Cable with circulating heat dissipation function

A technology of circulating heat dissipation and function, applied in the direction of insulated cables, cables, circuits, etc., can solve problems such as fire, loss of life and property, and untimely heat dissipation, and achieve the effect of maintaining stability, improving use safety, and avoiding high temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

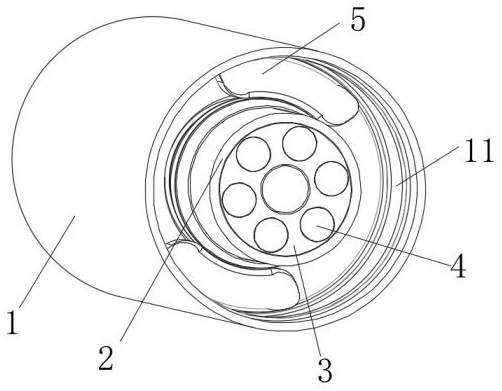

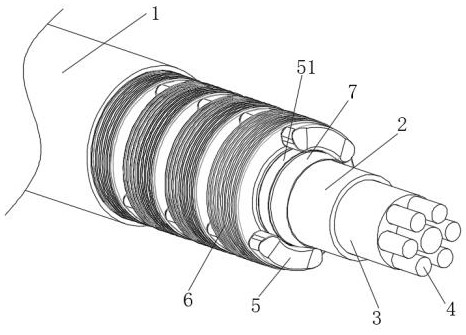

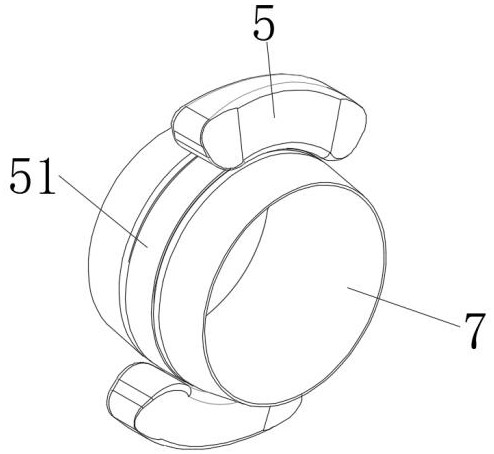

[0042] see Figure 1-10 , a cable with the function of circulating heat dissipation, including a core 4, a thermally conductive filling layer 3, an inner sheath 2, and an outer sheath 1 are arranged on the outer side of the core 4 in sequence, and the outer wall of the inner sheath 2 is equidistantly bonded with a number of thermally conductive Ring 7, the heat conduction ring 7 is arranged between the inner sheath 2 and the outer sheath 1, the outer circumference of the heat conduction ring 7 is provided with a slip ring 51, the heat conduction ring 7 is provided with a chute 72 matching the slip ring 51, and the slip ring Two cooling blocks 5 are fixed on the outside of the circumference of 51, and the two cooling blocks 5 are arranged in a rotationally symmetrical manner. There is an airtight compartment 53 inside the cooling block 5, and the inner wall of the airtight compartment 53 near the core 4 is provided with an arc-shaped concave surface, which is airtight. The inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com