Alginic acid inorganic nanometer composite gel microspheres and preparation method

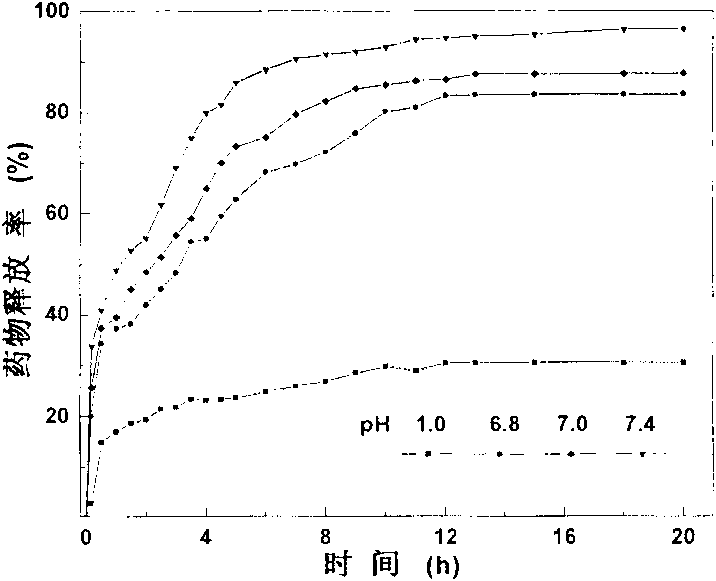

An inorganic nano-composite gel technology, applied in the preparation of microspheres, microcapsule preparations, pharmaceutical formulations, etc., can solve the problems of low mechanical strength and high water absorption, and achieve the effect of promoting sustained release and safe preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Sodium alginate is added to distilled water, mechanically stirred at room temperature of 20° C. and configured into a sodium alginate solution with a mass concentration of 2%, and then single-walled carbon nanotubes and quantitative EPE are added to distilled water. Stir evenly at room temperature at 20°C, set the power of ultrasonic dispersion to 100W, and the frequency of ultrasonic waves to 40 kHz. After ultrasonic dispersion for 20 minutes, the dispersion is obtained. Finally, the dispersion is centrifuged at 8000rpm for 10 minutes to remove solid precipitation and obtain the mass concentration. 2% carbon nanotube suspension solution;

[0033] 2) According to the volume ratio of the sodium alginate solution and the carbon nanotube suspension solution as 1:1, mix the sodium alginate solution and the carbon nanotube suspension solution, and stir to obtain a carbon nanotube sodium alginate mixed solution. At this time, the sodium alginate The mass percentage account...

Embodiment 2

[0038] The volume ratio of the sodium alginate solution and the carbon nanotube suspension solution is 3:1 to replace the volume ratio of the sodium alginate solution and the carbon nanotube suspension solution in Example 1 to be 1:1 with the volume ratio of the sodium alginate solution and the carbon nanotube suspension solution. The mass percentage of the total mass of sodium, carbon nanotubes and EPE is 75%; at the same time, multi-walled carbon nanotubes are used; other steps are the same as in Example 1.

[0039] The alginic acid inorganic nanocomposite gel microspheres prepared in this example have the following components and their mass percentages: 1.5% alginic acid, 0.5% carbon nanotubes, triblock surfactant polyethylene oxide-polymer Propylene oxide-polyethylene oxide 0.5%, the balance is water.

[0040] By increasing the mass fraction of sodium alginate in the solution, the structure of the prepared alginate gel microspheres is tighter, and the mechanical strength i...

Embodiment 3

[0042]1) Add potassium alginate to distilled water, and mechanically stir at room temperature to form a potassium alginate solution with a mass concentration of 6%; Stir evenly at high temperature, and ultrasonically disperse to obtain a dispersion; the dispersion is centrifuged at 8000 rpm for 10 minutes to remove solid precipitates, and a carbon nanotube suspension solution with a mass concentration of 10% is obtained;

[0043] 2) According to the volume ratio of potassium alginate solution and carbon nanotube suspension solution is 91:9, potassium alginate solution and carbon nanotube suspension solution are mixed, and now potassium alginate accounts for potassium alginate, carbon nanotube and EPE total The mass percentage of mass is 98%;

[0044] 3) Use a syringe with a 9# needle to drop the carbon nanotube potassium alginate mixture into a calcium chloride solution with a mass concentration of 10% to obtain an ion-crosslinked gel particle composited with alginate carbon n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com