Silicious expanding fire retardant and its prepn process

A technology of intumescent flame retardant and silane, applied in the field of silicon-containing intumescent flame retardant and its preparation, can solve the problems of application limitation of intumescent flame retardant, easy water absorption of phosphate compounds, etc., and achieve good flame retardant performance, heat Good stability and not easy to absorb water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

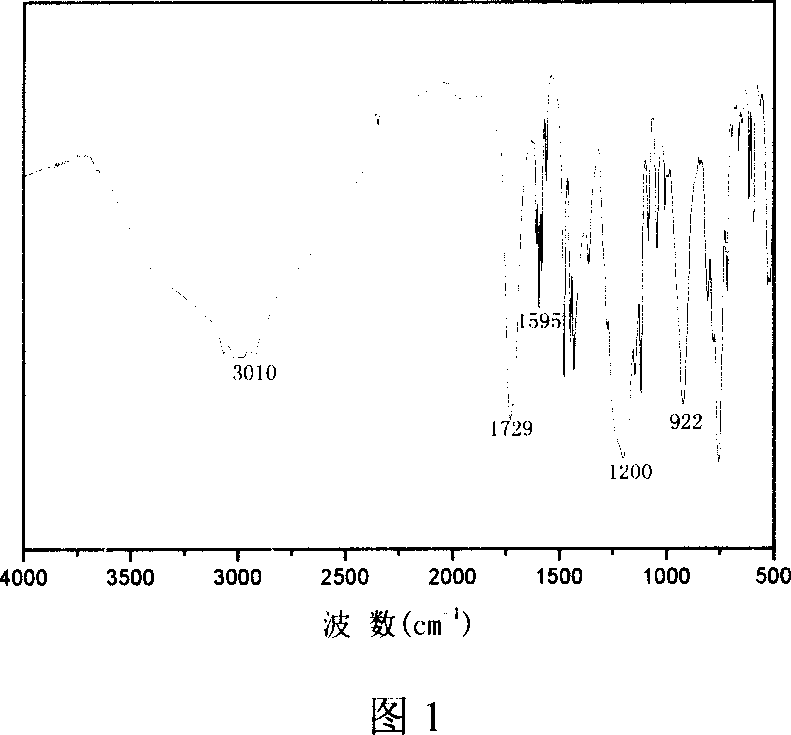

[0036] A. Add 21.6g (0.1mol) of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide and 7.2g (0.1mol) of acrylic acid into a three-necked flask, stir and heat to dissolve , control the temperature to 80°C, and reflux for 6 hours to obtain a light yellow and transparent mixed product; separate the mixed product by precipitation, dissolve the mixed product with 100ml acetone, add 1000ml chloroform as a precipitant, and filter to obtain a white solid product. Vacuum-dried in a vacuum oven at 80°C for 2 hours to obtain 10.8 g (0.004 mol) of the product 10-propionic acid-9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide. Fig. 1 is the infrared spectrogram of this product: FTIR (KBr, cm -1 ): 2800-3000 (-CH 2 ,-CH 3 ), 1729 (C=O), 1200 (C-O), 922 (P-O-Ph), 1595 (P-Ph).

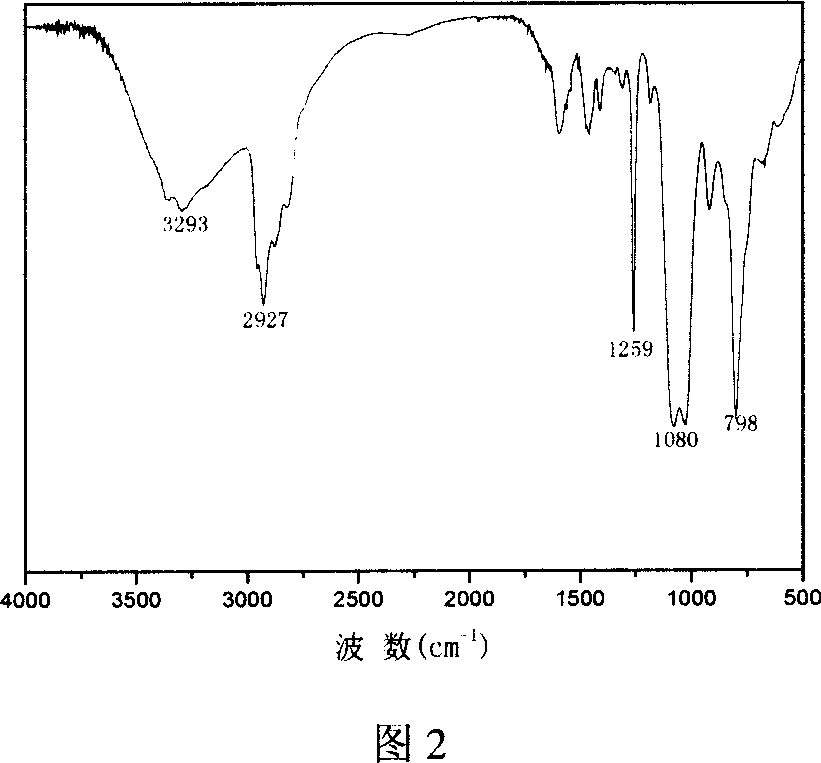

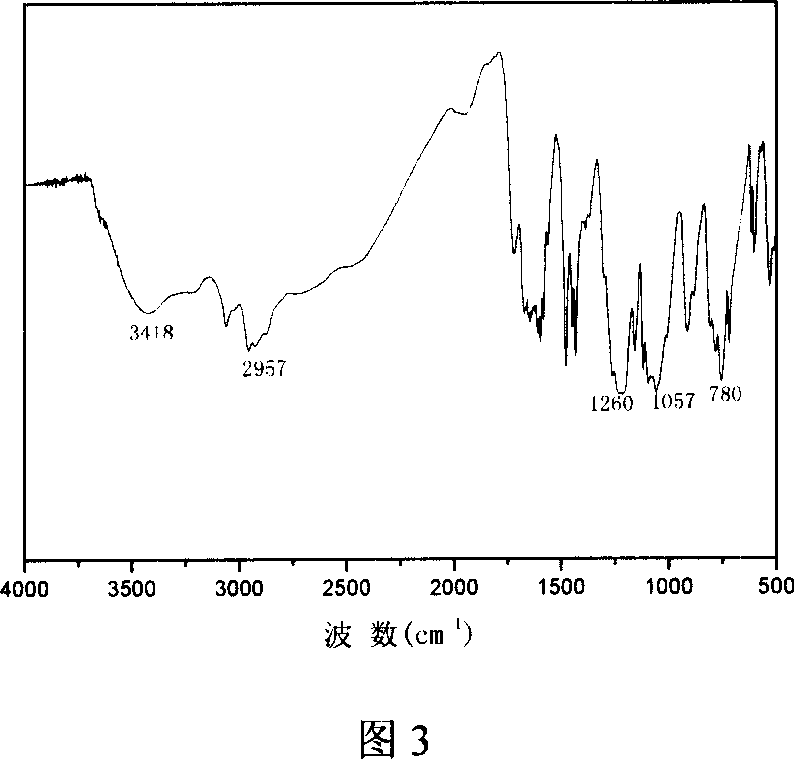

[0037] B. Weigh the amino-containing silane (R 1 for (CH 2 ) 3 NH(CH 2 ) 2 , R 2 for CH 3 O) 20.6g (0.1mol), add 3.6g (0.2mol) of water, 0.1g (0.002mol) of potassium hydroxide, heat up to 80°C, under the p...

Embodiment 2

[0041] A. Add 21.6g (0.1mol) of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide and 7.2g (0.1mol) of acrylic acid into a three-necked flask, stir and heat to dissolve , control the temperature at 70°C, reflux for 8 hours to obtain a light yellow and transparent mixed product; separate the mixed product by precipitation, dissolve the mixed product with 80ml acetone, add 800ml chloroform as a precipitant, filter to obtain a white solid product, and vacuum Vacuum-dry in an oven at 80°C for 2 hours to obtain 10.5 g (0.004 mol) of the product 10-propionic acid-9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide.

[0042] B. Weigh the amino-containing silane (R 1 for (CH 2 ) 3 , R 2 for CH 3 O) 19.1g (0.1mol), add 3.6g (0.2mol) of water, 0.5g (0.01mol) of potassium hydroxide, heat up to 100°C, under the protection of nitrogen, keep the temperature constant for 12 hours, remove the water, and obtain amino-containing silane 17.4 g (0.02 mol) of the hydrolyzed product.

[0043]...

Embodiment 3

[0046] Silicon-containing intumescent flame retardant 19.5g and polycarbonate (PC) 31.85g obtained according to the method for embodiment 1, acrylonitrile-butadiene-styrene terpolymer (ABS) 13.65g in internal mixer Mix uniformly, the mixing temperature is 220° C., and the mixing time is 5 minutes to obtain a flame-retardant PC / ABS alloy. Its oxygen index is 27.0 (PC / ABS alloy oxygen index is 21.0), and at 800 ° C, a higher carbon formation rate (13.2% in nitrogen, 9.9% in air, and PC / ABS without flame retardant alloys were 8.2% and 0), in addition to effectively reducing the heat release rate of PC / ABS alloy combustion (from 252.39kW / m 2 down to 152.64kW / m 2 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com