A kind of bulk silicon carbide polymer precursor ceramics and preparation method of blending and cracking

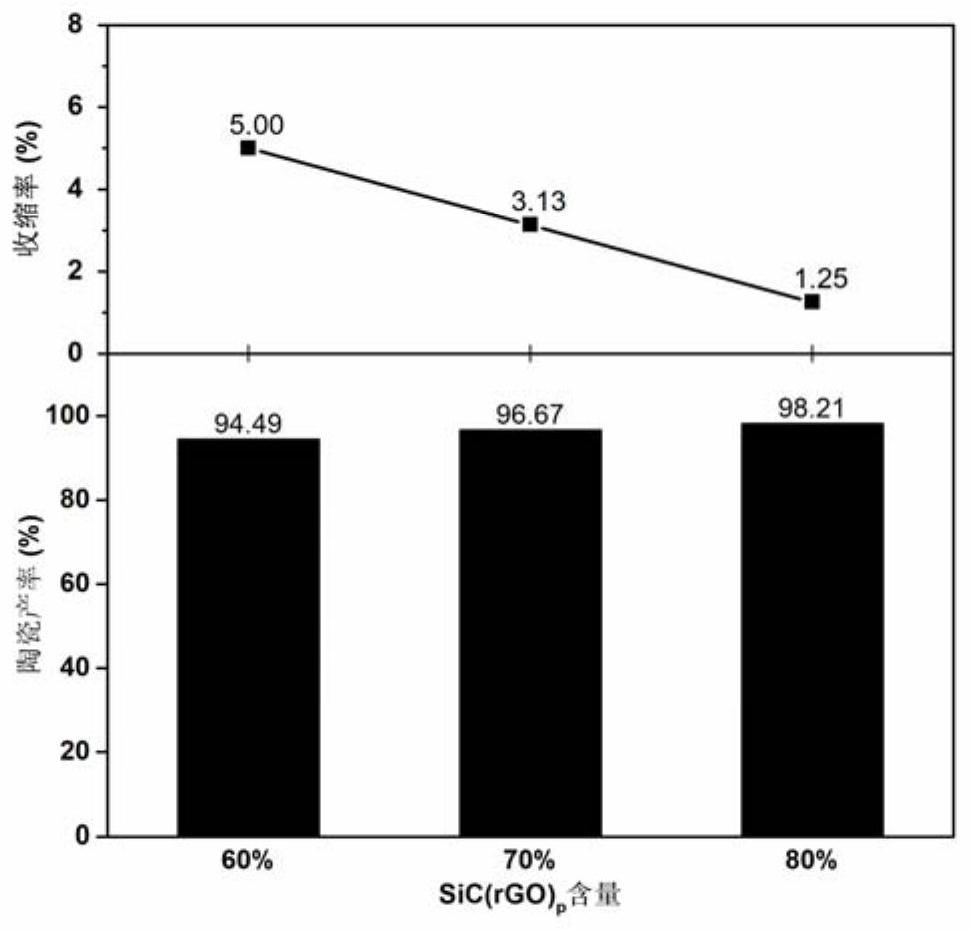

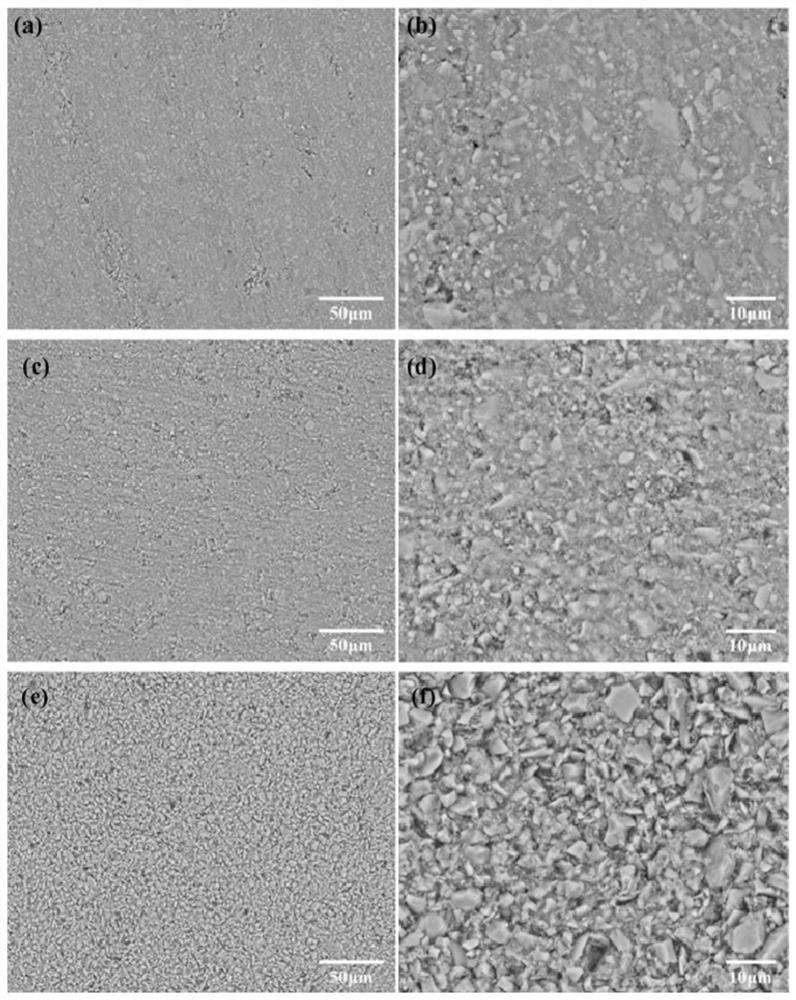

A precursor and silicon carbide technology, which is applied in the field of bulk silicon carbide polymer precursor ceramics and blending and cracking preparation, can solve the problems of low ceramic yield, large shrinkage rate of monolithic ceramics, and difficulty in block forming. Achieve good hardness and fracture toughness, ensure the integrity of the ceramic structure, and uniform and compact microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Dissolve 1g of PCS powder with a relative molecular weight of 1426g / mol in 20mL of xylene, add 1mL of VTES and an appropriate amount of Castor catalyst to it, and obtain a golden yellow transparent liquid;

[0030] 2. Disperse 0.01g of GO powder in 20mL of purified water, and then mix it with the xylene solution in step 1;

[0031] 3. Take the mixed solution in step 2 and heat it in a 60°C water bath, and stir the reaction with a magnetic stirrer for 30 minutes. After standing still, take the upper liquid and spin evaporate and grind it to obtain the precursor PVG solid powder;

[0032] 4. Put the precursor PVG powder in a crucible, and crack it in an argon atmosphere with a flow rate of 100mL / min. The cracking temperature is 1200°C, the heating rate is 4°C / min, and the holding time is 1min to obtain cracked SiC(rGO) p ceramic particles;

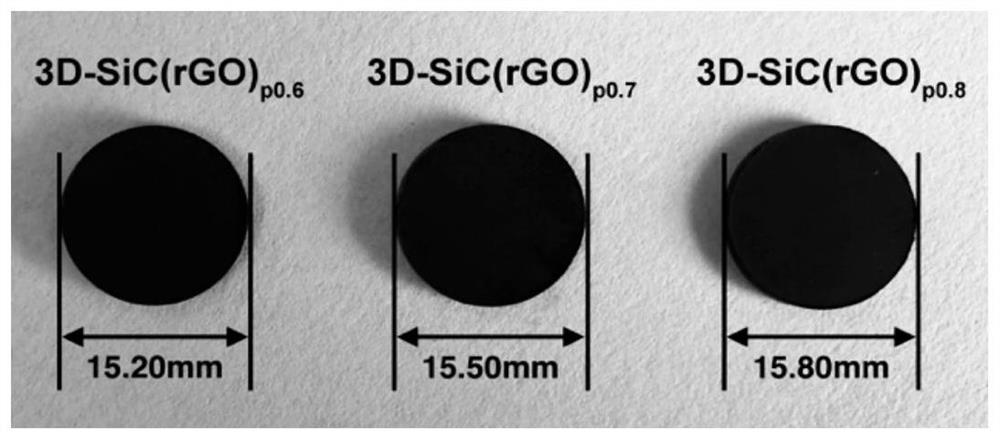

[0033] 5. Take cracked SiC(rGO) with a mass ratio of 6:4 p Ceramic particles and its precursor PVG powder to obtain SiC(rGO) p...

Embodiment 2

[0038] 1. Dissolve 1g of PCS powder with a relative molecular weight of 1426g / mol in 20mL of xylene, add 1mL of VTES and an appropriate amount of Castel catalyst to it, and obtain a golden yellow transparent liquid;

[0039] 2. Disperse 0.01g of GO powder in 20mL of purified water, and then mix it with the xylene solution in step 1;

[0040] 3. Take the mixed solution in step 2 and heat it in a 60°C water bath, and stir the reaction with a magnetic stirrer for 30 minutes. After standing still, take the upper liquid and spin evaporate and grind it to obtain the precursor PVG solid powder;

[0041] 4. Put the precursor PVG powder in a crucible, and crack it in an argon atmosphere with a flow rate of 100mL / min. The cracking temperature is 1200°C, the heating rate is 4°C / min, and the holding time is 1min to obtain cracked SiC(rGO) p ceramic particles;

[0042] 5. Take cracked SiC(rGO) with a mass ratio of 7:3 p Ceramic particles and its precursor PVG powder to obtain SiC(rGO) p...

Embodiment 3

[0047] 1. Dissolve 1g of PCS powder with a relative molecular weight of 1426g / mol in 20mL of xylene, add 1mL of VTES and an appropriate amount of Castor catalyst to it, and obtain a golden yellow transparent liquid;

[0048] 2. Disperse 0.01g of GO powder in 20mL of purified water, and then mix it with the xylene solution in step 1;

[0049] 3. Take the mixed solution in step 2 and heat it in a 60°C water bath, and stir the reaction with a magnetic stirrer for 30 minutes. After standing still, take the upper liquid and spin evaporate and grind it to obtain the precursor PVG solid powder;

[0050] 4. Put the precursor PVG powder in a crucible, and crack it in an argon atmosphere with a flow rate of 100mL / min. The cracking temperature is 1200°C, the heating rate is 4°C / min, and the holding time is 1min to obtain cracked SiC(rGO) p ceramic particles;

[0051] 5. Take cracked SiC(rGO) with a mass ratio of 8:2 p Ceramic particles and its precursor PVG powder to obtain SiC(rGO) p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com