Distribution isolation switch on-line monitoring system for kiln

An isolation switch and monitoring system technology, applied in the direction of using electrical devices, electromagnetic means, electrical radiation detectors, etc., can solve the problem that the isolation switch cannot provide comprehensive fault information, etc., and achieves low expansion and deformation, low cost, and enhanced wear resistance. damaging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

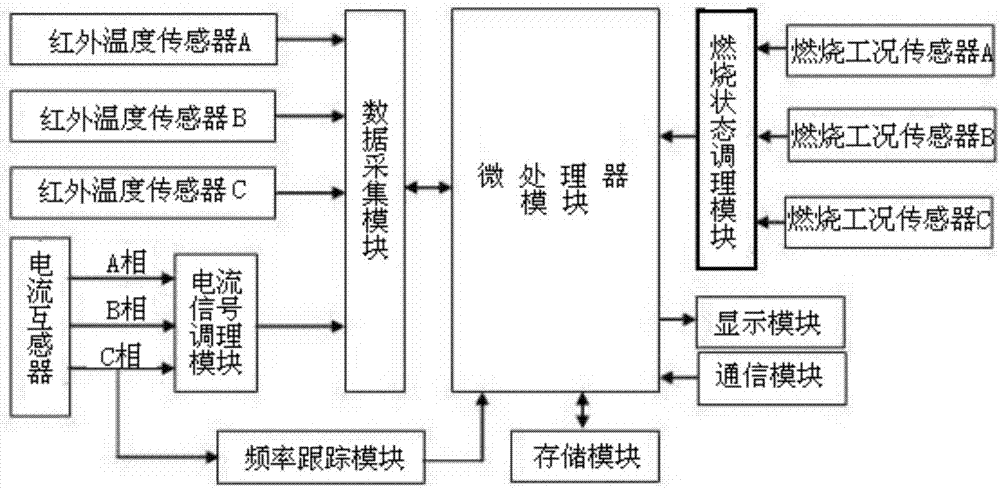

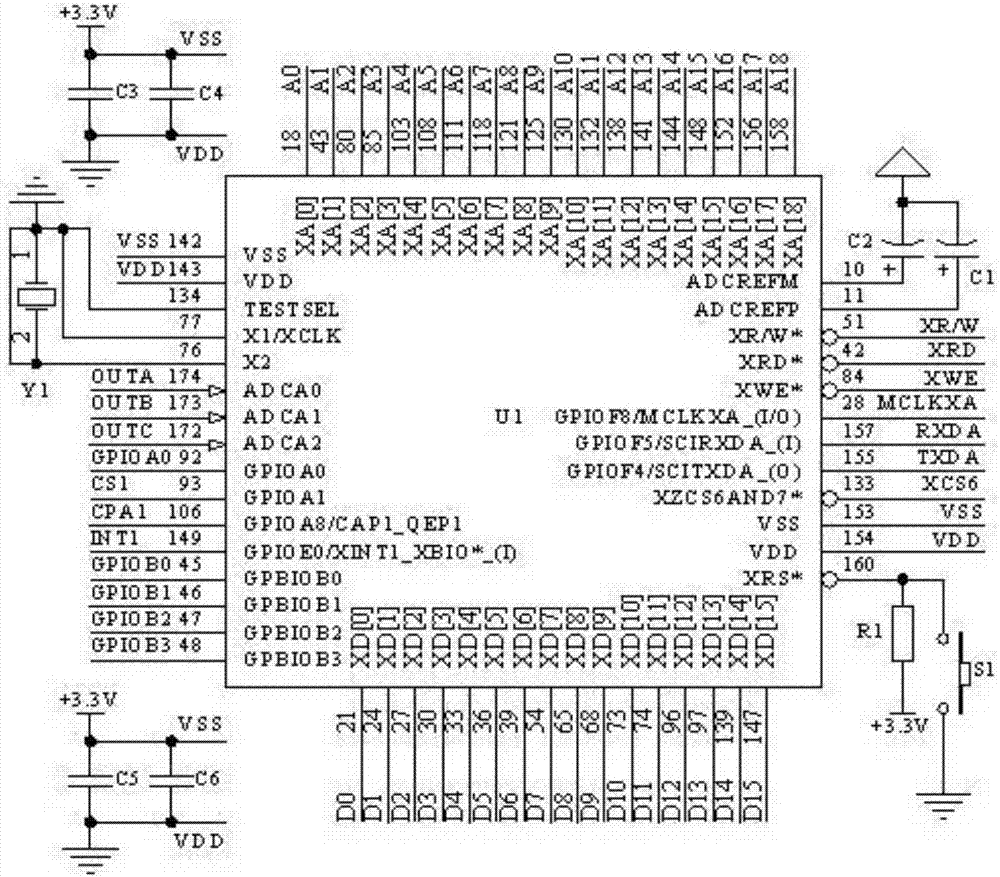

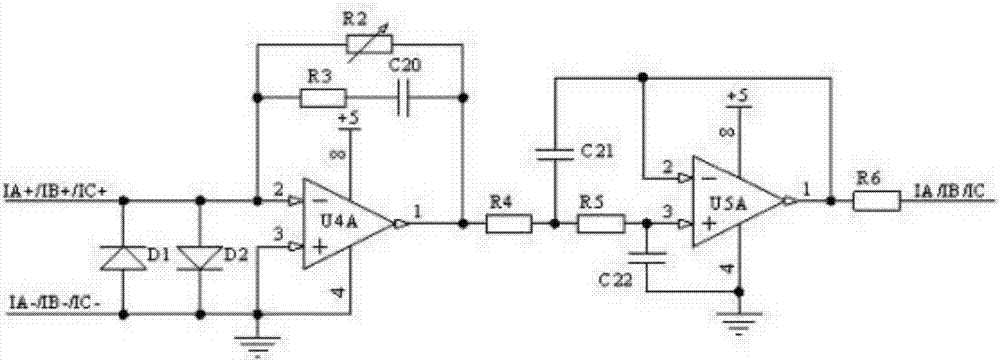

[0031] Such as figure 1As shown, an on-line monitoring system for power distribution isolating switches for kilns consists of a three-phase current transformer, three combustion condition sensors, three infrared temperature sensors, a current signal conditioning module, a combustion state conditioning module, a frequency tracking module, It consists of a data acquisition module, a microprocessor module, a data storage module, a communication module and a display module. The infrared temperature sensor obtains the temperature rise signal of the isolating switch contact, the current transformer obtains the current signal flowing through the isolating switch,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com