A kind of multi-layer composite material used for thermal diffusion of vapor chamber and its preparation method

A multi-layer composite material and thermal diffusion technology, which is applied in the direction of modification using liquid cooling, heat treatment equipment, chemical instruments and methods, etc. Good heat dissipation effect, simple and fast production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

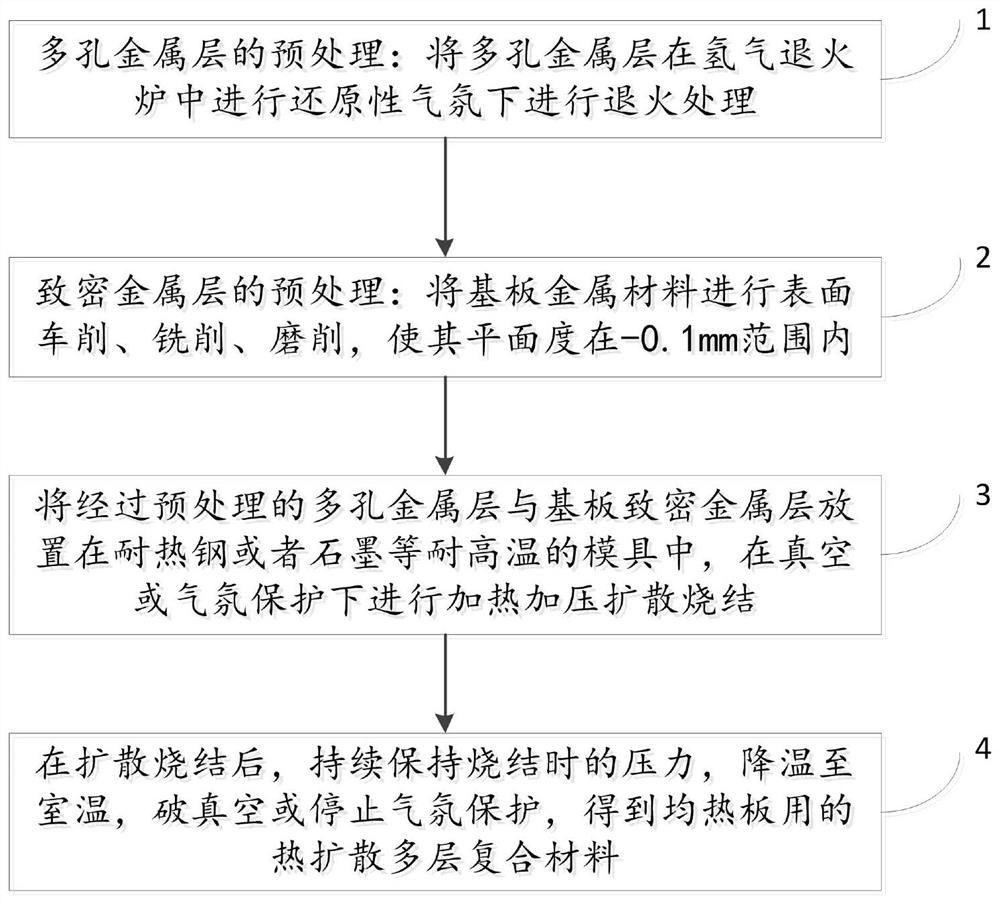

[0031] Such as image 3 As shown, the present invention also provides a method for preparing a multilayer composite material for thermal diffusion of a thermal plate, including:

[0032] Step 1, pretreatment of the porous metal layer: A porous metal layer is annealed under a reducing atmosphere in a hydrogen annealing furnace;

[0033] Step 2, the pretreatment of the dense metal layer: the substrate metal material is surface turning, milling, grinding, and the plane is in the range of -0.1 mm;

[0034] Step 3, the pre-treated porous metal layer and the substrate dense metal layer are placed in a high-temperature resistant to high temperature resistant steel or graphite or the like, and the heating and pressurization is carried out under vacuum or atmosphere protection;

[0035] Step 4, after the diffusion is sintered, the pressure at the time of sintering, cooling to room temperature, breaks vacuum or stopping the atmosphere protection, to obtain a multilayer composite material fo...

Embodiment 1

[0043] A multi-layer composite material for thermally diffusion of thermally diffusing is produced by a multi-hole metal nickel and a grade 5A05.

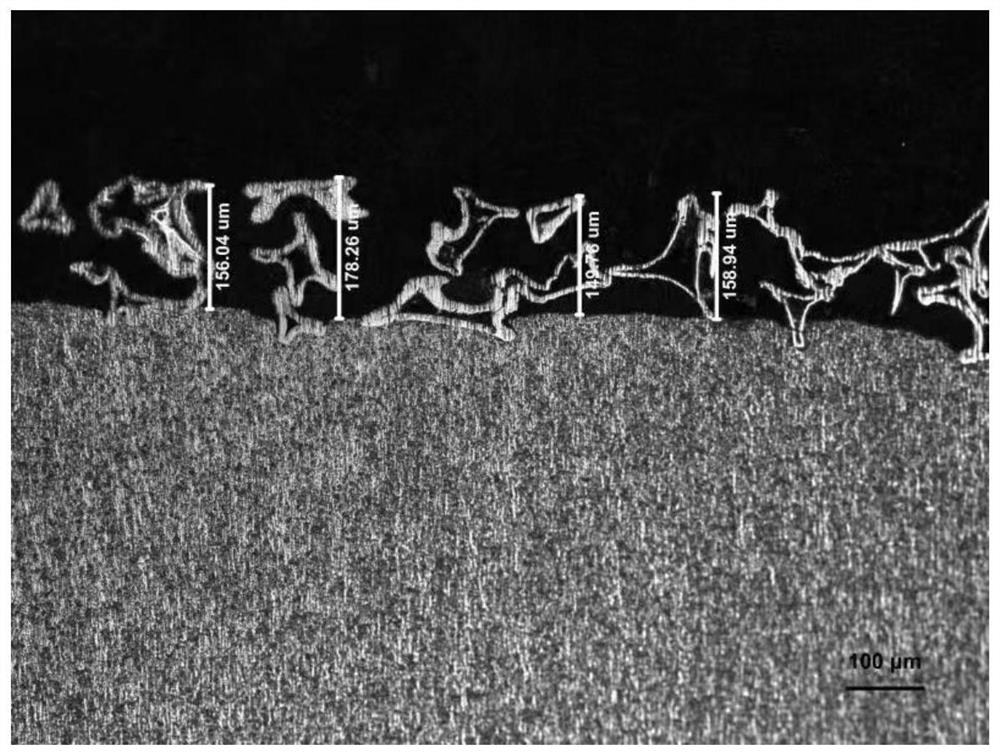

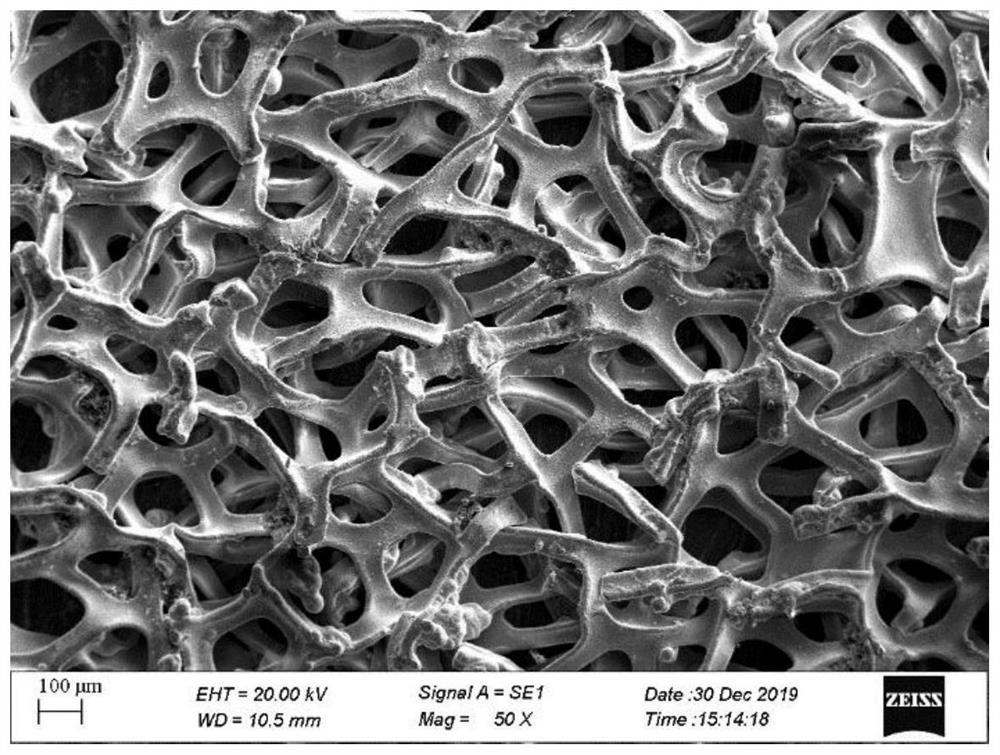

[0044] Step 1, pretreatment of the porous metal layer: Annealed porous metal nickel in the hydrogen furnace, wherein the porous metal nickel thickness is 0.1 mm to 0.5 mm, the porosity is 85% ~ 95%, the pore size is 50 μm ~ 200 μm, and the pore is all The through hole, the hole and the holes are completely connected; the annealing temperature is 600 ° C ~ 700 ° C, the annealing time is 60 ± 5 min;

[0045] Step 2, the pretreatment of the dense metal layer: the aluminum alloy sheet of 5A05 is surface turning and grinding, ensuring that the plane is in the range of -0.1mm, clean, has a fresh metal surface, and can not have oil, water Pollutants such as stains, dust;

[0046] Step 3, placing the pretreated porous metal nickel with a dense 5A05 aluminum alloy plate in a vacuum furnace, is fixed by graphite mold, and the two materials stack...

Embodiment 2

[0050] A multi-layer composite material for thermal diffusion for thermally diffusion of thermally diffusing is produced by a porous metal copper and a grade 6063.

[0051] Step 1, pretreatment of the porous metal layer: Annealed porous metal copper in a hydrogen furnace, wherein the porous metal copper thickness is 0.2mm to 1 mm, the porosity is 70% to 90%, the pore size is 100 μm ~ 500 μm, and all the pores are all The hole, the hole and the hole are completely connected; the annealing temperature is 500 ° C ~ 600 ° C, the annealing time is 80 to 90 min;

[0052] Step 2, the pretreatment of the dense metal layer: the aluminum alloy sheet having a grade 6063 is surface turning and grinding, ensuring that the plane is in the range of -0.1mm, the surface is clean, with a fresh metal surface, can not have oil, water Pollutants such as stains, dust;

[0053] Step 3, placing the pre-treated porous metal copper with a dense 6063 aluminum alloy plate in a vacuum furnace, is fixed with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com