Liquid colorant for coloring polyester fiber stock solution and preparation method thereof

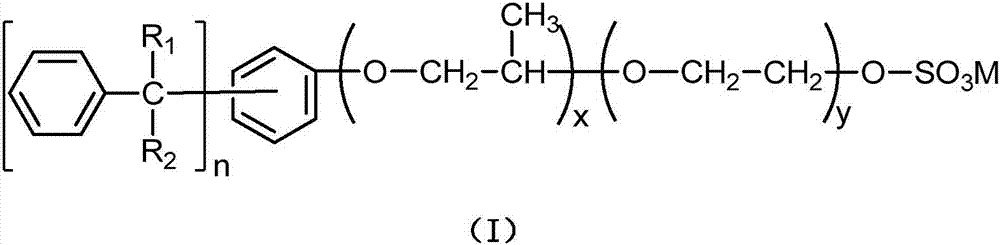

A technology of dope coloring and polyester fiber, which is applied in the direction of fiber chemical characteristics, adding pigments in spinning solution, single-component polyester artificial filament, etc. Low processing precision of pigments and other problems, to achieve the effect of reducing production process links, widening the selection range, and good coloring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific examples.

[0029] Preparation of liquid colorants:

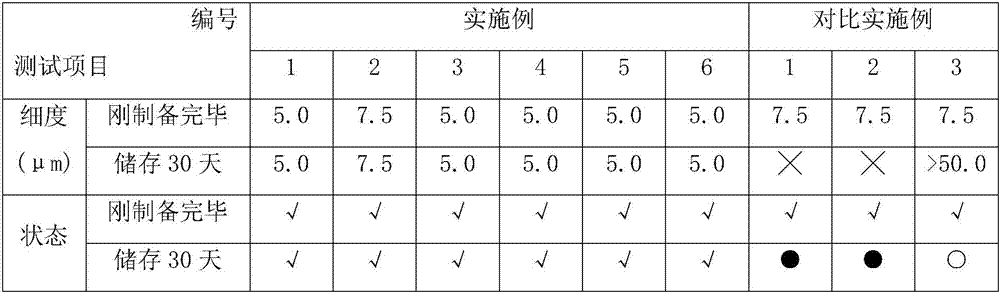

[0030] According to the dosage of each component given in Table 1, a liquid colorant was prepared. Its preparation process is as follows: 1) Add the dispersant in the prescribed amount into the liquid dispersion medium, stir evenly on a high-speed mixer at a speed of 800-3000 rpm, then add the pigment, and pre-disperse for 15-120 minutes to obtain a pre-dispersion , wherein, Examples 1 to 4 and Comparative Examples 1 to 3 were stirred at a speed of 1500 rpm and pre-dispersed for 60 minutes, Example 5 was stirred at a speed of 800 rpm and pre-dispersed for 120 minutes, and Example 6 was used Stir at a speed of 3000 rpm, and pre-disperse for 15 minutes; 2) Grind the pre-dispersion obtained in step 1 through a horizontal sand mill for 5-10 times to obtain a liquid dispersion, wherein Examples 1-4 and Comparative Examples 1-3 grinding 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com