Slow cooling sand box for lost foam casting

A technology of lost foam casting and slow cooling, which is used in casting molding equipment, molds, mold boxes, etc., can solve the problems of excessive cooling, discharge, and inapplicability of castings, and achieve the effect of fast cooling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings.

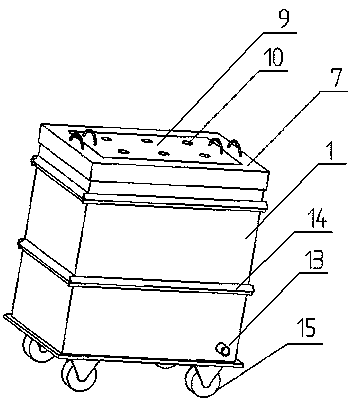

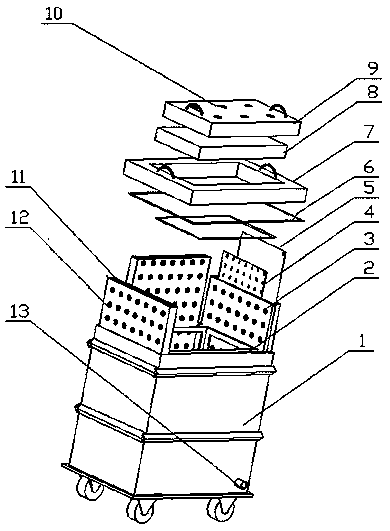

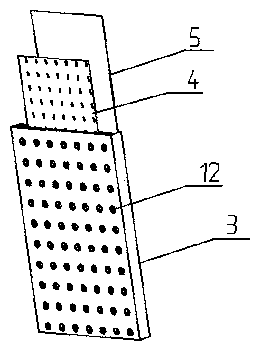

[0028] The reference signs in the drawings of the description include: box body 1, air pumping chamber 2, partition plate 3, gauze layer 4, insulation cotton layer 5, sealing ring 6, box cover 7, cover body insulation cotton 8, inner cover 9 , air vent 10, interlayer 11, through hole 12, air extraction pipe 13, stiffening beam 14, universal wheel 15.

[0029] The slow cooling sand box for lost foam casting in this specific embodiment, such as figure 1 , figure 2 and image 3 As shown, it includes a box body 1 in a rectangular parallelepiped shape. The upper part of the box body 1 is opened and covered by a box cover 7. The box body 1 is provided with four end-to-end partitions that match the shape of the inner cavity of the box body 1. 3. The partition 3 is vertically attached to the inner wall of the box body 1, and the bottom of the box body 1 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com