Annular thin-walled part shape correcting tool and shape correcting and rubber pouring method

A thin-walled part, shape correction technology, applied in the field of glue filling of parts, can solve the problems of difficult cleaning and shape correction of glue filling equipment, and achieve the effect of uniform internal structure of the colloid, reducing surface damage, and not easy to expand and deform.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

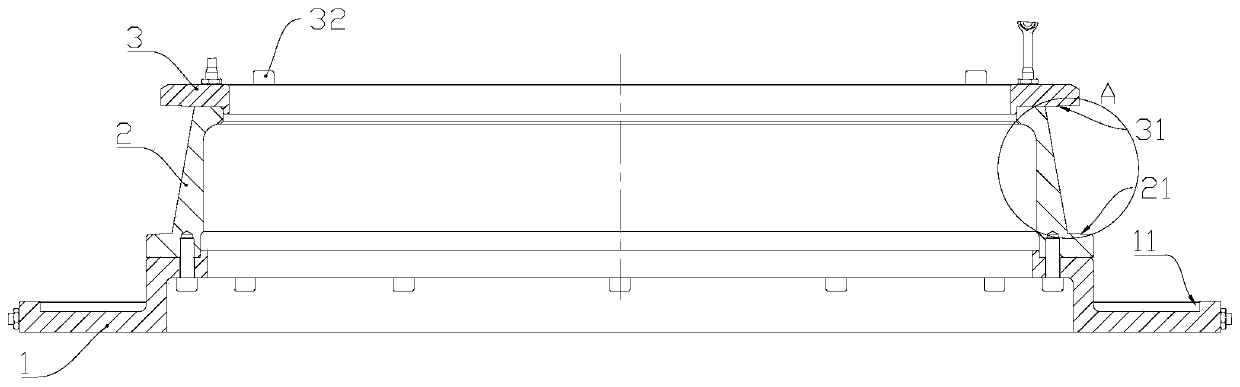

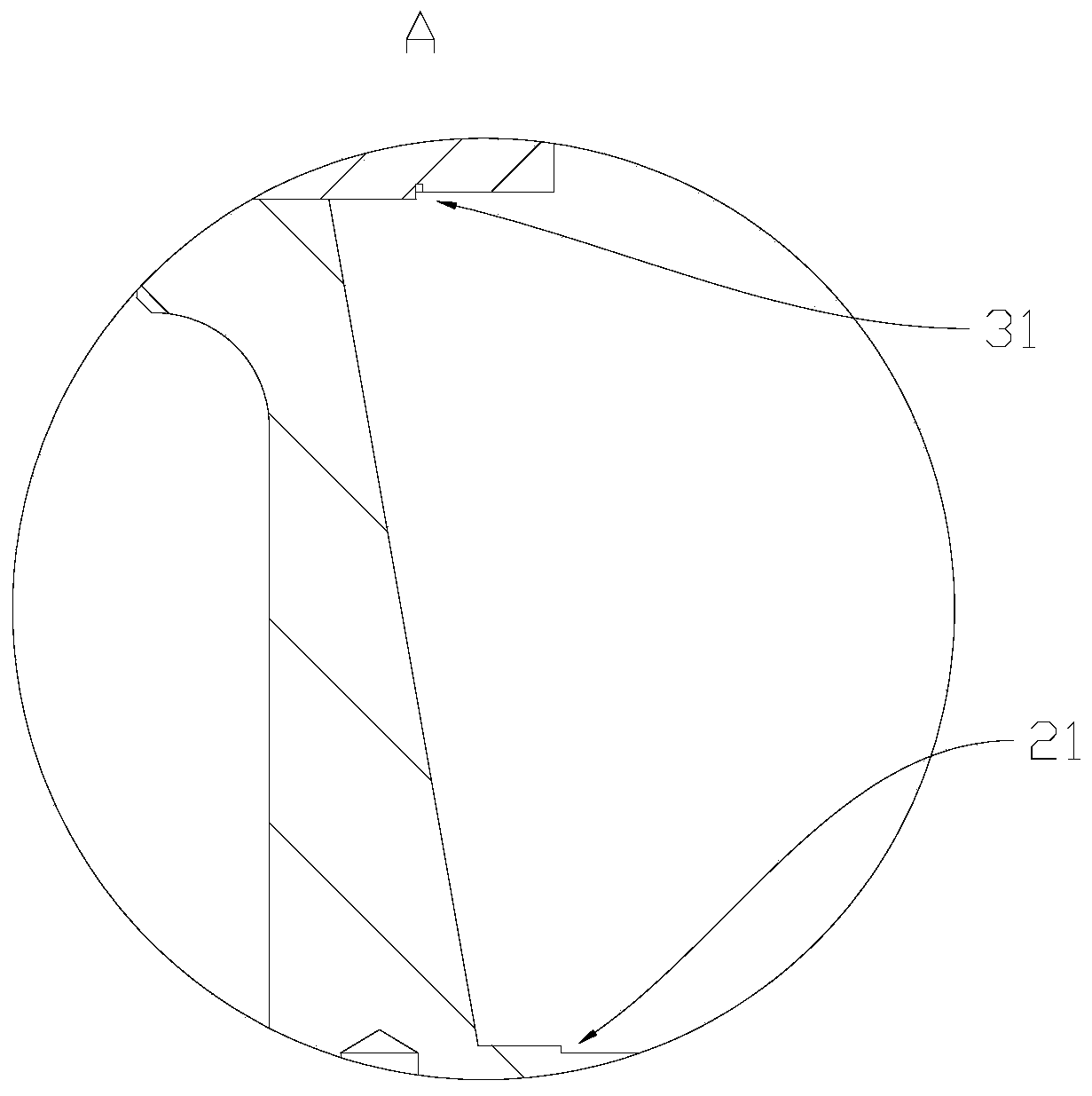

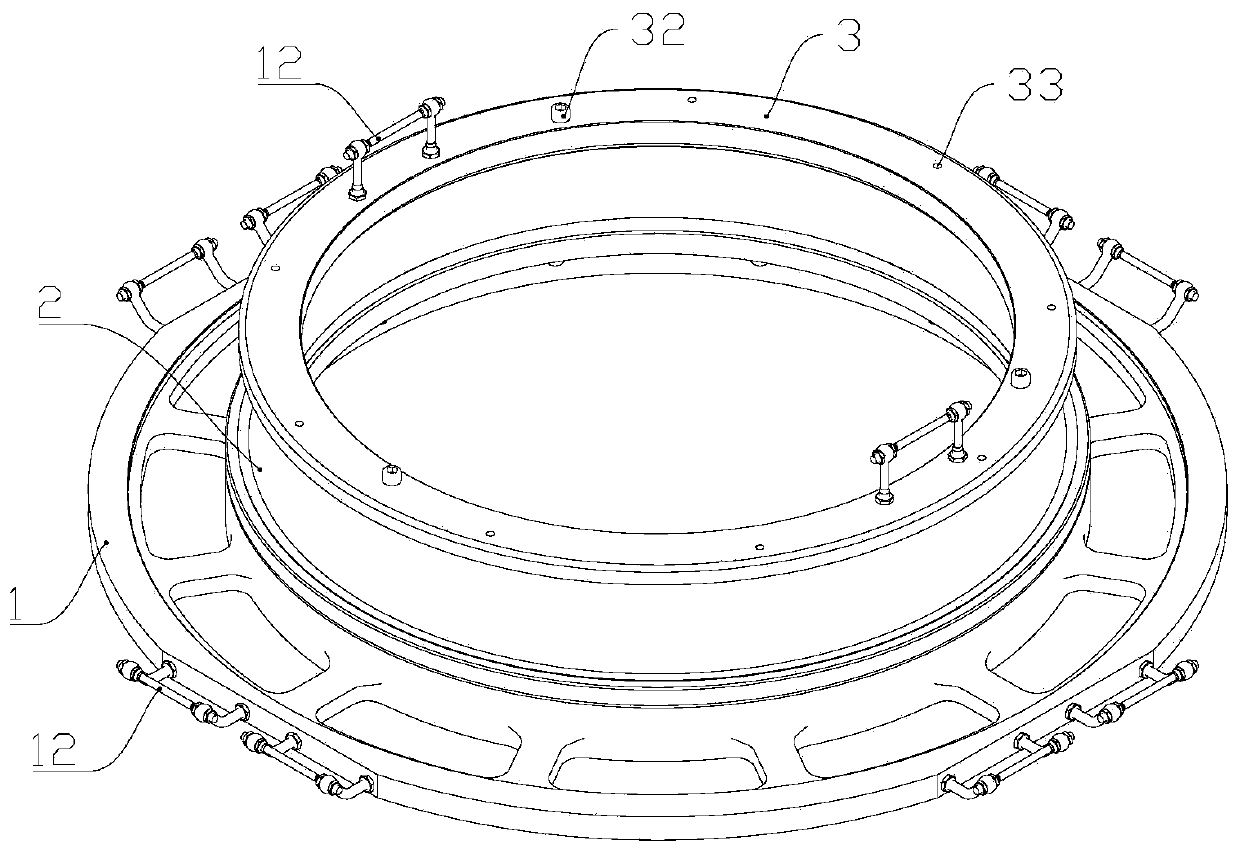

[0044] refer to figure 1 , an annular thin-walled part shape correction tool, comprising: a base 1, a positioning seat 2 and a positioning cover 3, the base 1 and the positioning cover 3 are respectively detachably arranged at both ends of the positioning seat 2, the base 1 and the positioning seat 2 is a cylindrical structure of a rotating body, and the positioning cover plate 3 is an annular plate-shaped structure, refer to figure 2 The bottom surface of the positioning cover plate 3 is provided with a first positioning female notch 31, the base 1, the positioning seat 2 and the positioning cover plate 3 are concentrically arranged, and the bottom ends of the base 1 and the positioning seat 2 are provided with outwardly protruding outer edges, refer to figure 2 , the outer edge of the positioning seat 2 is provided with a second positioning female notch 21, refer to figure 1, the outer edge of the base 1 is provided with a third positioning female notch 11, the positioni...

Embodiment 2

[0061] The difference between this embodiment and Embodiment 1 is that in step c of the glue liquid vacuum defoaming of the annular thin-walled part shape correction and glue pouring method, the vacuum defoaming pressure is 4.5KPa, the vacuum defoaming time is 20min, and the degassing 3 times; in step e curing and shaping, place the parts filled with glue at room temperature for 14 hours, and then heat and cure. The curing temperature is 100°C and the curing time is 1.3 hours.

Embodiment 3

[0063] The difference between this embodiment and Embodiment 1 and Embodiment 2 is that in step c of the glue solution vacuum defoaming in the shape correction of the annular thin-walled parts and the glue pouring method, the vacuum defoaming pressure is 4KPa, and the vacuum defoaming time is 25min , degassing 4 times; in step e curing and shaping, place the filled parts at room temperature for 15 hours, and then heat and cure. The curing temperature is 105°C and the curing time is 1 hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com