Method for synthesizing soluble ZrC ceramic precursor polymer

A technology of ceramic precursors and synthesis methods, which is applied in the field of synthesis of soluble ZrC ceramic precursor polymers, can solve the problems of uneven distribution of metal elements, low ceramic yield, high oxygen content of products, etc., to reduce the ceramicization temperature, Improvement of ceramic productivity and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

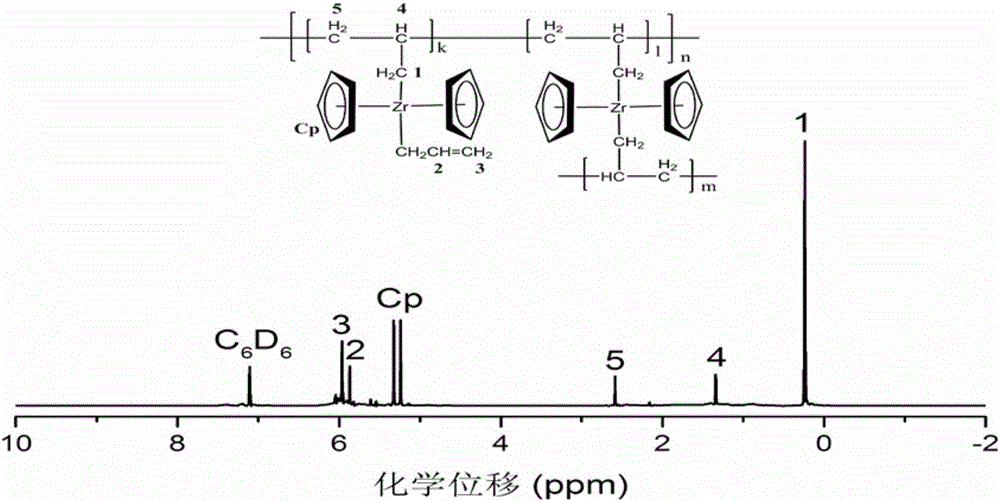

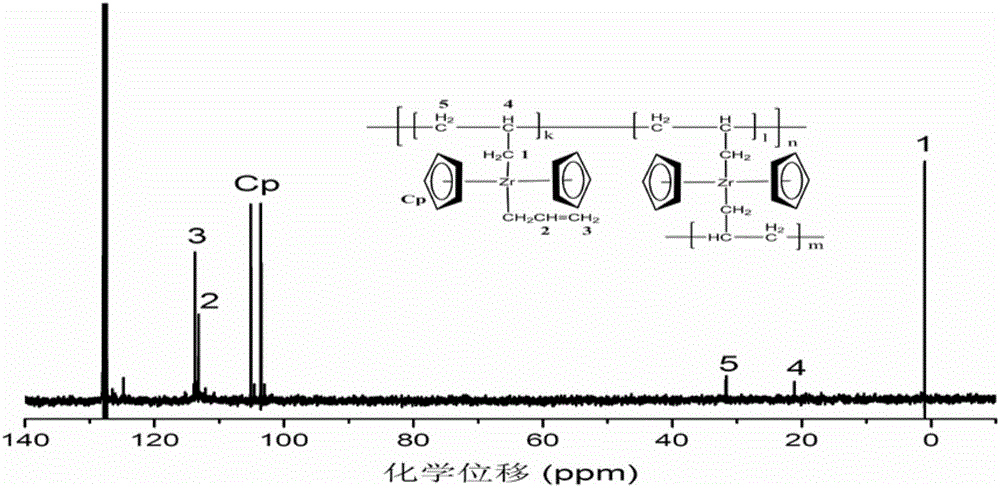

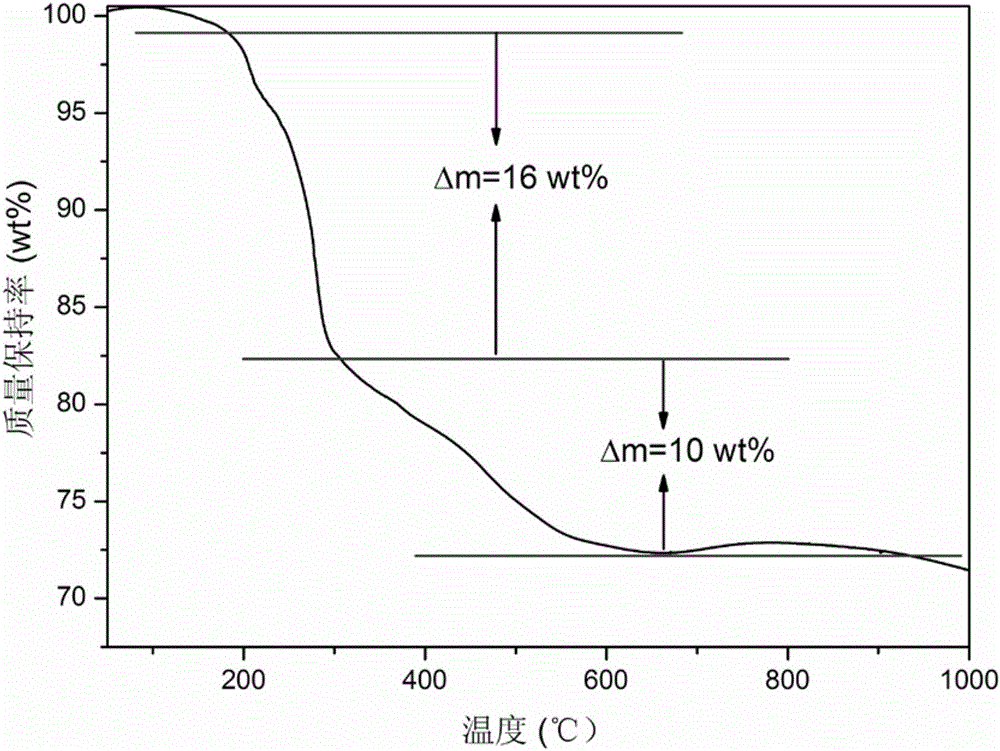

[0027] The preparation method provided by the invention uses zirconium dichloride (Cp 2 ZrCl 2 ) or trichlorozirconocene (CpZrCl 3 ) as a zirconium source, using Grignard reagents containing double bonds such as allyl Grignard reagents and 3-butene Grignard reagents as carbon sources, and reacting with anhydrous xylene as a solvent below -5°C for 4-12 hours . Adding an initiator with a mass fraction of 3wt%-8wt% to the obtained monomer, raising the temperature to 100-130° C. and refluxing for 6-48 hours to obtain a soluble ZrC ceramic precursor.

[0028] Reacting in this way can reduce the oxygen element introduced into the reaction system, and further ensure that the obtained ceramic product has lower porosity and high ceramic yield. Moreover, the precursor prepared by the method can be dissolved in organic solvents such as xylene and toluene, and has good solubility.

[0029] More preferably, the initiator is dicumyl peroxide. Using this as an initiator can effectively ...

Embodiment 1

[0044] (1) Add a magnetic stirrer to the dried 250ml three-necked flask, and install a constant pressure dropping funnel, a gas outlet piston, and a rubber stopper, and replace it with high-purity nitrogen three times;

[0045] (2) 3g of zirconocene dichloride was added to a three-necked flask, and 10ml of anhydrous xylene was used as a solvent, and the reaction device was cooled to -20°C;

[0046] (3) Allylmagnesium chloride Grignard reagent is added to the reaction system through a constant pressure dropping funnel at a molar ratio of Grignard reagent: zirconium source=2: 1; after the addition, keep the low temperature and stir for 4 hours;

[0047] (4) After the above reaction system was reacted at room temperature for 24 hours, the inorganic salt was filtered out to obtain the active monomer, and dicumyl peroxide was added as an initiator relative to the active monomer mass fraction of 5 wt %; heated to 130° C. Reflux for 20 hours;

[0048] (5) After the reflux was comple...

Embodiment 2

[0053] (1) Add a magnetic stirrer to the dried 250ml three-necked flask, and install a constant pressure dropping funnel, a gas outlet piston, and a rubber stopper, and replace it with high-purity nitrogen three times;

[0054] (2) 3g of zirconocene dichloride was added to a three-necked flask, and 10ml of anhydrous xylene was used as a solvent, and the reaction device was cooled to -5°C;

[0055] (3) 3-butenylmagnesium chloride Grignard reagent is added to the reaction system through a constant pressure dropping funnel at a molar ratio of Grignard reagent: zirconium source=2: 1; after the addition, keep the low temperature and stir for 8 hours ;

[0056] (4) After the above reaction system was reacted at room temperature for 18 hours, the inorganic salt was filtered out to obtain the active monomer, and dicumyl peroxide was added as an initiator relative to the active monomer mass fraction of 3wt%; heated to 100° C. Reflux for 18 hours;

[0057] (5) After the reflux was com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com