High voltage LED and production technology thereof

A manufacturing process and high-voltage technology, applied in electrical components, electric solid-state devices, circuits, etc., can solve problems such as brightness loss, and achieve the effect of reducing brightness loss and improving brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] 1. Production process:

[0020] 1. The N-GaN layer, the quantum well layer and the P-GaN layer are sequentially grown on the same side of the sapphire substrate;

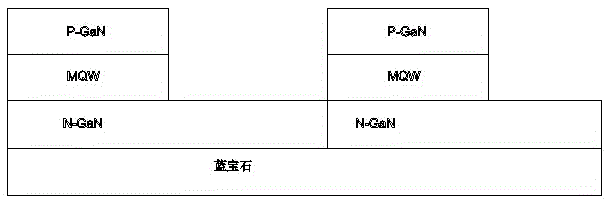

[0021] 2. In the yellow light lithography process, the P-GaN layer and part of the quantum well layer of each cell are etched and removed in a patterned manner by using induction couple and plasma (ICP), until the N-GaN layer is exposed, and the etching depth is about 10,000 ?~16000?, such as figure 2 shown.

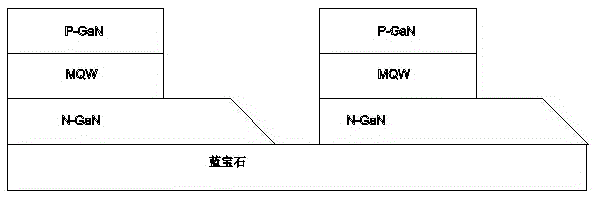

[0022] 3. On the basis of the N-GaN layer, use a thick photoresist with high resolution, and continue to use the etching induction couple and plasma (ICP) to adjust the ratio of etching gases BCl3 and Cl2, remove part of the N-GaN layer, etch The depth of etching is about 50000?~60000? until a part of the substrate is exposed to form a positive trapezoid with a side angle of about 130°~160°, such as image 3 shown.

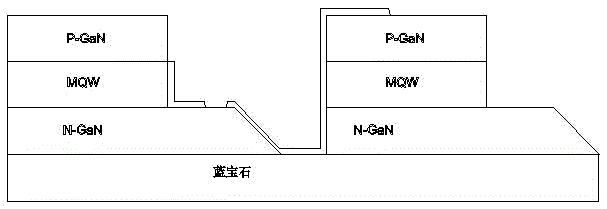

[0023] 4. Evaporate a DBR layer with a thickness of about 3000~7000? The substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com