White vitrified bead modified insulation masonry mortar and using method thereof

A technology of thermal insulation masonry mortar and vitrified microbeads, which is applied in the field of building materials, can solve the problems of mechanical properties and thermal insulation performance, poor fiber-matrix bonding performance, poor fiber dispersion performance, etc., and achieve strength performance The effect of superior indicators, easy quality control, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

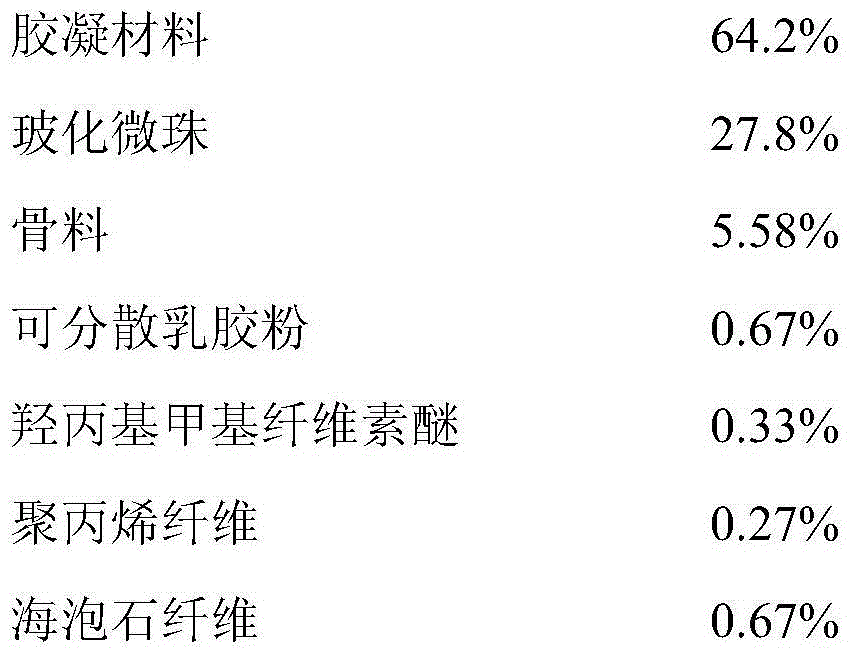

[0025]

[0026]

[0027] During construction, the dry powder of thermal insulation mortar and water are mixed according to the mass ratio of 1:0.47, stirred for 2 to 3 minutes, and the sample is formed after standing for 3 to 5 minutes.

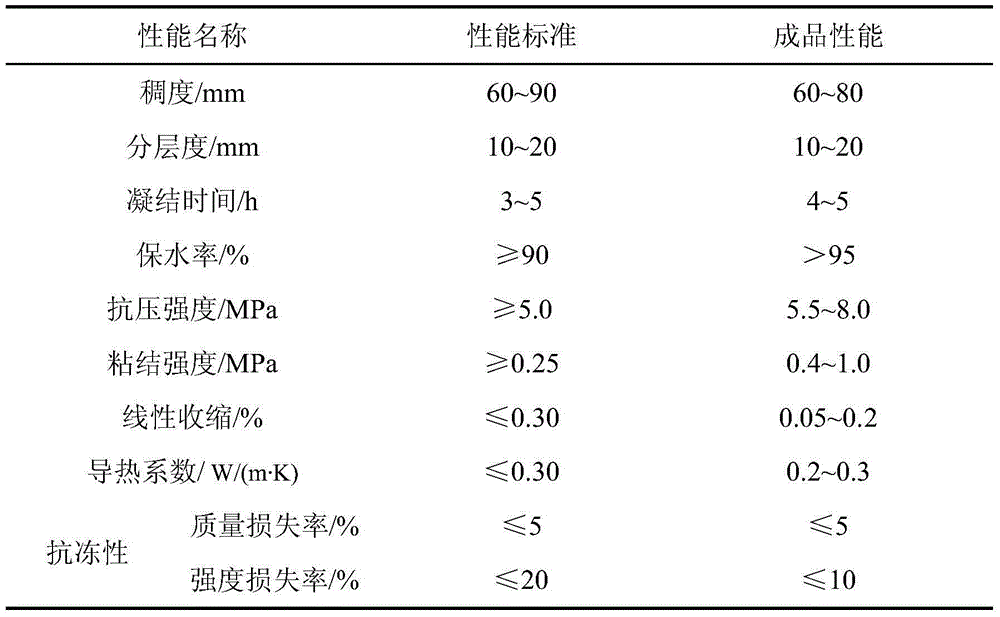

[0028] 14d measured its basic performance as follows:

[0029] Dry density is 885kg / m 3 , the compressive strength is 6.28MPa, and the thermal conductivity is 0.278W / (m·K).

Embodiment 2

[0031]

[0032] During construction, mix the dry powder of thermal insulation mortar and water according to the mass ratio of 1:0.49, stir for 2 to 3 minutes, and let it stand for 3 to 5 minutes before forming the sample.

[0033] 14d measured its performance as follows:

[0034] Dry density is 887kg / m 3 , the compressive strength is 6.93MPa, and the thermal conductivity is 0.296W / (m·K).

Embodiment 3

[0036]

[0037]

[0038] During construction, the dry powder of thermal insulation mortar and water are mixed according to the mass ratio of 1:0.50, and the ratio is stirred for 2 to 3 minutes, and the sample is formed after standing for 3 to 5 minutes.

[0039] 28d measured its performance as follows:

[0040] The dry density is 853kg / m 3 , the compressive strength is 7.2MPa, and the thermal conductivity is 0.240W / (m·K).

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com