Long short-term memory networks-based gear hobbing quality online evaluation method

A long-short-term memory and gear hobbing technology, which is applied in the field of CNC gear hobbing machine tool processing, can solve problems such as low efficiency, and achieve the effects of high efficiency, high precision and improved accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

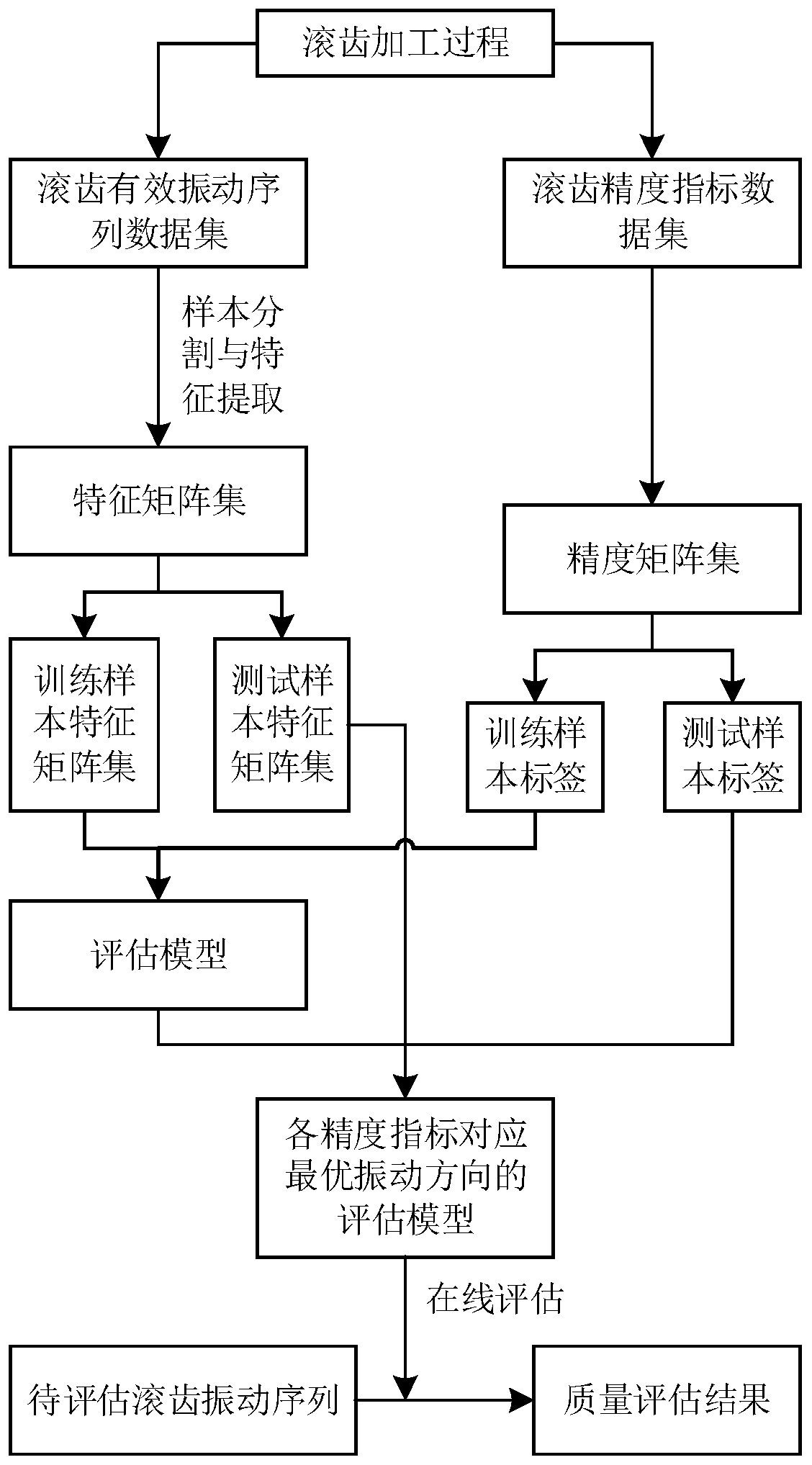

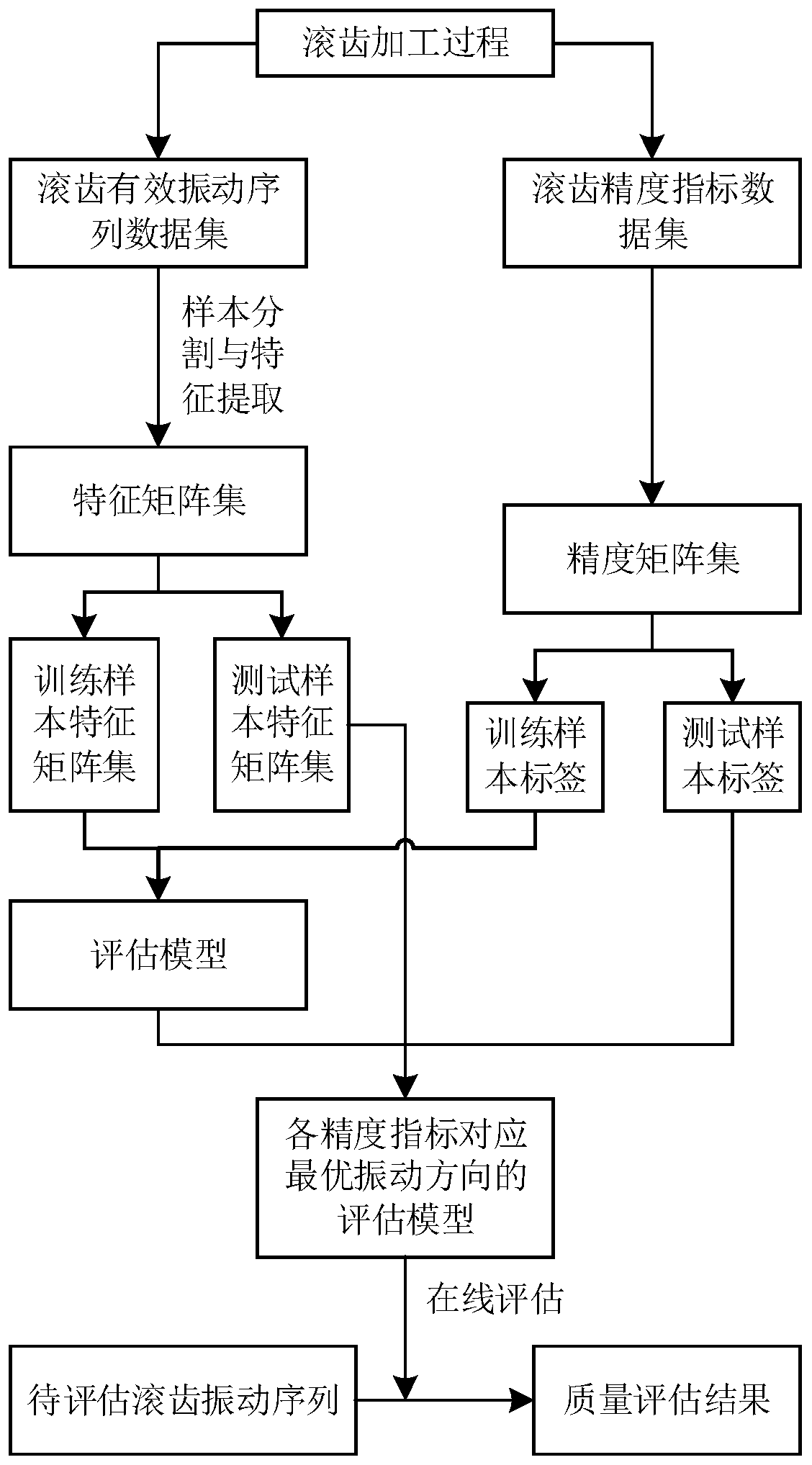

[0028] The flow chart of the online evaluation method of gear hobbing quality based on the long short-term memory network of the present invention is as follows: figure 1 shown, including the following steps:

[0029] Step S1: During the gear hobbing process, the vibration acceleration signals in three directions perpendicular to each other of the hob are collected, the effective processing time is determined according to the feed rate and the tooth thickness, and the effective vibration sequence of the gear is intercepted according to the effective processing time, and the processing The completed gears are tested for accuracy to obtain accuracy indicators, which include but are not limited to the total error of the tooth shape and the total error of the tooth direction.

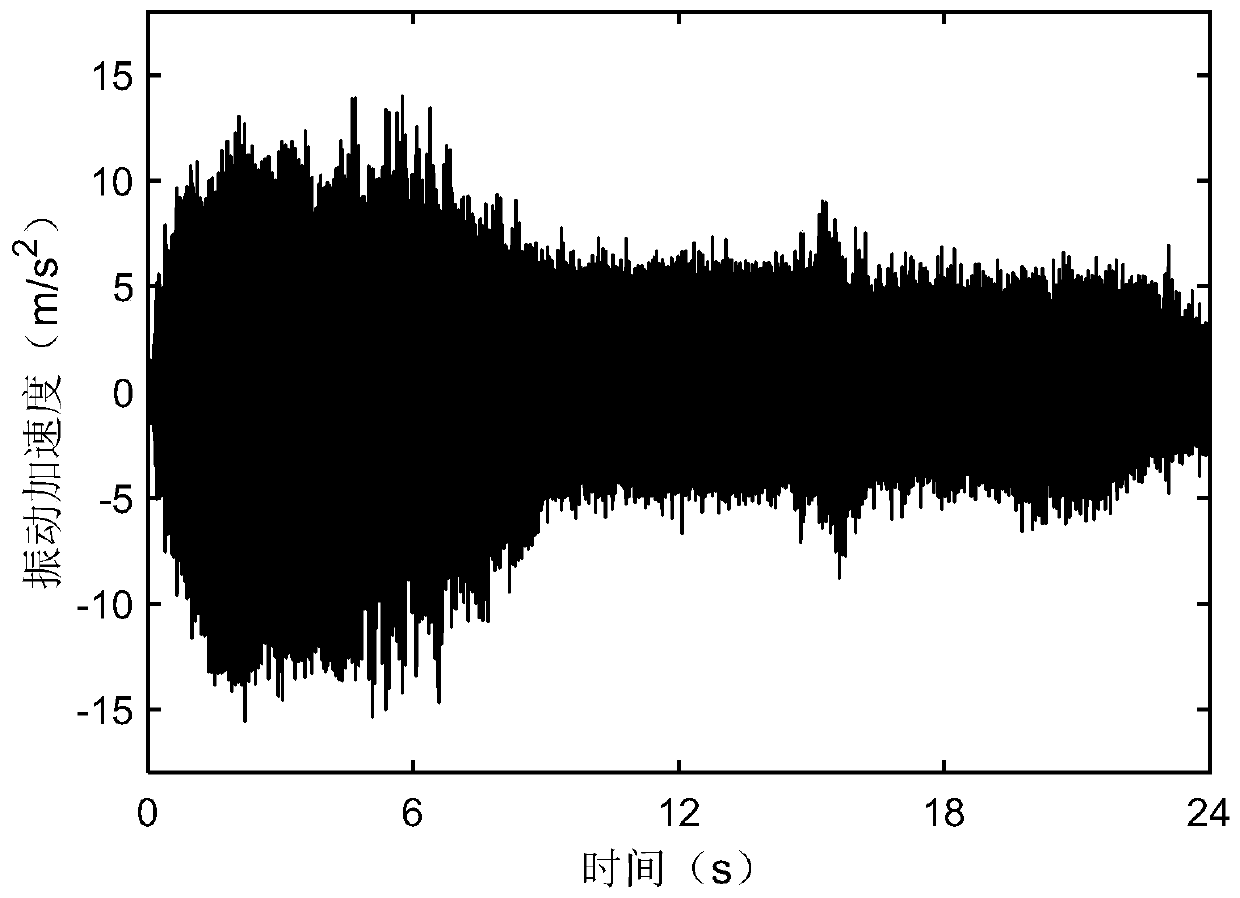

[0030] The effective vibration sequence of a gear in one direction is as figure 2 As shown, in this embodiment, the processed gear is a straight tooth, the modulus is 3mm, the number of teeth is 42, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com