Ceramic-based composite material and preparation method thereof

A composite material and ceramic-based technology, applied in the field of ceramic-based composite materials and their preparation, can solve the problems of long preparation cycle, low temperature, and great influence of fiber system, and achieve the advantages of shortening the impregnation cycle, improving the ceramic yield and reducing the preparation cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

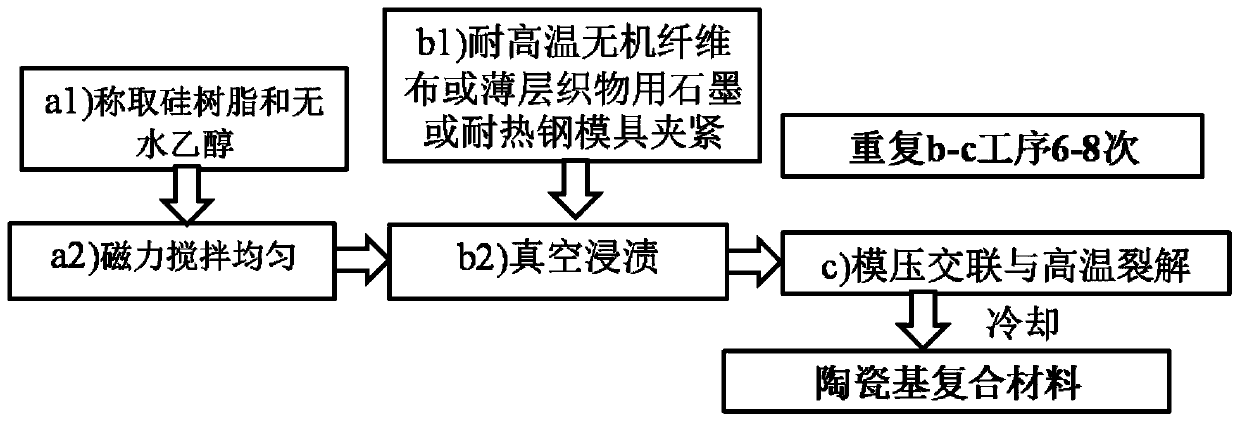

[0026] The present invention proposes a preparation method of a ceramic matrix composite material, comprising the following steps:

[0027] S1: Weigh the silicone resin and the organic solvent according to the mass ratio, and stir to form a silicone resin solution;

[0028] Preferably, the organic solvent is one of methanol, acetone and dehydrated ethanol, preferably dehydrated ethanol, which has good solubility, low toxicity and low corrosion; the mass ratio of the silicone resin and dehydrated alcohol is ( 1:1)~(1:5); the stirring rate is 800~1500rpm, and the time is 2~8h. Too much silicone resin will result in a thicker solution, which is not conducive to impregnation; too little will result in a thinner solution, prolonging the impregnation cycle of the material, which is not conducive to production; fully stir to obtain a uniform silicone resin solution.

[0029] S2: Needling, puncturing or sewing the inorganic fiber cloth or fabric;

[0030] Preferably, the number of l...

Embodiment 1

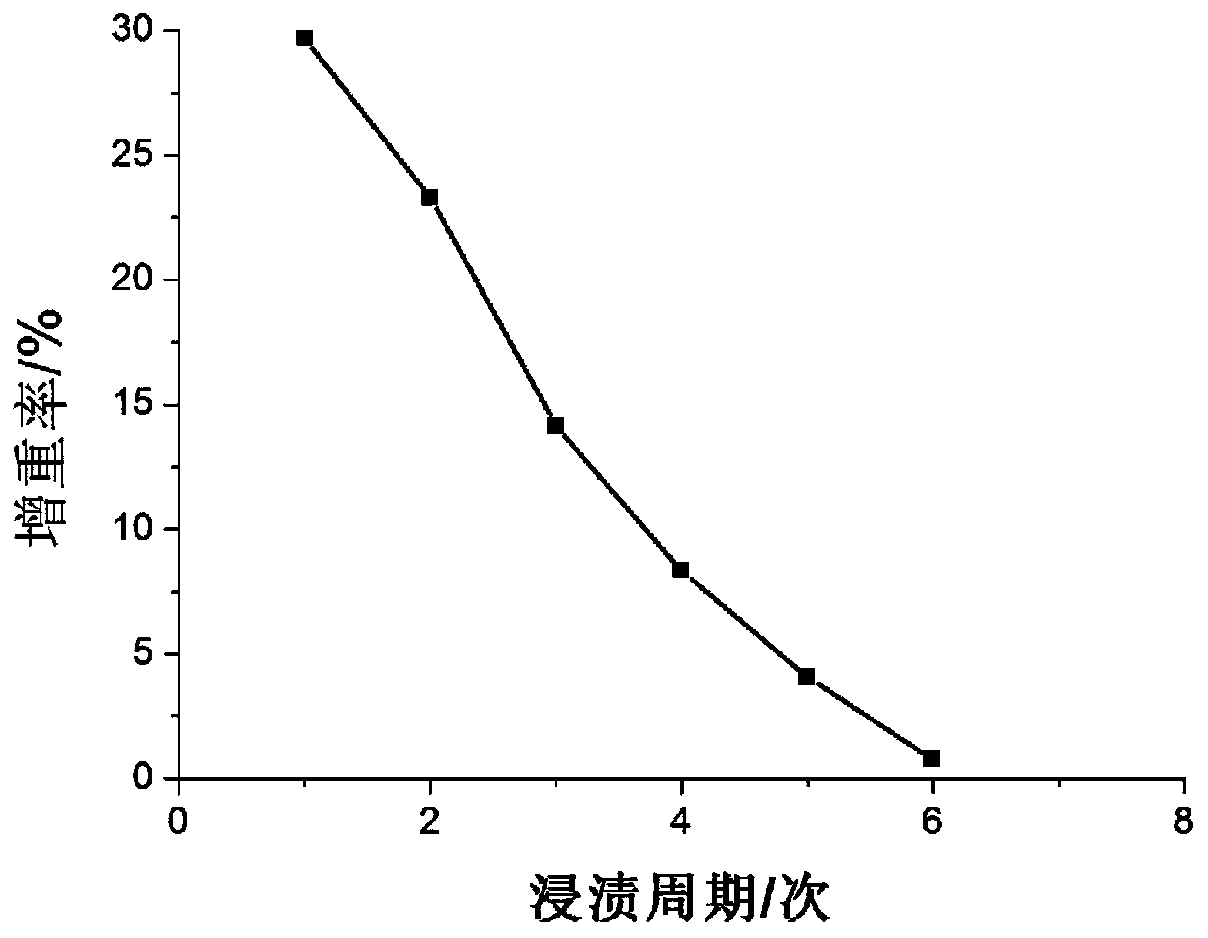

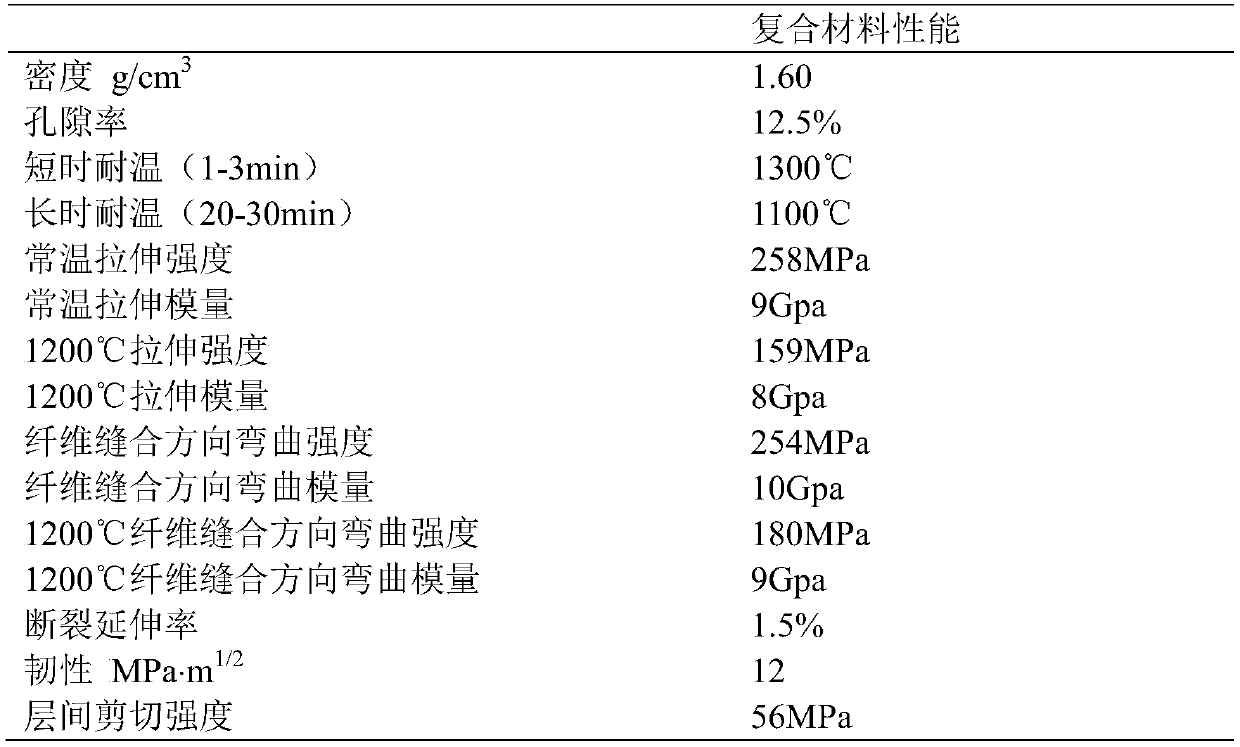

[0046] This embodiment provides a preparation method of a ceramic matrix composite material, such as figure 1 shown, including the following steps:

[0047] (1) Take silicone resin and dehydrated alcohol, wherein the mass ratio of silicone resin and dehydrated alcohol is 1:1, form silicone resin solution by magnetic stirring for 4h;

[0048] (2) Lay 8 layers of T300-1K carbon fiber cloth with a thickness of 0.28mm, and then suture them. The fibers used in the sutures are commercially available common T300-1K carbon fibers. The distance between sutures is 5mm;

[0049] (3) Clamp the carbon fiber cloth sewn in step (2) with a graphite mold, place it in a vacuum container, vacuum inhale the silicone resin solution (suspension) prepared in step (1), and impregnate for 8 hours;

[0050] (4) Arranging the carbon fibers impregnated in step (3) in a vacuum cracking furnace to carry out molding cross-linking and high-temperature cracking, specifically:

[0051] Raise the temperature...

Embodiment 2

[0060] This embodiment provides a method for preparing a ceramic matrix composite material, comprising the following steps:

[0061] (1) Take silicone resin and dehydrated alcohol, wherein the mass ratio of silicone resin and dehydrated alcohol is 1:2, form silicone resin solution by magnetic stirring for 8h;

[0062] (2) 8 layers of 0.23mm thick second-generation SiC fiber cloth produced by National University of Defense Technology (Qing Wang. Effects of ZrO 2 coating on the strength improvement of 2.5D SiCf / SiO 2 composites.Ceramics International 43(2017) 884–889), and then perform suture treatment. The fiber used in the suture is the above-mentioned second-generation SiC fiber. In order to obtain better mechanical properties, the distance between every two sutures is designed to be 8mm;

[0063] (3) Clamp the carbon fiber cloth sewn in step (2) with a heat-resistant steel mold, place it in a vacuum container, vacuum inhale the silicone resin solution (suspension) prepared...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com