Two-cavity closed type liquid static pressing guiding rail sliding block module

A technology of hydrostatic guide rails and sliders, which is applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., and can solve the problem that the throttling ratio cannot be controlled actively in real time, the throttling ratio is not adjustable, and the stiffness of the oil film is limited. problems, to achieve the effect of improving wear resistance, excellent straightness of motion, and high load-carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer and clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

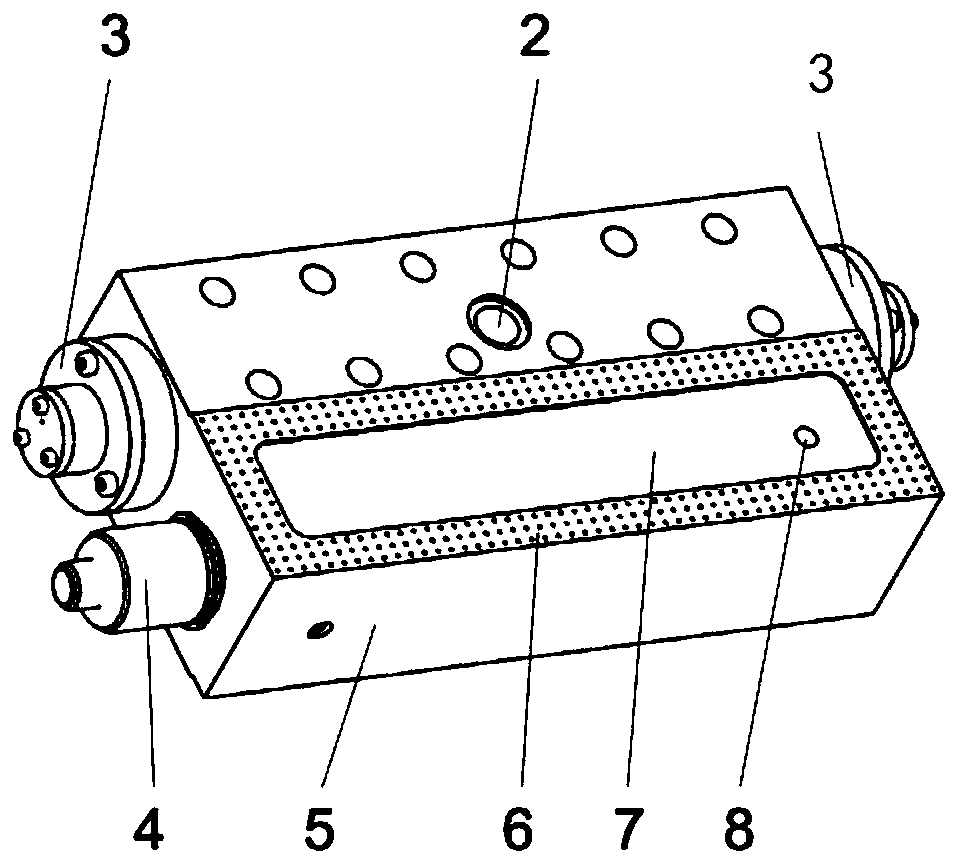

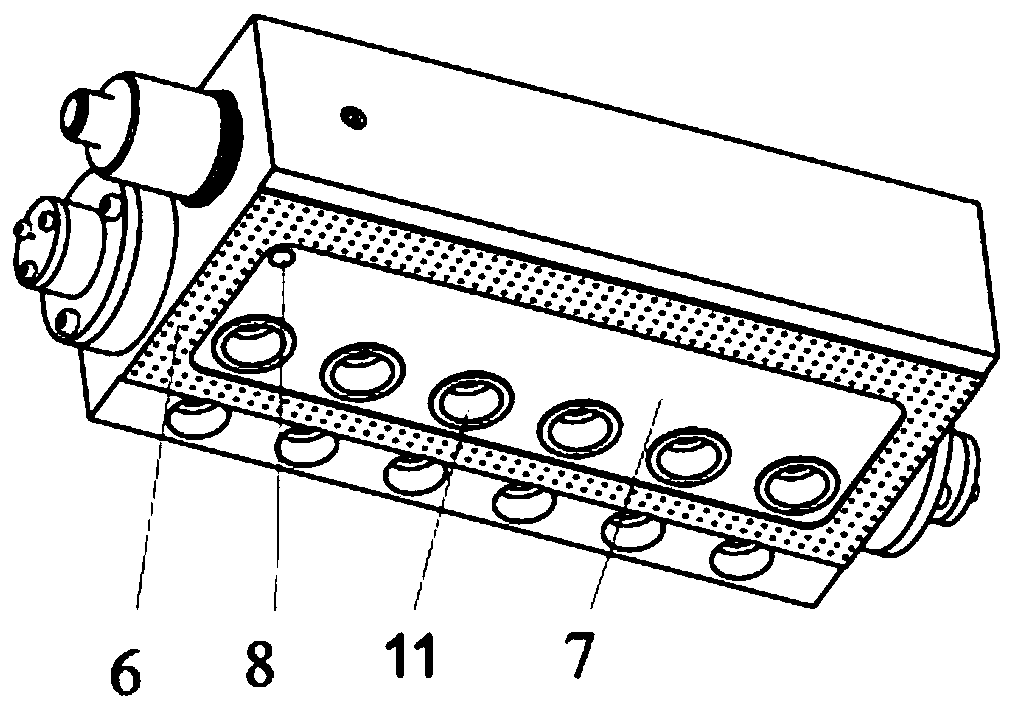

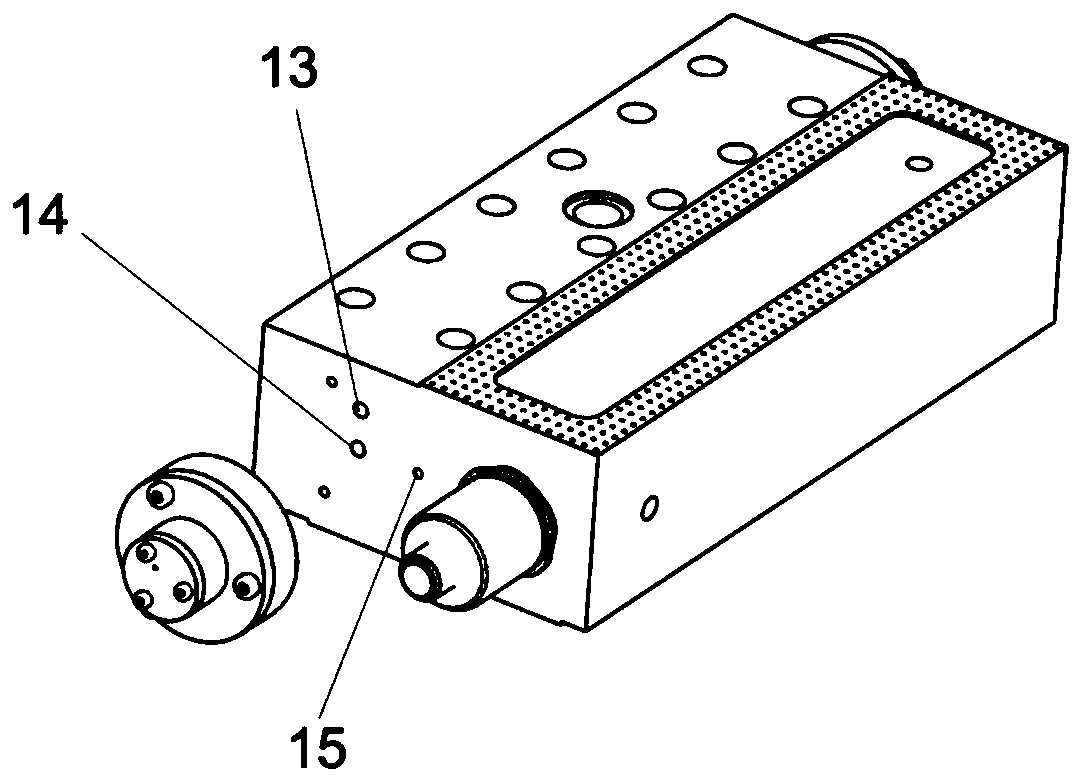

[0039] Such as Figure 1~5 As shown, the present invention includes a slider body 5 , a pressure sensor 4 and two flow controllers 3 .

[0040] The structure of the slider body 5 is as follows:

[0041] The upper surface of the slider body 5 is provided with a slider body oil inlet 2;

[0042] The slider body 5 is provided with two oil chambers 7, which are respectively arranged on the upper and lower surfaces of the slider body 5. The oil chamber 7 is provided with an oil outlet 8 of the oil chamber; the outer periphery of the oil chamber 7 is provided with a micro-textured oil seal surface 6, the height of the oil sealing surface 6 of the micro-texture is higher than the surface of the slider body 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com