Machining process of ball head assembly

A processing technology and assembly technology, which is applied in the processing technology field of ball head assemblies, can solve problems such as ball head component failure and ball head falling off, and achieve the effects of reducing friction, facilitating universal rotation, and not easy to knead and deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

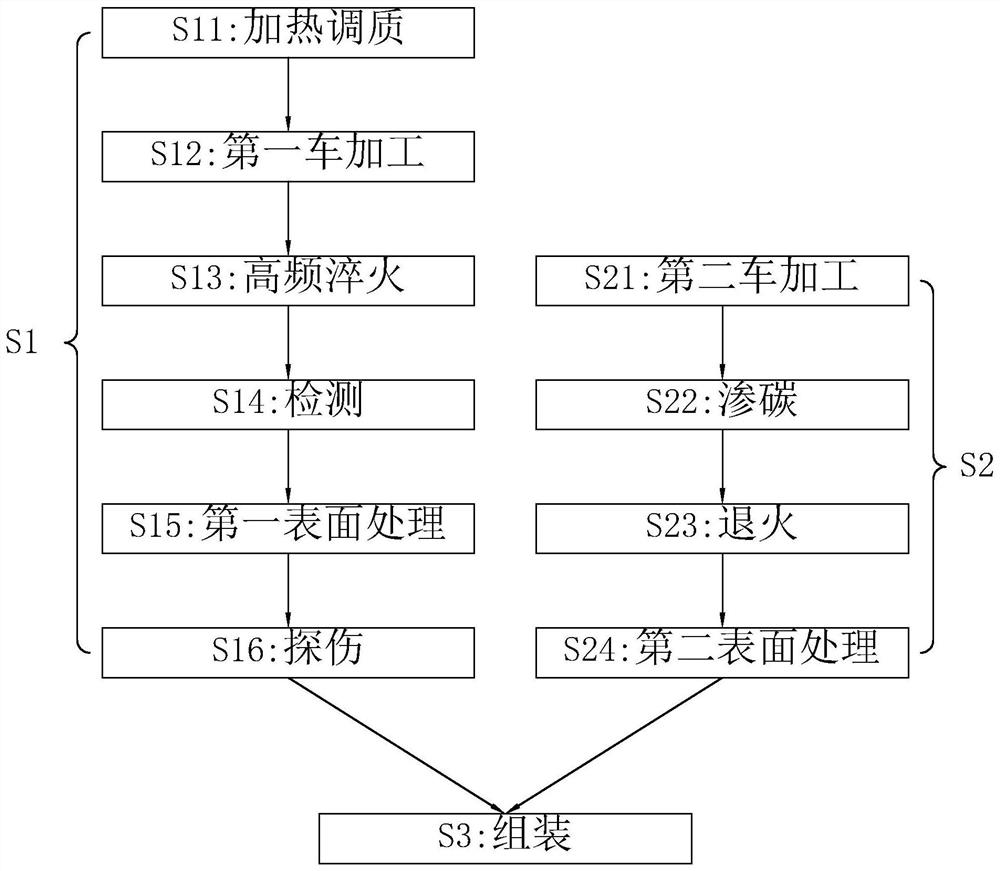

[0048] The following is attached Figure 1-4 The present invention is described in further detail.

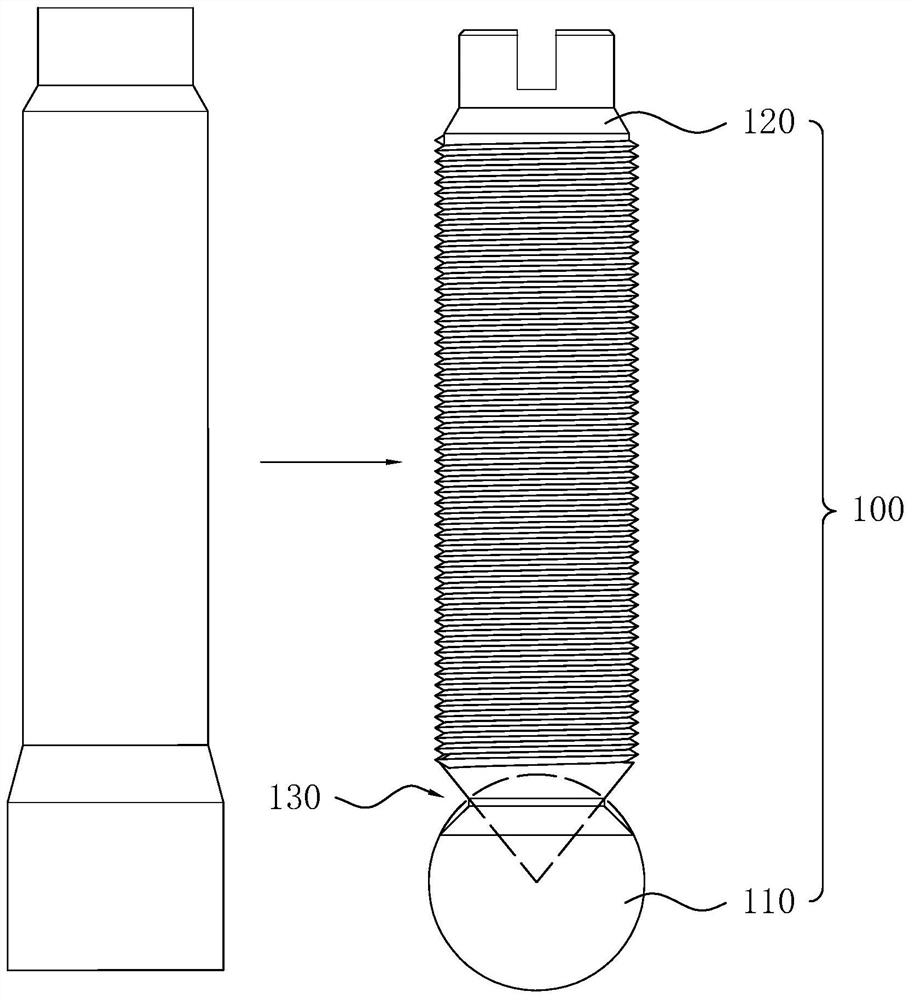

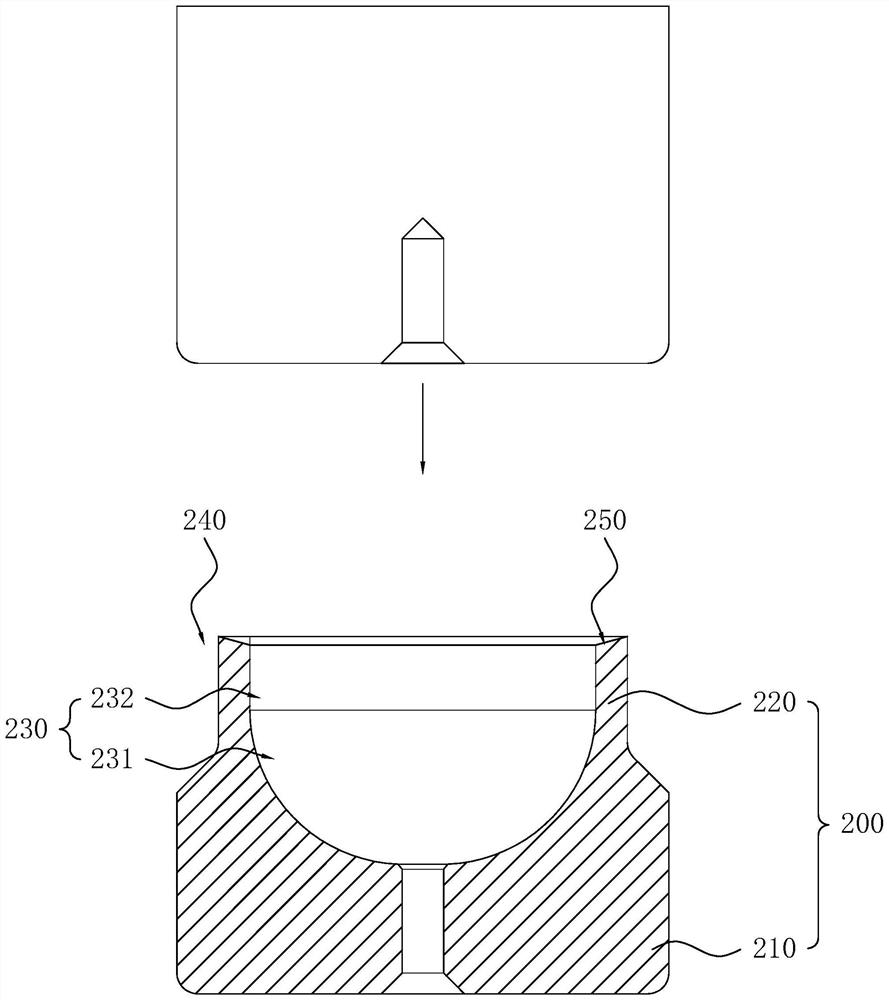

[0049] The embodiment of the present application discloses a processing technology of a ball head assembly. refer to figure 1 , the processing technology of the ball head assembly includes S1: the step of processing the ball head 100, S2: the step of processing the ball seat 200 and S3: the step of assembling; in the step of S1: processing the ball head 100, the blank is processed into The ball head rod 100 with the rod body 120 and the ball head 110; in S2: in the step of processing the ball seat 200, the blank is processed into the ball seat 200 with the ball groove 230; in S3: in the assembly step, the ball head rod 100 The ball head 110 is placed in the ball groove 230, and then the outer peripheral surface of the end of the ball seat 200 close to the ball groove 230 is squeezed, so that the end of the ball seat 200 close to the ball groove 230 shrinks toward the axis of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com