Addition type silica gel for remaking refined decorative pattern mold, preparation method and application thereof

A technology of addition molding and mold, which is applied in the field of preparation of addition molding silica gel, can solve the problems of poor wettability of two-component addition molding silica gel, inability of epoxy resin to flow completely, and low emulation rate of epoxy mold patterns, etc., and achieves improvement Good polarity, dimensional stability, and small linear shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

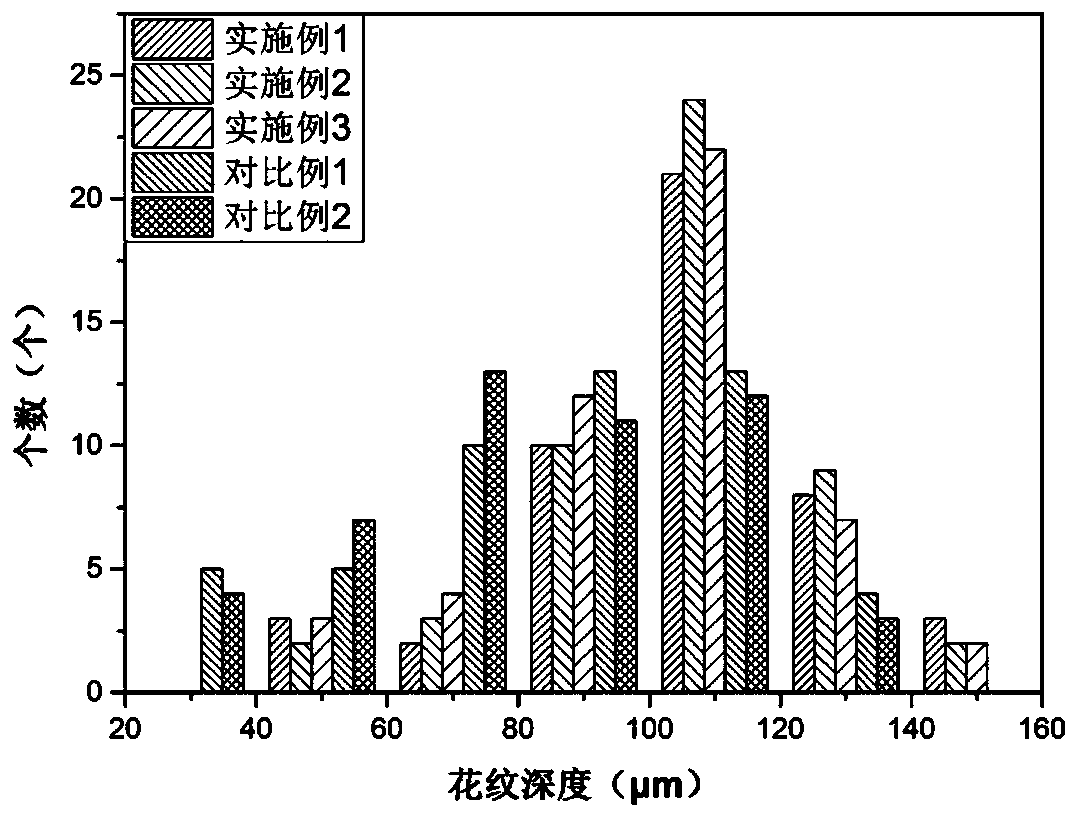

Embodiment 1

[0026] Preparation of component A: 25 parts of vinyl silicone oil, 25 parts of hydrogen silicone oil and 0.2 parts of polyether polymer surfactant;

[0027] Preparation of component B: 25 parts of vinyl silicone oil, 1 part of platinum catalyst, 0.3 part of inhibitor and 0.1 part of polyether polymer surfactant;

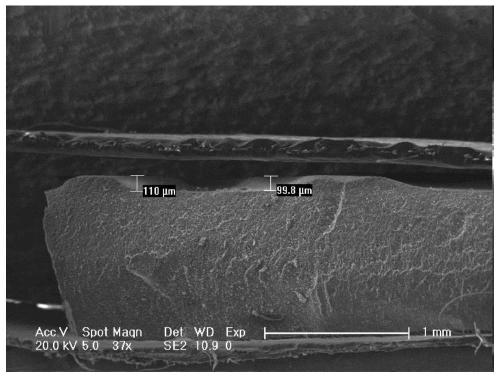

[0028] At 20-30°C, mix 10 parts of vinyl MQ silicone resin and 5 parts of fumed silica into components A and B, then mix evenly according to the mass ratio of 1:1, then vacuumize and defoam for 5 minutes. After the operation is completed, cure at 20-30°C for 3 hours. After the silicone is completely cured, pour epoxy resin into the silicone female mold. After the epoxy resin is completely cured, remove the mold and measure the depth of the pattern on the surface of the epoxy resin.

Embodiment 2

[0030] Preparation of component A: 30 parts of vinyl silicone oil, 30 parts of hydrogen silicone oil and 1 part of polyether polymer surfactant;

[0031] Preparation of component B: 30 parts of vinyl silicone oil, 1.5 parts of platinum catalyst, 0.6 parts of inhibitor and 0.5 parts of polyether polymer surfactant;

[0032] At 20-30°C, mix 15 parts of vinyl MQ silicone resin and 6 parts of fumed silica into components A and B, then mix evenly according to the mass ratio of 1:1, vacuumize and defoam for 5 minutes, and operate After completion, cure at 20-30°C for 3 hours. After the silicone is completely cured, pour epoxy resin into the silicone female mold. After the epoxy resin is completely cured, remove the mold and measure the depth of the pattern on the surface of the epoxy resin.

Embodiment 3

[0034] Preparation of component A: 35 parts of vinyl silicone oil, 30 parts of hydrogen silicone oil and 2 parts of polyether polymer surfactant;

[0035] Preparation of component B: 35 parts of vinyl silicone oil, 1.5 parts of platinum catalyst, 0.6 parts of inhibitor and 1 part of polyether polymer surfactant;

[0036] At 20-30°C, mix 20 parts of vinyl MQ silicone resin and 7 parts of fumed silica into components A and B, then mix evenly according to the mass ratio of 1:1, then vacuumize and defoam for 5 minutes. After the operation is completed, cure at 20-30°C for 3 hours. After the silicone is completely cured, pour epoxy resin into the silicone female mold. After the epoxy resin is completely cured, remove the mold and measure the depth of the pattern on the surface of the epoxy resin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com