Lead-acid storage battery with square winding structure and manufacturing method of lead-acid storage battery

A lead-acid battery, square technology, applied in the direction of lead-acid battery, lead-acid battery construction, secondary battery manufacturing, etc., can solve the problems of inconsistent current, reduced space utilization, shortened life, etc., to achieve strong corrosion resistance and flexibility The effect of increasing the specific surface area of the electrode and increasing the specific energy by weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

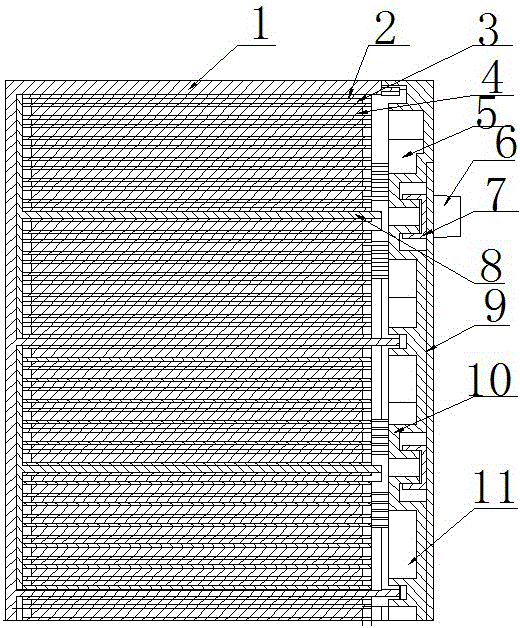

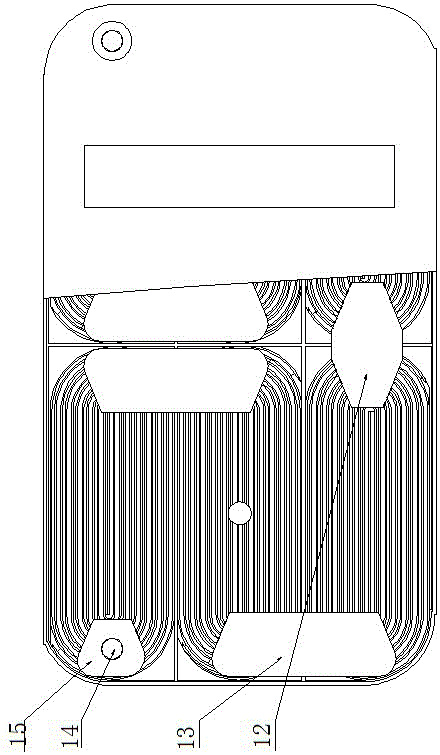

[0042] Such as figure 1 Shown: a lead-acid battery with a square winding structure, including a battery tank 1, a battery cover 10, a positive terminal 6 and a negative terminal 14, the terminal 6 and 14 are located at both ends of the battery cover 10, the battery cover 10 A vent valve 7 and a valve cover 9 are arranged on the top, and the positive pole terminal 6 and the negative pole terminal 14 are respectively inwardly connected with the positive pole bus bar 5 and the negative pole bus bar 15, and the battery tank 1 is also provided with a positive pole plate 4, a negative pole plate 3, Core plate 8, diaphragm 2.

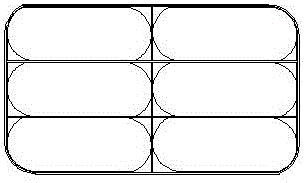

[0043] figure 2 The positive plate 4, the diaphragm 2, the negative plate 3 and the core plate 8 constitute the battery core of the single battery, and the diaphragm 2 has two pieces, which ensure that the positive plate 4 and the negative plate 3 are always isolated during the winding process, and The tabs of the positive plate and the tabs of the negative...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com