Asbestos-free straw fiber reinforced cement board and preparation method thereof

A technology of straw fiber and cement board, which is applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of reduced wood output, lack of wood resources, shortage and other problems, and achieve good water retention and adsorption, uniform fiber dispersion, and broom rate. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

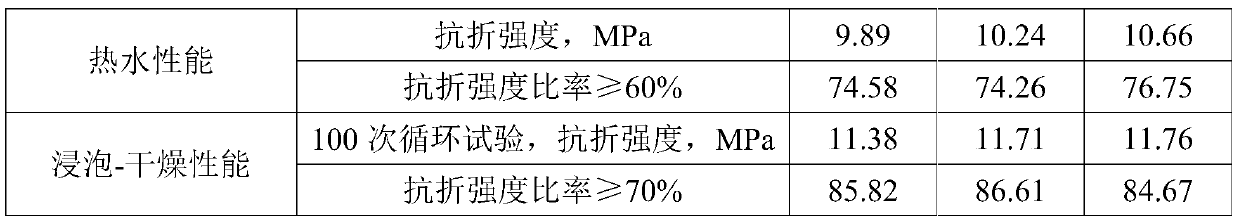

Embodiment 1

[0039] The non-asbestos straw fiber reinforced cement board of this embodiment is mainly made of the following raw materials in parts by weight:

[0040] 6.5 parts of modified wheat straw fiber, 5.5 parts of silica fume, 52 parts of cement, 10 parts of metakaolin, 21 parts of quartz sand, and 5 parts of fly ash.

[0041] The preparation method of the non-asbestos straw fiber reinforced cement board of the present embodiment comprises the following steps:

[0042] 1) Cut the dry wheat straw into short pieces with a length of 20-40 mm, soak them in water for 12 hours at room temperature to soften them, take them out and drain them until the dripping water no longer flows down in strands, to obtain the preparation material;

[0043] 2) Place the preparatory material obtained in step 1) in a steam explosion device for steam explosion. The steam temperature is 175° C., the explosion pressure is 2.8 MPa, the pressure holding time is 4.5 minutes, and then the pressure is released to ...

Embodiment 2

[0049] The non-asbestos straw fiber reinforced cement board of this embodiment is mainly made of the following raw materials in parts by weight:

[0050] 7 parts of modified wheat straw fiber, 6 parts of silica fume, 50 parts of cement, 11 parts of metakaolin, 20 parts of quartz sand, and 6 parts of fly ash.

[0051] The preparation method of the non-asbestos straw fiber reinforced cement board of the present embodiment comprises the following steps:

[0052] 1) Cut the dry wheat straw into a short material with a length of 20-40 mm, soak it in clean water for 14 hours at room temperature to soften it, take it out and drain until the dripping water no longer flows down in strands, and obtain the prepared material;

[0053] 2) Place the preparatory material obtained in step 1) in a steam explosion device for steam explosion. The steam temperature is 180° C., the explosion pressure is 2.4 MPa, the pressure holding time is 5.0 min, and the pressure is released to obtain the explo...

Embodiment 3

[0059] The non-asbestos straw fiber reinforced cement board of this embodiment is mainly made of the following raw materials in parts by weight:

[0060] 7.5 parts of modified wheat straw fiber, 5 parts of silica fume, 48 parts of cement, 12 parts of metakaolin, 22 parts of quartz sand, and 5.5 parts of fly ash.

[0061] The preparation method of the non-asbestos straw fiber reinforced cement board of the present embodiment comprises the following steps:

[0062] 1) Cut the dry wheat straw into short pieces with a length of 20-40mm. Under room temperature, first soak it in water for 16 hours to soften it, then soak it in a sodium hydroxide solution with a mass concentration of 3.0% for 20 minutes, take it out and drain until no water drips. Then it flows down in streams, and the material has to be prepared;

[0063] 2) Put the prepared material obtained in step 1) into a steam explosion device for steam explosion, the steam temperature is 180°C, the explosion pressure is 2.6M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com