Environmental barrier coating as well as preparation method and application thereof

An environmental barrier coating and coating technology, which is applied in the field of high temperature anti-oxidation/anti-corrosion composite coating preparation, can solve the problems of being unsuitable for large components and special-shaped parts, the coating is easy to shrink, and the preparation cost is high, and it is easy to crack. , the effect of improving ceramic yield and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

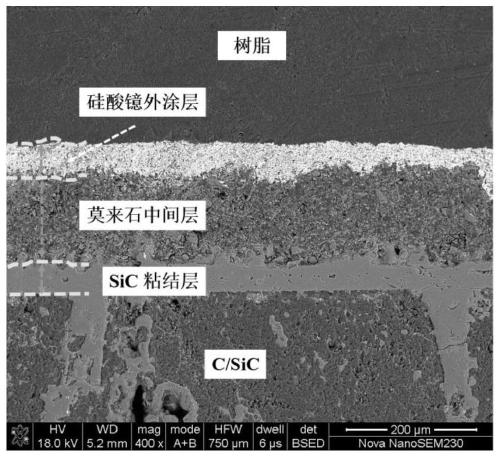

[0045] The environmental barrier coating disclosed by the invention is composed of a SiC bonding layer, a mullite middle layer and an ytterbium silicate outer coating which are coated on a C / SiC composite material and arranged in sequence from the inside to the outside. Its preparation method comprises the following steps:

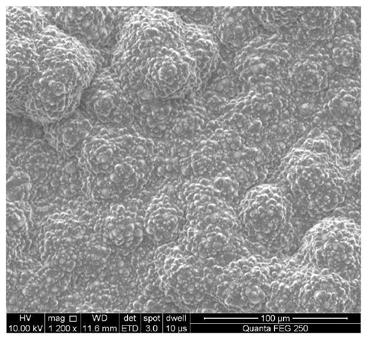

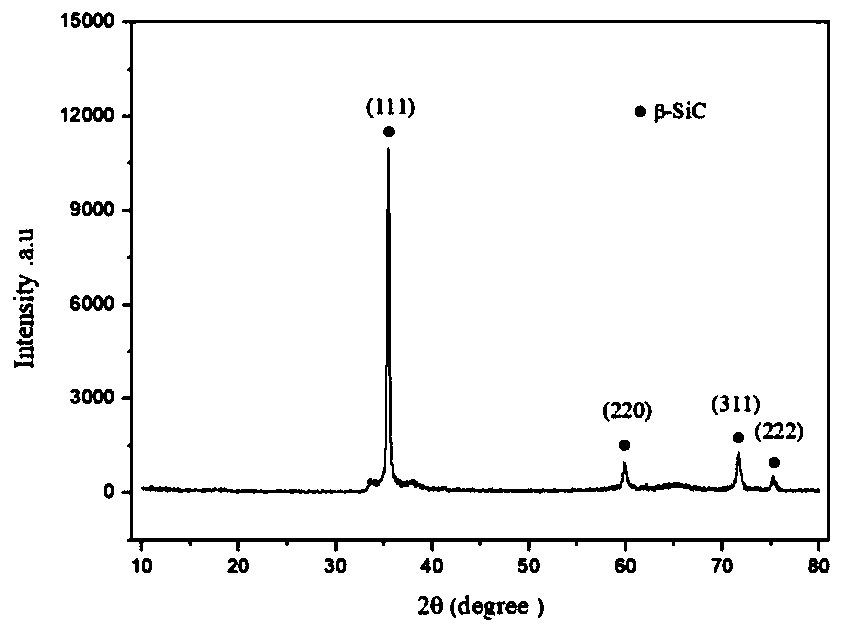

[0046] S1. Preparation of SiC bonding layer by secondary chemical vapor deposition

[0047] The surface of the C / SiC composite material was smoothed with sandpaper, ultrasonically cleaned and dried, and then placed in a chemical vapor deposition furnace; the deposition gas source (MTS), carrier gas (hydrogen) and dilution gas (argon) were continuously fed, Control the temperature in the furnace at 1050°C~1200°C; after the first deposition, turn the sample 180° in the vertical direction for the second deposition, and cool down with the furnace to obtain a SiC bonding layer-coated C / SiC composite material sample ; Specifically, the pressure in the depositio...

Embodiment 1

[0058] The preparation method of the environmental barrier coating of the present embodiment comprises the following steps:

[0059] S1. Preparation of SiC bonding layer by secondary chemical vapor deposition

[0060] The surface of the C / SiC composite material was smoothed with sandpaper, cleaned ultrasonically and dried, and then placed in a chemical vapor deposition furnace; trichloromethylsilane (MTS), hydrogen and argon were continuously fed, and the temperature in the furnace was controlled at 1100 ℃, the pressure in the furnace is 0.3~0.6kPa, the flow rate of trichloromethylsilane (MTS) is 800~1000mL / min, the flow rate of hydrogen gas is 1500~2500mL / min, the flow rate of argon gas is 1500~2500mL / min; the first deposition After 25 hours, turn the sample vertically 180° o Carry out the second deposition, the total deposition time is 50h, and obtain the SiC bonding layer-coated C / SiC composite material sample of the second deposition with furnace cooling;

[0061] S2. Pr...

Embodiment 2

[0069] The preparation method of the environmental barrier coating of the present embodiment comprises the following steps:

[0070] S1. Preparation of SiC bonding layer by secondary chemical vapor deposition

[0071] The surface of the C / SiC composite material was smoothed with sandpaper, ultrasonically cleaned and dried, and then placed in a chemical vapor deposition furnace; trichloromethylsilane (MTS), hydrogen and argon were continuously fed, and the temperature in the furnace was controlled at 1150 ℃, furnace pressure 0.3~0.6kPa, trichloromethylsilane (MTS) flow rate 800~1000mL / min, hydrogen flow rate 1500~2500mL / min, argon flow rate 1500~2500mL / min; first deposition 25h After that, turn the sample vertically 180 o Carry out the second deposition, the total deposition time is 50h, and obtain the SiC bonding layer-coated C / SiC composite material sample of the second deposition with furnace cooling;

[0072] S2. Preparation of mullite interlayer by sol-gel combined air s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com