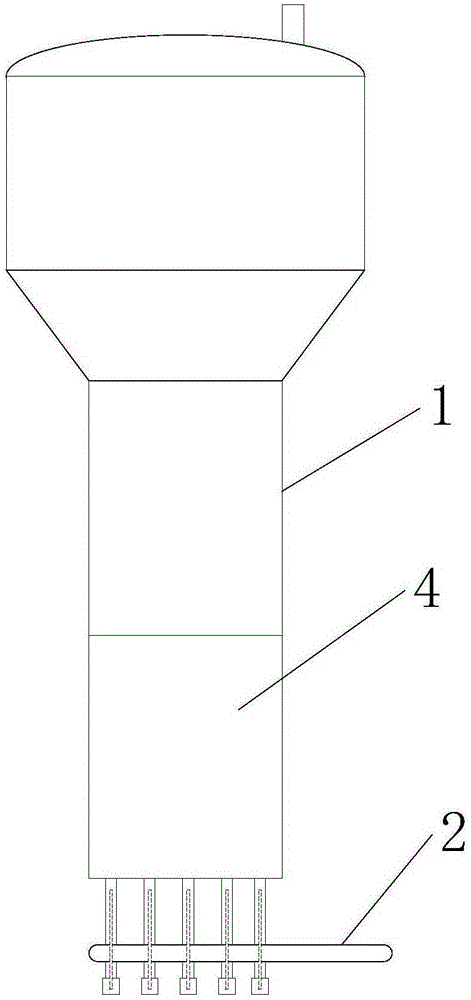

Fluidized bed reactor

ActiveCN105170037AReduced service lifeNot easy to expand and deformChemical/physical processesFluidized bedReaction zone

The present invention relates to the field of fluidized bed reactors, and discloses a fluidized bed reactor. The fluidized bed reactor comprises: a reactor main body (1) and a fluid distributor (2), wherein the reactor main body (1) comprises a reaction zone (4), wherein a plurality of fluid distribute holes (3) are formed in the bottom of the reaction zone (4), and the fluid distributor (2) comprises conveyor pipes that are connected with the fluid distribute holes (3), so that fluid materials can be conveyed to the reaction zone (4) by the conveyor pipes. The fluidized bed reactor disclosed by the present invention has the advantage that the fluid distributor is difficult to be corroded.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Processing method of pressure-moulded dog chewing gum

The present invention belongs to an animal food, in particular, it relates to a method for producing pressure-moulded dog chewing gum (a dog food) by utilizing edible hide material. It adopts the wetted fresh second layer of hide material as raw material, and includes three stages of preparing core body, making preform and producing finished product, and every stage respectively has the processes of drying and moulding.

Owner:张士平 +1

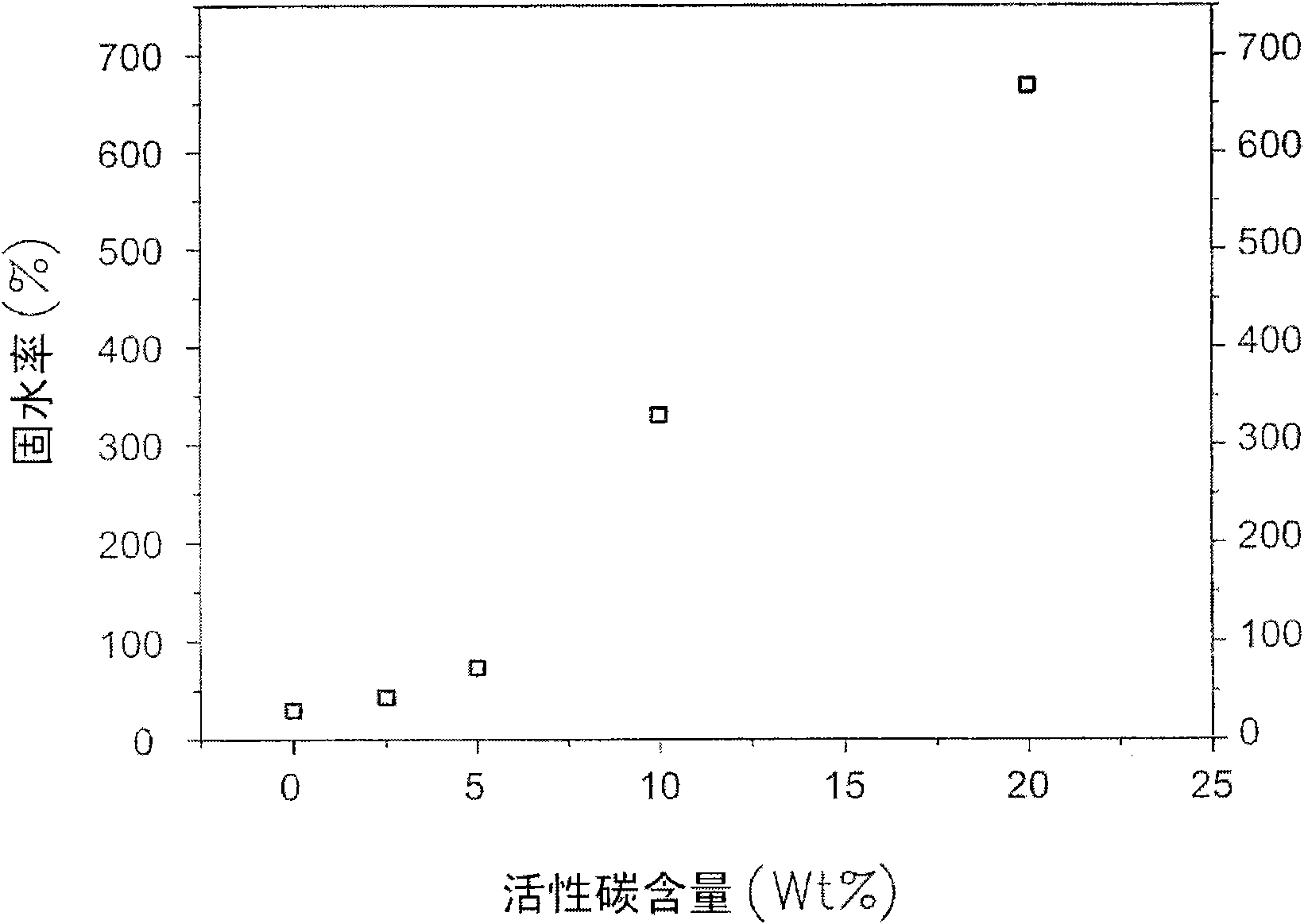

Bonding agent and membrane electrode group thereof

ActiveCN101752566AHigh tensile strengthExcellent water fixation coefficientCell electrodesBiochemical fuel cellsPolymer substratePolymer chemistry

The present invention provides a bonding agent used by a membrane electrode group. The bonding agent comprises a solvent system, a hyperbranched polymer and an organic polymer capable of conducting ions, wherein the branching degree of the hyperbranched polymer is bigger than 0.5, and the hyperbranched polymer and the organic polymer capable of conducting ions are dispersed in the solvent system.

Owner:IND TECH RES INST

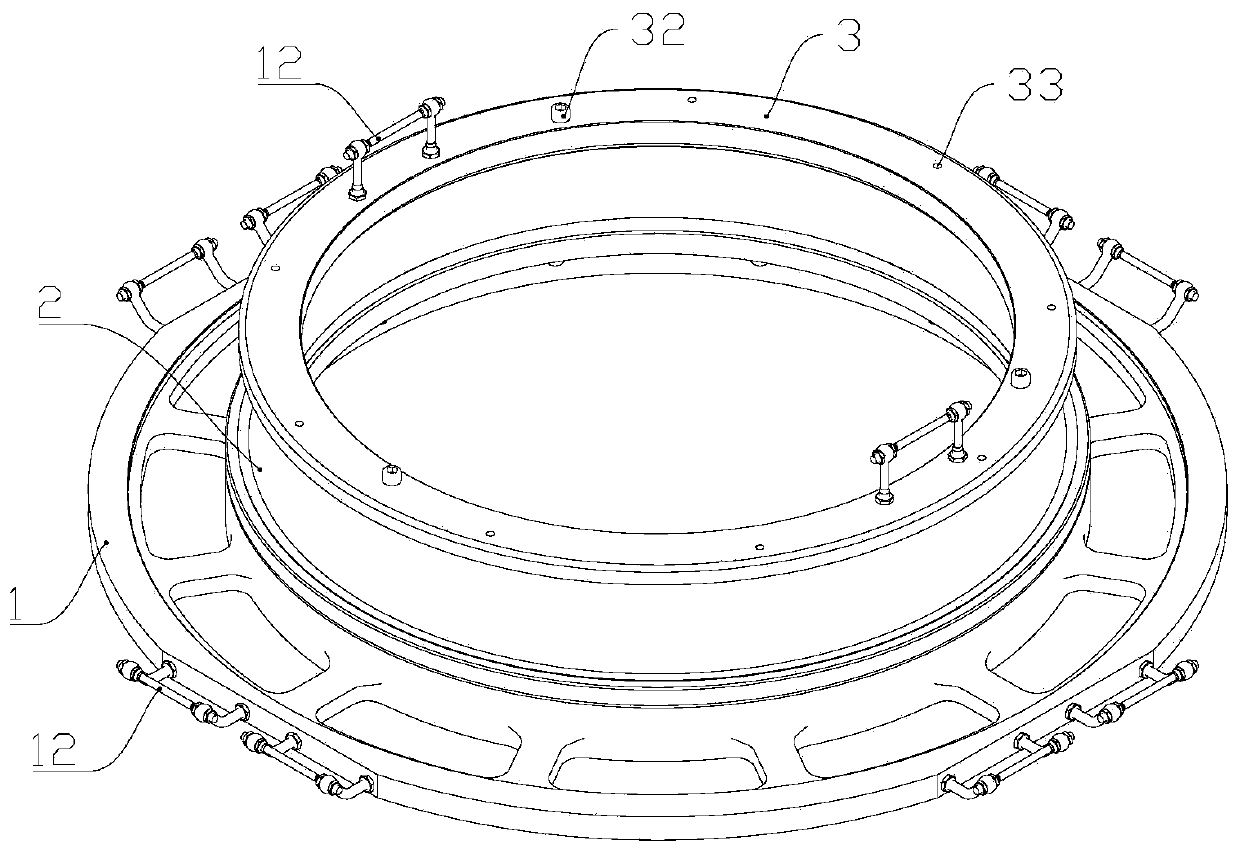

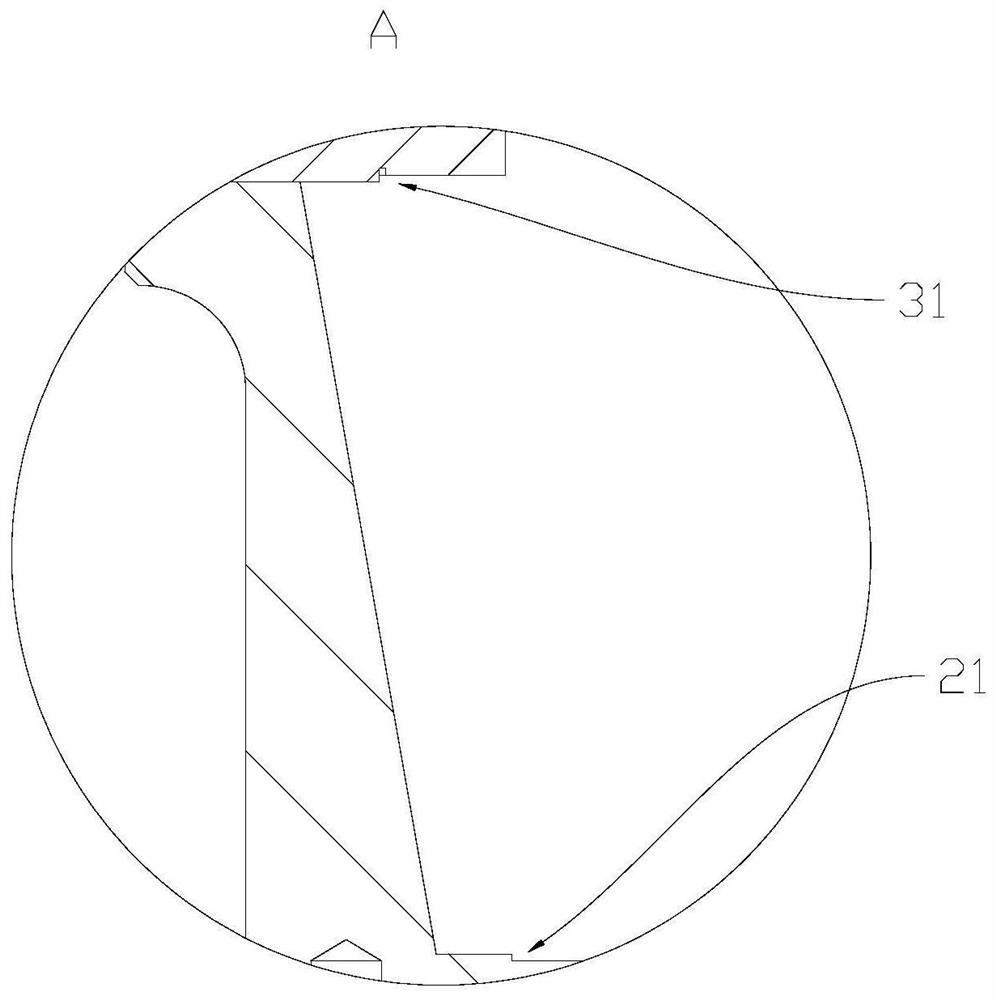

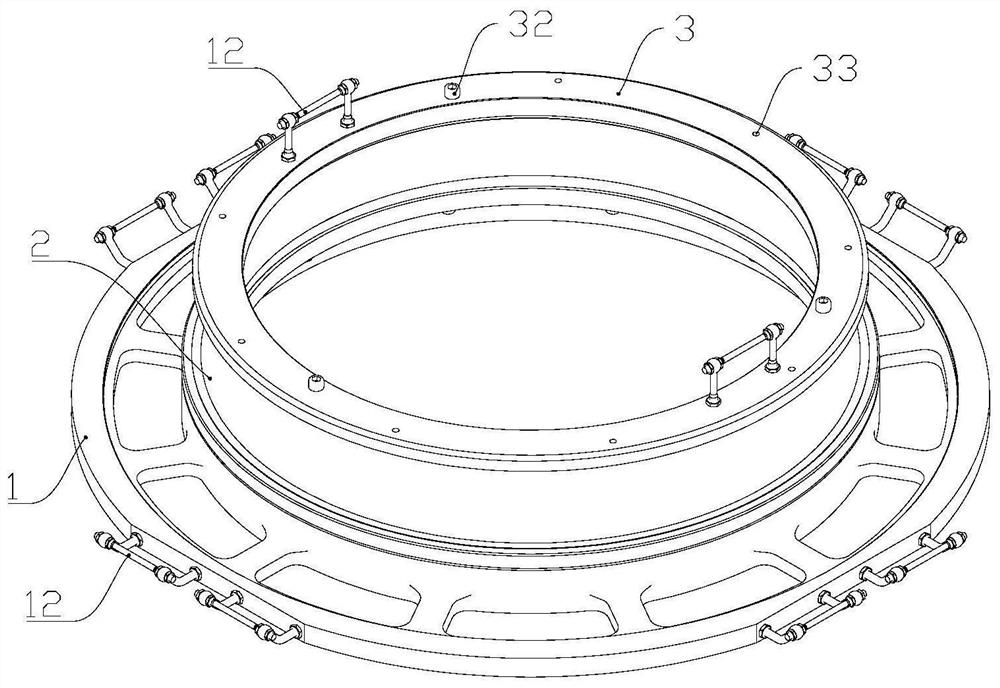

Annular thin-walled part shape correcting tool and shape correcting and rubber pouring method

ActiveCN110756623AGuaranteed dimensional accuracyQuality assuranceMetal-working apparatusDomestic articlesMechanical engineeringThin walled

The invention discloses an annular thin-walled part shape correcting tool and a shape correcting and rubber pouring method, and belongs to the technical field of part rubber pouring. The annular thin-walled part shape correcting tool comprises a base, a positioning seat and a positioning cover plate; the base and the positioning cover plate are detachably arranged at the two ends of the positioning seat; the base and the positioning seat are each of a rotation body cylindrical structure, and the positioning cover plate is of an annular plate-like structure; the base, the positioning seat and the positioning plate are concentrically arranged; the bottom end of the base and the bottom end of the positioning seat are both provided with outer edges protruding outwards; and the side surface ofthe positioning cover plate, the side surface of the positioning seat and the outer edge of the positioning seat form an inner ring shape correcting groove for a part, and the outer edge of the base and the side surface of the base form an outer ring positioning shape correcting groove for the part. The shape correcting and rubber pouring method for an annular thin-walled part comprises the stepsof shape pre-correcting, rubber liquid vacuum defoaming, rubber pouring and solidification, shape setting and the like. Through the shape correcting tool and the processing method, the size and shapeof the rubber pouring part and the inner quality of the rubber can be sufficiently ensured, and accordingly, a high-quality rubber poured product can be obtained.

Owner:AECC AERO SCI & TECH CO LTD

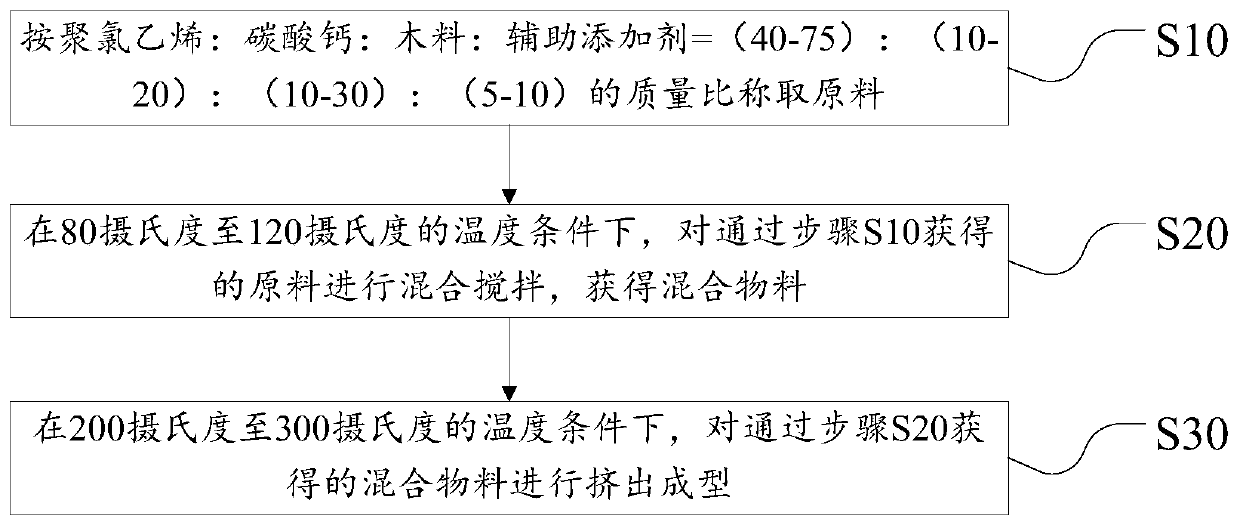

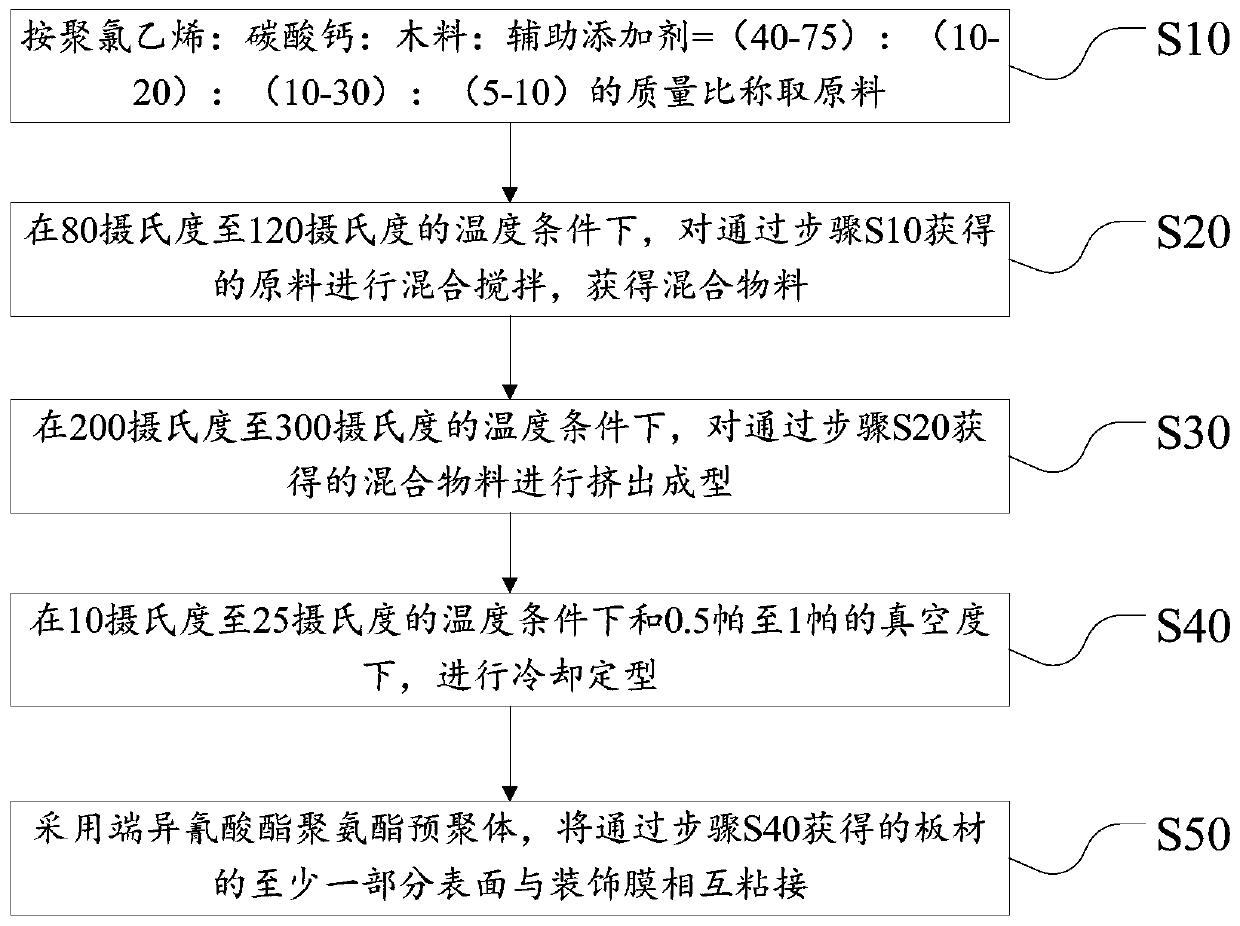

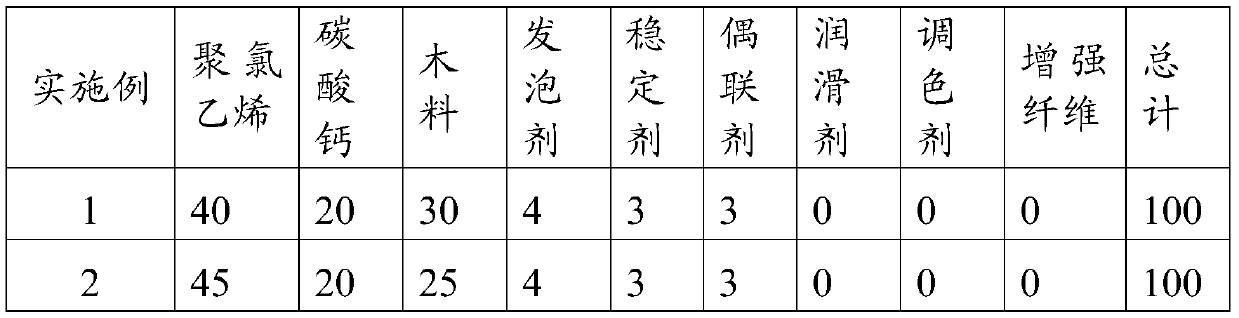

Sheet material, preparation method and use method

InactiveCN110894329AImprove mechanical propertiesHigh mechanical strengthPolyvinyl chlorideUltimate tensile strength

The invention provides a sheet material, a preparation method and a use method. The sheet material comprises the following raw materials in parts by mass: 40-75 parts of polyvinyl chloride; 10 to 20 parts of calcium carbonate; 10 to 30 parts of wood; and 5-10 parts of an auxiliary additive. The sheet material provided by the invention has the advantages of less formaldehyde release, high environmental protection degree, high mechanical strength, easy cleaning and good fireproof performance.

Owner:SHIBEIHAO MEDICAL TECH (GUANGZHOU) CO LTD

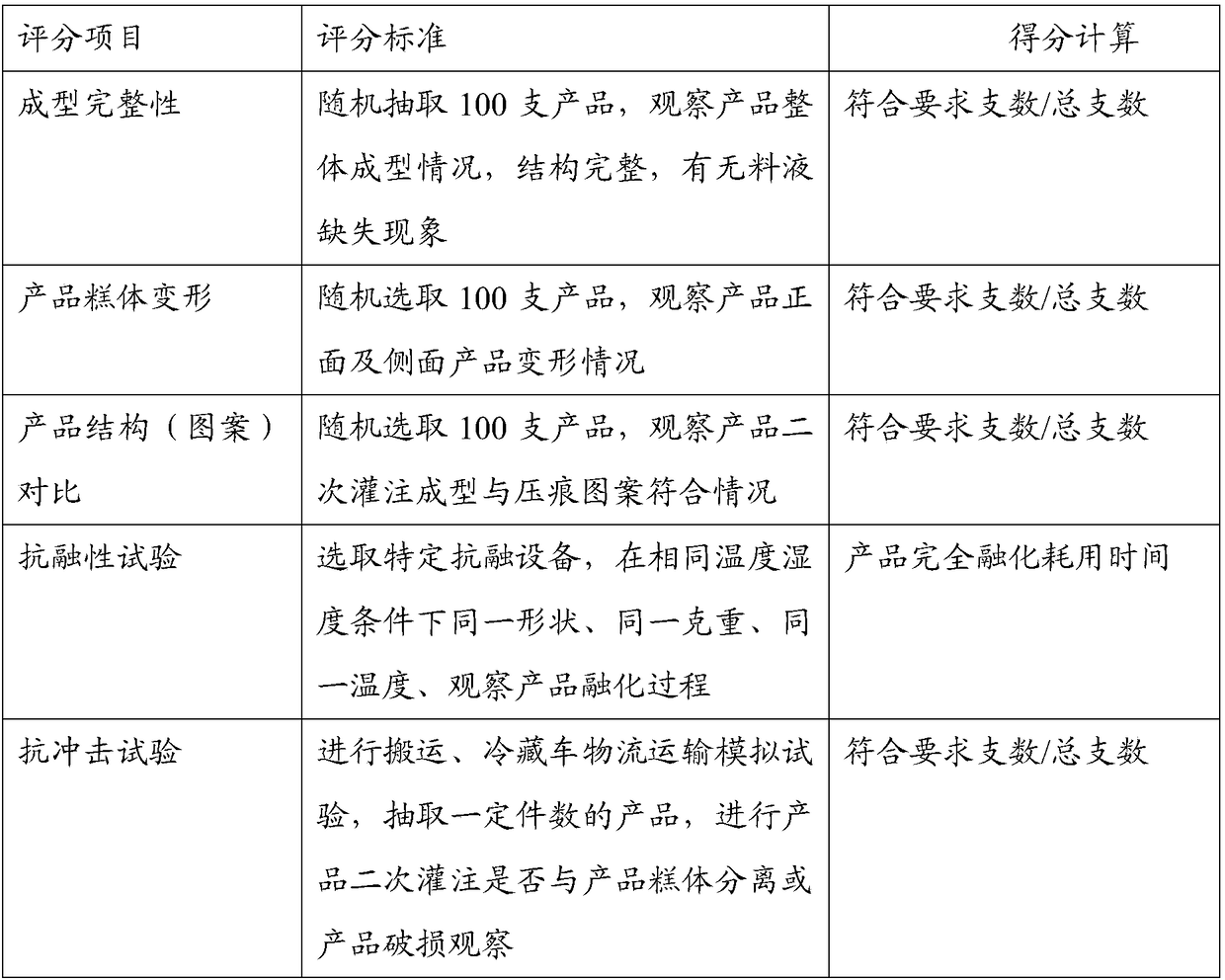

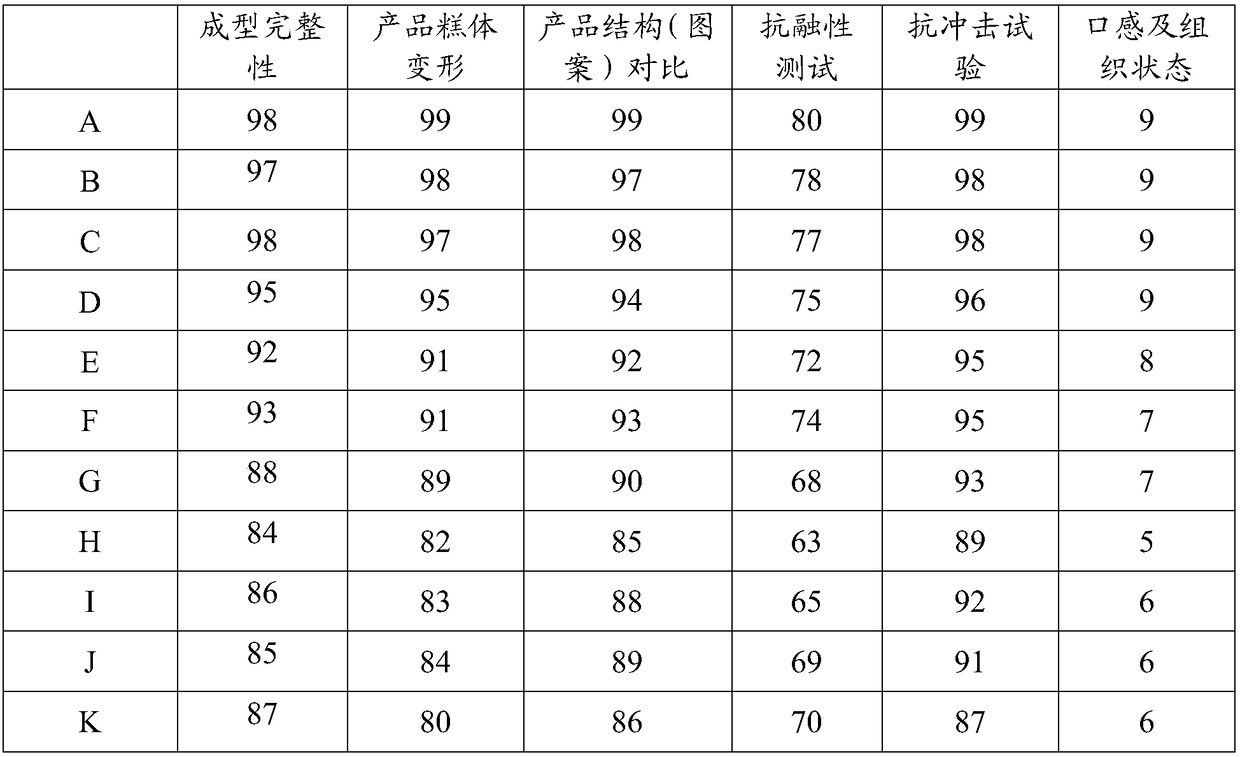

Preparation technology of sheet frozen drink

InactiveCN108271915ASuitable for productionSave time and costSugar food ingredientsFrozen sweetsEmulsionFood science

The invention belongs to the field of frozen drink, and particularly relates to a preparation technology of sheet frozen drink. According to the preparation technology disclosed by the invention, stuffing of fillers is performed in concave parts in the surfaces of sheeted matrix materials, so that combination that various material liquids generate in the same layer of the frozen drink is realized,and different mouth feels and visual impacts are brought to consumers; the content of solids in the matrix materials is further limited, so that the frozen drink can obtain favorable plasticity; thecomponent and the content of an emulsion stabilizer are further limited, so that the situation that the surface of the formed frozen drink is level and smooth is guaranteed, and the frozen drink has favorable mouth feel; the shape of the concave parts on the matrix materials is designed, so that frozen drinks of various shapes can be obtained, diversity of the products is realized, and requirements of different consuming groups are met.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

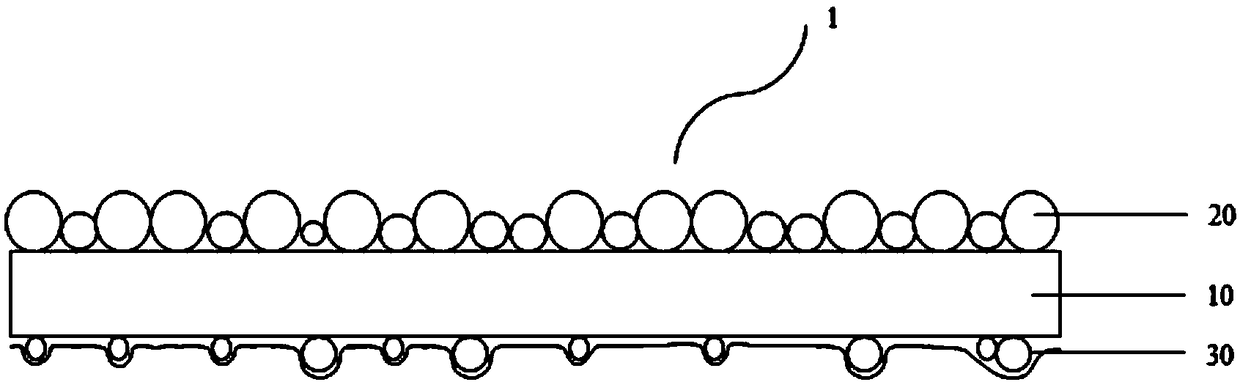

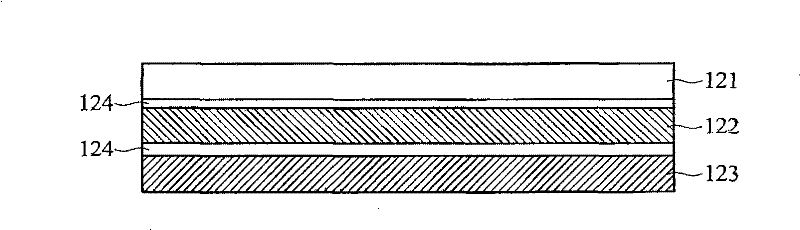

Scratch-resistant diffusion film, backlight module set and liquid crystal display

InactiveCN108732665AAvoid scratchesNot easy to scratchDiffusing elementsNon-linear opticsVitrificationLiquid-crystal display

The invention discloses a scratch-resistant diffusion film, a backlight module set and a liquid crystal display. The scratch-resistant diffusion film comprises a base material, a diffusion layer disposed on one side of the base material, and a back coating disposed on the other side of the base material; the diffusion layer includes first acrylic resin, first diffusion particles and a first curingagent; the vitrification conversion temperature of the first acrylic resin is lower than 50 DEG C; the particle diameter of the first diffusion particles ranges from 5 to 20 microns; the first diffusion particles comprise at least two kinds of polymethyl methacrylate with different particle sizes; the polymethyl methacrylate with the largest particle size is medium dispersed particles; and the value of the variation coefficient of the particle diameter of the medium dispersed particles ranges from 15% to 30%. With the scratch-resistant diffusion film of the invention adopted, a component in contact with the scratch-resistant diffusion film can be prevented from being scratched, and it can be also ensured that the scratch-resistant diffusion film itself has little possibility of being scratched. The scratch-resistant performance of the scratch-resistant diffusion film is excellent; and the scratch-resistant diffusion film can be applied to a backlight module sset and a liquid crystal display.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

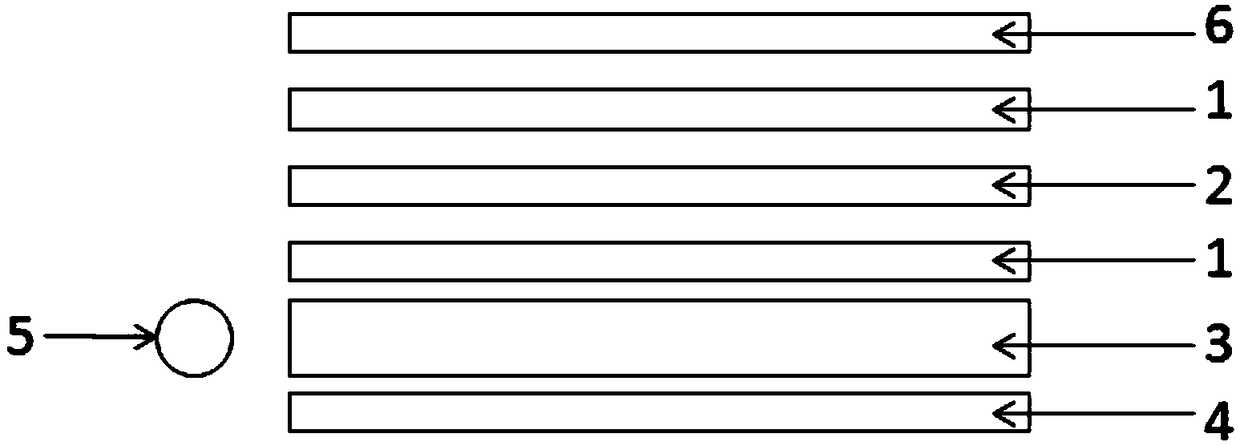

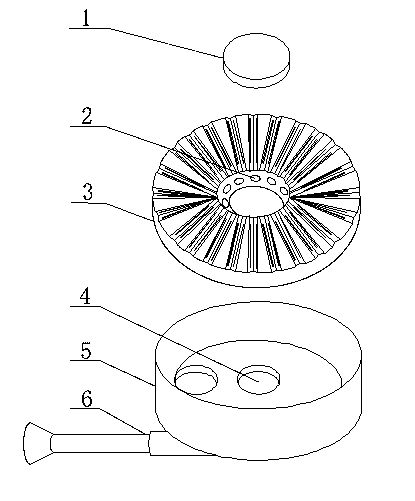

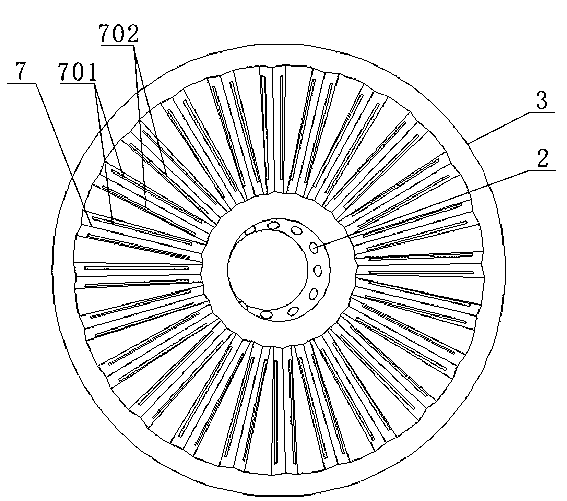

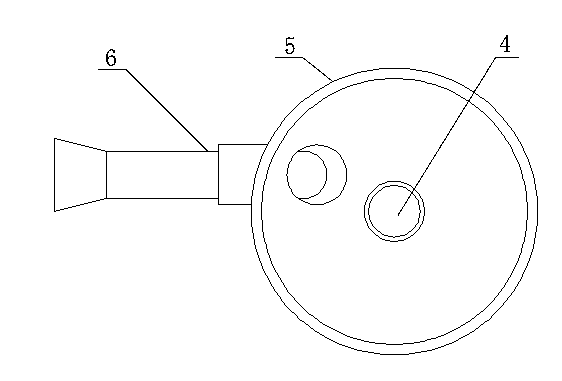

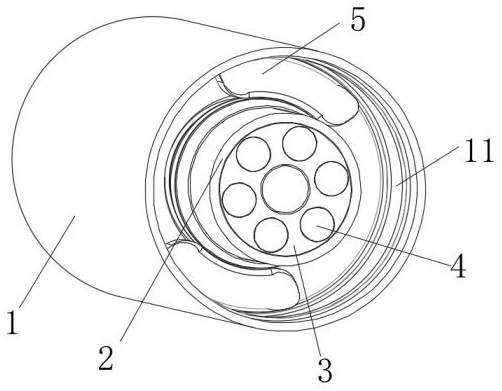

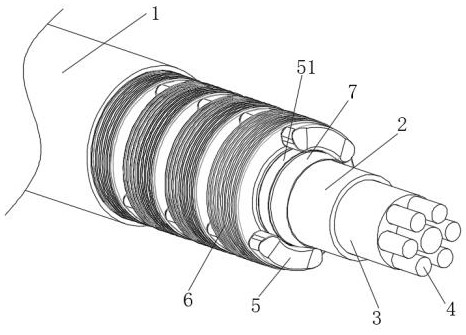

Gas stove head device

ActiveCN103343972AIncrease profitPut an end to yellow fireNon-combustible gases/liquids supplyGaseous fuel burnerEngineeringCombustion

A gas stove head device comprises a base, a cover body with a through hole in the center and a sealing plug arranged in the through hole. The base is matched with the cover body, the cover body is of an annular structure with a conical inward-concave face, and blind holes are circumferentially distributed in the wall of the through hole in the center of the cover body. The upper surface of the cover body is provided with V-shaped grooves which are arranged at intervals, and inclined faces on the two sides of each V-shaped groove are provided with a gas groove and an air groove respectively. The air grooves are communicated with the insides of the blind holes, and the gas grooves penetrate through the upper surface and the lower surface of the cover body. The lower bottom face of the base is provided with a side leading-in pipe and a ventilation opening for installing a supercharge turbo-blower. The ventilation opening is arranged corresponding to the through hole in the cover body. The gas stove head device can achieve convection of gas and air, air is added through the air grooves, so that gas gathers together upwards, heat loss is reduced, combustion is more sufficient, and the effect of energy conservation and environment protection is achieved. After the gas stove head device is used for a long time, the gas stove head device can not expand and deform easily, and service life is prolonged.

Owner:常加林

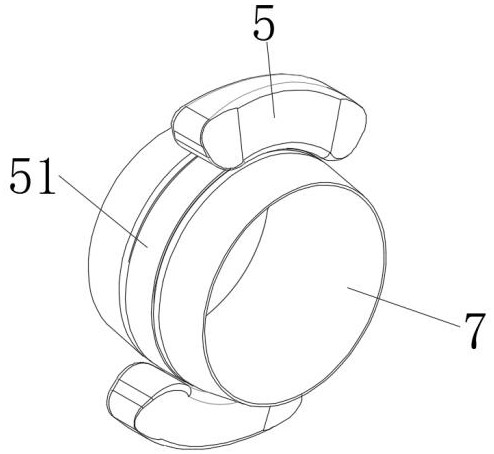

Cable with circulating heat dissipation function

ActiveCN113689988ARealize circulating heat dissipationQuick exportInsulated cablesInsulated conductorsThermodynamicsEngineering

Owner:HAIMEN TONGNENG COMM TECH

A kind of mahogany drying method

ActiveCN105666618BNot easy to absorb waterNot easy to expand and deformWood treatment detailsWood dampingVegetable oilFuel tank

The invention discloses a drying method for rosewood. The drying method comprises the following steps that 1, the rosewood is sawed into a finished material which is dried through a steam drying box; 2, the finished rosewood material is put into a pot to be boiled with boiling water and is subjected to degreasing for 110-130 min; 3, then the boiled finished rosewood material is subjected to drying and dewatering treatment; 4, the dewatered finished rosewood material is put into an oil tank to be soaked for six to eight days with vegetable oil and alums and is heated to 72 DEG C-78 DEG C; and 5, the soaked finished rosewood material is placed in a ventilated place so that the oil can be dried through blowing. The rosewood material obtained through the method is environmentally friendly, colorless and tasteless, and a human body is not injured through close contact. A rosewood plate processed through the method is not prone to absorbing water and being swelled and deformed as well as shrunk and torn through high-temperature baking and is especially suitable for production of seamless furniture.

Owner:南通美霆紫檀艺术品有限公司

Resin adhesive wet-pasting construction method of toilet

InactiveCN107435425ALabor savingShorten the timeAdhesivesFlooring insulationsArchitectural engineeringMaterials processing

The invention relates to a resin adhesive wet-pasting construction method of a toilet. The method specifically comprises the steps of (1) engineering technical disclosure and deepened paying-off disclosure, (2) base construction disclosure, (3) material processing, (4) allocation of materials and tools for site installation and (5) wet-pasting construction. The resin adhesive wet-pasting construction method of the toiler has the advantages that (1) time and labor are saved; (2) the mortar consumption is reduced, and stacking is simple; (3) pollution resistance, acid-base resistance and corrosion resistance are achieved, efflorescence and color change are avoided, and the connection strength is high; (4) floor loads are reduced, and the ground curing strength is increased; (5) seams are sealed tightly; and (6) the service life is long.

Owner:曹颖

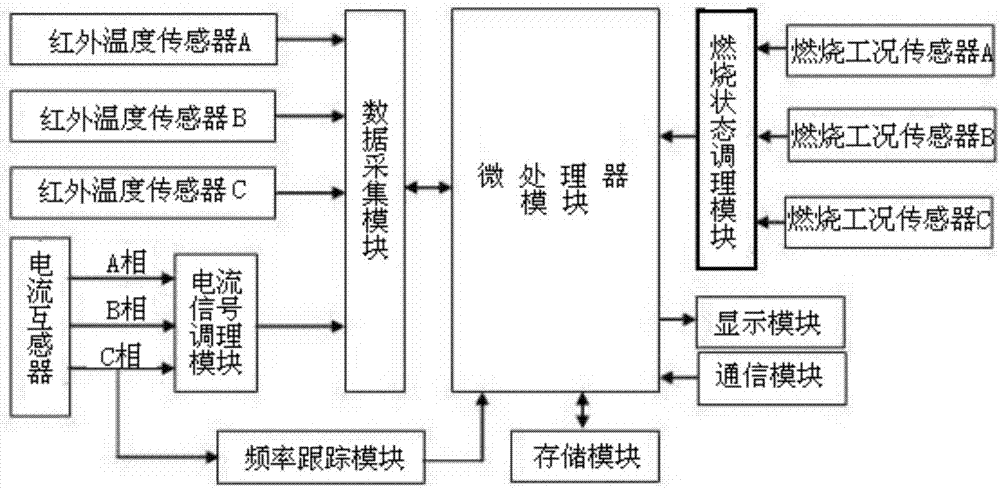

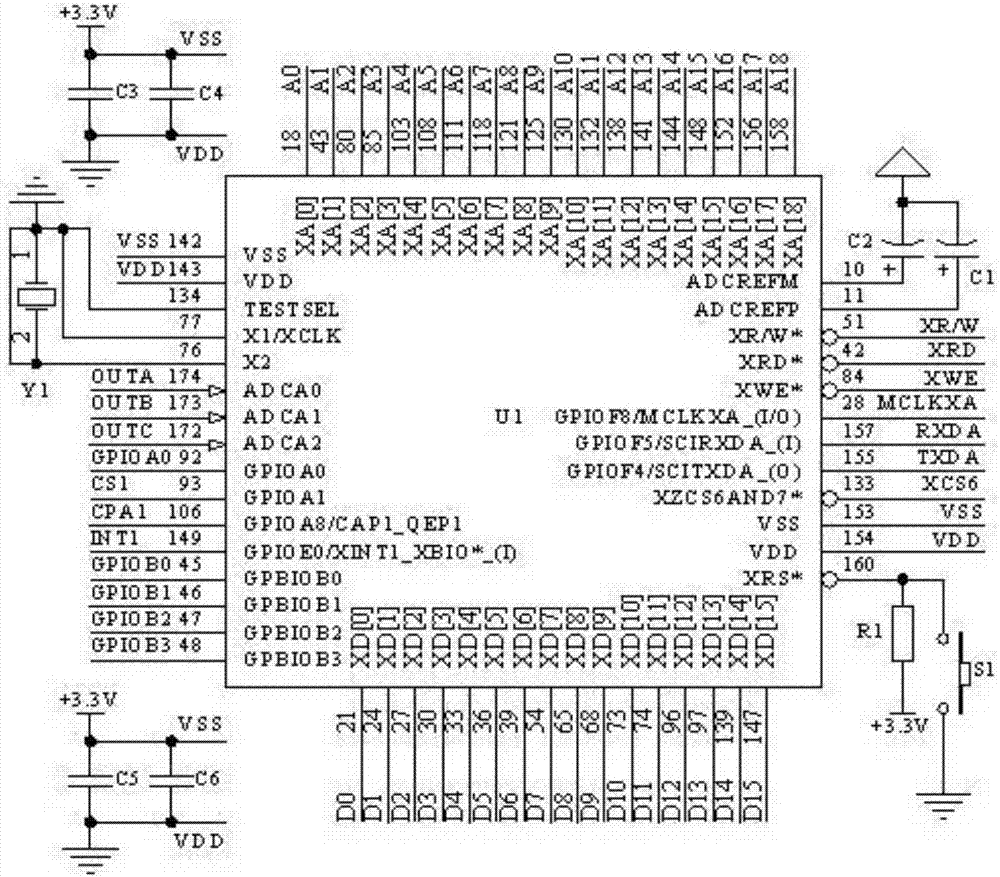

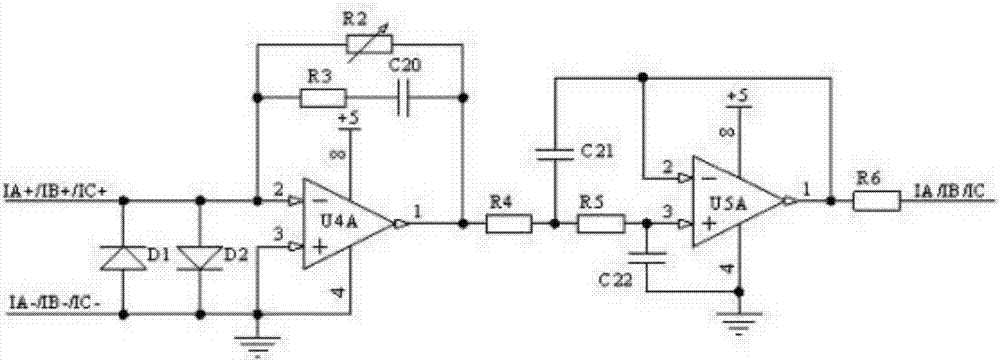

Distribution isolation switch on-line monitoring system for kiln

InactiveCN106932715AEnable online assessmentImprove securitySubsonic/sonic/ultrasonic wave measurementUsing electrical meansData acquisitionControl line

The invention discloses a distribution isolation switch on-line monitoring system for a kiln. The system comprises a current transformer, a combustion working condition sensor, infrared temperature sensors, a current signal conditioning module, a combustion state conditioning module, a data acquisition module, a frequency tracking module, a microprocessor module, a data storage module, a communication module, and a display module. The current transformer is connected to the current signal conditioning module. The combustion working condition sensor is connected to the combustion state conditioning module. The current signal conditioning module and the infrared temperature sensors are connected to the input port of the data acquisition module. The input end of the frequency tracking module is connected to any output port of the current signal conditioning module. The frequency tracking module is connected to the microprocessor module. The combustion state conditioning module, the data acquisition module, the data storage module, the communication module and the display module are connected to the AD port, data line, address line and control line, GPIO port and asynchronous serial interface of the microprocessor module. The online monitoring problem of isolation switch contact temperature, passing current and combustion state is solved.

Owner:北京兴达奇热工控制设备有限公司

Burner brick for industrial kiln

Owner:YIXING RUIJING BURDEN

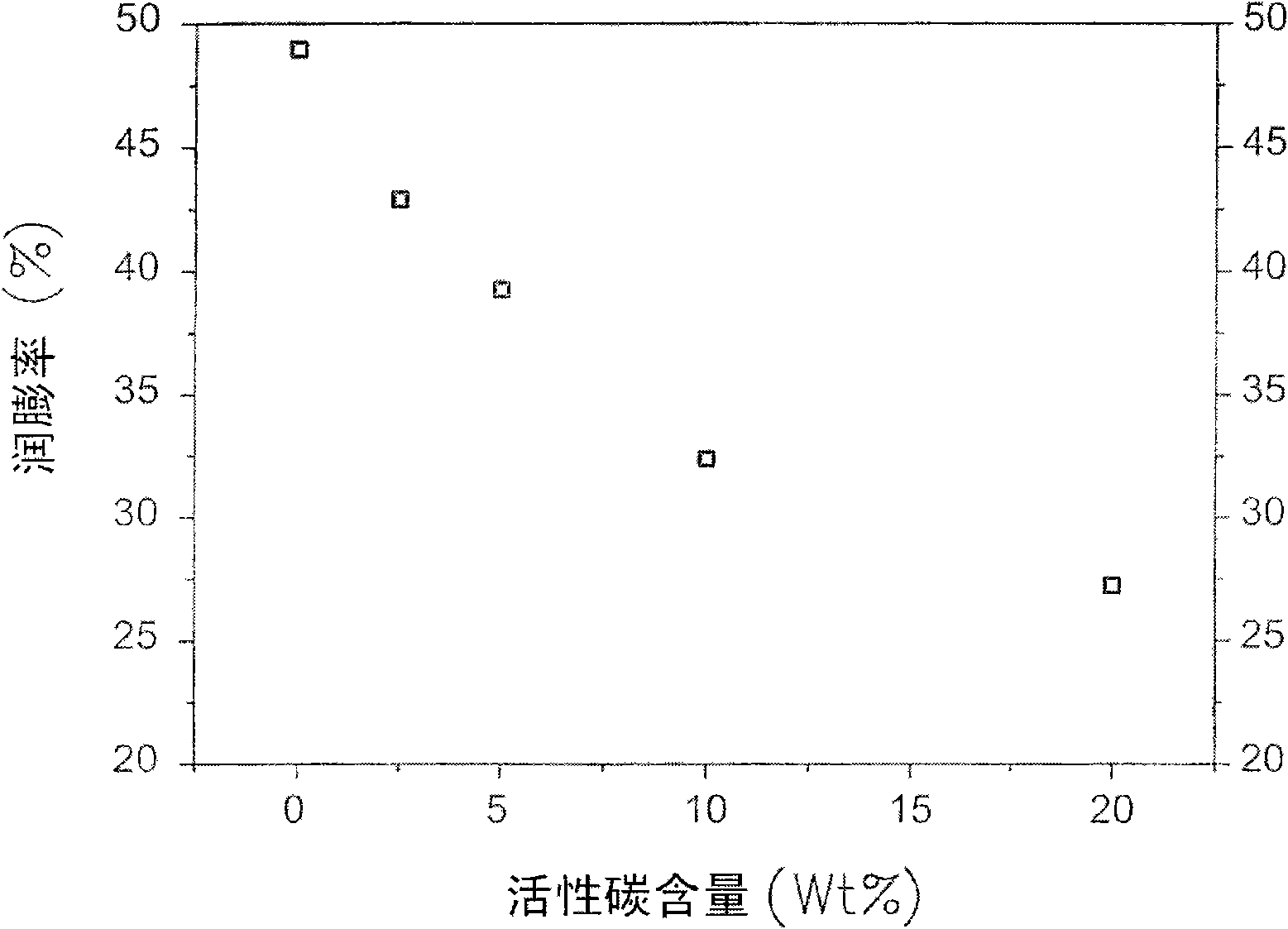

Composite plastic board

The invention discloses a composite plastic board. The composite plastic board is prepared by mixing the following components in parts by weight: 65 parts of polyvinyl chloride (PVC) resin, 18 parts of wood flour, 22 parts of light calcium powder, 6 parts of modified biochar, 0.6 part of stearic acid and 1.1 parts of a plasticizer. The composite plastic board disclosed by the invention is proof against water and moisture, is not easily rotten, expanded or deformed, has high environmental friendliness, is free of pollution, is harmless, and can be recycled. The composite plastic board containsno benzene substances, the formaldehyde content is 0.2, and the composite plastic board has a formaldehyde content lower than the E0-grade standard. The composite plastic board is characterized by being prepared by mixing the following components in parts by weight:, and the PVC resin is prepared by mixing the following components in parts by weight: 65 parts of PVC resin, 18 parts of wood flour,22 parts of light calcium powder, 6 parts of modified biochar, 0.6 part of stearic acid and 1.1 parts of a plasticizer.

Owner:扬州毅昌塑料制品有限公司

An installation structure of a plastic trim part of a car seat

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

A kind of modified polyurethane water-resistant adhesive film and preparation method thereof

ActiveCN105646829BImprove mechanical propertiesHigh tensile strengthN dimethylformamidePolymer science

The invention provides a modified polycarbamate water-resistant adhesive film and a preparation method thereof. The preparation method comprises the following steps: stirring polyethyleneglycol, diphenylmethane diisocyanate, ethyl acetate and N,N-dimethylformamide to react, adding 2,2-dimethylolpropionic acid and 2-methylpyridine, continuing stirring, adding ethyl orthosilicate, hydroxy silicon oil and polydimethylsiloxane, stirring, adding N,N-dimethyl cyclohexylamine, continuing stirring at uniform speed, adding acetone, stirring, adding butanediol to react, cooling to 30-35 DEG C, adding triethanolamine, stirring with a stirrer, slowly adding deionized water while continuing stirring, and finally, carrying out reduced pressure distillation to obtain the modified polycarbamate water-resistant adhesive film. The modified polycarbamate water-resistant adhesive film has the advantages of favorable mechanical properties, favorable toughness, low swelling strain tendency and excellent water resistance.

Owner:佛山霄绫包装材料有限公司

Modified polycarbamate water-resistant adhesive film and preparation method thereof

The invention provides a modified polycarbamate water-resistant adhesive film and a preparation method thereof. The preparation method comprises the following steps: stirring polyethyleneglycol, diphenylmethane diisocyanate, ethyl acetate and N,N-dimethylformamide to react, adding 2,2-dimethylolpropionic acid and 2-methylpyridine, continuing stirring, adding ethyl orthosilicate, hydroxy silicon oil and polydimethylsiloxane, stirring, adding N,N-dimethyl cyclohexylamine, continuing stirring at uniform speed, adding acetone, stirring, adding butanediol to react, cooling to 30-35 DEG C, adding triethanolamine, stirring with a stirrer, slowly adding deionized water while continuing stirring, and finally, carrying out reduced pressure distillation to obtain the modified polycarbamate water-resistant adhesive film. The modified polycarbamate water-resistant adhesive film has the advantages of favorable mechanical properties, favorable toughness, low swelling strain tendency and excellent water resistance.

Owner:佛山霄绫包装材料有限公司

Square winding structure lead-acid battery and manufacturing method thereof

ActiveCN106159128BReduce weightIncreased energy-to-weight ratioFinal product manufactureSmall-sized cells cases/jacketsElectrical batteryInternal resistance

The present invention is a lead-acid storage battery with a square winding structure and its manufacturing method. The positive and negative active materials are respectively coated on the flexible grid obtained by expansion, punching, continuous casting or other forms to make positive and negative plates. Plate, separator, and negative plate are wound on the same core plate to form a battery core, and the battery core is placed in a battery tank with a circular arc transition at both ends and a straight line in the middle. After drying by a special process, casting welding, sealing, and filling are completed. A series of physical and electrochemical processes such as acid and chemical formation, and finally, it becomes a lead-acid battery that can be used repeatedly for charging and discharging. The invention combines the advantages of cylindrical winding batteries and traditional square flat batteries. It not only has the characteristics of low internal resistance, high specific power and long life of winding batteries, but also has the characteristics of high volume utilization rate and wide application range of traditional batteries. It breaks through It overcomes the limitation that the cylindrical winding battery is only suitable for small and medium capacity batteries, and has broad application prospects.

Owner:山东超威磁窑电源有限公司

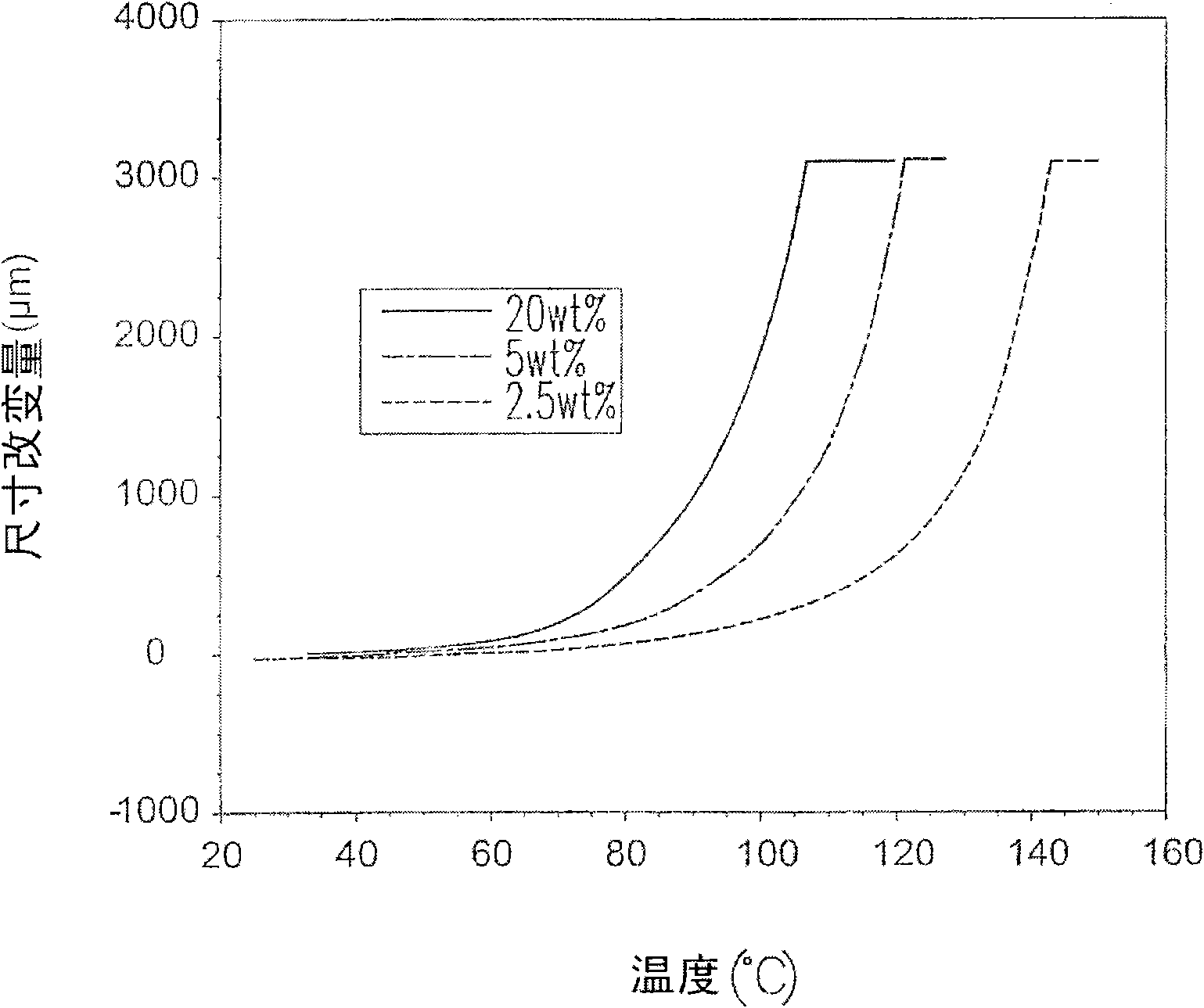

Organic/inorganic mixed proton exchange membrane

ActiveCN102117920BImprove water retentionHigh mechanical strengthCell component detailsFuel cell detailsGramPhosphoric acid

The invention discloses an organic / inorganic mixed proton exchange membrane which comprises the following components by weight percentage: 0.5 to 30 percent of inorganic material and 99.5 to 70 percent of organic material. The surface area of the inorganic material is 50 to 3000 square meters per gram. The organic material comprises a copolymerized high polymer containing a sulfoacid base or a polymer doped with phosphoric acid. The organic / inorganic mixed proton exchange membrane has excellent water-retaining property, excellent mechanical strength and excellent conductivity, and does not expand or deform easily in high-temperature water.

Owner:IND TECH RES INST

Quasi-two-pole winding-structure lead-acid battery and making method

InactiveCN100350666CIncrease specific energyImprove connection reliabilityFinal product manufactureLead-acid accumulators constructionInternal resistanceElectrical polarity

Positive active material and negative active material separated by lead wires are coated on two sides of composite slab lattice so as to constitute bipolar plate. The said lead wires can be cut into certainshape to become positive pole plate or negative pole plate with single pole. Single adjacent batteries separated by lead wires can be connected in series. Positive pole plate, diaphragm, and negative pole plate of single battery are winded on same core axle. Winded pole plates and diaphragm fixed by plastic fixture becomes battery core. Dried battery core is installed inside cylindrical battery box so as to complete electrochemical procedure. Then, firming agent is filled into the box. The invention combines advantages of both of quasi-bipolar battery and cylindrical winded battery, possessing features of low internal resistance, high specific energy, high specific power, and long service life.

Owner:李向秀

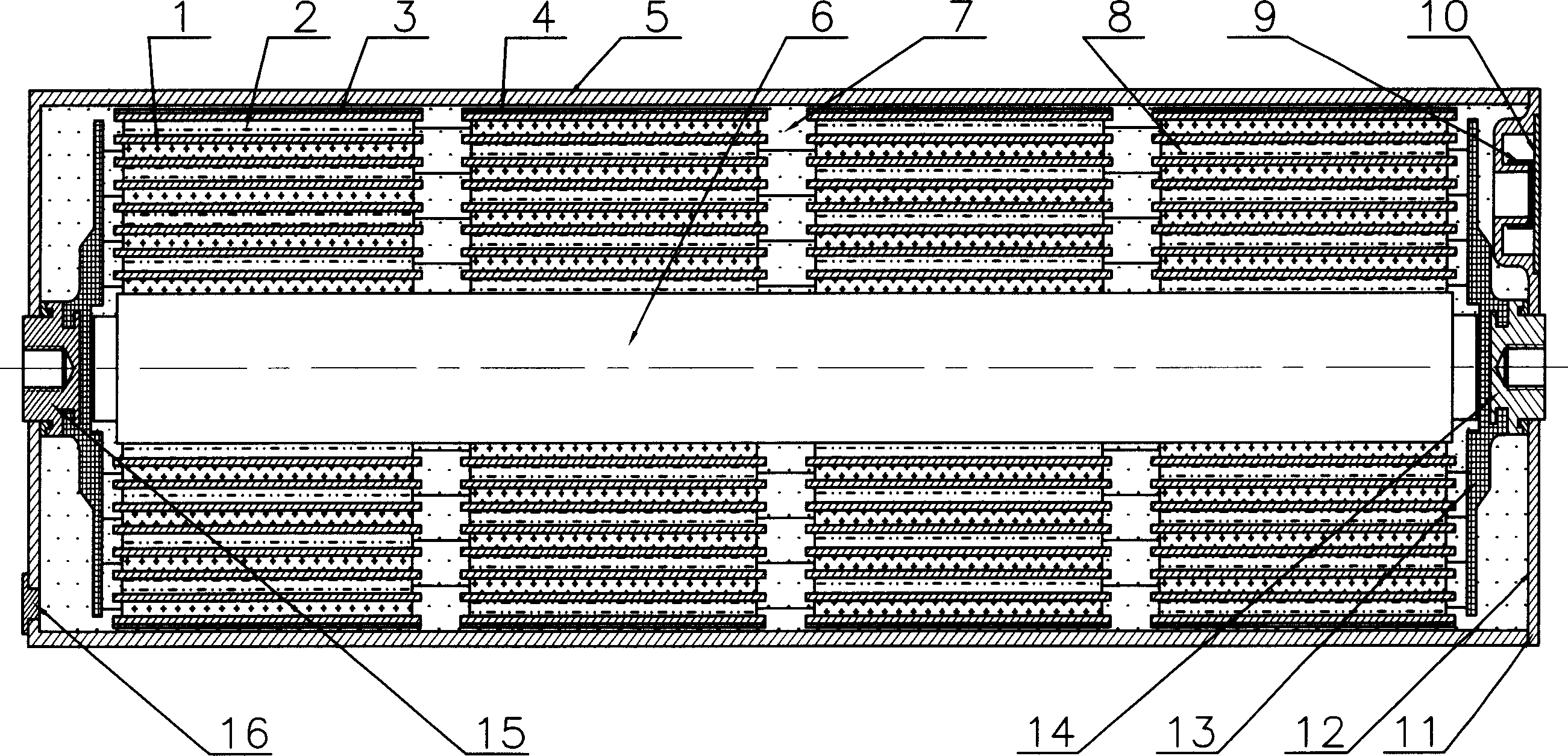

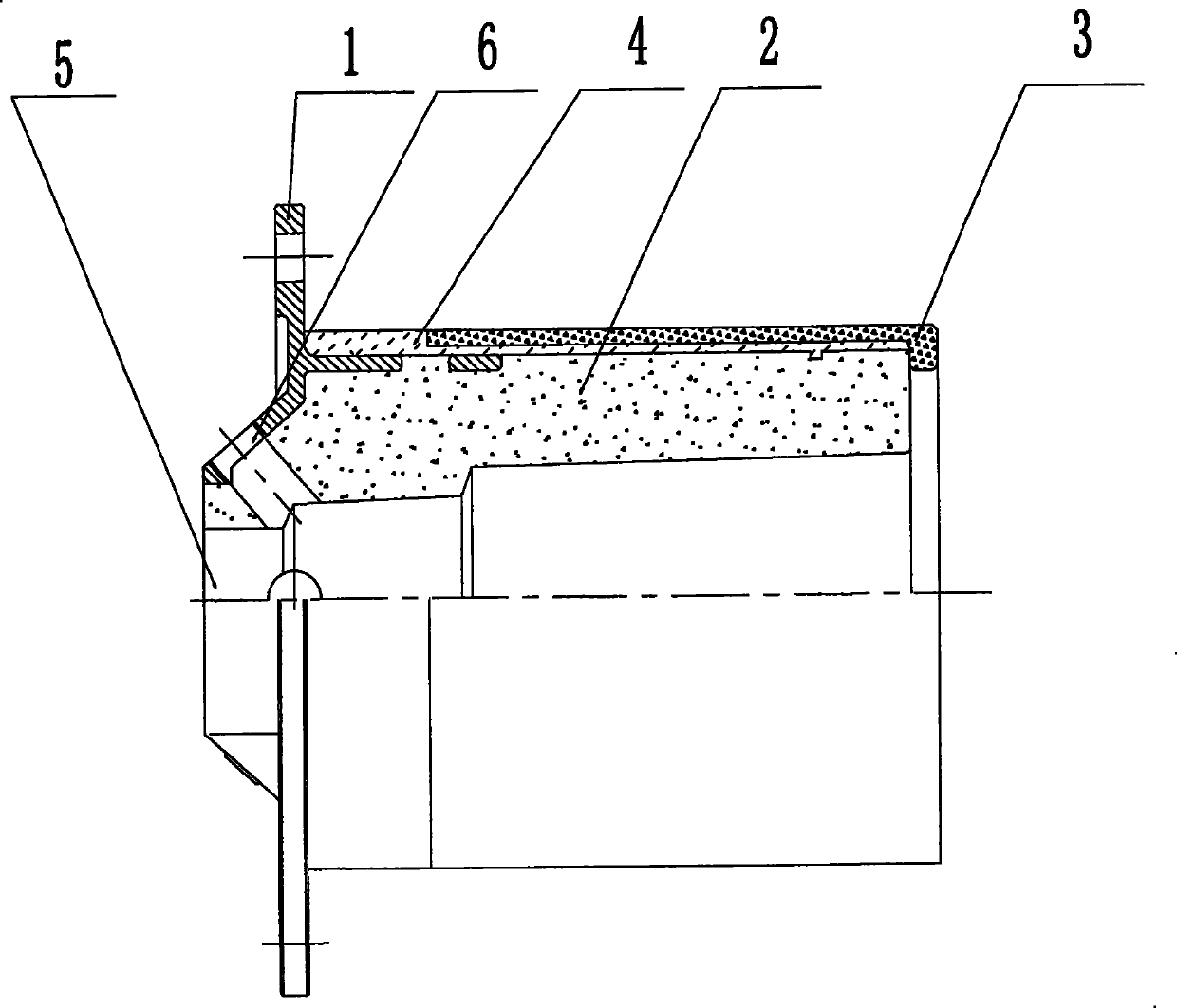

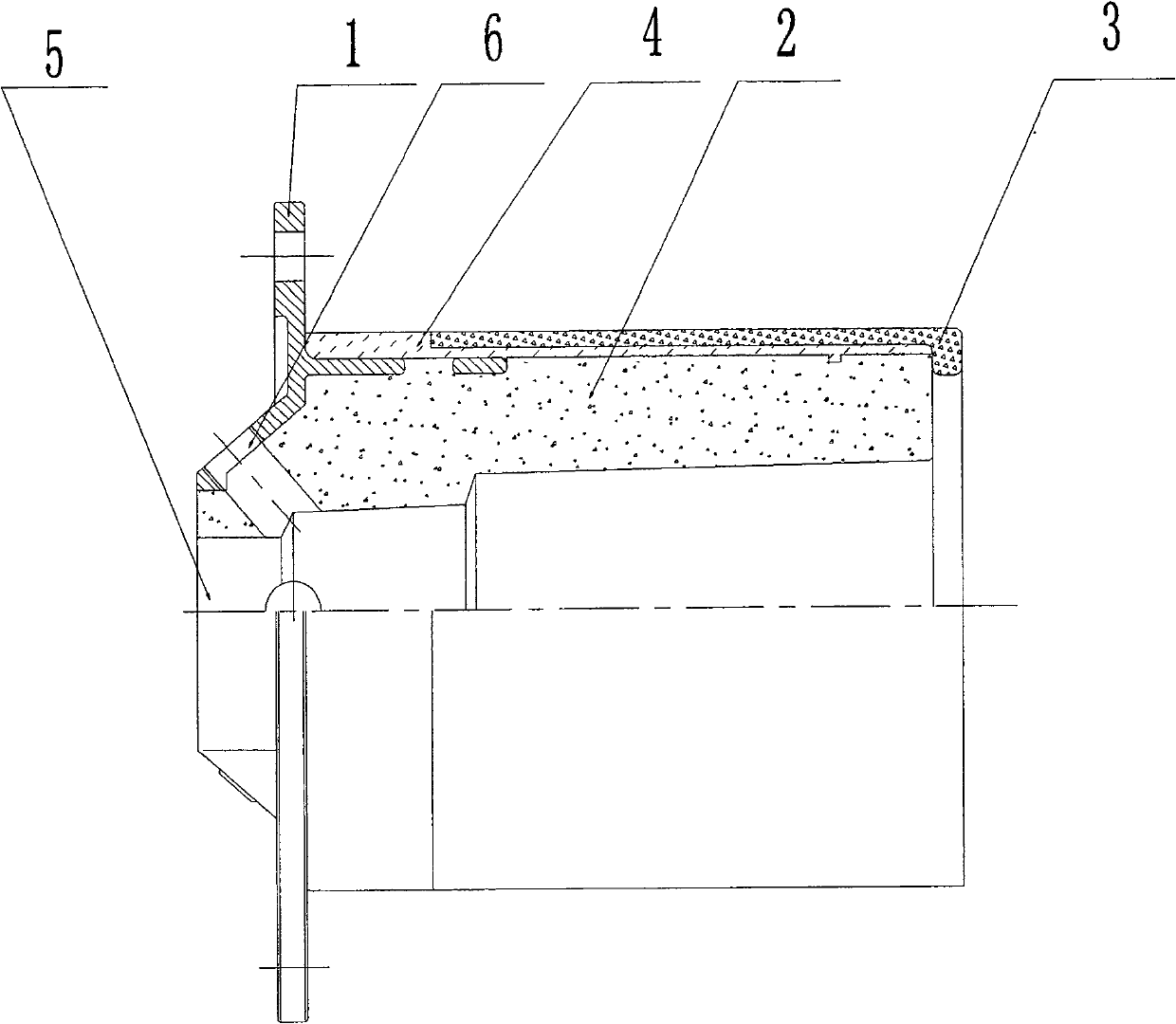

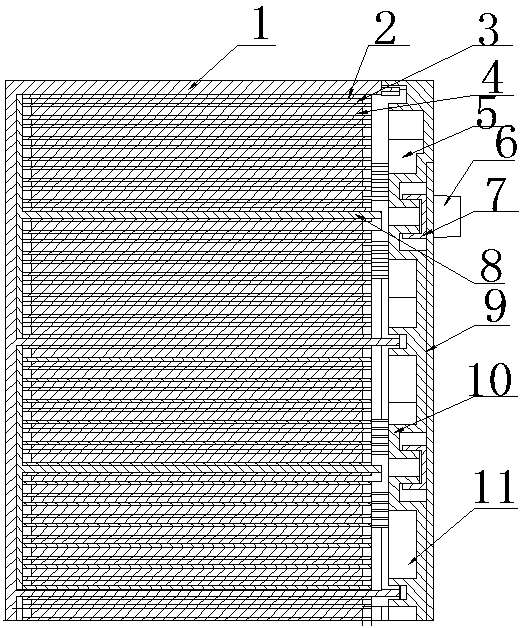

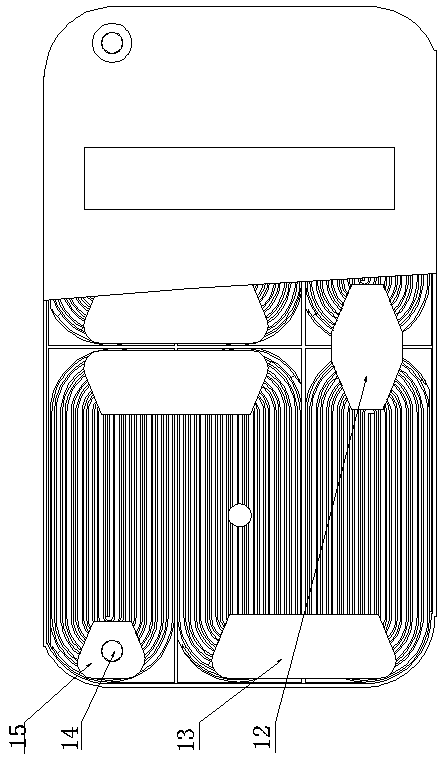

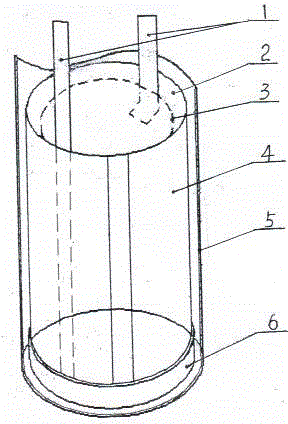

Dry-type power capacitor with built-in pressure explosion-proof equipment

InactiveCN106449089AThe effect of stretchingNot easy to expand and deformFixed capacitor housing/encapsulationEpoxyEngineering

The invention belongs to power accessories, and particularly relates to a dry-type power capacitor with built-in pressure explosion-proof equipment. The dry-type power capacitor comprises a capacitor packet (3), wherein leads (1) are respectively and fixedly connected to the upper and lower ends of the capacitor packet (3); the periphery of the capacitor packet (3) is coated with a mylar (4), and a gap is reserved between the capacitor packet (3) and the mylar (4); a lower insulation sleeve (6) is arranged at the bottom end of the capacitor packet (3) coated by the mylar (4) in a sleeving manner; the space between the coating of the mylar (4) and the capacitor packet (3) is filled with an epoxy resin (2) for sealing; the periphery of the coating of the mylar (4) and the lower insulation sleeve (6) is coated with an aluminum housing (5), and a gap is formed between the aluminum housing (5) and the coating of the mylar (4). According to the dry-type power capacitor with the built-in pressure explosion-proof equipment, the phenomenon that the stretching action of the aluminum housing is influenced when the pressure inside the capacitor is suddenly increased can be avoided, the epoxy resin is difficult to expand and deform, and the performance is safe and reliable.

Owner:隋会芳

Bonding agent and membrane electrode assembly including same

ActiveCN101752566BHigh tensile strengthImprove brittlenessCell electrodesBiochemical fuel cellsPolymer substrateOrganic polymer

The present invention provides a bonding agent used by a membrane electrode group. The bonding agent comprises a solvent system, a hyperbranched polymer and an organic polymer capable of conducting ions, wherein the branching degree of the hyperbranched polymer is bigger than 0.5, and the hyperbranched polymer and the organic polymer capable of conducting ions are dispersed in the solvent system.

Owner:IND TECH RES INST

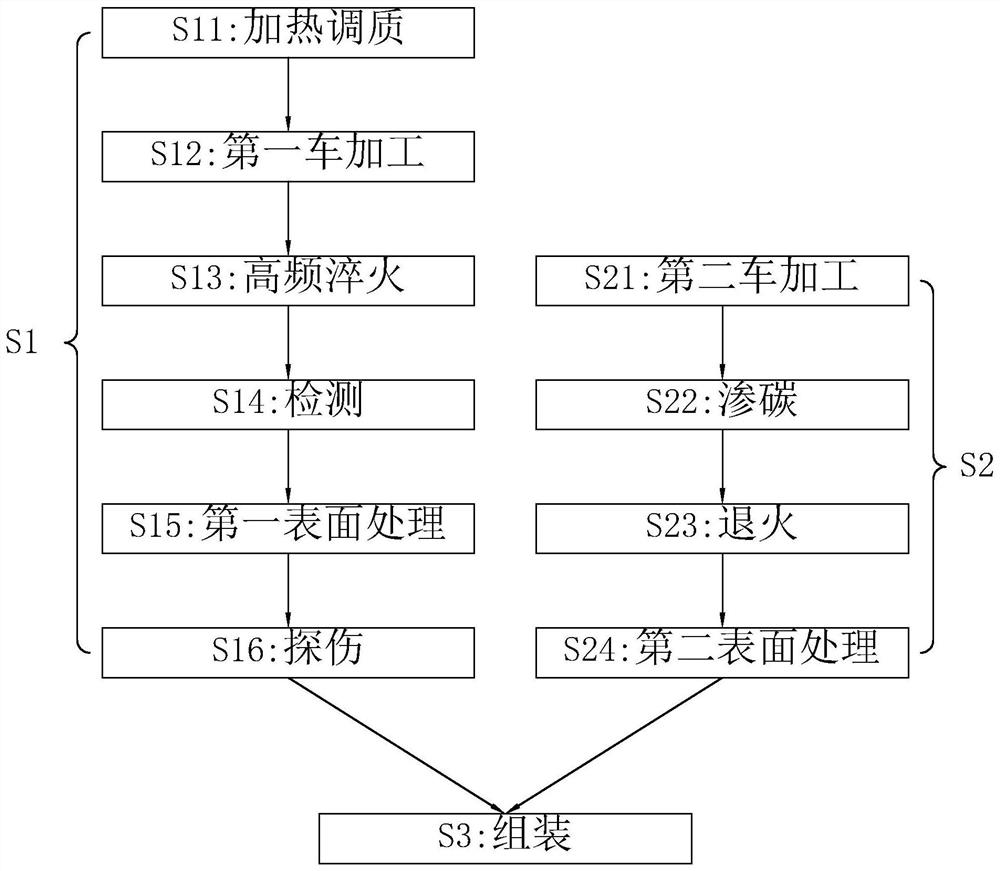

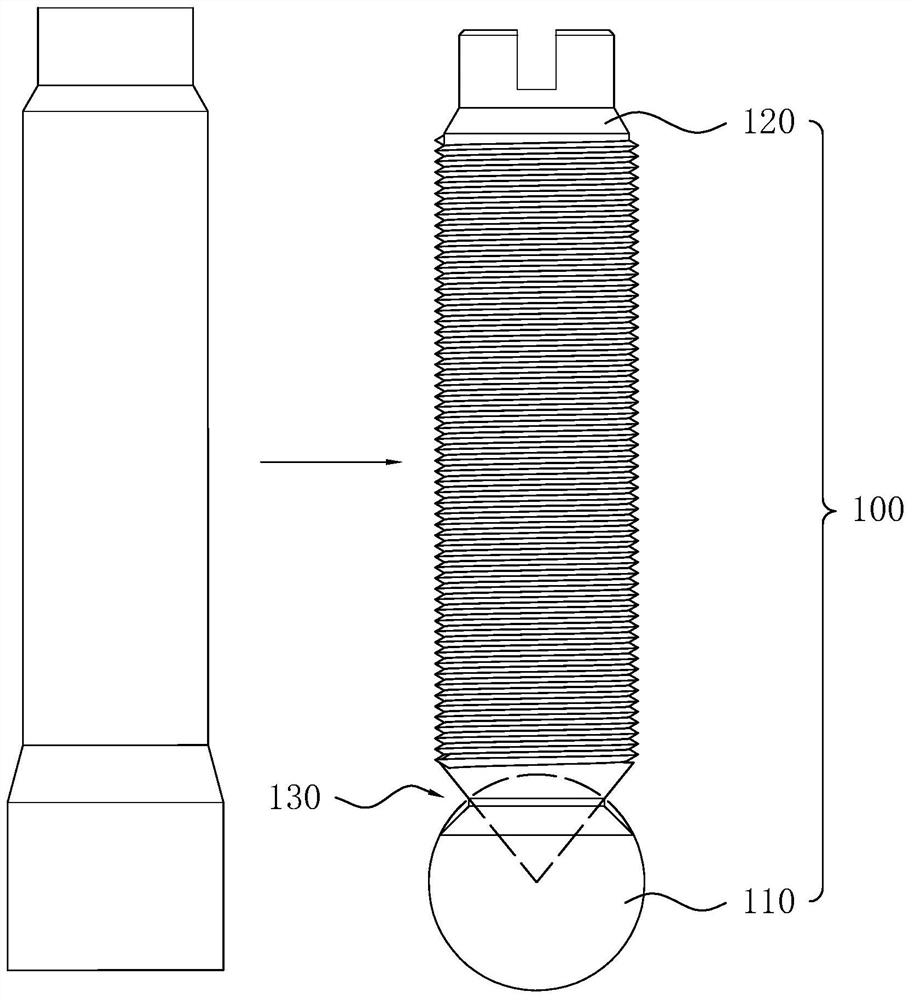

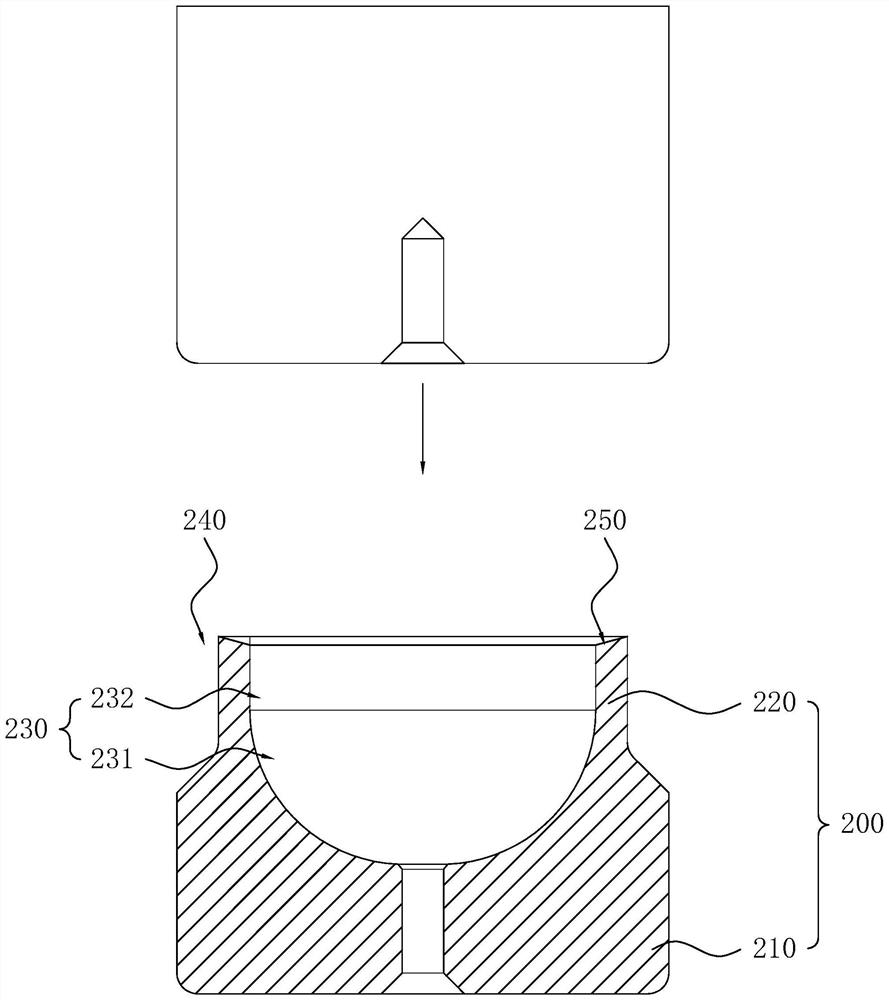

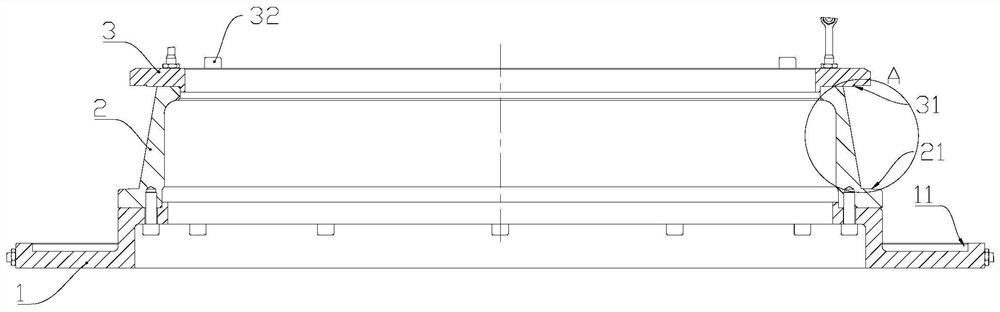

Machining process of ball head assembly

ActiveCN113494517AHigh surface hardnessReduce deformation rateBearing assemblyShaft assemblyEngineeringMachining process

The invention relates to the technical field of ball head assembly machining, in particular to a machining process of a ball head assembly. The machining process comprises the steps of machining a ball head rod, machining a ball seat and assembling, and the step of machining the ball head rod further comprises a first turning step and a high-frequency quenching step; the first turning step: cutting the blank to enable the blank to form a rod body and a ball head; and the high-frequency quenching step: carrying out high-frequency quenching on the rod body and the ball head, wherein the surface hardness of the quenched rod body and ball head is not smaller than HRC58, and the surface decarburization phenomenon of the rod body and ball head is not allowed. The surface hardness of the ball head rod can be improved, the probability of deformation of the ball head is reduced, and the probability that the ball head falls off from the ball groove to cause failure of the ball head assembly is reduced; and moreover, the ball head is not easy to rub and deform in the ball groove, so that the friction force of the ball head in the ball groove is reduced, the universal rotation of the ball head in the ball groove is facilitated, and the service life of the ball head assembly is prolonged.

Owner:EXCELLENT FASTENING SYST SHANGHAI

A kind of shape-calibrating tooling and shape-calibrating and glue-pouring method of annular thin-walled parts

ActiveCN110756623BGuaranteed dimensional accuracyQuality assuranceMetal-working apparatusDomestic articlesEngineeringMechanical engineering

Owner:AECC AERO SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com