A kind of environment-friendly high-hardness and high-transparency polyurethane resin and preparation method thereof

A polyurethane resin, high hardness technology, applied in the field of polyurethane resin, can solve the problems of easy yellowing, poor toughness, non-compliance with environmental protection requirements, etc., and achieve the effects of low linear shrinkage, high strength, excellent yellowing resistance and transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

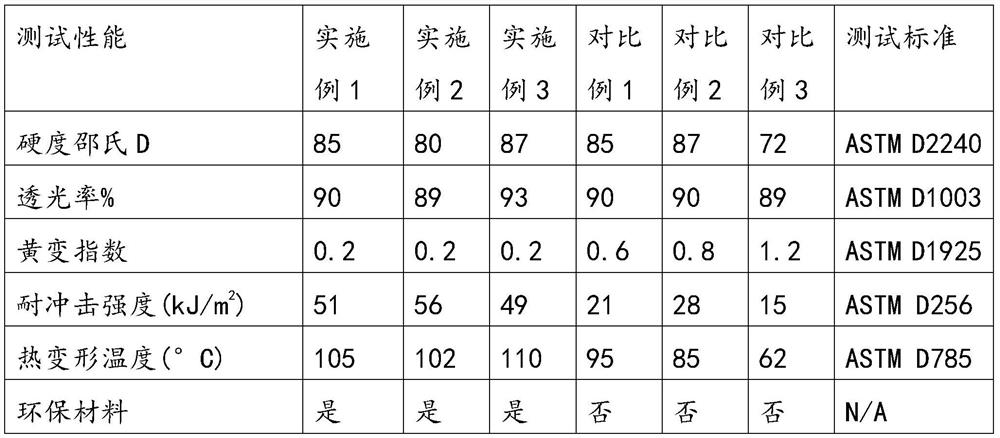

Examples

Embodiment 1

[0035] An environmentally friendly high-hardness and high-transparency polyurethane resin, comprising the following raw materials in parts by weight: 65 parts by weight of a polymer and 100 parts by weight of a curing agent;

[0036] The polymer is composed of the following raw materials by weight: 96 parts by weight of castor oil-modified polyester polyol with a hydroxyl value of 315mg / KOH, 10,760.5 parts by weight of antioxidant, 0.5 parts by weight of ultraviolet absorber UV328, organic neodecanoic acid 0.3 parts by weight of bismuth acid and organic zinc neodecanoate mixture;

[0037] The curing agent is composed of the following raw materials in parts by weight: 85 parts by weight of 4,4'-dicyclohexylmethane diisocyanate, 5 parts by weight of N,N,N',N'-tetra(2-hydroxypropyl)ethylenediamine parts by weight;

[0038] The preparation method of the environment-friendly high-hardness and high-transparency polyurethane resin described in Embodiment 1 comprises the following st...

Embodiment 2

[0043] An environmentally friendly high-hardness and high-transparency polyurethane resin, comprising the following raw materials in parts by weight: 75 parts by weight of a polymer and 100 parts by weight of a curing agent;

[0044] The polymer is composed of the following raw materials in parts by weight: 96.5 parts by weight of castor oil-modified polyester polyol with a hydroxyl value of 315mg / KOH, 10,760.6 parts by weight of antioxidant, 0.6 parts by weight of ultraviolet absorber UV328, organic neodecanoic acid 0.35 parts by weight of bismuth acid compound;

[0045] The curing agent is composed of the following raw materials in parts by weight: 88 parts by weight of 4,4'-dicyclohexylmethane diisocyanate, 88 parts by weight of N,N,N',N'-tetrakis(2-hydroxypropyl)ethylenediamine 8 parts by weight.

[0046] The preparation method of the environment-friendly high-hardness and high-transparency polyurethane resin described in embodiment 2 comprises the following steps:

[00...

Embodiment 3

[0051] An environmentally friendly high-hardness and high-transparency polyurethane resin, comprising the following raw materials in parts by weight: 80 parts by weight of a polymer and 100 parts by weight of a curing agent;

[0052] The polymer is composed of the following raw materials by weight: 97 parts by weight of castor oil-modified polyester polyol with a hydroxyl value of 315mg / KOH, 10,760.7 parts by weight of antioxidant, 0.7 parts by weight of ultraviolet absorber UV328, organic neodecanoic acid 0.4 parts by weight of zinc acid compound;

[0053] The curing agent is composed of the following raw materials in parts by weight: 90 parts by weight of 4,4'-dicyclohexylmethane diisocyanate, 10 parts by weight of N,N,N',N'-tetra(2-hydroxypropyl)ethylenediamine parts by weight.

[0054] The preparation method of the environment-friendly high-hardness and high-transparency polyurethane resin described in Embodiment 3 comprises the following steps:

[0055] (1) Preparation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com