Preparation method of high-temperature-resistant coating for ceramic-based composite material

A composite material and ceramic-based technology, applied in the field of preparation of high-temperature resistant coatings for ceramic-based composite materials, can solve problems such as poor high temperature resistance and oxidation resistance, achieve excellent high temperature resistance, improve ceramic productivity, and simple molding tools Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

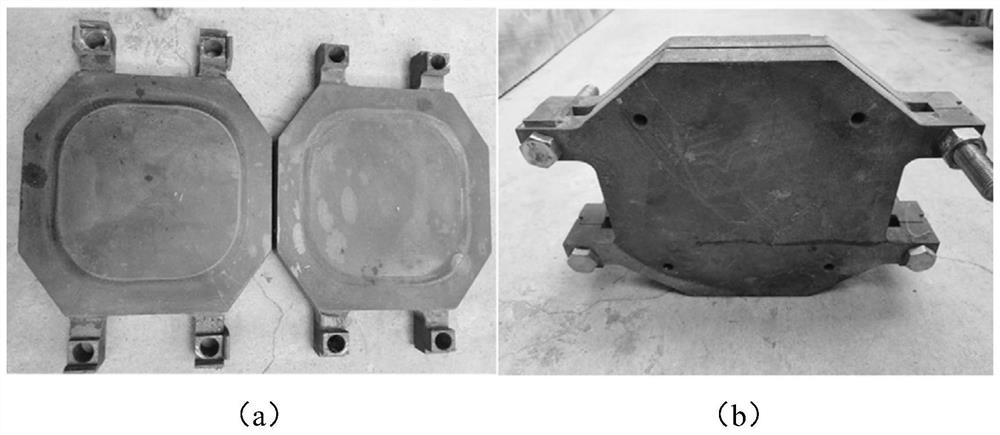

[0047] A molding tool, the structure of which is as figure 2 As shown, including upper and lower templates with matching dimensions; as figure 2 As shown in (a), the lower formwork is a plate with a groove in the center, and the upper formwork is a plate with a protrusion in the center. The height of the protrusion is smaller than the depth of the groove to place the prefabricated parts to be compressed; the edges of the upper template and the lower template are respectively provided with corresponding connection holes, such as figure 2 As shown in (b), the upper formwork and the lower formwork are connected and pressed by bolts through connecting holes.

[0048] Preferably, the material of the upper template and the lower template is stainless steel, and the thickness of the upper template and the lower template are each 20 mm; the material of the bolts is high temperature resistant stainless steel.

[0049] The design of the molding tool in this embodiment can well cont...

Embodiment 2

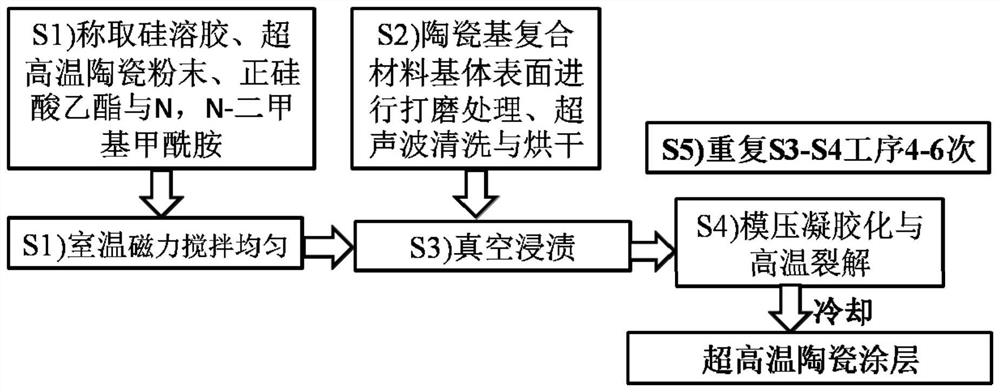

[0051] A kind of ceramic matrix composite material uses ZrO 2 -SiO 2 The preparation method of the coating, the technological process is shown as figure 1 shown, including the following steps:

[0052] S1: Weigh silica sol and ZrO according to mass ratio 2 powder, adding tetraethyl orthosilicate and N,N-dimethylformamide, among them, ZrO 2 Powder size is 200 mesh, silica sol and ZrO 2 The mass ratio of powder is 1:5, and the mass ratio of silicone resin, tetraethylorthosilicate and N,N-dimethylformyl is 1:0.1:0.1; magnetically stir at room temperature to form silica sol containing ceramic powder Suspension, wherein the rate of magnetic stirring is 1000rpm, and the time is 2h;

[0053] S2: Use SiC sandpaper on C f / The surface of the SiC composite material substrate is polished to remove residual grease and other pollutants on the surface of the substrate, and then ultrasonically cleaned with deionized water for 30 minutes and placed in a 70°C oven to dry for use;

[005...

Embodiment 4

[0071] A kind of ZrC-SiO for ceramic matrix composite material 2 The preparation method of the coating, the technological process is shown as figure 1 shown, including the following steps:

[0072] S1: Take silica sol and ZrC powder by mass ratio, add tetraethyl orthosilicate and N,N-dimethylformamide, wherein, ZrC powder size is 150 orders, the mass ratio of silica sol and ZrC powder is 1: 1. The mass ratio of silicone resin, tetraethyl orthosilicate to N,N-dimethylformyl is 1:0.2:0.2; stir magnetically at room temperature, the stirring rate is 1500rpm, and the time is 1h to form ceramic powder silica sol suspension.

[0073] S2: Use SiC sandpaper on C f / SiOC composite substrate surface is polished to remove residual grease and other pollutants on the substrate surface, and then ultrasonically cleaned with deionized water for 30 minutes and placed in an oven at 80°C for drying before use;

[0074] S3: C that will pass through S2 under vacuum f / SiOC composite material i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Strength retention | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com