Exterior-clearance throttle cavity internal-hole type scavenging hydrostatic bearing

A technology for hydrostatic bearings and throttling chambers, which is applied to bearings, bearing components, shafts and bearings, etc., can solve problems affecting the oil film stiffness of internal feedback throttling hydrostatic bearings, high manufacturing precision requirements, and complex structures. Achieve the effects of simple structure, reduced risk, and convenient processing and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

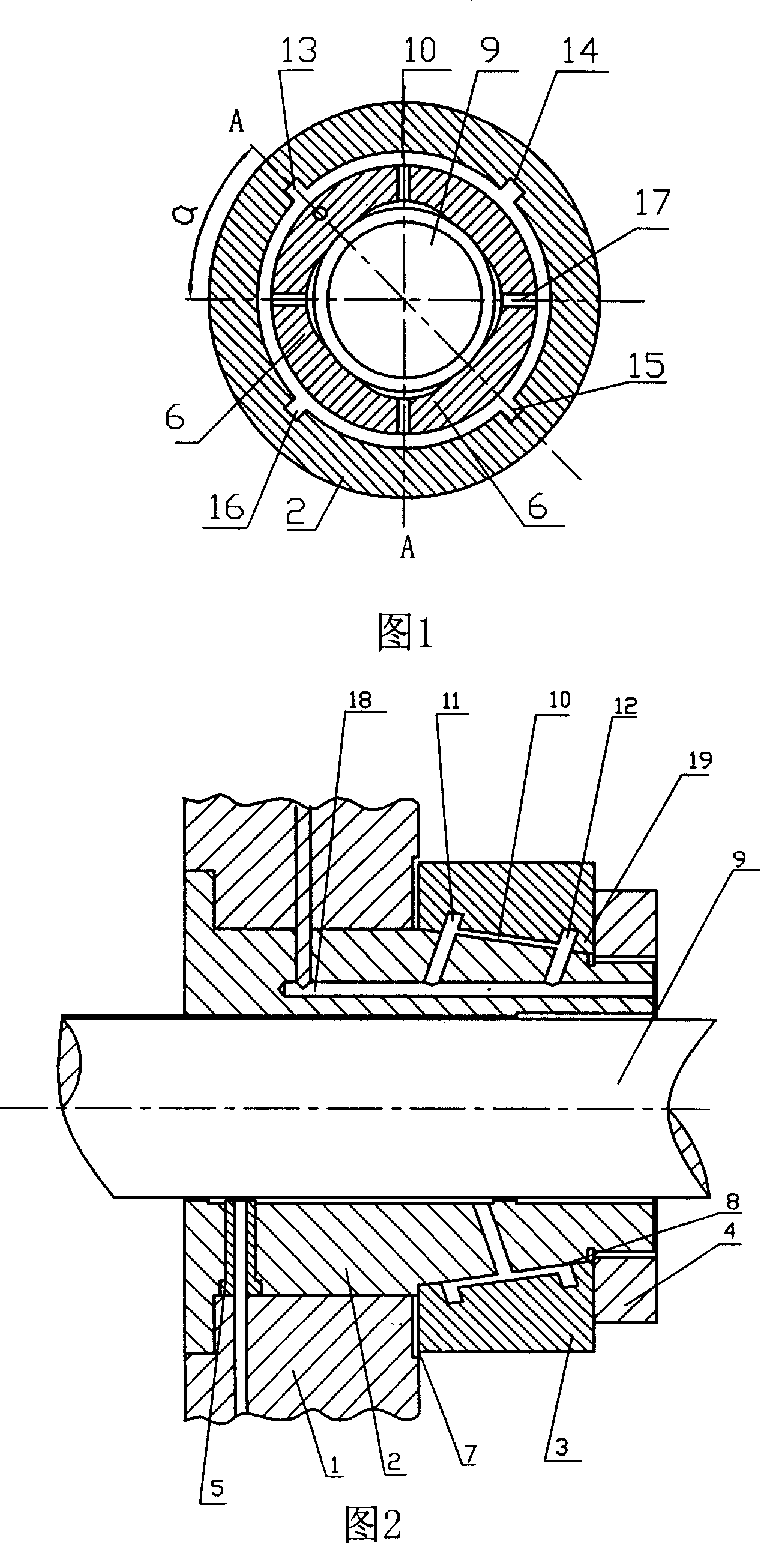

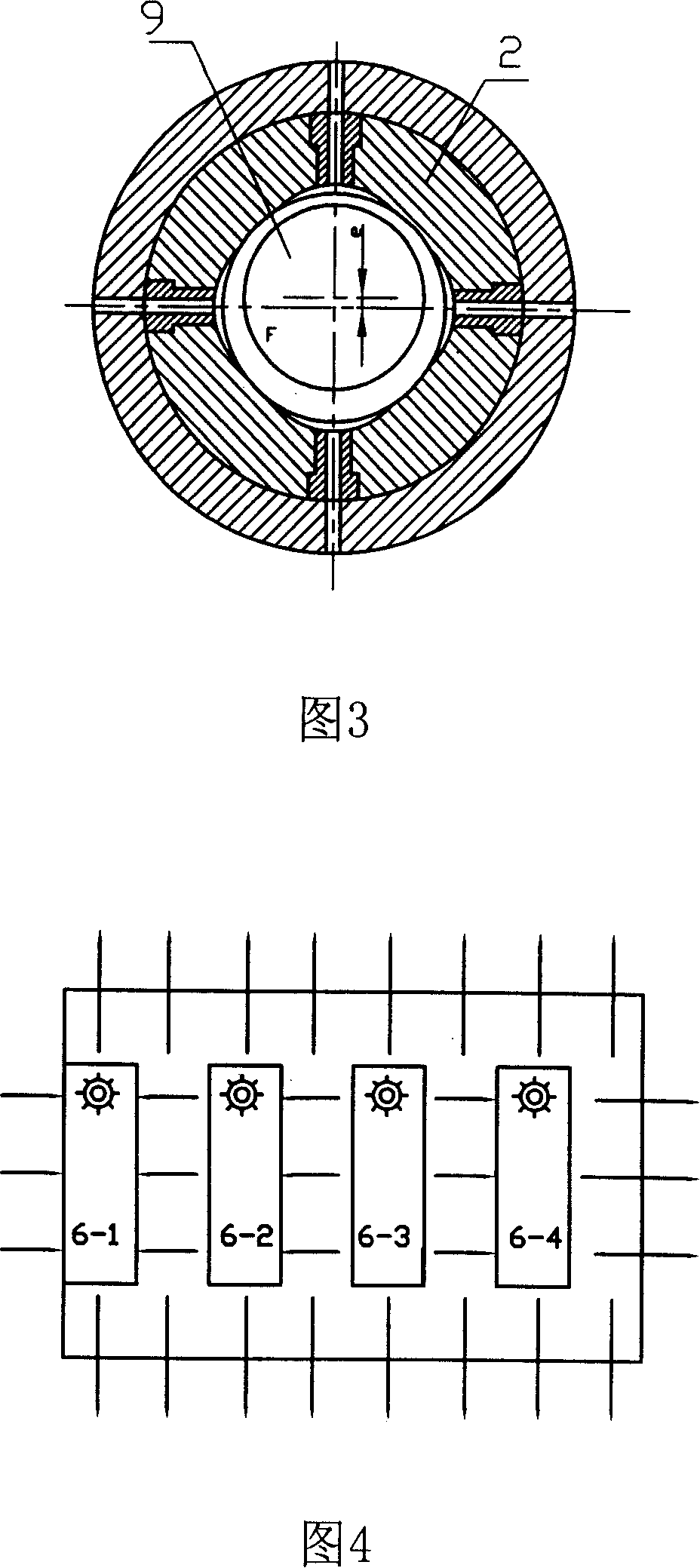

[0035]As shown in Fig. 1 and Fig. 2, the bearing body 2 of the hydrostatic bearing of the present invention is installed in the grinding wheel frame body shell 1, and the inner surface of the bearing body 2 has four bearing oil chambers 6 evenly distributed along the circumference. The cone of the bearing body 2 is equipped with a corresponding taper sleeve 3 and a lock nut 4 is installed at the rear end of the bearing body. Two annular grooves 7, 8 are opened on the outer tapered surface of the cone. There is a throttling ring gap 10 connecting the two annular grooves 7, 8 between the outer tapered surface between the grooves 7, 8 and the corresponding inner surface of the taper sleeve 3, and the inner surface of the taper sleeve 3 has two corresponding and parallel Connect the annular grooves 11, 12 of the annular grooves 7, 8 on the outer conical surface, and the inner surface of the taper sleeve 3 is provided with four oil grooves 13, 14, which are evenly distributed along ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com