Area light source device and method for making same

A surface light source and light source technology, which is applied in the direction of light source, electric light source, lighting device, etc., can solve the problems of easy cracking due to heat, large area, flammability, etc., so as not to expand and deform, improve low transmittance, and reduce brightness loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

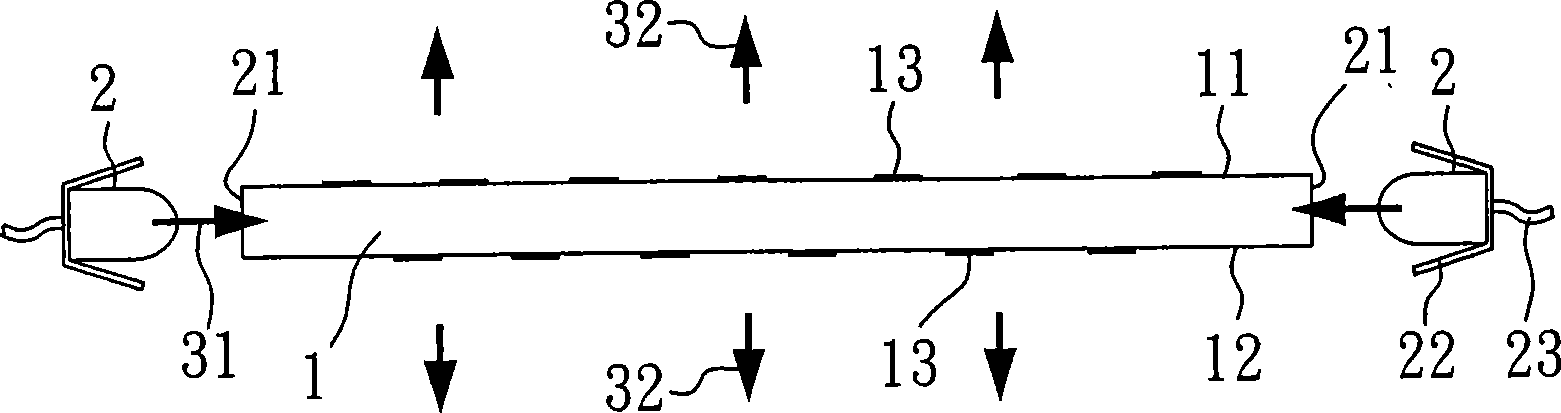

[0053] see image 3 , which is the surface light source device of the first embodiment, including an ultra-clear glass light guide plate 1 and two side-illuminated LED light sources 2 . Wherein, the ultra clear glass light guide plate 1 has a first surface 11 , a second surface 12 opposite to the first surface 11 , and two light incident surfaces 21 perpendicular to the first surface 11 and the second surface 12 . The ultra-clear glass light guide plate 1 has a light guide pattern 13 with white paint dots arranged on the first surface 11 and the second surface 12 . The two side-illuminated LED light sources 2 respectively have a lampshade 22 and a circuit control system 23 , and are arranged on the light incident surface 21 of the glass light guide plate 1 . And emit an incident light 31 into the ultra clear glass light guide plate 1 , and finally emit an outgoing light 32 from the first surface 11 and the second surface 12 .

[0054] In this embodiment, both the first surfa...

Embodiment 2

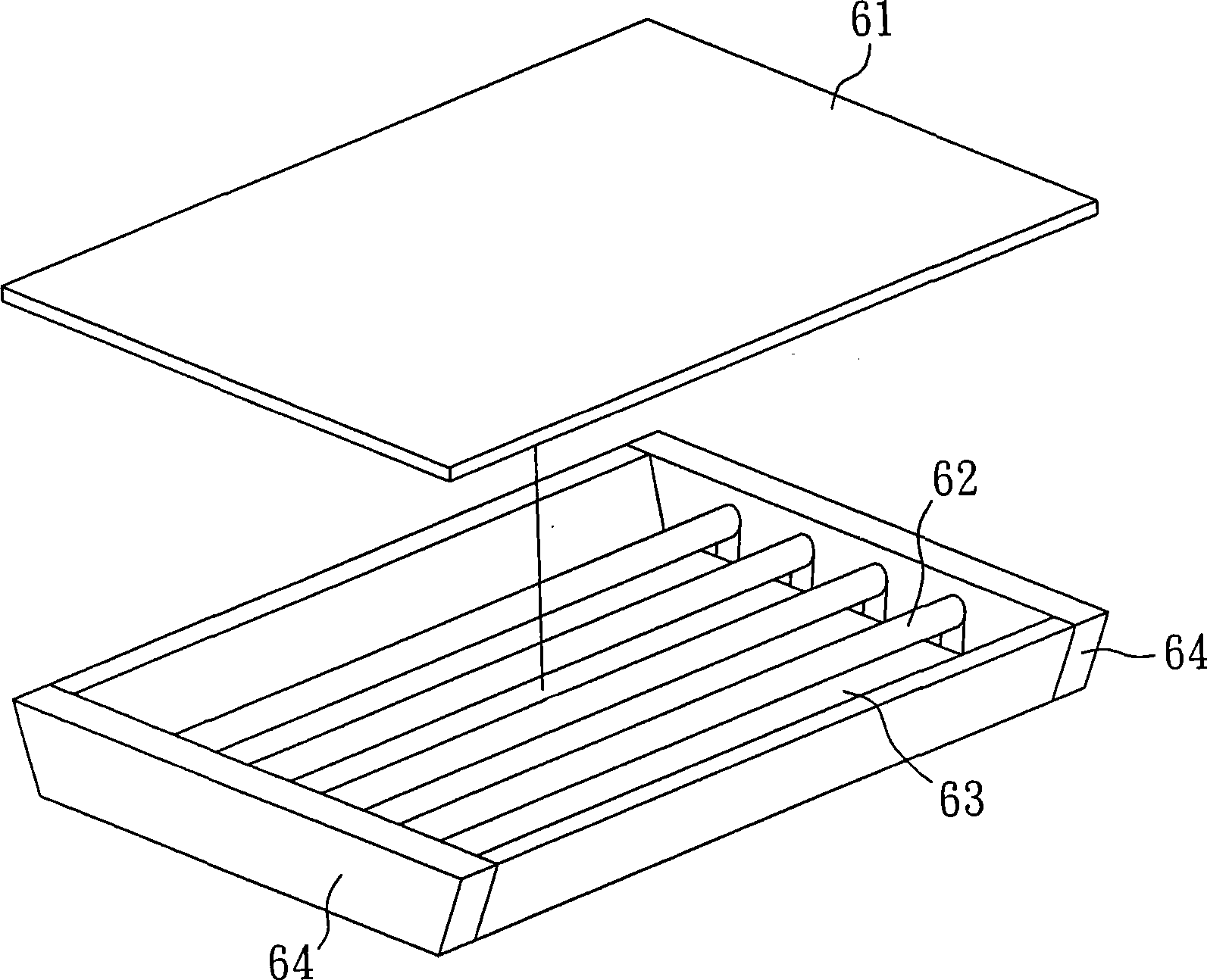

[0056] see Figure 4 , which is the surface light source device of the second embodiment, like the first embodiment, including an ultra-clear glass light guide plate 1 and two side-illuminated LED light sources 2 . The difference is that in the second embodiment, the first surface 11 has an etched dot pattern 15 , and the second surface 12 has a metal coating layer 14 . After the incident light 31 enters the ultra-clear glass light guide plate 1 from the incident surface 21 , it is reflected by the metal coating layer 14 so that the light only exits from the first surface 11 to increase the light quantity of the outgoing light 32 .

Embodiment 3

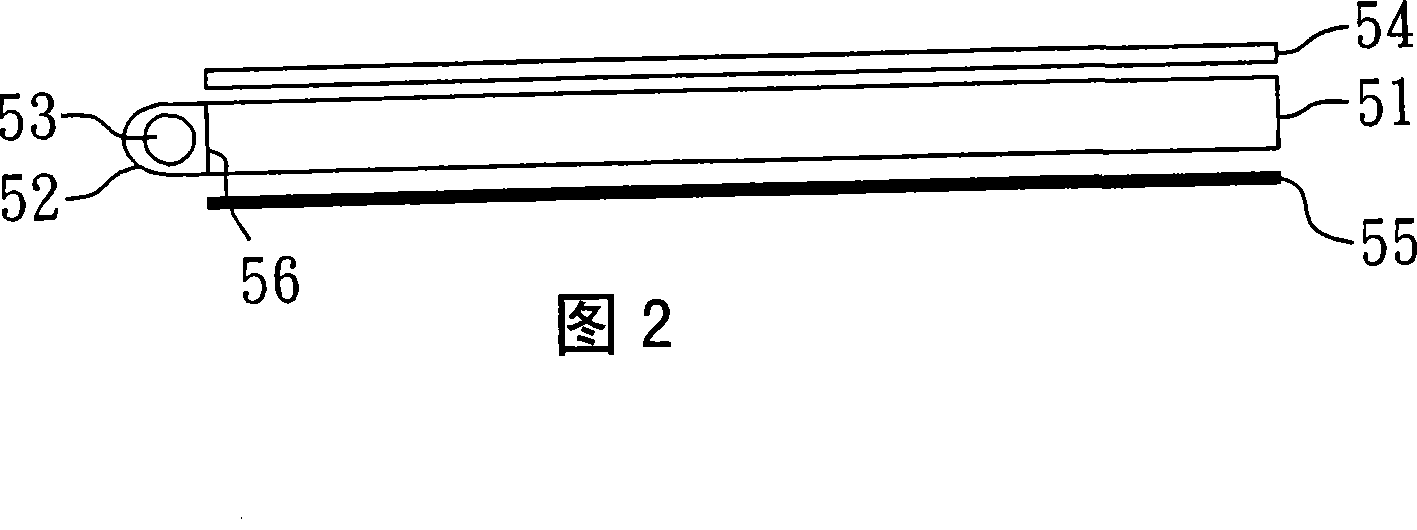

[0058] see Figure 5 , which is the surface light source device of the third embodiment, including an ultra-clear glass light guide plate 1 and a side-illuminated LED light source 2 . Wherein, the first surface 11 of the ultra-clear glass light guide plate 1 does not have any pattern, and the second surface 12 has a light guide pattern 13 laid with white paint and a metal coating layer 14 . After the side-illuminated LED light source 2 emits incident light 31 , the incident light 31 enters the ultra-clear glass light guide plate 1 through the incident surface 21 , and then exits from the first surface 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com