Novel heat insulating plate and manufacturing method thereof

A thermal insulation board, a new type of technology, applied in the field of thermal insulation boards, can solve the problems of high thermal conductivity, low mechanical strength, and strong water absorption of expanded perlite thermal insulation boards, and achieve the effects of high thermal conductivity, low mechanical strength, and excellent fireproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

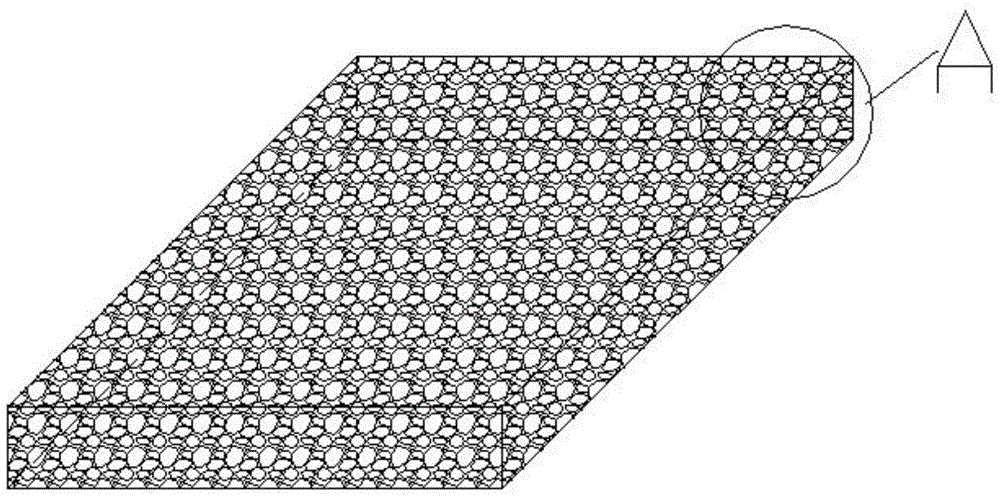

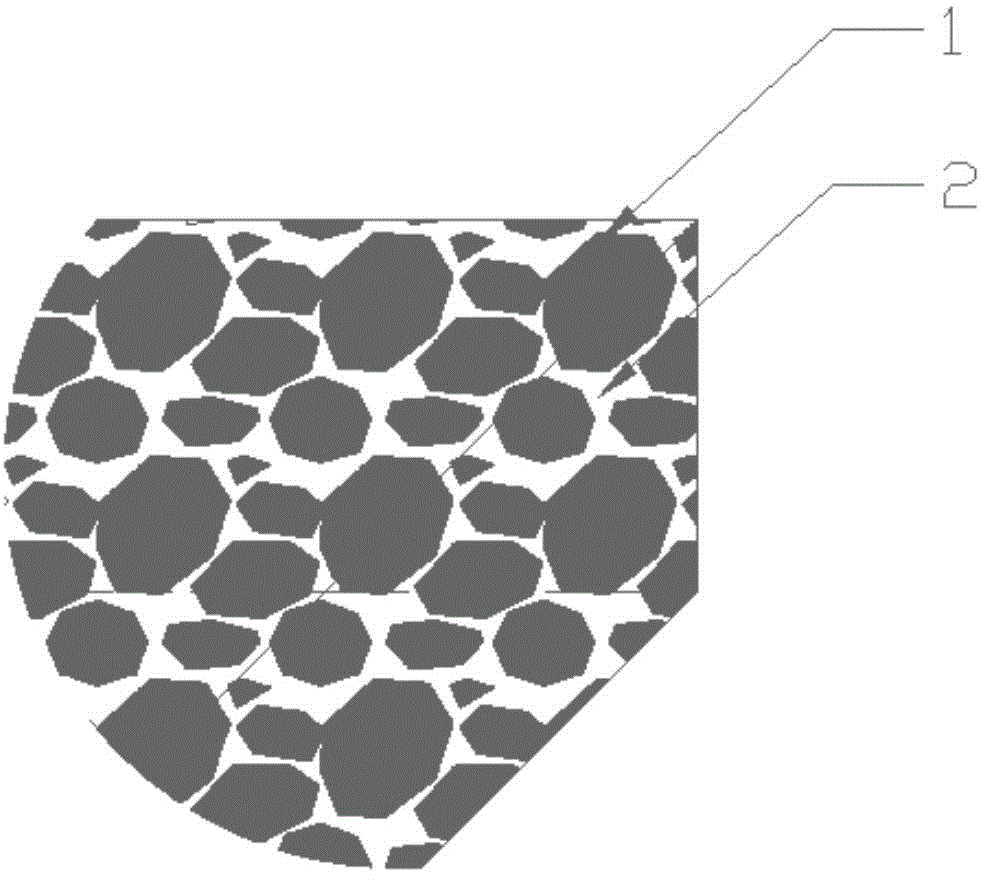

[0031] This embodiment provides a new type of insulation board, the structure of which is as follows: figure 1 and figure 2 As shown, it is prepared using the following raw materials:

[0032] Expanded perlite particles, 80kg;

[0033] Unsaturated phenolic resin, 10kg;

[0034] Modifier silane coupling agent, 0.2kg;

[0035] Silica powder, 0.4kg;

[0036] Foaming agent n-pentane, 0.1kg;

[0037] Curing agent hexamethylenetetramine, 0.5kg.

[0038] The novel insulation board is prepared by the following method:

[0039] (1) Take the organic coating film material, modifying agent, inorganic micropowder, foaming agent according to the above weight, and after diluting with 4kg of ethanol, the coating slurry is obtained;

[0040] (2) According to the above weight, the expanded perlite particles are added to the mixer together with the coating slurry described in step (1), the particle size of the expanded perlite particles is 0.2mm, and the porosity is 85%. Under stirring co...

Embodiment 2

[0043] This embodiment provides a novel insulation board, which is prepared from the following raw materials:

[0044] Vitrified microbeads, 90kg;

[0045] Polyurethane, 20kg;

[0046] Modifier stearic acid, 0.5kg;

[0047] Calcium carbonate, 3kg;

[0048] Foaming agent petroleum ether, 0.5kg;

[0049] Curing agent polyamide, 1kg.

[0050] The novel insulation board is prepared by the following method:

[0051] (1) Take the organic coating film material, modifying agent, inorganic micropowder, foaming agent according to the above weight, and after diluting with 4kg of ethanol, the coating slurry is obtained;

[0052] (2) Take the vitrified microbead particle according to the above weight and add it to the mixer together with the coating slurry described in step (1), the particle size of the vitrified microbead particle is 2.5mm, and the porosity is 80%. , making it fully mixed for 10 minutes under stirring conditions, so that each expanded perlite particle is evenly coat...

Embodiment 3

[0055] This embodiment provides a novel insulation board, which is prepared from the following raw materials:

[0056] The mixture of expanded perlite, vitrified microspheres, foam glass and ceramic microspheres in a mass ratio of 1:1:1:1, 95kg;

[0057] A mixture of polyurethane, polystyrene, epoxy resin, unsaturated phenolic resin, and urea-formaldehyde resin in a mass ratio of 1:1:1:1, 30kg;

[0058] The modifier is a mixture of silane coupling agent, titanate coupling agent, aluminate coupling agent, and stearic acid in a mass ratio of 1:1:1:1:1, 2kg;

[0059] A mixture of silica, calcium carbonate, silicon carbide, alumina, and graphite in a mass ratio of 1:1:1:1, 10kg;

[0060] Foaming agent n-heptane, 2kg;

[0061] The curing agent is a mixture composed of hexamethylenetetramine, p-phenylmethanesulfonic acid, aliphatic polyamine, and polyamide in a mass ratio of 1:1:1:1, 3kg.

[0062] The novel insulation board is prepared by the following method:

[0063] (1) Take ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com