Recyclable multifunctional dynamic covalent polymer aerogel materials and their preparation methods and applications

A multifunctional, polymer technology that is used in aerogel preparation, carbon preparation/purification, chemical instruments and methods to achieve high sound absorption coefficient, low thermal conductivity, and strong load-bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This example provides a preparation method for preparing a dynamic recyclable multifunctional polymer. Specifically include the following steps:

[0049] Step 1: Dissolve 26.11 mmol of 2,5-dimethoxy-terephthalaldehyde in 50 ml of dimethyl sulfoxide, after complete dissolution, add 7.84 mmol of diethylenetriamine, and stir at 25°C for 12 h to obtain Polyimide prepolymer.

[0050] Step 2: 12.18 mmol of tris(2-aminoethyl)amine was added to the above-mentioned polyimine prepolymer, fully stirred, poured into a mold, and then moved to a 25° C. environment for aging for 3 days.

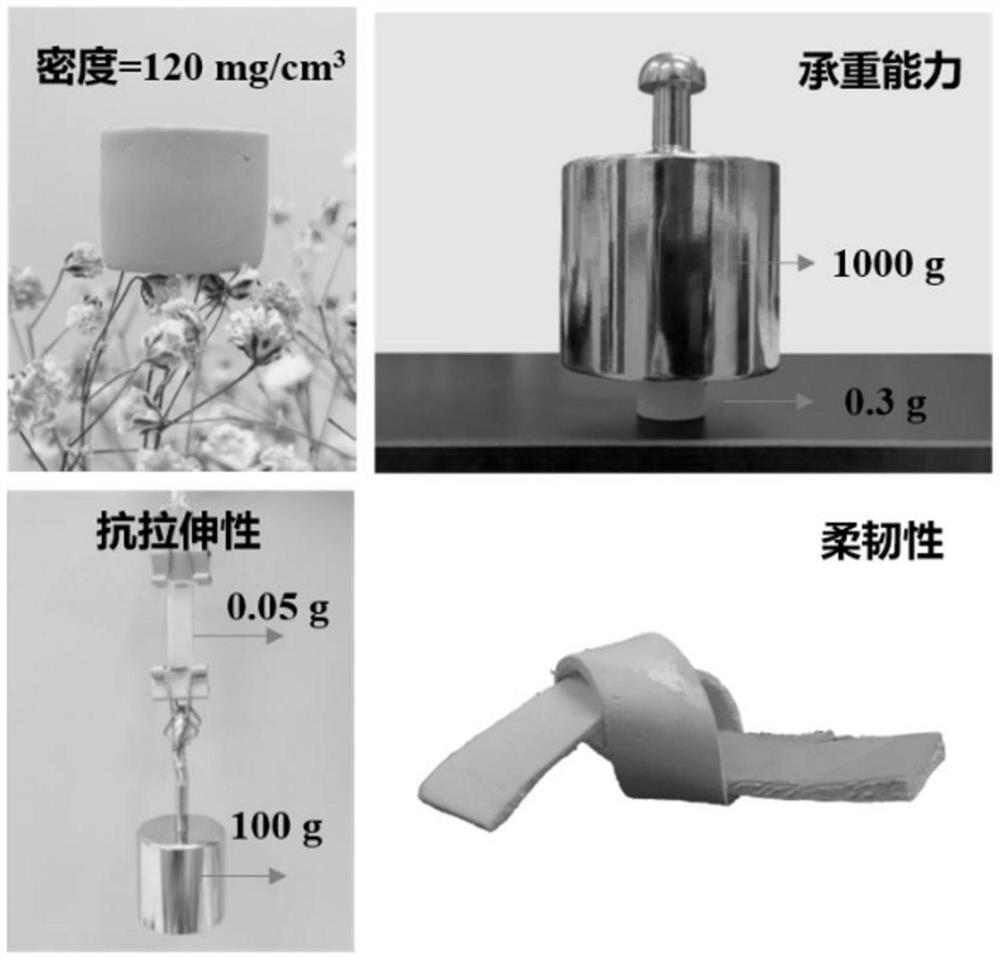

[0051] Step 3: Use dimethyl sulfoxide / anhydrous ethanol / acetone solvent system to perform solvent exchange on the gel obtained in step 2. After the end, place the sample in a 25°C environment to dry naturally. After drying, move it into a 60°C oven for drying. 12h. The resulting aerogel has a density of 120 mg / cm 3 , the linear shrinkage rate is 12%.

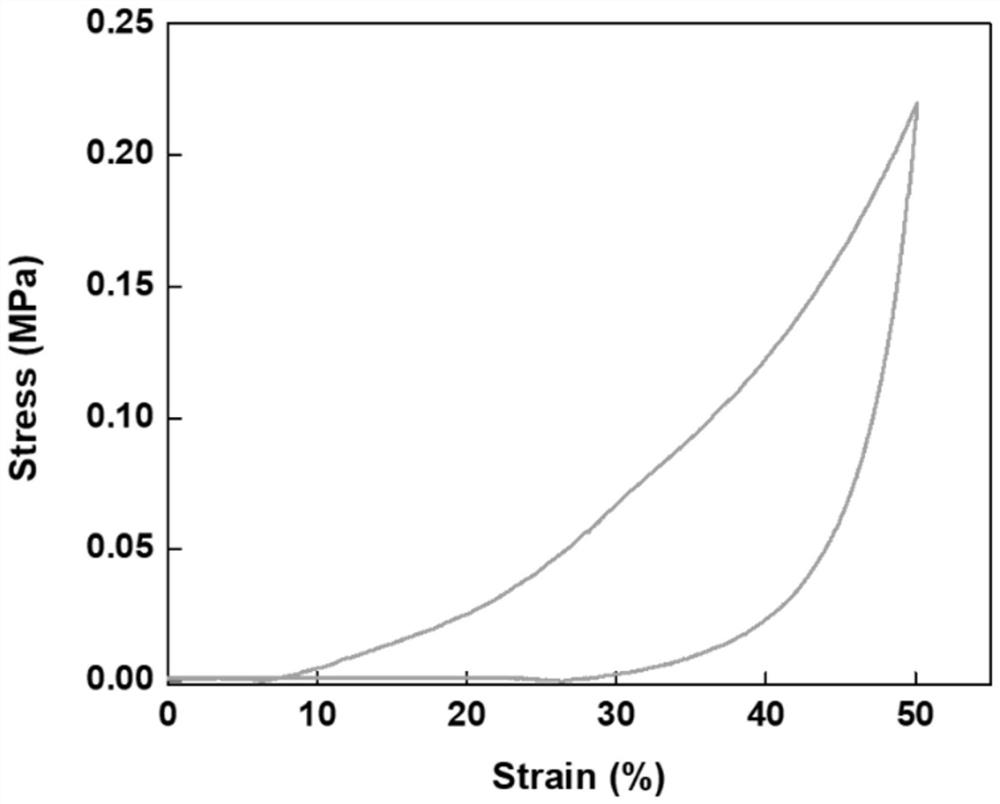

[0052] The aerogel prepared in Example 1 wa...

Embodiment 2

[0055] This example provides a preparation method for preparing a dynamic recyclable multifunctional polymer. Specifically include the following steps:

[0056] Step 1: Dissolve 3.73 mmol of terephthalaldehyde in 7 ml of absolute ethanol, after complete dissolution, add 1.12 mmol of diethylenetriamine, and stir at 35° C. for 12 h to obtain a polyimine prepolymer.

[0057] Step 2: 1.74 mmol of tris(2-aminoethyl)amine was added to the above-mentioned polyimine prepolymer, fully stirred, poured into a mold, and then moved to a 25° C. environment for aging for 2 days.

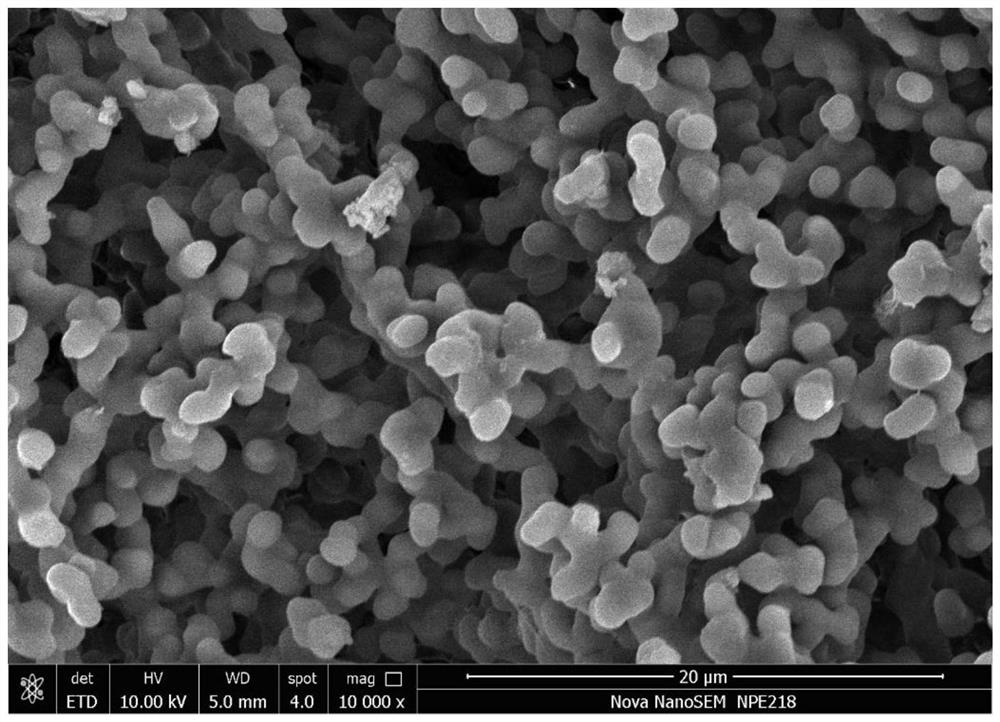

[0058] Step 3: Use anhydrous ethanol / acetone solvent system to perform solvent exchange on the gel obtained in step 2. After the end, the sample is placed in a 25°C environment to dry naturally. After drying, it is transferred to a 60°C oven for 12 hours. The resulting aerogel has a density of 115 mg / cm 3 , the linear shrinkage rate is 15%. like image 3 As shown in the SEM image of the aerogel sample prepared ...

Embodiment 3

[0060] (1) the aerogel of embodiment 2 is carried out recyclable experiment, specifically comprises the following steps:

[0061] Step 1: Dissolve 3.73 mmol of terephthalaldehyde in 7 ml of absolute ethanol, after complete dissolution, add 1.12 mmol of diethylenetriamine, and stir at 35° C. for 12 h to obtain a polyimine prepolymer.

[0062] Step 2: 1.74 mmol of tris(2-aminoethyl)amine was added to the above-mentioned polyimine prepolymer, fully stirred, poured into a mold, and then moved to a 25° C. environment for aging for 2 days.

[0063] Step 3: Use anhydrous ethanol / n-hexane solvent system to perform solvent exchange on the gel obtained in step 2 to obtain a polyimide aerogel, and then place the sample in a 25°C environment to dry naturally, and move it to 60°C after drying. Oven dry for 12h.

[0064] Step 4: Add 2.24 mmol of diethylenetriamine and 3.48 mmol of tris(2-aminoethyl)amine to 20 ml of absolute ethanol to prepare a recovery solution, and then cut the dried po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com