Numerical control turning center with hydrostatic guide rails and hydrostatic spindle system

A hydrostatic guide rail and hydrostatic spindle technology, applied in turning equipment, turning equipment, manufacturing tools, etc., can solve the problems of the influence of machine tool accuracy and machining accuracy, low machine tool accuracy, poor vibration resistance, etc., to improve machining accuracy, The effect of high oil film stiffness and vibration isolation of machine tool deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

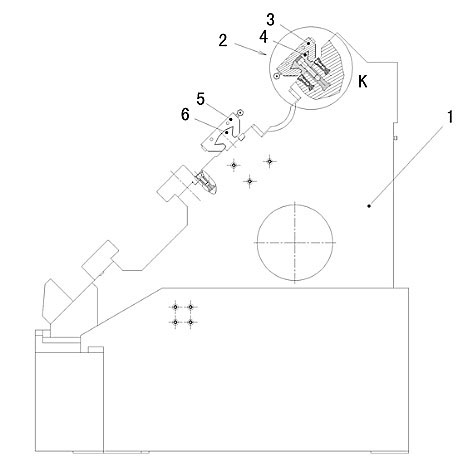

[0015] Such as figure 1 , 2 , Shown in 3, 4: 1 is 45 ° inclined bed, and inclined bed 1 is artificial granite material, and headstock mechanism is installed on one end on inclined bed 1. All parts fixedly connected with the inclined bed 1 adopt the method of embedding nuts in the inclined bed 1 and fixing each part on the inclined bed 1 by bolts.

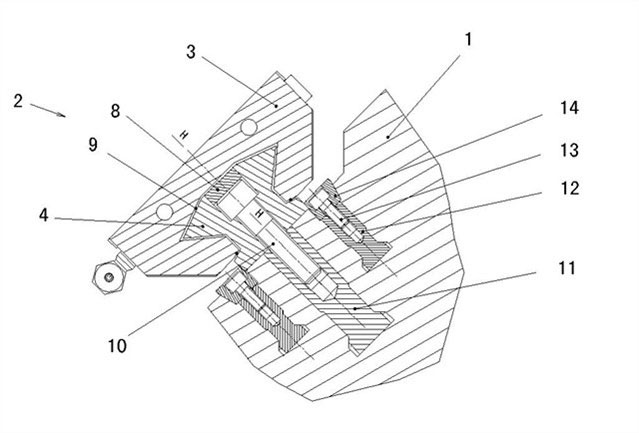

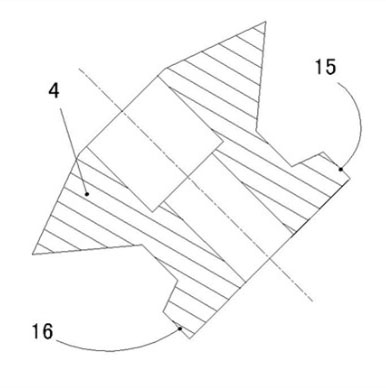

[0016] An upper guide rail 4 and a lower guide rail 6 parallel to each other are fixed longitudinally on the inclined bed 1 to form a hydrostatic guide rail structure 2 . The fixing structure between each guide rail and the inclined bed 1 is as follows: the above guide rail 4 is taken as an example, and steel guide rail fixing nuts 11 are arranged and inlaid inside the inclined bed 1, and counterbores are added on the upper guide rail 4, The guide rail fixing bolt 10 is fastened with the guide rail fixing embedded nut 11 through the counterbore, so that the upper guide rail 4 is fixed on the inclined bed 1, and a plug 8 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com